Abstract

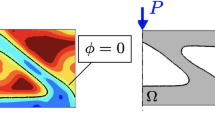

This work addresses the treatment of lower density regions of structures undergoing large deformations during the design process by the topology optimization method (TOM) based on the finite element method. During the design process the nonlinear elastic behavior of the structure is based on exact kinematics. The material model applied in the TOM is based on the solid isotropic microstructure with penalization approach. No void elements are deleted and all internal forces of the nodes surrounding the void elements are considered during the nonlinear equilibrium solution. The distribution of design variables is solved through the method of moving asymptotes, in which the sensitivity of the objective function is obtained directly. In addition, a continuation function and a nonlinear projection function are invoked to obtain a checkerboard free and mesh independent design. 2D examples with both plane strain and plane stress conditions hypothesis are presented and compared. The problem of instability is overcome by adopting a polyconvex constitutive model in conjunction with a suggested relaxation function to stabilize the excessive distorted elements. The exact tangent stiffness matrix is used. The optimal topology results are compared to the results obtained by using the classical Saint Venant–Kirchhoff constitutive law, and strong differences are found.

Similar content being viewed by others

References

Allaire G, Jouve F, Toader AM (2004) Structural optimization using sensitivity analysis and a level-set method. J Comput Phys 194(1):363–393

Armero F, Love E (2003) An arbitrary Lagrangian–Eulerian finite element method for finite strain plasticity. Int J Numer Methods Eng 57(4):471–508

Ball JM (1943) Convexity conditions and existence theorems in nonlinear elasticity. Arch Ration Mech Anal 63(4):337–403

Bendsøe MP (1989) Optimal shape design as a material distribution problem. Struct Optim 1:192–202

Bendsøe MP, Kikuchi N (1988) Generating optimal topologies in structural design using a homogenization method. Comput Methods Appl Mech Eng 71(2):197–224

Bendsøe MP, Sigmund O (2004) Topology optimization, 2nd edn. Springer, Berlin

Bertran A (2008) Elasticity and plasticity of large deformation, an introduction, 2nd edn. Springer, Berlin

Bonet J, Wood RD (2008) Nonlinear continuum mechanics for finite element analysis, 2nd edn. Cambridge University Press, Cambridge

Bourdin B (2001) Filters in topology optimization. Int J Numer Methods Eng 50(9):2143–2158

Bruns TE (2005) A reevaluation of the SIMP method with filtering and an alternative formulation for solid void topology optimization. Struct Multidiscip Optim 30(6):428–436

Bruns TE, Tortorelli DA (2001) Topology optimization of non-linear elastic structures and compliant mechanisms. Comput Methods Appl Mech Eng 190(26–27):3443–3459

Bruns TE, Tortorelli DA (2003) An element removal and reintroduction strategy for the topology optimization of structures and compliant mechanisms. Int J Numer Methods Eng 57(10): 1413–1430

Bruns TE, Sigmund O, Tortorelli DA (2002) Numerical methods for the topology optimization of structures that exhibit snap-through. Int J Numer Methods Eng 55(10):1215–1237

Buhl T, Pedersen C, Sigmund O (2000) Stiffness design of geometrically nonlinear structures using topology optimization. Struct Multidiscip Optim 19(2):93–104

Campello EMB, Pimenta PM, Wriggers P (2003) A triangular finite shell element based on a fully nonlinear shell formulation. Comput Mech 31(6):505–518

Cho S, Jung H-S (2003) Design sensitivity analysis and topology optimization of displacement-loaded non-linear structures. Comput Methods Appl Mech Eng 192:2539–2553

Ciarlet PG (1988) Mathematical elasticity, vol 1, 1st edn. Elsevier, Amsterdam

Dacorogna B (2000) Direct methods in the calculus of variations, vol 78, 2nd edn. Elsevier, Amsterdam

Eschenauer HA, Olhoff N (2001) Topology optimization of continuum structures: a review. Appl Mech Rev 54(4):331–390

Gea HC, Luo J (2001) Topology optimization of structures with geometrical nonlinearities. Comput Struct 79:1977–1985

Gurtin ME, Fried E, Anand L (2010) The mechanics and thermodynamics of continua, vol 1, 1st edn. Cambridge University Press, Cambridge

Haftka RT (1985) Simultaneous analysis and design. AIAA J 23:1099–1103

Jog C (1996) Distributed-parameter optimization and topology design for non-linear thermoelasticity. Comput Methods Appl Mech Eng 132:117–134

Kawamoto A (2003) Stabilization of geometrically nonlinear topology optimization by the Levenberg–Marquardt method. Struct Multidiscip Optim 37(4):429–433

Kemmler R, Lipka A, Ramm E (2005) Large deformations and stability in topology optimization. Struct Multidiscip Optim 30(6):459–476

Klarbring A, Stromberg N (2012) Topology optimization of hyperelastic bodies including non-zero prescribed displacements. Struct Multidiscip Optim 47:37–48

Kuhl E, Askes H, Steinmann P (2006) An illustration of the equivalence of the loss of ellipticity conditions in spatial and material settings of hyperelasticity. Eur J Mech A 25(2):199–214

Kuritz SP, Fleury C (1989) Mixed variable structural optimization ung convex linearization techniques. Eng Optim 15:27–41

Morrey CB Jr (1952) Quasi-convexity and the lower semicontinuity of multiple integrals. Pac J Math 2:25–53

Nakasone PH, Silva ECN (2010) Dynamic design of piezoelectric laminated sensors and actuators using topology optimization. J Intell Mater Syst Struct 22:2161–2172

Pedersen CBW, Buhl T, Sigmund O (2001) Topology synthesis of large-displacement compliant mechanisms. Int J Numer Methods Eng 50:2683–2705

Penzler P, Rumpf M, Wirth B (2012) A phase-field model for compliance shape optimization in nonlinear elasticity. ESAIM Control Optim Calc Var 18:229–258

Pimenta PM, Campello EMB, Wriggers P (2004) A fully nonlinear multi-parameter shell model with thickness variation and a triangular shell finite element. Comput Mech 34:181–193. doi:10.1007/s00466-004-0564-2

Raoult A (1986) Non-polyconvexity of the stored energy function of a Saint Venant–Kirchhoff material. Apl Mat 31:417–419

Reddy JN (2004) An introduction to nonlinear finite element analysis, 1st edn. Oxford University Press, New York

Rozvany GIN, Zhou M, Birker T (1992) Generalized shape optimization without homogenization. Struct Multidiscip Optim 4(2):250–252

Schillinger D, Düster A, Rank E (2012) The hp-d-adaptive finite cell method for geometrically nonlinear problems of solid mechanics. Int J Numer Methods Eng 89(9):1171–1202

Simo JC, Hughes TRJ (1991) Plasticity and viscoplasticity: numerical analysis and computational aspects. Springer, Berlin

Stegmann J, Lund E (2004) Nonlinear topology optimization of layered shell structures. Struct Multidiscip Optim 29(5):349–360

Svanberg K (1987) The method of moving asymptotes—a new method for structural optimization. Int J Numer Methods Eng 24:359–373

Treloar LRG (1943) The elasticity of a network of long chain molecules-i. Trans Faraday Soc 39:36–41

Wriggers P (2008) Nonlinear finite element methods, 1st edn. Springer, Berlin

Yoon GH, Kim YY (2005) Element connectivity parameterization for topology optimization of geometrically nonlinear structures. Int J Solids Struct 42(7):1983–2009

Yuge K (1999) Optimization of 2-d structures subjected to nonlinear deformations using the homogenization method. Struct Optim 17:286–299

Acknowledgments

The authors would like to thank Professor Krister Svanberg who supplied a copy of the MMA algorithm. The first author would like to thank FUSP (“Fundação de Apoio à Universidade de São Paulo”) for the training and research fellowship provided for the development of this work (Project Number 182208) and CAPES (“Coordenação de Aperfeiçoamento de Pessoal de Nível Superior”) for his doctoral scholarship. The second author would like to thank CNPq (Conselho Nacional de Desenvolvimento Científico e Tecnológico) and FAPESP (“Fundação de Amparo a Pesquisa do Estado de São Paulo”) for the doctoral scholarship provided (5949-11-4). The third and fourth authors thank CNPq (Conselho Nacional de Desenvolvimento Científico e Tecnológico) for the Research Grants 305869/2009-4 and 301279/2009-8, respectively. The last author would like to thank CNPq (Conselho Nacional de Desenvolvimento Científico e Tecnológico) and FAPESP (“Fundação de Amparo a Pesquisa do Estado de São Paulo”) for the Research Grants 303689/2009-9, and 2011/02387-4. Thanks also to the reviewers who contributed enormously to improve the quality of this lengthy paper.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Appendix

Appendix

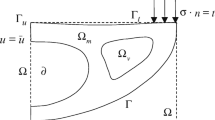

1.1 Kinematics

The following kinematical quantities are used for the description of the stress and tangent tensor. The first of them are the components of the deformation gradient \({\varvec{F}} = {\varvec{f}}_i \otimes {\varvec{e}}_i\), which represents the stretching of the fibers (Fig. 13).

Another important kinematical variables are

that measures the areas of fibers \({\varvec{f}}_i \), and the last equation is \( J = {\varvec{f}}_{(i)} \cdot {\varvec{g}}_{(i)}\), that measures the volume changes (see Fig. 13).

1.2 Saint Venant–Kirchhoff material

The constitutive relation (10) applied to Eq. (12), gives

that is, the stress as a function of the strain. The component \({\varvec{f}}_3 = 1 + \gamma _{33}\) is due to the 2D assumption adopted. In what follows, we present its values and tangent operator for the PE and PS assumptions.

1.2.1 Plane strain (PE)

The PE condition \( \gamma _{33} = 0 \), can be applied directly to Eq. (51). The PE components of first Piola–Kirchhoff stress tensor and strain invariant are given by

The material tangent tensor given by its derivation is

1.2.2 Plane stress (PS)

As explained in Sect. 3.6, the PS condition mathematically consistent is given by the solution of the equation \(\tau _{33}^0 \!=\! 0 \) [15]. The PS components of first Piola–Kirchhoff stress tensor and strain invariant are given by

The components of first Piola–Kirchhoff stress tensor from Eq. (54) can be split into two different tensors, the stress tensor from PE condition and the stress tensor of the PS effect condition \((1+\gamma {33}) {\varvec{e}}_{3}\) and are displayed bellow

where \(\varvec{\omega }_\alpha ^0\) is given by

To obtain the \(\varvec{\omega }_\alpha ^0\) tensor, it is necessary to find \(\gamma _{33}\), however, first, it is necessary to isolate the term \(\tau _{33}^0\), by substituting Eq. (14) into Eq. (54). From \(\varvec{\tau }_{3}^0\), after some algebra arises to

By applying \(\tau _{33}^0 = {\varvec{\tau }}_3^0 \cdot {\varvec{e}}_3 \) into Eq. (57), we obtain

For the plane problem (2D), the stress components \(\tau _{\alpha 3}^0\) and \(\tau _{3\alpha }^0\) are equal to \(0\), and by applying the PE condition \(\tau _{33}^0=0\) into Eq. (57), \(\gamma _{33}\) can be obtained

By substituting \(\gamma _{33}\) from Eq. (59) into Eq. (56), the tensor \(\varvec{\omega }_\alpha ^0\) for plane problem (2D) emerges as

From Eqs. (53), (55), and (60), it is possible to compute the material tangent tensor for PS assumption, leading to

where \({\varvec{Q}}_{\alpha \beta }^0\) is given by

1.3 Neo-Hookean of Simo–Ciarlet material

The constitutive relation (10) applied to Eq. (13), gives

1.3.1 Plane strain (PE)

The PE condition is simply given by \( {\varvec{f}}_{3} = 0\), so that the material tangent tensor is given by

1.3.2 Plane stress (PS)

The solution of the PS condition obtained from Campello et al. [15] for plane problem (2D) is given by

and the material tangent tensor is given by

where

Rights and permissions

About this article

Cite this article

Lahuerta, R.D., Simões, E.T., Campello, E.M.B. et al. Towards the stabilization of the low density elements in topology optimization with large deformation. Comput Mech 52, 779–797 (2013). https://doi.org/10.1007/s00466-013-0843-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00466-013-0843-x