Abstract

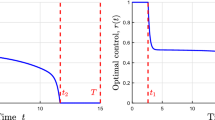

Complete solutions are provided for cell-mass maximization for free and fixed final times and constant and variable yields. The optimal feed rate profile is a concatenation of maximum, minimum and singular feed rates. The exact sequence and duration of each feed rate depends primarily on the initial substrate concentration, and degenerate cases arise due to the magnitude constraint on the feed rate and the length of final time t f. When the final time is free and not in the performance index, it is infinite for constant yield so that any form of feed rate leads to the same amount of cells, while for variable yield the singular feed rate is exponential and maximizes the yield. For fixed final time the singular feed rate for constant yield is exponential and maximizes the specific growth rate by maintaining the substrate concentration constant, while for variable yield, it is semi-exponential and the substrate concentration starts near the maximum specific growth rate and moves toward the maximum yield. A simple sufficient condition for existence of singular feed rate requires an existence of a region bounded by the maxima of specific growth and cellular yield. Otherwise, the optimal feed rate profile is a bang-bang type and the bioreactor operates in batch mode.

Similar content being viewed by others

Abbreviations

- F :

-

feed rate (cm3/s)

- F max :

-

maximum feed rate (cm3/s)

- F min :

-

minimum feed rate (cm3/s)

- F sin :

-

singular feed rate (cm3/s)

- H :

-

Hamiltonian function

- H 1 :

-

a part of Hamiltonian function

- PI:

-

performance index

- S :

-

substrate concentration (g/cm3)

- S m :

-

substrate concentration at which μ is maximum (g/cm3)

- S Y :

-

substrate concentration at which \(Y_{{X \mathord{\left/ {\vphantom {X S}} \right. \kern-\nulldelimiterspace} S}} \) is maximum (g/cm3)

- S 0 :

-

initial substrate concentration (g/cm3)

- t :

-

time (s)

- t F :

-

time at which the bioreactor is full (s)

- t f :

-

final time (s)

- V :

-

bioreactor volume (cm3)

- V max :

-

maximum bioreactor volume (cm3)

- V 0 :

-

initial volume (cm3)

- V s :

-

volume at the start of singular feed rate (cm3)

- \({\mathbf{x}}\) :

-

state vector (x 1 x 2 x 3 x 4)T

- x 1 :

-

total cell mass (g)

- x 2 :

-

total substrate (g)

- x 3 :

-

bioreactor volume (cm3)

- x 4 :

-

auxiliary state to handle the final time in PI (s)

- X :

-

cell-mass concentration (g/cm3)

- X 0 :

-

initial cell-mass concentration (g/cm3)

- X s :

-

cell-mass concentration at the start of singular feed rate (g/cm3)

- $cell mass :

-

price per unit weight of cell mass

- $operating :

-

operating cost per unit time

- ϕ:

-

switching function

- \({\mathbf{\lambda}}\) :

-

adjoint vector (λ1 λ2 λ3 λ4)

- μ:

-

specific growth rate (/s)

- μm :

-

maximum specific growth rate (/s)

- σ:

-

specific substrate consumption rate (/s)

- σm :

-

maximum specific substrate consumption rate (/s)

References

Berber R, Pertev C, Turker M (1999) Optimization of feeding profile for baker’s yeast production by dynamic programming. Bioprocess Eng 20(3):263–269

Birol G, Ündey C, Parulekar SJ, Çinar AA (2002) Morphologically structured model for penicillin production. Biotechnol Bioeng 77:538–552

Cazzador L (1988) On the optimal control of fed-batch reactors with substrate-inhibited kinetics. Biotechnol Bioeng 31:670–674

Modak JM, Lim HC (1989) Simple nonsingular control approach to fed-batch fermentation optimization. Biotechnol Bioeng 33:11–15

San KY, Stephanopoulos G (1984) A note on the optimality criteria for maximum biomass production in a fed-batch fermentation. Biotechnol Bioeng 26:1261–1264

San KY, Stephanopoulos G (1986) The effect of growth rate delays in substrate-inhibited kinetics on the optimal profile of fed-batch reactors. Biotechnol Bioeng 28:356–361

Weigand WA (1981) Maximum cell productivity by repeated fed-batch culture, constant yield case. Biotechnol Bioeng 23:249–266

Bryson AE, Ho YC (1975) Applied Optimal Control. Wiley, New York

Dunn JC (1967) On the classification of singular and nonsingular extremals for the Pontryagin maximum principle. J Math Anal Appl 17:1–36

Kelley HJ (1965) A transformation approach to singular sub-arcs in optimal trajectory and control problems. J SIAM Control 2:234–241

Acknowledgment

One of the authors (H.S.S) was supported in part by Korea Science and Engineering Foundation (KOSEF) and University of California, Irvine.

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

Proof that zero substrate concentration at the final time S(t f) = 0 implies that the final time t f is infinity

During the filling stage, 0 ≤ t ≤ t F, F > 0, the substrate concentration cannot be zero. Therefore, we consider the subsequent batch period, t F < t ≤ t f in which F = 0 and V = V(t f) = V max. The mass balance equations are

Since the specific rates μ (S)andσ (S) are usually ratios of polynomials in S and must vanish at S = 0, we can rewrite, for example,

where P(S) and Q(S) are polynomials in S and the degree of P(S) is greater than that of SQ(S). Substituting Eq. 4 into 2 and rearranging, we obtain

Using Heaviside expansion we can expand the left-hand side (LHS) assuming the roots of Q(S), a i , i = 1,2,3,...,n are non-repeating (case of repeating roots can be similarly handled),

which at t = t f reduces to

where the last equality is obtained by integrating Eq. 1. If S(t f) = 0, the LHS is negative infinity. Therefore, in order for the RHS to be negative infinity the final time t f must be infinity since the integrand is finite. In other words, the final time must be infinity, t f = ∞, in order for the substrate concentration to reach a zero value, S(t f) = 0. This conclusion holds true, unless there is a zero-order term in specific rates due to a maintenance term or cell lysis.

Rights and permissions

About this article

Cite this article

Shin, H.S., Lim, H.C. Cell-mass maximization in fed-batch cultures. Bioprocess Biosyst Eng 29, 335–347 (2006). https://doi.org/10.1007/s00449-006-0082-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-006-0082-z