Abstract

The present article proposes a mortar-type finite element formulation for consistently embedding curved, slender beams into 3D solid volumes. Following the fundamental kinematic assumption of undeformable cross-section s, the beams are identified as 1D Cosserat continua with pointwise six (translational and rotational) degrees of freedom describing the cross-section (centroid) position and orientation. A consistent 1D-3D coupling scheme for this problem type is proposed, requiring to enforce both positional and rotational constraints. Since Boltzmann continua exhibit no inherent rotational degrees of freedom, suitable definitions of orthonormal triads are investigated that are representative for the orientation of material directions within the 3D solid. While the rotation tensor defined by the polar decomposition of the deformation gradient appears as a natural choice and will even be demonstrated to represent these material directions in a \(L_2\)-optimal manner, several alternative triad definitions are investigated. Such alternatives potentially allow for a more efficient numerical evaluation. Moreover, objective (i.e. frame-invariant) rotational coupling constraints between beam and solid orientations are formulated and enforced in a variationally consistent manner based on either a penalty potential or a Lagrange multiplier potential. Eventually, finite element discretization of the solid domain, the embedded beams, which are modeled on basis of the geometrically exact beam theory, and the Lagrange multiplier field associated with the coupling constraints results in an embedded mortar-type formulation for rotational and translational constraint enforcement denoted as full beam-to-solid volume coupling (BTS-FULL) scheme. Based on elementary numerical test cases, it is demonstrated that a consistent spatial convergence behavior can be achieved and potential locking effects can be avoided, if the proposed BTS-FULL scheme is combined with a suitable solid triad definition. Eventually, real-life engineering applications are considered to illustrate the importance of consistently coupling both translational and rotational degrees of freedom as well as the upscaling potential of the proposed formulation. This allows the investigation of complex mechanical systems such as fiber-reinforced composite materials, containing a large number of curved, slender fibers with arbitrary orientation embedded in a matrix material.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Embedding fibers or beams, i.e. solid bodies that can mechanically be modeled as dimensionally reduced 1D structures since one spatial dimension is much larger than the other two, into a 3D matrix material is a common approach to enhance the mechanical properties of a structure. Fiber-reinforced structures can be found in many different fields, e.g. in form of steel reinforcements within concrete structures, lightweight fiber-reinforced composite materials based on carbon, glass or polymer fibers in a plastic matrix, or additively manufactured components allowing for a very flexible and locally controlled reinforcement of plastic, metal, ceramic or concrete matrix materials [32, 33, 42]. At a different length scale, fiber embeddings play a key role for essential processes in countless biological systems, e.g. in the form of embedded networks (e.g. cytoskeleton, extracellular matrix, mucus) or bundles (e.g. muscle, tendon, ligament) [2, 21, 31, 41]. Most of these applications are characterized by geometrically complex embeddings of arbitrarily oriented, slender and potentially curved fibers. Computational models predicting the response of such reinforced structures are essential for a time- and cost-efficient design and development of technical products, but also to gain fundamental understanding of biological systems at length scales that are not accessible via experiments. In the context of computational modeling, as considered in the following, the embedded 1D structures will be referred to as fibers or beams, respectively, and the 3D matrix as solid.

One common modeling approach for this physical beam-to-solid volume coupling problem is based on homogenized, anisotropic material models for the combined fiber-matrix structure [1, 70]. This widely used approach is appealing since, e.g. no additional degrees of freedom are required to model individual fibers, and existing simulation tools can be used as long as they support anisotropic material laws. However, such models cannot give detailed information about the interactions between fibers and surrounding matrix as, e.g. required to study mechanisms of failure. Moreover, the fiber distribution in the solid has to be sufficiently homogeneous and a separation of scales is required, i.e. the fiber size has to be sufficiently small as compared to the smallest dimension of the overall structure. Eventually, when modeling new fiber arrangements, the homogenization step inherent to these continuum models requires sub-scale information, e.g. provided by a model with resolved fiber geometries.

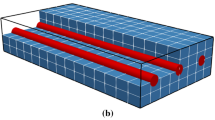

Another modeling approach consists of fully describing the fibers and surrounding solid material as 3D continua. This leads to a surface-to-surface coupling problem at the 2D interface between fiber surface and surrounding solid. In the context of the finite element method, these surfaces can be tied together by either applying fiber and solid discretizations that are conforming at the shared interface or via interface coupling schemes accounting for non-matching meshes, such as the mortar method [45, 47,48,49]. Alternatively, extended finite element methods (XFEM) [40] or immersed finite element methods [29, 55] can be used to represent 2D fiber surfaces embedded in an entirely independent background solid mesh. While such fully resolved modeling approaches allow to study local effects with high spatial resolution, the significant computational effort associated with these models prohibits their usage for large-scale systems with a large number of slender fibers.

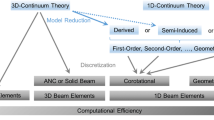

The class of applications considered here typically involves very slender fibers. In this regime it is well justified, and highly efficient from a computational point of view, to model individual fibers as beams, e.g. based on the geometrically exact beam theory [9, 12, 14, 24, 30, 36, 38, 51, 52, 59,60,61], which is known to combine high model accuracy and computational efficiency [5, 53]. Based on the fundamental kinematic assumption of undeformable cross-section s, such beam models can be identified as 1D Cosserat continua with six degrees of freedom defined at each centerline point to describe the cross-section position (three translational degrees of freedom) and orientation (three rotational degrees of freedom). Thus, the problem of beams embedded in a 3D solid volume can be classified as mixed-dimensional 1D-3D coupling problem between 1D Cosserat continua and a 3D Boltzmann continuum. A variety of 1D-3D coupling approaches exist in the literature, however most of them involve truss/string models, i.e. 1D structural models account only for internal elastic energy contributions from axial tension, e.g. [13, 17, 20, 25, 26, 43, 50]. Work on the 1D-3D coupling between beams, i.e. full Cosserat continua, and solids is much rarer. In [16], collocation along the beam centerline is applied to couple beams with a surrounding solid material. A mortar-type coupling approach is proposed in the authors’ previous work [63], where a Lagrange multiplier field is defined along the beam centerline to weakly enforce the coupling constraints. The 1D-3D coupling between beams and a surrounding fluid field, as relevant for fluid-structure-interaction (FSI) problems, has been considered in some recent contributions [22, 68].

All the aforementioned 1D-3D beam-to-solid coupling schemes have in common that only the beam centerline positions, but not the cross-section orientations, are coupled to the solid, which will be denoted as translational 1D-3D coupling. In such models, an embedded fiber can still perform local twist/torsional rotations, i.e. cross-section rotations with respect to its centerline tangent vector, relative to the solid. While this simplified coupling procedure can reasonably describe the mechanics of certain problem classes where such relative rotations will rarely influence the global system response, e.g. embedding of straight fibers with circular cross-section shape, for most practical applications a more realistic description of the physical problem requires to also couple the rotations of beam and solid.

In a very recent approach by [27] the full 1D-3D coupling problem involving positions and rotations has been addressed for the first time. The coupling of the two directors spanning the (undeformable) beam cross-section with the underlying solid continuum together with the coupling of the cross-section centroids results in a total of nine coupling constraints. One specific focus of this interesting contribution lies on a static condensation strategy, which allows to eliminate the associated Lagrange multipliers and the beam balance equations from the final, discrete system of equations. The requirement of a \(C^1\)-continuous spatial discretization of the solid domain, as resulting from the proposed condensation strategy, is satisfied by employing NURBS-based test and trial functions.

The present work proposes a full 1D-3D coupling approach based on only six, i.e. three translational and three rotational, coupling constraints between the cross-section s of 1D beams, modeled according to the geometrically exact beam theory, and a 3D solid. The finite element method is employed for spatial discretization of all relevant fields. Consistently deriving the full 1D-3D coupling on the beam centerline from a 2D-3D coupling formulation on the beam surface via a first-order Taylor series expansion of the solid displacement field would require to fully couple the two orthonormal directors spanning the (undeformable) beam cross-section with the (in-plane projection of the) solid deformation gradient evaluated at the cross-section centroid position. It is demonstrated that such an approach, which suppresses all in-plane deformation modes of the solid at the coupling point, might result in severe locking effects in the practically relevant regime of coarse solid mesh sizes. Therefore, as main scientific contribution of this work, different definitions of orthonormal triads are proposed that are representative for the orientation of material directions of the 3D continuum in an average sense, without additionally constraining in-plane deformation modes when coupled to the beam cross-section. It is shown that the rotation tensor defined by the polar decomposition of the (in-plane projection of the) deformation gradient appears as a natural choice for this purpose, which even represents the average orientation of material directions of the 3D continuum in a \(L_2\)-optimal manner. Moreover, several alternative solid triad definitions are investigated that potentially allow for a more efficient numerical evaluation.

Once these solid triads have been defined, objective (i.e. frame-invariant) rotational coupling constraints in the form of relative rotations are formulated for each pair of triads representing the beam and solid orientation. Their variationally consistent enforcement either based on a penalty potential or a Lagrange multiplier potential, with an associated Lagrange multiplier field representing a distributed coupling moment along the beam centerline, is shown. Eventually, finite element discretization of the Lagrange multiplier and relative rotation vector field along the beam centerline results in an embedded mortar-type formulation for rotational constraint enforcement. In combination with a previously developed mortar-type formulation (BTS-TRANS) for translational 1D-3D coupling [63], this results in a full 1D-3D coupling approach denoted as full beam-to-solid volume coupling scheme (BTS-FULL). Finite element discretization of the solid and the embedded (potentially curved) beams inevitably results in non-matching meshes, which underlines the importance of a consistently embedded mortar-type formulation as proposed in this work. Based on elementary numerical test cases, it is demonstrated that a consistent spatial convergence behavior can be achieved and potential locking effects can be avoided if the proposed BTS-FULL scheme is combined with a suitable solid triad definition. Eventually, real-life engineering applications are considered to illustrate the importance of consistently coupling both translational and rotational degrees of freedom as well as the upscaling potential of the proposed formulation to study complex mechanical systems such as fiber-reinforced composite materials, containing a large number of curved, slender fibers with arbitrary orientation embedded in a matrix material.

The remainder of this work is organized as follows: In Sect. 2, we state the fundamental modeling assumptions of the proposed BTS-FULL scheme. Specifically, the importance of enforcing both rotational and translational coupling conditions is demonstrated, and the general implications of a 1D-3D coupling approach are discussed. In Sect. 3, we give a short summary of the theory of large rotations as required to formulate rotational coupling conditions. In Sect. 4, the governing equations for the solid and beam domains are presented, and objective rotational coupling constraints are defined and enforced in a variationally consistent manner, either based on a penalty or a Lagrange multiplier potential. In Sect. 5, we propose different definitions of orthonormal triads that are suitable to represent the orientation of solid material directions in an average sense. In Sect. 6, discretization of the coupling conditions based on the finite element method is considered, once in a Gauss point-to-segment manner and once as mortar-type approach along with a weighted penalty regularization. Finally, numerical examples, carefully selected to verify different aspects of the proposed formulation, are presented in Sect. 7.

2 Motivation and modeling assumptions

In Sect. 2.1, the main modeling assumptions generally underlying 1D-3D coupling schemes will be discussed. Subsequently, in Sect. 2.2, the importance of a full position and rotation coupling (BTS-FULL) will be motivated for general application scenarios, and special cases will be discussed, where also a purely translational coupling (BTS-TRANS) can be considered as reasonable approximation.

2.1 Modeling assumptions underlying the 1D-3D coupling

The considered class of 1D-3D coupling schemes is based on the assumption that the fiber material is stiff compared to the solid material, and local fiber cross-section dimensions are small compared to the global solid dimensions. Thus, the solid may be discretized without subtracting the fiber volume, formally resulting in overlapping solid and fiber domains. While consistent 2D-3D coupling on the fiber surface would allow for high-resolution stress field predictions in the direct vicinity of the 2D fiber-solid interface, such approaches require an evaluation of coupling constraints on a 2D interface and a sufficient discretization resolution of the solid with mesh sizes smaller than the fiber cross-section dimensions, thus in large parts deteriorating the advantages provided by a reduced dimensional description of the fibers.

In truly 1D-3D coupling approaches, the coupling conditions are exclusively defined along the beam centerline, thus preserving the computational advantages of the dimensionally reduced beam models. Of course, such approaches inevitably introduce a modeling error as compared to the 2D-3D coupling, i.e. the surface tractions on the 2D beam-solid interface are approximated by localized resultant line forces and moments acting on the beam centerline. This has a significant impact on the analytical solution of the problem, as line loads acting on a 3D continuum result in singular stress and displacement fields, cf. [19, 44, 66]. Thus, convergence of the 1D-3D solution towards the 2D-3D solution is not expected. However, in the realm of the envisioned applications, we are rather interested in global system responses than in local stress distributions in the direct vicinity of the fibers. Thus, practically relevant solid element sizes are considered that are larger than the fiber cross-section dimensions. In this regime of mesh resolutions, this inherent modeling error of 1D-3D approaches can typically be neglected.

To verify this statement, consider a plane problem of a beam cross-section, loaded with a moment, that is coupled to a solid finite element as depicted in Fig. 1. As long as the cross-section diameter is smaller than the solid finite element mesh size, the resulting discrete nodal forces \(F_S\) acting on the solid are independent of the employed coupling approach, i.e. either 1D-3D coupling with associated coupling moment M (Fig. 1, left) or 2D-3D coupling with associated coupling surface load \(\tau \) (Fig. 1, right). Obviously, this is an idealized setting, but it illustrates that 1D-3D coupling approaches can be considered as valid models for solid mesh sizes larger than the cross-section diameter, which will also be verified in Sect. 7. For a more detailed discussion of this topic the interested reader is referred to our previous publication [63], specifically to Figure 15 in [63], which depicts an analogous scenario for the coupling of translational degrees of freedom.

2.2 Motivation for full translational and rotational coupling

To differentiate the scope of validity of the proposed BTS-FULL scheme (coupling of positions and rotations) and of existing BTS-TRANS schemes (coupling of positions only), two application scenarios are discussed.

As first scenario, systems are considered (i) that contain only transversely isotropic fibers (e.g. circular cross-section shape and initially straight) and (ii) whose global system response is dominated by the axial and bending stiffness of the fibers, i.e. the torsional contribution is negligible. As demonstrated in [63], BTS-TRANS schemes can be considered as a reasonable mechanical model in this case, since local (twist/torsional) rotations of the fibers with respect to their straight axes will rarely influence the global system response. Torsion-free beam models [37] represent an elegant mechanical description of the fibers for such applications.

As second scenario, systems are considered that contain transversely anisotropic fibers (e.g. non-circular cross-section shape or initially curved). First, it is clear that twist rotations of the fiber cross-section s with respect to the centerline tangent (even if not possible in their simplest form as rigid body rotations) will change the global system response, since such fibers exhibit distinct directions of maximal/minimal bending stiffness or initial curvature. Second, due to the inherent two-way coupling of bending and torsion in initially curved beams [37], bending deformation will inevitably induce torsion in such application scenarios, i.e. the global system stiffness is approximated as too soft if these torsional rotations are not transferred to the matrix by a proper coupling scheme. Thus, a unique and consistent mechanical solution for this scenario can only be guaranteed by BTS-FULL schemes.

Remark 2.1

In fact, both aforementioned application scenarios might lead to non-unique static solutions if neglecting the rotational coupling. However, for transversely isotropic fibers the non-uniqueness only occurs at the local fiber level, i.e. the twist orientation of the fibers is not uniquely defined, which does not influence the global system response. The locally non-unique fiber orientation is typically only an issue from a numerical point of view (e.g. linear solvers), and can be effectively circumvented by employing, e.g. torsion-free beam models not exhibiting the relevant rotational degrees of freedom. For transversely anisotropic fibers, such local twist rotations will change the global system response. This gives rise to non-unique static solutions on the global level and, thus, has significant implications from a physical point of view.

3 Large rotations

This section gives a brief overview on the mathematical treatment of finite rotations as required for the formulation of rotational coupling constraints. For a more comprehesive treatment of this topic, the interested reader is referred to [8, 12, 24, 38, 52, 60]. Let us consider a rotation tensor

where \(SO^3\) is the special orthogonal group and the base vectors \(\underline{\varvec{{g}}}_{i}\) form an orthonormal triad, that maps the Cartesian basis vectors \(\underline{\varvec{{e}}}_{i}\) onto \(\underline{\varvec{{g}}}_{i}\). In the following, a rotation pseudo-vector \(\underline{\varvec{{\psi }}}\) is used for its parametrization, i.e. \(\underline{\varvec{{\varLambda }}}= \underline{\varvec{{\varLambda }}}(\underline{\varvec{{\psi }}})\). The rotation vector describes a rotation by an angle \(\psi = \left\| \underline{\varvec{{\psi }}}\right\| \) around the rotation axis \(\underline{\varvec{{e}}}_{\psi }= \underline{\varvec{{\psi }}}/ \left\| \underline{\varvec{{\psi }}}\right\| \). The parametrization can be given by the well-known Rodrigues formula [3]

where \(\exp (\cdot )\) is the exponential map. Furthermore,  is a skew-symmetric tensor, where \(\hbox {so}^3\) represents the set of skew-symmetric tensors with

is a skew-symmetric tensor, where \(\hbox {so}^3\) represents the set of skew-symmetric tensors with  . The inverse of the Rodrigues formula (2), i.e. the rotation vector as a function of the rotation tensor, will be denoted as \(\underline{\varvec{{\psi }}}(\underline{\varvec{{\varLambda }}}) = {{\,\mathrm{rv}\,}}(\underline{\varvec{{\varLambda }}})\) in the remainder of this work. In practice, Spurrier’s algorithm [62] can be used for the extraction of the rotation vector.

. The inverse of the Rodrigues formula (2), i.e. the rotation vector as a function of the rotation tensor, will be denoted as \(\underline{\varvec{{\psi }}}(\underline{\varvec{{\varLambda }}}) = {{\,\mathrm{rv}\,}}(\underline{\varvec{{\varLambda }}})\) in the remainder of this work. In practice, Spurrier’s algorithm [62] can be used for the extraction of the rotation vector.

Two triads \(\underline{\varvec{{\varLambda }}}_1(\underline{\varvec{{\psi }}}_{1})\) and \(\underline{\varvec{{\varLambda }}}_2(\underline{\varvec{{\psi }}}_{2})\), with their respective rotation vectors \(\underline{\varvec{{\psi }}}_{1}\) and \(\underline{\varvec{{\psi }}}_{2}\), can be related by the relative rotation \(\underline{\varvec{{\varLambda }}}_{21}(\underline{\varvec{{\psi }}}_{21})\). The relative rotation is given by

with the identity \(\underline{\varvec{{\varLambda }}}^{\mathrm T}=\underline{\varvec{{\varLambda }}}^{-1}\) for all elements of \(SO^3\). Thus, the (non-additive) rotation vector  describes the relative rotation between \(\underline{\varvec{{\varLambda }}}_1\) and \(\underline{\varvec{{\varLambda }}}_2\).

describes the relative rotation between \(\underline{\varvec{{\varLambda }}}_1\) and \(\underline{\varvec{{\varLambda }}}_2\).

In a next step, the infinitesimal variations of the rotation tensor shall be considered, which can be expressed either by an infinitesimal additive variation \(\delta \underline{\varvec{{\psi }}}\) of the rotation vector

or by a infinitesimal multiplicative rotation variation \(\delta \underline{\varvec{{\theta }}}\), which is also denoted as spin vector:

While the definition of the multiplicative rotation variation (5) can often be found in the literature, e.g. in [14, 24, 61], the notation introduced for the additive rotation variation (4) simply represents the standard definition of partial differentiation, which is based on additive increments. With the relation above and the definition of  , the variations of the triad basis vectors \(\delta \underline{\varvec{{g}}}_{i}\) read

, the variations of the triad basis vectors \(\delta \underline{\varvec{{g}}}_{i}\) read

The infinitesimal additive and multiplicative rotation vector variations can be related according to

where the transformation matrix \(\underline{\varvec{{T}}}(\underline{\varvec{{\psi }}})\) [61] is defined as

In [34], the objective variation \(\delta _{o}\) of a spatial quantity defined in a moving frame \(\underline{\varvec{{\varLambda }}}_1\) is defined as the difference between the total variation and the variation of the base vectors of the moving frame. In the context of rotational coupling constraints this will be required when expressing the objective variation of a relative rotation vector \(\underline{\varvec{{\psi }}}_{21}\):

For a detailed derivation of this expression for the objective variation the interested reader is referred to [34].

Remark 3.1

Via right-multiplication of (8) with the rotation vector \(\underline{\varvec{{\psi }}}\) it can easily be shown that \(\underline{\varvec{{\psi }}}\) is an eigenvector (with eigenvalue 1) of \(\underline{\varvec{{T}}}\) and also of \(\underline{\varvec{{T}}}^{\mathrm T}\), i.e. \(\underline{\varvec{{T}}}\underline{\varvec{{\psi }}}= \underline{\varvec{{\psi }}}\) and \(\underline{\varvec{{T}}}^{\mathrm T}\underline{\varvec{{\psi }}}= \underline{\varvec{{\psi }}}\). This property will be beneficial for derivations presented in subsequent sections. Every vector parallel to \(\underline{\varvec{{\psi }}}\) is also an eigenvector of \(\underline{\varvec{{T}}}\). This can be interpreted in a geometrical way: If the additive increment \(\delta \underline{\varvec{{\psi }}}\) to a rotation vector \(\underline{\varvec{{\psi }}}\) is parallel to the rotation vector, i.e. \(\delta \underline{\varvec{{\psi }}}= \delta \psi \underline{\varvec{{e}}}_{\psi }\) and \(\underline{\varvec{{\psi }}}= \psi \underline{\varvec{{e}}}_{\psi }\), the resulting compound rotation  is still defined around the rotation axis \(\underline{\varvec{{e}}}_{\psi }\). In this case, the rotation increment is a plane rotation relative to \(\underline{\varvec{{\varLambda }}}(\underline{\varvec{{\psi }}})\), and the multiplicative and additive rotational increments are equal to each other, \(\delta \underline{\varvec{{\psi }}}= \delta \underline{\varvec{{\theta }}}\).

is still defined around the rotation axis \(\underline{\varvec{{e}}}_{\psi }\). In this case, the rotation increment is a plane rotation relative to \(\underline{\varvec{{\varLambda }}}(\underline{\varvec{{\psi }}})\), and the multiplicative and additive rotational increments are equal to each other, \(\delta \underline{\varvec{{\psi }}}= \delta \underline{\varvec{{\theta }}}\).

Remark 3.2

In addition to \(\underline{\varvec{{\varLambda }}}\), also the symbol \(\underline{\varvec{{R}}}\) will be used in the following to represent rotation tensors.

4 Problem formulation

We consider a 3D finite deformation full beam-to-solid volume coupling problem (BTS-FULL) as shown in Fig. 2. All quantities are refereed to a Cartesian frame \(\underline{\varvec{{e}}}_1, \underline{\varvec{{e}}}_2, \underline{\varvec{{e}}}_3\). For simplicity, we focus on quasi-static problems in this work, while the presented BTS-FULL method is directly applicable to dynamic problems as well. The principle of virtual work serves as basis for the proposed finite element formulation. Contributions to the total virtual work of the system can be split into solid, beam and coupling terms, where the solid and beam terms are independent of the coupling constraints, i.e. well-established modeling and discretization techniques can be used for these single fields, cf. [63].

4.1 Solid formulation

The solid body is modeled as a 3D Boltzmann continuum, defined by its domain \(\varOmega _{S,0}\subset {\mathbb {R}}^{3}\) in the reference configuration, with boundary \(\partial \varOmega _{S,0}\). Throughout this work, the subscript \((\cdot )_0\) indicates a quantity in the reference configuration. A solid material point can be identified by its reference position \(\underline{\varvec{{X}}}_S\in {\mathbb {R}}^{3}\). The current position \(\underline{\varvec{{x}}}_S\in {\mathbb {R}}^{3}\) relates to \(\underline{\varvec{{X}}}_S\) via the displacement field \(\underline{\varvec{{u}}}_S\in {\mathbb {R}}^{3}\), i.e.

The domain and surface of the solid in the deformed configuration are \(\varOmega _S\) and \(\partial \varOmega _S\), respectively. Virtual work contributions \(\delta W^S\) of the solid are given by

where \(\delta \) denotes the (total) variation of a quantity, \(\underline{\varvec{{S}}}\in {\mathbb {R}}^{3\times 3}\) is the second Piola–Kirchhoff stress tensor, \(\underline{\varvec{{E}}}\in {\mathbb {R}}^{3\times 3}\) is the work-conjugated Green–Lagrange strain tensor, \(\hat{\underline{\varvec{{b}}}}\in {\mathbb {R}}^{3}\) is the body load vector and \(\hat{\underline{\varvec{{t}}}}\in {\mathbb {R}}^{3}\) are surface tractions on the Neumann boundary \(\varGamma _\sigma \subset \partial \varOmega _{S,0}\). The Green-Lagrange strain tensor is defined as  , where the deformation gradient \(\underline{\varvec{{F}}}\in {\mathbb {R}}^{3\times 3}\) is defined according to

, where the deformation gradient \(\underline{\varvec{{F}}}\in {\mathbb {R}}^{3\times 3}\) is defined according to

For the compressible or nearly incompressible solid material, we assume existence of a hyperelastic strain energy function \(\varPsi (\underline{\varvec{{E}}})\), which allows to determine the second Piola–Kirchhoff stress tensor according to \(\underline{\varvec{{S}}}=\frac{\partial \varPsi (\underline{\varvec{{E}}})}{\partial \underline{\varvec{{E}}}}\).

4.2 Geometrically exact beam theory

The beams are modeled as 1D Cosserat continua embedded in 3D space based on the geometrically exact Simo–Reissner beam theory. Thus, each beam cross-section is described by six degrees of freedom, namely three positional and three rotational degrees of freedom. This results in six deformation modes of the beam: axial tension, bending (\(2\times \)), shear (\(2\times \)) and torsion.

The cross-section centroids are connected by the centerline curve \(\underline{\varvec{{r}}}(s) \in {\mathbb {R}}^{3}\), where \(s\in [0,L] =: \varOmega _{B,0}\subset {\mathbb {R}}^{}\) is the arc-length coordinate along the beam centerline \(\varOmega _{B,0}\) in the reference configuration, and L the corresponding reference length. The displacement of the beam centerline \(\underline{\varvec{{u}}}_B(s)\in {\mathbb {R}}^{3}\) relates the reference position \(\underline{\varvec{{r}}}_0\) to the current position \(\underline{\varvec{{r}}}\) via

The orientation of the beam cross-section field is described by the following field of right-handed orthonormal triads \(\underline{\varvec{{\varLambda }}}_{B}(s) := [\underline{\varvec{{g}}}_{B1}(s), \underline{\varvec{{g}}}_{B2}(s), \underline{\varvec{{g}}}_{B3}(s)]=\underline{\varvec{{\varLambda }}}_{B}(\underline{\varvec{{\psi }}}_{B}(s)) \in SO^3\), which maps the global Cartesian basis vectors \(\underline{\varvec{{e}}}_i\) onto the local cross-section basis vectors \(\underline{\varvec{{g}}}_{Bi}(s) = \underline{\varvec{{\varLambda }}}_{B}\underline{\varvec{{e}}}_i\) for \(i=1,2,3\). Therein, \(\underline{\varvec{{\psi }}}_{B}\in {\mathbb {R}}^{3}\) is the rotation pseudo-vector chosen as parametrization for the triad. Moreover, the triad field in the reference configuration is denoted as \(\underline{\varvec{{\varLambda }}}_{B,0}(s) := [\underline{\varvec{{g}}}_{B1,0}(s), \underline{\varvec{{g}}}_{B2,0}(s), \underline{\varvec{{g}}}_{B3,0}(s)]=\underline{\varvec{{\varLambda }}}_{B,0}(\underline{\varvec{{\psi }}}_{B,0}(s))\), and the relative rotation between the triads in reference and current configuration is denoted as \(\underline{\varvec{{R}}}_B:= \underline{\varvec{{\varLambda }}}_{B}\underline{\varvec{{\varLambda }}}_{B,0}^{\mathrm T}\). According to the fundamental kinematic assumption of undeformable cross-section s, the position of an arbitrary material point within the beam cross-section either in the reference or in the current configuration can be expressed as follows:

where \(\alpha \) and \(\beta \) represent in-plane coordinates. Based on a hyperelastic stored-energy function according to

the material force stress resultants \(\underline{\varvec{{F}}}=\frac{\partial {\tilde{\varPi }}_{\text {int},B}}{\partial \underline{\varvec{{\varGamma }}}}\) and moment stress resultants \(\underline{\varvec{{M}}}=\frac{\partial {\tilde{\varPi }}_{\text {int},B}}{\partial \underline{\varvec{{\varOmega }}}}\) can be derived. Here, \(\underline{\varvec{{\varGamma }}}\in {\mathbb {R}}^{3}\) is a material deformation measure representing axial tension and shear, \(\underline{\varvec{{\varOmega }}}\in {\mathbb {R}}^{3}\) is a material deformation measure representing torsion and bending, and \(\underline{\varvec{{C}}}_F\in {\mathbb {R}}^{3\times 3}\) and \(\underline{\varvec{{C}}}_M\in {\mathbb {R}}^{3\times 3}\) are cross-section constitutive matrices. Eventually, the beam contributions to the weak form are given by

with the virtual work \(\delta W^B_{\text {ext}}\) of external forces and moments.

4.3 Full beam-to-solid volume coupling (BTS-FULL)

In the proposed BTS-FULL method, the pointwise six degrees of freedom associated with the beam centerline positions and cross-section triads are coupled to the surrounding solid, i.e.

Herein, \(\varGamma _{c}= \varOmega _{S,0}\cap \varOmega _{B,0}\) is the one-dimensional coupling domain between the beam centerline and the solid volume, i.e. the part of the beam centerline that lies within the solid. The rotational coupling between beam cross-section and solid as presented in this section is in close analogy to the generalized cross-section interaction laws proposed in [34]. The rotation vector \(\underline{\varvec{{\psi }}}_{SB}\) describes the relative rotation between a beam cross-section triad \(\underline{\varvec{{\varLambda }}}_{B}\) and a corresponding triad \(\underline{\varvec{{\varLambda }}}_{S}\) associated with the current solid configuration,

Opposite to \(\underline{\varvec{{\varLambda }}}_{B}\), which is well defined along the beam centerline, there is no obvious or unique definition for \(\underline{\varvec{{\varLambda }}}_{S}\) in the solid domain. In Sect. 5, different definitions of the solid triad \(\underline{\varvec{{\varLambda }}}_{S}\) are presented and investigated. However, for the derivation of the coupling equations, it is sufficient to assume the general form \(\underline{\varvec{{\varLambda }}}_{S}= \underline{\varvec{{\varLambda }}}_{S}(\underline{\varvec{{F}}})\), i.e. formulating the solid triad as a general function of the solid deformation gradient in the current configuration.

The formulation of the constraint equations along the beam centerline brings about an advantageous property of the BTS-FULL method: the translational (18) and rotational (19) coupling constraints are completely decoupled. Therefore, the rotational coupling equations (19) can be interpreted as a direct extension to the BTS-TRANS method, which only couples the beam centerline positions to the solid as derived and thoroughly discussed in [63]. In what follows, two different constraint enforcement strategies for the rotational coupling conditions will be presented.

Remark 4.1

In Sect. 7, we compare the BTS-FULL method to a full 2D-3D coupling approach that enforces constraints at the 2D beam-solid interface. The governing equations, as well as the discretized coupling terms for this 2D-3D coupling scheme are stated in Appendices 2 and 3.

4.3.1 Penalty potential

We consider a quadratic space-continuous penalty potential between beam cross-section triads and solid triads defined along the beam centerline:

with the cross-section coupling potential \(\pi _{{\epsilon _\theta }}= \pi _{{\epsilon _\theta }}(s)\) and the symmetric penalty tensor \(\underline{\varvec{{c}}}\in {\mathbb {R}}^{3\times 3}\). Variation of the penalty potential leads to the following contribution to the weak form:

Therein, \(\delta _{o}\underline{\varvec{{\psi }}}_{SB}\) is the objective variation of the rotation vector \(\underline{\varvec{{\psi }}}_{SB}\). Making use of (9), the variation of the total potential becomes, cf. [34],

where \(\delta \underline{\varvec{{\theta }}}_{S}\) and \(\delta \underline{\varvec{{\theta }}}_{B}\) are multiplicative variations associated with the solid and beam triad, respectively. Here, we consider penalty tensors of the form \(\underline{\varvec{{c}}}= \epsilon _{\theta }\underline{\varvec{{I}}}\) with a scalar penalty parameter \(\epsilon _{\theta }\in {\mathbb {R}}^{+}\) with physical unit \(\hbox {Nm/m}\). With this definition and the identity \(\underline{\varvec{{T}}}^{\mathrm T}(\underline{\varvec{{\psi }}}) \underline{\varvec{{\psi }}}= \underline{\varvec{{\psi }}}\) (cf. Remark 3.1) the variation of the penalty potential simplifies to

It is well-known from the geometrically exact beam theory that the (multiplicative) virtual rotations \(\delta \underline{\varvec{{\theta }}}_{B}\) are work-conjugated to the moment stress resultants. Therefore, \(\epsilon _{\theta }\underline{\varvec{{\psi }}}_{SB}\) can be directly interpreted as the (negative) coupling moment acting on the beam cross-section.

4.3.2 Lagrange multiplier potential

Alternatively, the Lagrange multiplier method can be employed to impose the rotational coupling constraints. A Lagrange multiplier field \(\underline{\varvec{{\lambda }}}_{\theta }= \underline{\varvec{{\lambda }}}_{\theta }(s) \in {\mathbb {R}}^{3}\) is therefore defined on the coupling curve \(\varGamma _{c}\). For now, this field is a purely mathematical construct in the sense of generalized coupling forces associated with the coupling conditions (19). The Lagrange multiplier potential for the rotational coupling is

Variation of the Lagrange multiplier potential again leads to a constraint contribution to the weak form, i.e.

Therein, \(\delta W_{\lambda _\theta }\) and \(\delta W_{C_\theta }\) are the variational form of the coupling constraints and the virtual work of the generalized coupling forces \(\underline{\varvec{{\lambda }}}_{\theta }\), respectively. With (9) the virtual work of the generalized coupling forces becomes

Since the multiplicative rotation variations \(\delta \underline{\varvec{{\theta }}}_{B}\) are work-conjugated to the moment stress resultants of the beam, the term \(-\underline{\varvec{{T}}}^{\mathrm T}(\underline{\varvec{{\psi }}}_{SB}) \underline{\varvec{{\lambda }}}_{\theta }\) can be interpreted as a distributed coupling moment acting along the beam centerline.

Remark 4.2

For a vanishing relative rotation \(\underline{\varvec{{\psi }}}_{21} = \underline{\varvec{{0}}}\), as enforced in the space-continuous problem setting according to (19), the identity \(-\underline{\varvec{{T}}}^{\mathrm T}(\underline{\varvec{{\psi }}}_{SB}) = \underline{\varvec{{I}}}\) holds true and the rotational Lagrange multipliers exactly represent the coupling moments along the beam centerline. However, for the discretized problem this is only an approximation.

4.3.3 Objectivity of full beam-to-solid volume coupling

As indicated above, the solid triad field depends on the solid deformation gradient \(\underline{\varvec{{F}}}\). It can easily be shown, that the presented solid triad definitions \({\hbox {STR}-\text {POL}}\), \({\hbox {STR}-{\text {AVG}}}\) and \({\hbox {STR}-\text {ORT}}\), in Sect. 5 are objective with respect to an arbitrary rigid body rotation \(\underline{\varvec{{R}}}^{*}\in SO^3\), i.e.

The geometrically exact beam model employed in this contribution is also objective [36, 38], i.e.

Equations (28) and (29) inserted into the definition of the relative beam-to-solid rotation vector according to (20) gives the rotated relative rotation vector,

where the identity \({{\,\mathrm{rv}\,}}(\underline{\varvec{{R}}}^{*}\underline{\varvec{{\varLambda }}}{\underline{\varvec{{R}}}^{*}}^{\mathrm T}) = \underline{\varvec{{R}}}^{*}{{\,\mathrm{rv}\,}}(\underline{\varvec{{\varLambda }}})\) has been used. Thus, the rotational coupling conditions (19) in combination with the proposed solid triad definitions and the employed geometrically exact beam models are objective. As shown in [34], in this case also an associated penalty potential of type (21) or an associated Lagrange multiplier potential of type (25) is objective.

The previous considerations show objectivity of the proposed (space-continuous) 1D-3D coupling approaches. However, in the realm of the finite element method, cf. Sect. 6, it is important to demonstrate that objectivity is preserved also in the discrete problem setting. It is well known that the discretized deformation gradient, as required for the definition of solid triads, is objective as long as standard discretization schemes (e.g. via Lagrange polynomials) are applied to the displacement field of the solid. Also the employed beam finite element formulation based on the geometrically exact beam theory is objective, even though this topic is not trivial and the interested reader is referred to [36, 38]. Therefore, it can be concluded that the proposed 1D-3D coupling schemes are objective for the space-continuous as well as for the spatially discretized problem setting.

Remark 4.3

Objectivity is the main reason for formulating the rotational coupling constraints (19) based on the relative rotation vector, i.e. \(\underline{\varvec{{\psi }}}_{SB}= \underline{\varvec{{0}}}\), cf. [34]. As alternative choice for the rotational coupling constraints the difference between the beam and solid triad rotation vectors, i.e. \(\underline{\varvec{{\psi }}}_{B}- \underline{\varvec{{\psi }}}_{S}= \underline{\varvec{{0}}}\), could be considered. However, such coupling constraints would result in a non-objective coupling formulation [34].

5 Definition of solid triad field

One of the main aspects of the present work is the definition of a suitable right-handed orthonormal triad field \(\underline{\varvec{{\varLambda }}}_{S}\) in the solid, which is required for the coupling constraint (19). This is by no means a straightforward choice, and different triad definitions will lead to different properties of the resulting numerical coupling scheme. In the following, a brief motivation will be given for the concept of solid triads before different solid triad definitions will be proposed.

5.1 Motivation of the solid triad concept

If the embedded beam is considered as a 3D body, a consistent 2D-3D coupling constraint between the 2D beam surface and the surrounding 3D solid can be formulated as

Therein, \(\varGamma _{\text {2D-3D}}\) is the 2D-3D coupling surface, i.e. the part of the beam surface that lies withing the solid volume. In the following, let \(\underline{\varvec{{X}}}_{S,r}\) denote the line of material solid points that coincide with the beam centerline in the reference configuration, i.e. \(\underline{\varvec{{X}}}_{S,r}=\underline{\varvec{{r}}}_0\). Furthermore, the orthonormal triad \(\underline{\varvec{{\varLambda }}}_{S,0}= [\underline{\varvec{{g}}}_{S1,0}, \underline{\varvec{{g}}}_{S2,0}, \underline{\varvec{{g}}}_{S3,0}]\) shall represent material directions of the solid that coincide with the beam triad in the reference configuration according to

The corresponding quantities in the deformed configuration are denoted as \(\underline{\varvec{{x}}}_{S,r}\) and \(\underline{\varvec{{\varLambda }}}_{S}\). Let us now expand the position field in the solid as Taylor series around \(\underline{\varvec{{x}}}_{S,r}\), i.e.

where \(\underline{\varvec{{F}}}\) is the deformation gradient of the solid according to (12). The 1D-3D coupling strategy underlying the proposed BTS-FULL scheme relies on the basic assumption of slender beams, i.e. \(R \ll L\), where R is a characteristic cross-section dimension (e.g. the radius of circular cross-section s). This assumption allows to truncate the Taylor series after the linear term as long as small increments \(\varDelta \underline{\varvec{{X}}}=\alpha \underline{\varvec{{g}}}_{S2,0} + \beta \underline{\varvec{{g}}}_{S3,0}\), with \(\alpha ,\beta \le R\), are considered:

which results in an error of order \({\mathcal {O}}(R^2)\). Here, the directors \({\underline{\varvec{{g}}}}_{S2}\) and \({\underline{\varvec{{g}}}}_{S3}\), which are not orthonormal in general, represent the push-forward of the solid directions \(\underline{\varvec{{g}}}_{S2,0}\) and \(\underline{\varvec{{g}}}_{S3,0}\):

It follows from (34) and (15) that the 2D-3D coupling conditions (31) between the beam surface and the expanded solid position field are exactly fulfilled if the following 1D-3D coupling constraints are satisfied:

Coupling constraints of the form (37) enforce that the material fibers \(\underline{\varvec{{g}}}_{S2}\) and \(\underline{\varvec{{g}}}_{S3}\) of the solid remain orthonormal during deformation, thus enforcing vanishing in-plane strains of the solid at the coupling point \(\underline{\varvec{{x}}}_{S,r}=\underline{\varvec{{r}}}\). In Sect. 7, it will be demonstrated that constraints of this type lead to severe locking effects when applied to finite element discretizations that are relevant for the proposed BTS-FULL scheme, i.e. solid mesh sizes that are larger than the beam cross-section dimensions. It will be demonstrated that such locking effects can be avoided if the solid triad field is defined in a manner that only captures the purely rotational contributions to the local solid deformation at \(\underline{\varvec{{x}}}_{S,r}=\underline{\varvec{{r}}}\) without additionally constraining the solid directors in the deformed configuration. As will be demonstrated in the next sections, the rotation tensor defined by the polar decomposition of the deformation gradient is an obvious choice for this purpose, but also alternative solid triad definitions are possible. Table 1 gives an overview of the solid triad variants proposed in the following.

All of these solid triad definitions \(\underline{\varvec{{\varLambda }}}_{S}=[\tilde{\underline{\varvec{{g}}}}_{S1}, \tilde{\underline{\varvec{{g}}}}_{S2}, \tilde{\underline{\varvec{{g}}}}_{S3}]\) will be a function of the solid deformation gradient \(\underline{\varvec{{F}}}\), i.e. \(\underline{\varvec{{\varLambda }}}_{S}= \underline{\varvec{{\varLambda }}}_{S}(\underline{\varvec{{F}}})\). Moreover, all solid triad definitions will be constructed in a manner such that the associated orthonormal base vectors \(\tilde{\underline{\varvec{{g}}}}_{S2}\) and \(\tilde{\underline{\varvec{{g}}}}_{S3}\) represent the effective rotation of the non-orthonormal directors \({\underline{\varvec{{g}}}}_{S2}\) and \({\underline{\varvec{{g}}}}_{S3}\) in an average sense. Thus, it will be required that \(\tilde{\underline{\varvec{{g}}}}_{S2}\) and \(\tilde{\underline{\varvec{{g}}}}_{S3}\) lie within a plane defined by the normal vector

in the following denoted as the \(\underline{\varvec{{n}}}\)-plane. Eventually, in the examples in Sect. 7, two desirable properties of the solid triad field for the proposed BTS-FULL method are identified:

-

(i)

The solid triad should be invariant, i.e. symmetric/ unbiased with respect to the reference in-plane beam cross-section basis vectors \(\underline{\varvec{{g}}}_{B2,0}\) and \(\underline{\varvec{{g}}}_{B3,0}\).

-

(ii)

The resulting BTS-FULL method should not lead to locking effects in the spatially discretized coupled problem.

These properties will be investigated for the following solid triad definitions.

5.2 Polar decomposition of the deformation gradient (\({\hbox {STR}-\text {POL}}\))

Based on polar decomposition, the deformation gradient of the solid problem can be split into a product \(\underline{\varvec{{F}}}= \underline{\varvec{{v}}} \underline{\varvec{{R}}}_S = \underline{\varvec{{R}}}_S \underline{\varvec{{U}}} \) consisting of a rotation tensor \(\underline{\varvec{{R}}}_S \in SO^3\) and a (spatial or material) positive definite symmetric tensor \(\underline{\varvec{{v}}}\) or \(\underline{\varvec{{U}}}\), respectively, which describes the stretch. An explicit calculation rule for the rotation tensor, e.g. based on \(\underline{\varvec{{v}}}\), can be stated as:

As mentioned above, it is desirable that the orthonormal base vectors \(\tilde{\underline{\varvec{{g}}}}_{S2}\) and \(\tilde{\underline{\varvec{{g}}}}_{S3}\) of the solid triad \(\underline{\varvec{{\varLambda }}}_{S}\) lie in a plane with normal vector \(\underline{\varvec{{n}}}\) according to (38). It can easily be verified that the rotation tensor \(\underline{\varvec{{R}}}_S\) associated with the total deformation gradient \(\underline{\varvec{{F}}}\) according to (40) will in general not satisfy this requirement. Thus, a modification will be presented in the following to preserve this property.

5.2.1 Construction of \({\hbox {STR}-\text {POL}}\) triad

Since the sought-after solid triad shall be uniquely defined already by the two in-plane directors \(\underline{\varvec{{g}}}_{S2}\) and \(\underline{\varvec{{g}}}_{S3}\), a modified version of the deformation gradient will be considered,

which consists of the projection of the total deformation gradient \(\underline{\varvec{{F}}}\) into the \(\underline{\varvec{{n}}}\)-plane extended by the additional term \(\underline{\varvec{{n}}}\otimes \underline{\varvec{{g}}}_{S1,0}\). This modified deformation gradient ensures that the two relevant in-plane basis vectors are correctly mapped, i.e. \(\underline{\varvec{{g}}}_{S2}=\underline{\varvec{{F}}}^{\underline{\varvec{{n}}}}\underline{\varvec{{g}}}_{S2,0}\) and \(\underline{\varvec{{g}}}_{S3}=\underline{\varvec{{F}}}^{\underline{\varvec{{n}}}}\underline{\varvec{{g}}}_{S3,0}\), while the third basis vector, which is not relevant for the proposed coupling procedure, is mapped onto the normal vector of the \(\underline{\varvec{{n}}}\)-plane, i.e. \(\underline{\varvec{{n}}}= \underline{\varvec{{F}}}^{\underline{\varvec{{n}}}}\underline{\varvec{{g}}}_{S1,0}\). This specific definition of a deformation gradient allows for the following multiplicative split:

where \(\underline{\varvec{{R}}}^{\underline{\varvec{{n}}}}\) describes the (pure) rotation from the initial solid triad \(\underline{\varvec{{\varLambda }}}_{S,0}\) onto a (still to be defined) orthonormal intermediate triad \({\bar{\underline{\varvec{{\varLambda }}}}}=[\bar{\underline{\varvec{{g}}}}_{1},\bar{\underline{\varvec{{g}}}}_{2},\bar{\underline{\varvec{{g}}}}_{3}]\), whose base vectors \(\bar{\underline{\varvec{{g}}}}_{2}\) and \(\bar{\underline{\varvec{{g}}}}_{3}\) lie within the \(\underline{\varvec{{n}}}\)-plane, and \(\underline{\varvec{{F}}}^{\text {2D}}\) represents a (quasi-2D) in-plane deformation between \(\bar{\underline{\varvec{{g}}}}_{2}\) and \(\bar{\underline{\varvec{{g}}}}_{3}\) and the non-orthonormal base vectors \({\underline{\varvec{{g}}}}_{2}\) and \({\underline{\varvec{{g}}}}_{3}\). Now, by applying the polar decomposition only to the in-plane deformation, i.e.

a solid triad can be defined from the initial triad \(\underline{\varvec{{\varLambda }}}_{S,0}\) as:

Once an intermediate triad \({\bar{\underline{\varvec{{\varLambda }}}}}\) is defined, the required rotation tensors \(\underline{\varvec{{R}}}_{S}^{\text {2D}}\) and \(\underline{\varvec{{R}}}^{\underline{\varvec{{n}}}}\) can be calculated as follows:

-

1.

\(\underline{\varvec{{R}}}^{\underline{\varvec{{n}}}}= {\bar{\underline{\varvec{{\varLambda }}}}} \underline{\varvec{{\varLambda }}}_{S,0}^{\mathrm T}\),

-

2.

\(\underline{\varvec{{F}}}^{\text {2D}}= \underline{\varvec{{F}}}^{\underline{\varvec{{n}}}}(\underline{\varvec{{R}}}^{\underline{\varvec{{n}}}})^{\mathrm T}\),

-

3.

\((\underline{\varvec{{v}}}^{\text {2D}})^2 = \underline{\varvec{{F}}}^{\text {2D}}(\underline{\varvec{{F}}}^{\text {2D}})^{\mathrm T}\),

-

4.

\(\underline{\varvec{{R}}}_{S}^{\text {2D}}= (\underline{\varvec{{v}}}^{\text {2D}})^{-1} \underline{\varvec{{F}}}^{\text {2D}}\).

The last remaining question is the definition of the triad \({\bar{\underline{\varvec{{\varLambda }}}}}\). It can be shown that the choice of this triad is arbitrary and does not influence the result, since a corresponding in-plane rotation offset would be automatically considered/compensated (in the sense of a superposed rigid body rotation) via the rotational part \(\underline{\varvec{{R}}}_{S}^{\text {2D}}\) of the in-plane polar decomposition (43). For example, a simple choice is given by \(\bar{\underline{\varvec{{g}}}}_{1}\!=\underline{\varvec{{n}}}\), \(\bar{\underline{\varvec{{g}}}}_{2}\!={\underline{\varvec{{g}}}}_{S2}/ \Vert {\underline{\varvec{{g}}}}_{S2}\Vert \) and \(\bar{\underline{\varvec{{g}}}}_{3}\!=\underline{\varvec{{n}}} \times \bar{\underline{\varvec{{g}}}}_{2}\), which coincides with the solid triad definition later discussed in Sect. 5.3.1.

Remark 5.1

It can be verified that \(\underline{\varvec{{R}}}_{S}= \underline{\varvec{{R}}}_{S}^{\text {2D}}\underline{\varvec{{R}}}^{\underline{\varvec{{n}}}}\) is fulfilled for quasi-2D deformation states, e.g. for pure torsion load cases where the beam axis remains straight during the entire deformation (see example in Sect. 7.5). In this case, the (simpler) polar decomposition of the total deformation gradient \(\underline{\varvec{{F}}}\) according to (40) can exploited.

5.2.2 Properties of \({\hbox {STR}-\text {POL}}\) triad

In contrast to alternative solid triad definitions that will be investigated in the following sections, the definition according to (44), referred to as \({\hbox {STR}-\text {POL}}\) or by the subscript \((\cdot )_{\text {POL}}\), is not biased by an ad-hoc choice of material directors in the solid that are coupled to the beam. Instead, the rotation tensor \(\underline{\varvec{{R}}}_{S}\) describes the rotation of material directions coinciding with the principle axes of the deformation (i.e. it maps the principle axes from the reference to the spatial configuration), which has two important implications: First, the choice of material directions that are coupled depend on the current deformation state and will in general vary in time. Second, the principle axes represent an orthonormal triad per definition, and, thus the coupling to the beam triad will not impose any constraints on the local in-plane deformation of the solid. Consequently, this solid triad variant fulfills both requirements (i) and (ii) as stated above.

Eventually, a further appealing property of the \({\hbox {STR}-\text {POL}}\) triad shall be highlighted. Let \(\theta _0 \in [-\pi , \pi ]\) represent the orientation of arbitrary in-plane directors in the reference configuration defined to coincide for solid and beam according to \(\underline{\varvec{{g}}}_{S,0}(\theta _0)=\underline{\varvec{{g}}}_{B,0}(\theta _0)=\cos {(\theta _0)} \, \underline{\varvec{{g}}}_{B2,0} +\sin {(\theta _0)} \, \underline{\varvec{{g}}}_{B3,0}\). Their push-forward is given by \(\underline{\varvec{{g}}}_{S}(\theta _S(\theta _0)) = \underline{\varvec{{F}}}^{\underline{\varvec{{n}}}}\, \underline{\varvec{{g}}}_{S,0}(\theta _0)\) for the solid and \(\underline{\varvec{{g}}}_{B}(\theta _B(\theta _0)) = \underline{\varvec{{R}}}_B \, \underline{\varvec{{g}}}_{B,0}(\theta _0)\) for the beam, where the angles \(\theta _S \in [-\pi ,\pi ]\) and \(\theta _B \in [-\pi ,\pi ]\) represent the corresponding in-plane orientations in the deformed configuration (see Appendix 1 for a detailed definition). Since in-plane shear deformation is permissible for the solid but not for the beam, the orientations \(\theta _S(\theta _0)\) and \(\theta _B(\theta _0)\) cannot be identical for all \(\theta _0 \in [-\pi ,\pi ]\) and arbitrary deformation states. However, as demonstrated in Appendix 1, when coupling the beam triad to the \({\hbox {STR}-\text {POL}}\) triad according to (44), the beam directors \(\underline{\varvec{{g}}}_{B}(\theta _B(\theta _0)\) represent the orientation of the solid directors \(\underline{\varvec{{g}}}_{S}(\theta _S(\theta _0)\) in an average sense such that the following \(L_2\)-norm is minimized:

In conclusion, \({\hbox {STR}-\text {POL}}\) is an obvious choice for the solid triad with many favorable properties, e.g. it represents the average orientation of material solid directions in a \(L_2\)-optimal manner. However, it requires the calculation of the square root of a tensor, and more importantly, for latter variation and linearization procedures also the first and second derivatives of the tensor square root with respect to the solid degrees of freedom. This results in considerable computational costs, since this operation has to be performed at local Gauss point level. Therefore, alternative solid triad definitions will be proposed in the following that can be computed more efficiently, while still being able to represent global system responses with sufficient accuracy.

5.3 Alternative solid triad definitions

All solid triad variants considered in the following rely on the non-orthonormal solid directors \(\underline{\varvec{{g}}}_{S2}\) and \(\underline{\varvec{{g}}}_{S3}\) according to (35), their normalized counterparts

and the corresponding normal vector \(\underline{\varvec{{n}}}\) according to (38). Based on these definitions, three different variants will be exemplified in the following.

5.3.1 Fixed single solid director (\({\hbox {STR}-{\text {DIR}_{\text {2/3}}}}\))

In the first variant, denoted as \({\hbox {STR}-{\text {DIR}_{\text {2/3}}}}\), the orientation of one single solid director, either \(\underline{\varvec{{g}}}_{S2}'\) or \(\underline{\varvec{{g}}}_{S3}'\), is fixed to the solid triad, cf. Figure 3(b). The choice which solid material direction to couple is arbitrary. Therefore, two variants will be distinguished:

Since the variant \({\hbox {STR}-{\text {DIR}_{\text {2/3}}}}\) does not fulfill the requirement (i) as stated above, it will only be considered for comparison reasons in the 2D verification examples in Sect. 7.

5.3.2 Fixed average solid director (\({\hbox {STR}-{\text {AVG}}}\))

In order to solve this problem, i.e. to define a solid triad that is symmetric with respect to the base vectors \(\underline{\varvec{{g}}}_2'\) and \(\underline{\varvec{{g}}}_3'\), an alternative variant denoted as \({\hbox {STR}-{\text {AVG}}}\) is proposed, which relies on the average of the directors \(\underline{\varvec{{g}}}_2'\) and \(\underline{\varvec{{g}}}_3'\), cf. Fig. 3(c):

With this average vector the solid triad can be constructed as:

The rotation tensor  in (50) represents a “back-rotation” of the constructed reference triad \(\underline{\varvec{{\varLambda }}}_{S,{\text {AVG}},\text {ref}}\) by an angle of \(-\pi /4\) to ensure that the resulting solid triad aligns with the beam triad in the reference configuration according to (32). In Sect. 7, it will be shown numerically that the variant \({\hbox {STR}-{\text {AVG}}}\), similar to the variant \({\hbox {STR}-\text {POL}}\), fulfills both requirements (i) and (ii) stated above.

in (50) represents a “back-rotation” of the constructed reference triad \(\underline{\varvec{{\varLambda }}}_{S,{\text {AVG}},\text {ref}}\) by an angle of \(-\pi /4\) to ensure that the resulting solid triad aligns with the beam triad in the reference configuration according to (32). In Sect. 7, it will be shown numerically that the variant \({\hbox {STR}-{\text {AVG}}}\), similar to the variant \({\hbox {STR}-\text {POL}}\), fulfills both requirements (i) and (ii) stated above.

Remark 5.2

Theoretically, an additive director averaging procedure such as (49) can result in a singularity if the underlying vectors are anti-parallel, i.e. \(\underline{\varvec{{g}}}_{S2}' =- \underline{\varvec{{g}}}_{S3}'\). However, since the associated material directors are orthogonal in the reference configuration, i.e. \(\underline{\varvec{{g}}}_{S2,0}^{\mathrm T}\underline{\varvec{{g}}}_{S3,0}=0\), and shear angles smaller than \(\pi /2\) can be assumed, this singularity will not be relevant for practical applications.

Illustration of \({\hbox {STR}-{\text {DIR}_{2}}}\), \({\hbox {STR}-{\text {AVG}}}\) and \({\hbox {STR}-\text {ORT}}\) solid triad definitions for an exemplary 2D problem setting. For simplicity it is assumed that the beam reference triad aligns with the Cartesian frame \(\underline{\varvec{{e}}}_1, \underline{\varvec{{e}}}_2, \underline{\varvec{{e}}}_3\), i.e. \(\underline{\varvec{{\varLambda }}}_{B,0}= \underline{\varvec{{I}}}\). a Reference configuration, b \({\hbox {STR}-{\text {DIR}_{2}}}\), c \({\hbox {STR}-{\text {AVG}}}\) and d \({\hbox {STR}-\text {ORT}}\)

5.3.3 Fixed orthogonal solid material directions (\({\hbox {STR}-\text {ORT}}\))

In the last considered solid triad definition, both material directors \(\underline{\varvec{{g}}}_{S2}'\) and \(\underline{\varvec{{g}}}_{S3}'\) are coupled to the solid triad simultaneously. This variant enforces that the directors \(\underline{\varvec{{g}}}_{S2}'\) and \(\underline{\varvec{{g}}}_{S3}'\) remain orthogonal to each other, and thus it is denoted as \({\hbox {STR}-\text {ORT}}\), indicated by a subscript \((\cdot )_{\text {ORT}}\). The \({\hbox {STR}-\text {ORT}}\) variant is realized by applying the rotational coupling constraints (19) twice, once with \(\underline{\varvec{{\varLambda }}}_{S,{\text {DIR}_{2}}}\) according to (47) and once with \(\underline{\varvec{{\varLambda }}}_{S,{\text {DIR}_{3}}}\) according to (48).

Opposed to the other triad definitions in this section, this version additionally imposes a constraint on the solid displacement field by enforcing all shear strain components to vanish at the coupling point. In Sect. 7, it will be demonstrated that this over-constrained solid triad definition can lead to severe shear locking effects, i.e. requirement (ii) from Sect. 5.1 is not satisfied. Thus, also this variant will only be considered for comparison reasons in the 2D verification examples in Sect. 7.

5.4 Variation of the solid rotation vector

In the coupling contributions to the weak form (24) and (26) the multiplicative rotation vector variation \(\delta \underline{\varvec{{\theta }}}_{S}\) (spin vector) of a solid rotation vector \(\underline{\varvec{{\psi }}}_{S}\) arises. The spin vector is work-conjugated with the coupling moments, i.e. it is required to calculate the virtual work of a moment acting on the solid in a variationally consistent manner. In contrast to the beam spin vector \(\delta \underline{\varvec{{\theta }}}_{B}\), which represents the multiplicative variation of primal degrees of freedom in the finite element discretization of the geometrically exact Simo–Reissner beam theory and is discretized directly, no such counterpart exists for the solid field. Therefore, it is assumed that the solid spin vector can be stated as a function of a set of generalized solid degrees of freedom \(\varvec{{q}}\) (which will later be identified as nodal position vectors in the context of a finite element discretization) and their variations \(\delta \varvec{{q}}\). The additive variation of the solid rotation vector \(\underline{\varvec{{\psi }}}_{S}(\varvec{{q}})\) then reads

The multiplicative and additive variations are related via (7), which gives the spin vector associated with the solid triad as a function of the generalized solid degrees of freedom:

Remark 5.3

Alternatively, the solid spin vector can be expressed by the variations of the corresponding solid triad basis vectors \(\underline{\varvec{{g}}}_{Si}\) and their variations \(\delta \underline{\varvec{{g}}}_{Si}\), cf. [36, 38]:

This formulation for the solid spin vector is equivalent to the one in (52), but only contains the solid triad basis vectors and their variations. Therefore, this definition of the solid spin vector is better suited for solid triads constructed via their basis vector. Especially in the implementation of the finite element formulation, it is advantageous to avoid the computation and inversion of the transformation matrix in (52). Nonetheless, in the remainder of this contribution, the solid spin vector as defined in (52) is used to improve readability of the equations.

6 Spatial discretization

In this work, spatial discretization of the beam, solid and coupling problem will exclusively be based on the finite element method. In the following, a subscript \((\cdot )_h\) refers to an interpolated field quantity, superscripts \({(e)}\) and \({(f)}\) indicate that the quantity is defined for a solid element \(e\) and a beam element \(f\), respectively. Accordingly, \({(e,f)}\) refers to coupling terms between the solid element \(e\) and beam element \(f\). The global element count is made up of \(n_{\text {el},S}\) solid finite elements and \(n_{\text {el},B}\) beam finite elements.

6.1 Solid and beam problem

For the solid domain an isoparametric finite element approach is used to interpolate position, displacement and virtual displacement field within each solid element \(\varOmega _{S,h}^{(e)}\):

Therein, \(\varvec{{N}}^{(e)}\in {\mathbb {R}}^{3\times n_{\text {dof}}^{(e)}}\) is the element shape function matrix, which depends on the solid element parameter coordinates \(\xi ^S, \eta ^S, \zeta ^S\in {\mathbb {R}}^{}\). Furthermore, \({\varvec{{X}}^{S{(e)}}}\in {\mathbb {R}}^{n_{\text {dof}}^{(e)}}\), \({\varvec{{d}}^{S{(e)}}}\in {\mathbb {R}}^{n_{\text {dof}}^{(e)}}\) and \({\delta {\varvec{{d}}^{S{(e)}}}}\in {\mathbb {R}}^{n_{\text {dof}}^{(e)}}\) are the element reference position vector, element displacement vector and element virtual displacement vector, respectively. Each solid element has \(n_{\text {dof}}^{(e)}\) degrees of freedom.

The beam finite elements used in this work are based on the Simo–Reissner formulation presented in [35, 38]. Figure 4. illustrates the degrees of freedom for a single beam finite element. The beam centerline interpolation is \(C^{1}\)-continuous based on third-order Hermite polynomials with two centerline nodes per element. Each node for the centerline interpolation has 6 degrees of freedom: 3 for the nodal position \({\hat{\underline{\varvec{{r}}}}}^{(f)}_i\) and 3 for the centerline tangent \(\hat{\underline{\varvec{{t}}}}^{(f)}_i\) at the node, thus resulting in a total of 12 element degrees of freedom describing the beam centerline position. The interpolated position of the beam centerline is

with the beam position shape function matrix \(\varvec{{H}}^{(f)}\in {\mathbb {R}}^{3\times 12}\), the beam centerline reference position vector \(\varvec{{X}}^{B{(f)}}\in {\mathbb {R}}^{12}\) and the beam centerline displacement vector \(\varvec{{d}}^{B{(f)}}\in {\mathbb {R}}^{12}\). Furthermore, \(\xi ^B\in {\mathbb {R}}^{}\) is the parameter coordinate along the beam centerline.

A triad interpolation scheme based on three element nodal rotation vectors \({\hat{\underline{\varvec{{\psi }}}}}^{(f)}_1\), \({\hat{\underline{\varvec{{\psi }}}}}^{(f)}_2\) and \({\hat{\underline{\varvec{{\psi }}}}}^{(f)}_3\) is utilized [14]. The third node is placed in the middle of the element and carries no translational degrees of freedom, only rotational ones. The three local nodal rotation vectors serve as primal degrees of freedom for the interpolated rotation field along the beam centerline. Each local rotation vector has 3 degrees of freedom, thus resulting in a total of 9 rotational degrees of freedom per beam finite element. The interpolation of the beam cross-section triad along the beam centerline is a non-trivial task and requires an orthonormal interpolation scheme for the interpolated triad \(\underline{\varvec{{\varLambda }}}_{B,h}^{(f)}(\xi ^B)\) to guarantee that the interpolated triad field is still a member of the rotational group \(SO^3\). Furthermore, objectivity of the discrete beam deformation measures has to be preserved by the interpolation, which is a challenging task if rotational degrees of freedom are involved. In this contribution we will refer to the interpolated triad field  as an abstract nonlinear function of the beam parameter coordinate and the nodal rotation vectors. The corresponding interpolated field of multiplicative rotation vector increments \(\varDelta \underline{\varvec{{\theta }}}_{B,h}^{(f)}(\xi ^B)\) has been consistently derived in [14] and reads:

as an abstract nonlinear function of the beam parameter coordinate and the nodal rotation vectors. The corresponding interpolated field of multiplicative rotation vector increments \(\varDelta \underline{\varvec{{\theta }}}_{B,h}^{(f)}(\xi ^B)\) has been consistently derived in [14] and reads:

Therein, \(\tilde{\underline{\varvec{{I}}}}^{(f)}_i \in {\mathbb {R}}^{3\times 3}\) are generalized shape function matrices for the multiplicative nodal rotation increments \(\varDelta \hat{\underline{\varvec{{\theta }}}}^{(f)}_i\), and \(\tilde{\varvec{{I}}}^{(f)}\in {\mathbb {R}}^{3 \times 9}\) and \(\varDelta \hat{\varvec{\theta }}_{B}^{(f)} \in {\mathbb {R}}^{9}\) are the corresponding element-wise assembled quantities. It should be pointed out that \(\tilde{\underline{\varvec{{I}}}}^{(f)}_i\) are nonlinear functions of the beam parameter coordinate and the nodal rotation vectors of the beam element, i.e. these rotational shape functions are deformation-dependent. To avoid this nonlinearity in the discretized spin vector, i.e. the virtual rotation field \({\delta \underline{\varvec{{\theta }}}_{B,h}^{(f)}}\), which would require additional linearization contributions to calculate a consistent tangent, the beam finite elements employed in this work follow a Petrov–Galerkin discretization approach. Therein, standard Lagrange shape functions are used to interpolate the discretized nodal spin vectors:

Here, \(L^{(f)}_i \in {\mathbb {R}}^{}\) are standard second-order Lagrange polynomials, and \(\delta \hat{\underline{\varvec{{\theta }}}}^{(f)}_i\) are the nodal spin vectors. Again, this equation can be assembled element-wise, thus resulting in the shape function matrix \({\varvec{{L}}^{(f)}}\in {\mathbb {R}}^{3 \times 9}\) and the element spin vector \({\delta \hat{\varvec{{\theta }}}_B^{(f)}}\in {\mathbb {R}}^{9}\).

In what follows, all coupling terms are evaluated on the beam centerline. This requires the projection of points along the beam centerline parameter space into the solid element parameter space, which in turn is achieved by solving the set of nonlinear equations  , for a given \(\xi ^B\). To improve readability, the superscripts indicating the beam and solid elements will be omitted from now on. They will however be stated in the virtual work contributions and the integration domains in order to clearly indicate pair-wise values. Additionally, any dependency on element parameter coordinates will not be stated explicitly.

, for a given \(\xi ^B\). To improve readability, the superscripts indicating the beam and solid elements will be omitted from now on. They will however be stated in the virtual work contributions and the integration domains in order to clearly indicate pair-wise values. Additionally, any dependency on element parameter coordinates will not be stated explicitly.

Remark 6.1

While the \(C^1\)-continuous centerline representation of the employed beam elements [35] is not mandatory for the considered beam-to-solid volume coupling problem, it offers significant advantages in problems additionally involving beam-to-beam [39] or beam-to-solid contact interaction, which will be addressed in our future research.

6.2 Gauss point-to-segment coupling of cross-section rotations

Evaluating the variation of the total coupling potential (24) based on the discretized solid position field and beam cross-section rotation field as presented in the last section yields the discrete variation of the coupling potential:

Therein, \(\varGamma _{c,h}^{{(e,f)}}= \varOmega _{B,h}^{(f)}\cap \varOmega _{S,h}^{(e)}\) is the discretized coupling domain between beam element \({(f)}\) and solid element \({(e)}\). The integral in (59) is evaluated numerically via a Gauss–Legendre quadrature, resulting in a Gauss point-to-segment (GPTS) coupling scheme. From a mechanical point of view this can be interpreted a weighted enforcement of the rotational constraints at each integration point along the beam, i.e. a Gauss point-to-segment type coupling:

where \(n_{\text {GP}}\) is the number of Gauss–Legendre points, \({\tilde{\xi }}^B_{i}\) is the beam element parameter coordinate for Gauss–Legendre point \(i\) with the corresponding weight \(w_i\). Again, in order to improve the readability of the remaining equations in this subsection, the explicit indication of the evaluation at the Gauss–Legendre points will be omitted in the following. The previous equation can now be stated in matrix form as

Therein, the abbreviations \(\varvec{{f}}_{c,\text {GP}}^{B}\in {\mathbb {R}}^{9}\) and \(\varvec{{f}}_{c,\text {GP}}^{S}\in {\mathbb {R}}^{n_{\text {dof}}^{(e)}}\) for the generalized Gauss point coupling forces on the rotational beam degrees of freedom and the generalized solid element degrees of freedom, respectively, have been introduced:

Furthermore, \(\varvec{{r}}_{c,\text {GP}}^B\in {\mathbb {R}}^{9}\) and \(\varvec{{r}}_{c,\text {GP}}^S\in {\mathbb {R}}^{n_{\text {dof}}^{(e)}}\) are the beam and solid coupling residual vectors. Employing a Newton–Raphson algorithm to solve the global system of nonlinear equations, a linearization of the residual vectors with respect to the element degrees of freedom is required, which reads:

Therein, the transformation matrix \(\underline{\varvec{{T}}}(\underline{\varvec{{\psi }}}_{B,h})\) appears, since the linearization is performed with respect to the multiplicative rotation increments \(\varDelta \underline{\varvec{{\theta }}}_{B,h}\). Furthermore, the generalized shape function matrix \(\tilde{\varvec{{I}}}\) follows from the interpolation of the multiplicative rotation increments, cf. (57). The previously derived matrices and vectors are all defined on beam-to-solid element pair level. Since no additional degrees of freedom are introduced, the pair-wise contributions can simply be assembled and added to the global linear system of equations. The Gauss point-to-segment coupling approach is presented here to illustrate how the rotational coupling conditions can be enforced in a point-wise manner. However, in [63] it has been shown that a Gauss point-to-segment coupling approach leads to spurious contact locking for embedded one-dimensional beams in three-dimensional solid volumes. Therefore, this approach will not be investigated further in the remainder of this contribution, but a mortar-type coupling is proposed instead.

6.3 Mortar-type coupling of cross-section rotations

Employing a mortar-type coupling approach, the rotational Lagrange multiplier field \(\underline{\varvec{{\lambda }}}_{\theta }\) introduced in Sect. 4.3.2 is also approximated with a finite element interpolation, cf. [7, 46, 71]. The rotational Lagrange multiplier field is defined along the beam centerline and accordingly its finite element approximation is defined along the beam finite element and reads as follows:

where \(n_{\lambda }^{(f)}\) is the number of Lagrange multiplier nodes on beam element \({(f)}\), \(\varPhi ^{(f)}_i\) is the shape function for the local node i and \(\varvec{{\lambda }}^{(f)}_{\theta ,i}\in {\mathbb {R}}^{3}\) is the rotational Lagrange multiplier at node i. Furthermore, \({\varvec{{\varPhi }}^{(f)}}\in {\mathbb {R}}^{3 \times 3 n_{\lambda }^{(f)}}\) is the element-wise assembled Lagrange multiplier shape function matrix for a beam element and \({\varvec{{\lambda }}_{\theta }^{(f)}}\in {\mathbb {R}}^{3 n_{\lambda }^{(f)}}\) is the vector with all corresponding discrete rotational Lagrange multiplier values per beam element. As indicated by the dependency on beam parameter coordinate \(\xi ^B\), the Lagrange multiplier field is defined along the beam centerline. However, there is no requirement that the Lagrange multiplier shape functions are identical to the beam centerline shape functions, or even that the number of beam nodes matches the number of Lagrange multiplier nodes. A more thorough discussion on the choice of Lagrange multiplier shape functions is given at the end of this section.

When inserting the finite element interpolations, the discretized variation of the coupling constraints (26) reads

Therein, the abbreviations \(\varvec{{g}}_{c,\lambda _\theta }\in {\mathbb {R}}^{n_{\text {dof},\lambda }^{(f)}}\) and \(\varvec{{r}}_{c,\lambda _\theta }\in {\mathbb {R}}^{n_{\text {dof},\lambda }^{(f)}}\) represent the integrand of the pair constraint equations and the residual of the pair constraints equations, respectively. The discretized virtual work of the coupling forces (27) reads

Therein, the abbreviations \(\varvec{{f}}_{c,\lambda _\theta }^{B}\in {\mathbb {R}}^{9}\) and \(\varvec{{f}}_{c,\lambda _\theta }^{S}\in {\mathbb {R}}^{n_{\text {dof}}^{(e)}}\) represent the integrand of the beam and solid element coupling forces, i.e.

Furthermore, \(\varvec{{r}}_{c,\lambda _\theta }^B\in {\mathbb {R}}^{9}\) and \(\varvec{{r}}_{c,\lambda _\theta }^S\in {\mathbb {R}}^{n_{\text {dof}}^{(e)}}\) are the beam and solid coupling residual vectors, respectively. Again, a linearization of the residual contributions with respect to the discrete beam-to-solid pair degrees of freedom is required for the Newton–Raphson algorithm. The linearization is:

Therein, the abbreviations \(\varvec{{q}}_{(\cdot )}\) for the stiffness matrices of the pair-wise coupling terms have been introduced, i.e.

As in the GPTS case, the previously derived vectors and matrices are all defined on beam-to-solid element pair level. However, in this case additional unknowns have been introduced, i.e. the rotational Lagrange multipliers \(\varvec{{\lambda }}_{\theta }\) on pair level. In practice, all derivatives explicitly stated in (66) and (68) are evaluated using forward automatic differentiation (FAD), cf. [28], using the Sacado software package [56], which is part of the Trilinos project [67].

At this point it should be pointed out that all coupling integrals are evaluated numerically using so-called segment-based integration, cf. [18, 63]. Therein, the beam finite element parameter space is divided into subsegments at points where the beam crosses a solid finite element face. Each subsegment is subsequently integrated using a Gauss–Legendre quadrature with a fixed number of integration points. This leads to a highly accurate numerical integration procedure and allows for the resulting finite element coupling method to pass classical patch tests in surface-to-surface problems as well as constant stress transfer tests in beam-to-solid problems, cf. [18, 63].