Abstract

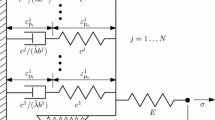

In this paper, a finite strain material model for complex plastic anisotropy with nonlinear isotropic and kinematic hardening is consistently derived. The model is based on the classical multiplicative decomposition of the deformation gradient and derived in a thermodynamically consistent way. An important new aspect of the work is the straightforward implementation of general and anisotropic yield criteria into a constitutive model, which is entirely formulated in the reference configuration. Nevertheless, and for the sake of illustrating the potential of the model, in this work a Barlat-type (Yld2004-18p) yield criterion is employed. The kinematic hardening formulation follows the continuum mechanical extension of the classical rheological model of Armstrong–Frederick hardening. The numerical integration of the evolution equations is carried out using the exponential map approach, which is able to preserve plastic incompressibility. For numerical efficiency purposes, the exponential tensor functions are evaluated in a closed form using the spectral decomposition, and special attention is given to the preservation of the internal variables’ symmetry. The model is assessed by means of several numerical simulations for anisotropic materials at finite strains, including sheet metal forming processes with comparison to experimental data.

Similar content being viewed by others

References

Aretz, H., Barlat, F.: New convex yield functions for orthotropic metal plasticity. Int. J. Nonlin. Mech. 51, 97–111 (2013)

Armstrong, P.J., Frederick, C.O.: A mathematical representation of the multiaxial Bauschinger effect. Central Electricity Generating Board Report, Berkeley Nuclear Laboratories, RD/B/N (1966). p 741

Banabic, D., Aretz, H., Comsa, D.S., Paraianu, L.: An improved analytical description of orthotropy in metallic sheets. Int. J. Plast. 21, 493–512 (2005)

Barlat, F., Lege, D.J., Brem, J.C.: A six-component yield function for anisotropic materials. Int. J. Plast. 7, 693–712 (1991)

Barlat, F., Brem, J.C., Yoon, J.W., Chung, K., Dick, R.E., Lege, D.J., Pourboghrat, F., Choi, S.H., Chu, E.: Plane stress yield function for aluminum alloy sheets. Part 1: theory. Int. J. Plast. 19, 1297–1319 (2003)

Barlat, F., Aretz, H., Yoon, J.W., Karabin, M.E., Brem, J.C., Dick, R.E.: Linear transformation-based anisotropic yield functions. Int. J. Plast. 21, 1009–1039 (2005)

Barlat, F., Grácio, J.J., Lee, M.G., Rauch, E., Vincze, G.: An alternative to kinematic hardening in classical plasticity. Int. J. Plast. 27, 1309–1327 (2011)

Bertram, A.: An alternative approach to finite plasticity based on material isomorphisms. Int. J. Plast. 52, 353–374 (1998)

Cazacu, O., Barlat, F.: Generalization of Drucker’s yield criterion to orthotropy. Math. Mech. Solids 6, 613–630 (2001)

Chaboche, J.L.: Time independent constitutive theories for cyclic plasticity. Int. J. Plast. 2, 149–188 (1986)

Chaboche, J.L.: A review of some plasticity and viscoplasticity constitutive theories. Int. J. Plast. 24, 1642–1693 (2008)

Choi, Y., Han, C.S., Lee, J.K., Wagoner, R.H.: Modeling multi-axial deformation of planar anisotropic elasto-plastic materials, part I: Theory. Int. J. Plast. 22, 1745–1764 (2006)

Dettmer, W., Reese, S.: On the theoretical and numerical modelling of Armstrong–Frederick kinematic hardening in the finite strain regime. Comput. Methods Appl. Mech. Eng. 193, 87–116 (2004)

Eidel, B., Gruttmann, F.: Elastoplastic orthotropy at finite strains: multiplicative formulation and numerical implementation. Comput. Mater. Sci. 28, 732–742 (2003)

Grilo, T.: Development of Computational Anisotropic Hypoelastic- and Hyperelastic-based Models Including Nonlinear Kinematic Hardening. PhD thesis. http://hdl.handle.net/10773/14428 (2015)

Grilo, T.J., Souto, N., Valente, R.A.F., Andrade-Campos, A., Thuillier, S., Alves de Sousa, R.J.: On the development and computational implementation of complex constitutive models and parameters’ identification procedures. Key Eng. Mat. 554–557, 936–948 (2013)

Grilo, T.J., Valente, R.A.F, Alves de Sousa, R.J.: Modelling non-quadratic anisotropic yield criteria and mixed isotropic-nonlinear kinematic hardening: analysis of forward- and backward-Euler formulations. Int. J. Mater. Form. doi:10.1007/s12,289-014-1176-9 (2014)

Han, C.S., Chung, K., Wagoner, R.H., Oh, S.I.: A multiplicative finite elasto-plastic formulation with anisotropic yield functions. Int. J. Plast. 19, 197–211 (2003)

Henann, D.L., Anand, L.: A large deformation theory for rate-dependent elastic–plastic materials with combined isotropic and kinematic hardening. Int. J. Plast. 25, 1833–1878 (2009)

Hill, R.: A theory of the yielding and plastic flow of anisotropic metals. Proc. R. Soc. Lond. A 193, 281–297 (1948)

Hill, R.: A user-friendly theory of orthotropic plasticity in sheet metals. Int. J. Mech. Sci. 35, 19–25 (1993)

Hosford, W.F.: On yield loci of anisotropic cubic metals. In: Proceedings of 7th North American Metalworking Conference, SME, Dearborn, pp. 191–197 (1979)

Hu, W.: An orthotropic yield criterion in a 3-d general stress state. Int. J. Plast. 21, 1771–1796 (2005)

Kim, J.H., Lee, M., Barlat, F., Wagoner, R.H., Chung, K.: An elasto-plastic constitutive model with plastic strain rate potentials for anisotropic cubic metals. Int. J. Plast. 24, 2298–2334 (2008)

Lion, A.: Constitutive modelling in finite thermoviscoplasticity: a physical approach based on nonlinear rheological models. Int. J. Plast. 16, 469–494 (2000)

Menzel, A., Steinmann, P.: Ontfunctions formulation of anisotropic multiplicative elasto-plasticity. Comput. Methods Appl. Mech. Eng. 192, 3431–3470 (2003)

Miehe, C.: Exponential map algorithm for stress updates in anisotropic multiplicative elastoplasticity for single crystals. Int. J. Numer. Meth. Eng. 39, 3367–3390 (1996)

Miehe, C., Apel, N.: Anisotropic elastic-plastic analysis of shells at large strains. A comparison of multiplicative and additive approaches to enhanced finite element design and constitutive modelling. Int. J. Numer. Meth. Eng. 61, 2067–2113 (2004)

Miehe, C., Apel, N., Lambrecht, M.: Anisotropic additive plasticity in the logarithmic strain space: modular kinematic formulation and implementation based on incremental minimization principles for standard materials. Comput. Methods Appl. Mech. Eng. 191, 5383–5425 (2002)

Mollica, F., Rajagopal, K.R., Srinivasa, A.R.: The inelastic behaviour of metals subject to loading reversal. Int. J. Plast. 17, 1119–1146 (2001)

Papadopoulos, P., Lu, J.: On the formulation and numerical solution of problems in anisotropic finite plasticity. Comput. Methods Appl. Mech. Eng. 190, 4889–4910 (2001)

Prager, W.: Recent developments in the mathematical theory of plasticity. J. Appl. Phys. 20, 235–241 (1949)

Reese, S., Christ, D.: Finite deformation pseudo-elasticity of shape memory alloys—constitutive modelling and finite element implementation. Int. J. Plast. 24, 455–482 (2008)

Reese, S., Govindjee, S.: A theory of finite viscoelasticity and numerical aspects. Int. J. Solids Struct. 35, 3455–3482 (1998)

Sansour, C., Karšaj, I., Sorić, J.: A formulation of anisotropic continuum elastoplasticity at finite strains. Part I: modelling. Int. J. Plast. 22, 2346–2365 (2006)

Schröder, J., Gruttmann, F., Löblein, J.: A simple orthotropic finite elasto-plasticity model based on generalized stress–strain measures. Comput. Mech. 30, 48–64 (2002)

Shutov, A.V., Kreißig, R.: Finite strain viscoplasticity with nonlinear kinematic hardening: phenomenological modeling and time integration. Comput. Methods Appl. Mech. Eng. 197, 2015–2029 (2008)

Simo, J.C.: Algorithms for static and dynamic multiplicative plasticity that preserve the classical return mapping schemes of the infinitesimal theory. Comput. Methods Appl. Mech. Eng. 99, 61–112 (1992)

Simo, J.C., Hughes, T.J.R.: Computational Inelasticity. Springer, Berlin (1998)

Alves de Sousa, R.J., Yoon, J.W., Cardoso, R.P.R., Valente, R.A.F., Grácio, J.J.: On the use of a reduced enhanced solid-shell (RESS) element for sheet forming simulations. Int. J. Plast. 23, 490–515 (2007)

Stoughton, T.B., Green, D.E., Iadicola, M.: Specification for BM3: two-stage channel/cup draw. In: Cao, J., Shi, M.F., Stoughton, T.B., Wang, C.T., Zhang, L. (eds.) Proceedings of Numisheet 05, CP778, vol B, pp. 1157–1172. American Institute of Physics, College Park (2005)

Svendsen, B.: On the modelling of anisotropic elastic and inelastic material behaviour at large deformation. Int. J. Solids Struct. 38, 9579–9599 (2001)

Taherizadeh, A., Green, D.E., Yoon, J.W.: Evaluation of advanced anisotropic models with mixed hardening for general associated and non-associated flow metal plasticity. Int. J. Plast. 27, 1781–1802 (2011)

Tsakmakis, C.: Kinematic hardening rules in finite plasticity. Part I: a constitutive approach. Continuum Mech. Thermodyn. 8, 215–231 (1996)

Vladimirov, I.N., Pietryga, M.P., Reese, S.: On the modelling of non-linear kinematic hardening at finite strains with application to springback - comparison of time integration algorithms. Int. J. Numer. Meth. Eng. 75, 1–28 (2008)

Vladimirov, I.N., Pietryga, M.P., Reese, S.: Prediction of springback in sheet forming by a new finite strain model with nonlinear kinematic and isotropic hardening. J. Mater. Process. Technol. 209, 4062–4075 (2009)

Vladimirov, I.N., Pietryga, M.P., Reese, S.: Anisotropic finite elastoplasticity with nonlinear kinematic and isotropic hardening and application to sheet metal forming. Int. J. Plast. 26, 659–687 (2010)

Yoon, J.W., Barlat, F., Dick, R.E., Karabin, M.E.: Prediction of six or eight ears in a drawn cup based on a new anisotropic yield function. Int. J. Plast. 22, 174–193 (2006)

Yoshida, F., Uemori, T.: A model of large-strain cyclic plasticity and its application to springback simulation. Int. J. Mech. Sci. 45, 1687–1702 (2003)

Acknowledgments

The authors acknowledge the financial support by the Grants SFRH/BD/82286/2011 and PTDC/EME-TME/115876/2009 from the Fundação para a Ciência e a Tecnologia, Ministerio da Educação e Ciência (Portugal).

Author information

Authors and Affiliations

Corresponding author

Appendix: Representation of Hill’s 1948 [20] yield function in the reference configuration

Appendix: Representation of Hill’s 1948 [20] yield function in the reference configuration

Regarding the yield function proposed by Hill [20], the effective stress is given by \(\bar{\sigma }=\sqrt{{\varvec{\eta }}^{*}:{{\mathbb {A}}}:{\varvec{\eta }}^{*}}\). Introducing the relation (20) in this yield function, one obtains

The fourth-order tensor \({\bar{\mathbb {A}}}\) acts on stress quantities defined in the reference configuration and is related to the anisotropic tensor \({\mathbb {A}}\) following the expression

The fourth-order anisotropic tensor \({\mathbb {A}}\) can be represented by means of structural tensors (see, e.g. [47]), following

where the auxiliary fourth-order tensors \(\mathbb {G}_1\) and \(\mathbb {G}_2\) are given by

The coefficients \(a_i\), with \(i=1 \ldots 6\) are related to the classical Hill coefficients (F, G, H, L, M and N). The structural tensors represent the symmetry of the material and are expressed as

where \({\mathbf{N}}_{i}\) are the privileged directions of the material.

Applying Eq. 37 to the anisotropic tensor defined by Eq. 38, and considering, for the sake of simplicity, only the second term on the right-hand side, it yields

where the structural tensor in the reference configuration is expressed as

which is dependent on two privileged directions that evolve distinctly according to

The representation of the remaining terms of Eq. 38 in the reference configuration may be done following the same procedure.

Rights and permissions

About this article

Cite this article

Grilo, T.J., Vladimirov, I.N., Valente, R.A.F. et al. A finite strain constitutive model for non-quadratic yield criteria and nonlinear kinematic/isotropic hardening: application to sheet metal forming. Arch Appl Mech 86, 147–163 (2016). https://doi.org/10.1007/s00419-016-1117-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00419-016-1117-9