Abstract

Many physical properties of rocks are sensitive to grain size and hence to the structure of grain boundaries. Depending on their properties, such as deformation and transport behaviour, boundaries may be divided into two broad types, namely special and general grain boundaries. Electron backscattered diffraction (EBSD) is used to investigate the misorientation distributions of grain boundaries and, more recently, to determine the population of grain boundary planes. Studies on metals and ceramics suggest that the grain boundary plane, rather than the misorientation, is the key parameter when defining special and general grain boundaries. In this study, the distribution of grain boundary plane orientations has been successfully determined using EBSD for a slightly deformed, synthetic NaCl material containing 22 ppm water. Boundaries showed a preference for {100} planes, which occurred with twice the frequency of a random distribution. The grain boundary plane distributions found in NaCl were largely in agreement with studies on MgO. Grain boundaries, with a coincident site lattice (CSL) misorientation, also showed a preference for {100} planes, rather than the planes of high coincident density associated with the CSL. Three main types of boundary were identified, namely {100} twist boundaries, boundaries with {100}{hkl} planes and general {hkl}{hkl} boundaries. As the properties of these three types of boundary differ, then the transport and creep properties in wet NaCl will depend on the fraction of the different boundary types found in the grain boundary population.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In Earth materials, many rocks contain intergranular fluids that dramatically affect a number of large scale processes, by providing fast diffusion paths during deformation, metamorphism and diagenesis (Carter et al. 1990; Hickman and Evans 1992). In rocksalt, understanding the distribution of intergranular fluids is important for predicting the location of impermeable cap rocks that trap mobile fossil fuels, and also in determining the long term stability of caverns and back-fill used for storage of oil, gas and nuclear waste (Spiers et al. 1989; Spiers and Carter 1996; Breunese et al. 2003; Pennock et al. 2007; Zhang et al. 2007).

During creep deformation of halite, NaCl, intergranular brine enhances both grain boundary migration and dissolution–precipitation (pressure solution) processes (Spiers et al. 1986; Schenk and Urai 2004). The details of the structure and properties of the brine present along boundaries, such as the thickness and diffusivity, is controversial, particularly under dynamic deformation conditions (De Meer et al. 2005; Schenk et al. 2006). An important property of intergranular behaviour is the crystallography of the two surfaces that comprise the grain boundary. For instance, the thickness and diffusivity of the fluid film have been shown to depend on the orientation of the grain boundary planes (De Meer et al. 2005; Van Noort et al. 2007); in particular {100} twist boundaries are resistant to dissolution–precipitation creep and rapidly heal (Hickman and Evans 1992; Van Noort et al. 2007). A description of the types of boundary planes present in polycrystalline NaCl would therefore provide useful information for understanding creep and transport behaviour.

A macroscopic description of a grain boundary plane requires five parameters; three to describe the misorientation across the boundary and two to describe the grain boundary plane (Wolf and Lutsko 1989; Randle 1993; Randle and Davies 2001). Recent electron backscattered diffraction (EBSD) studies, involving the automatic detection of a large number of grain orientations and grain boundary traces, can provide statistical output of boundary plane densities, for all boundary types present in a sample, based on serial sections (Saylor et al. 2003a), orthogonal sections (Saylor et al. 2004e) or a single planar section (Saylor et al. 2004b). The orientation data are used to determine the ‘grain boundary distribution’, which is defined as the relative areas of grain boundaries, characterized by their lattice misorientation and the grain boundary plane normal, and expressed in units of multiples of a random distribution (MRD) (Saylor et al. 2003a; 2004e; Rohrer et al. 2004b). The grain boundary plane normal can be determined by serial sectioning but the process is time consuming and requires great care. Recently, a new stereological technique has been developed that enables the probability distribution of grain boundary planes to be derived from a single planar section, providing the lattice preferred orientation (LPO) is sufficiently random (Larsen and Adams 2004; Saylor et al. 2004b). The grain boundary populations derived from this single section method were in good agreement with serial section analysis (Saylor et al. 2004b). The single section method (Saylor et al. 2004b) is briefly summarised here. A grain boundary between two crystals intersects a specimen surface as a line, or trace. In crystallographic space, the possible boundary planes for one of the two crystals have normals that must lie on a great circle in a stereographic projection: the neighbouring crystal defines a second great circle. Each bicrystal, with the same misorientation, therefore provides information on possible grain boundary planes. In a polycrystal, there are a large number of traces. By combining a large number of traces, from similarly misoriented bicrystals, any tendency for the true plane to be present in the microstructure will show up as maxima in a probability distribution. The accumulated data from all the possible grain boundary planes form a continuous distribution. To analyse this distribution, the data are partitioned into discrete cells, each cell having an angular resolution of approximately 10° (Saylor et al. 2004b). The data set is quantified in terms of grain boundary area by incorporating the length of the grain boundary traces. For cubic materials, more than 50,000 grain boundary traces are needed for an accurate estimate of the grain boundary distribution, based on a 10° partitioning of the data.

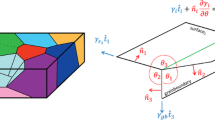

There are several ways of presenting the grain boundary distribution (see for example, (Saylor et al. 2003a, 2004d). A common representation is to plot the distribution of plane normals in stereographic projection. Once contoured in units of MRD, plane normals with greater than 1 MRD are more favoured than expected from a random distribution. The data is often presented averaged over all possible misorientations. These averaged plots show which types of planes are the most (and least) favoured. Detailed information, for instance, about the tilt and twist nature of boundaries, is illustrated by examining series of misorientations, about a given axis, 〈uvw〉, and a range of angles. In this type of plot, each misorientation contains the data from a complete family of rotation axes 〈uvw〉, that are superimposed into a single direction, [uvw], so that the types of boundary (tilt, twist, general) are more clearly illustrated. Each specific misorientation plot shows only a fraction of the total grain boundary population. Figure 1 is a schematic diagram for a [100] rotation axis, showing the locations of twist, symmetric and asymmetric tilt grain boundary normals for a 30° misorientation. The angles between the peaks for the asymmetric tilt boundary normals are geometrically dictated by the misorientation angle.

Location of high symmetry grain boundary normals for a [100] misorientation axis (arrow) and a misorientation angle, ψ°~30° (001 stereographic projection and a centro-symmetric cubic bicrystal). The plane normals for a pure twist grain boundary are parallel to the misorientation axis (grey circles), whereas tilt grain boundaries have normals that are perpendicular to the misorientation axis and lie on the thick line. For any grain boundary, the normals of the two planes that form the boundary must be separated by the misorientation angle, ψ°. For tilt boundaries, both planes are of the type {0kl}: for a symmetric tilts, the grain boundary plane normals are the same for both crystals and are geometrically confined to be located at ψ/2° about the {100} poles (black circles). These define the locations of a coherent CSL boundary (Rohrer et al. 2004b). For b asymmetric tilt boundaries, the two boundary plane normals associated with each grain boundary are geometrically confined to be ψ° from each other and are (open circles). The bicrystal can have additional symmetry that reduces the range of unique grain boundaries, such that there is no symmetry about the misorientation axis (Saylor et al. 2003a); e.g. for 30° about the [100] illustrated here, there are only two positions for the tilt boundary, each with two boundary plane normals

A surprising result from the grain boundary population studies on a wide range of engineering materials (single phase ceramics and metals, annealed at high homologous temperatures) is that preferred orientations of low index boundary planes occur, rather than boundaries with a special misorientation relationship (Rohrer et al. 2004a, 2006; Saylor et al. 2004a; Randle 2006). Special misorientation relationships can be described by a coincident site lattice (CSL) in which a fraction of the lattice points on either side of the boundary coincide; the ratio of the CSL to lattice sites is described by Σ (McLaren 1986; Randle 1992). The low index grain boundary planes found in the EBSD studies are the same as the low energy, crystal growth forms of single crystals. Grain boundary energy distributions were modelled for MgO, based on dislocation structures for low angle boundaries and surface energy anisotropy for higher angle boundaries; an inverse relationship was found between the grain boundary energy and the grain boundary population (Saylor et al. 2003b). A similar study on SrTiO3 confirmed that the energy of the grain boundary planes inversely correlated with the grain boundary plane population, apart from the coherent twin boundary, which comprises two {111} planes rotated around the [111] by 60° (Saylor et al. 2004c).

In polycrystals of NaCl, distinct square shaped grains are common, in both natural and synthetic material, and for a wide range of deformation and annealed conditions (Spiers et al. 1986). A recent two dimensional EBSD study examined misorientation angle distributions and grain boundary traces in a range of synthetic NaCl materials: three types of boundary were identified, namely general high angle grain boundaries, boundaries with a CSL misorientation relationship and boundaries of square shaped grains, which had traces that were within 12° of the trace of {100} planes (Pennock et al. 2006b). The population of the CSL related boundaries were no different to that expected from the texture, which implies that the occurrence of CSL boundaries in NaCl is not particularly favoured over other boundaries. Furthermore, in ‘wet’ NaCl (where wet signifies that very small amounts of water, >5–11 ppm, are present), grain boundary microstructures of CSL misoriented boundaries, and special, {100} types of boundary, were similar to general boundaries after low temperature deformation. As grain boundary migration only occurs below ~400°C, if assisted by the presence of intergranular brine, these results suggest that the boundaries were wetted. However, in this two dimensional EBSD study, the number of trace analyses was limited and conventional two dimensional trace analyses cannot define grain boundary plane orientations, or provide information about the character of boundaries, such as the importance of tilt, twist and general boundaries.

In the present study we use the five parameter EBSD technique, described above, to examine the grain boundary character distribution in a single section of a slightly deformed, synthetic polycrystalline NaCl. The small amount of intergranular brine present in this sample (Watanabe and Peach 2002; Ter Heege et al. 2005) was sufficient to enhance grain growth in a subset of grains that developed a square shape (Pennock et al. 2006a). The microstructures of the NaCl sample differ from the ideal annealed microstructures reported for MgO, which is isostructural to NaCl (Saylor et al. 2003a, b): for NaCl, subgrain boundaries, with low misorientation angles, were present and grain shapes were more convoluted at triple junctions. Average grain sizes were about 300 μm for the NaCl compared to 109 μm for MgO. The texture was random for NaCl, whereas MgO showed a 〈111〉 texture parallel to the surface normal.

Materials and methods

Sample preparation

The NaCl sample used in this study (sample p40t115) has been studied in several previous studies concerned with the influence of water on the mechanical and transport properties, texture and microstructure (Watanabe and Peach 2002; Ter Heege et al. 2005; Pennock et al. 2006a, b). The polycrystalline sample was prepared by cold pressing granular NaCl with a small amount of water (Watanabe and Peach 2002) followed by annealing at 150°C (0.4 Tm) (Peach and Spiers 1996). This produced a fully recrystallized microstructure, with <0.5% porosity and an average grain size of ~300 μm and ~32 ppm intergranular water. The undeformed material showed mainly equiaxed grains, with a few distinct square shaped grains (ter Heege et al. 2004). A cylinder of this material (50 mm × 120 mm) was deformed in axisymmetric compression under 50 MPa confining pressure, at 125°C and at a constant displacement rate of ~5 × 10 −7 s−1 to a final natural strain of 0.07 and a flow stress of 11 MPa before finally cooling under pressure, reaching a temperature below ~50°C within 0.5–1.5 h after deformation was stopped (Watanabe and Peach 2002).

Samples were stored in a dry room (<15% relative humidity) and sections cut parallel to the compression axis from the centre of the sample soon after deformation to inhibit static recrystallization (Urai et al. 1987). Standard metallographic techniques were used to polish flat, parallel sections, using evaporating oil as lubricant (Shell S4919); a 95% saturated NaCl solution containing ~0.8 wt.% FeCl3·6H2O was used to lightly etch the surfaces to remove abrasive damage caused by polishing, thereby improving the analysis quality of EBSD. Several polished sections were needed to obtain a sufficient number of grains for the analysis.

The microstructure before deformation comprised both a random LPO and microstructure, comprising equiaxed grains, a few square shaped grains and predominantly 120° triple junctions; arrays of brine were present along grain boundaries and occasional intragranular brine inclusions (Peach and Spiers 1996; Watanabe and Peach 2002; Ter Heege et al. 2005; Pennock et al. 2006a). A few island (internal) grains and subgrains were present after annealing (Pennock et al. 2006a). After 0.07 strain, a subset of square shaped grains, having a very weak 〈111〉 maxima parallel to the compression axis, had slightly larger than average grain sizes; subgrains were present in most grains and tended to be located predominantly near grain boundaries of larger grains (Pennock et al. 2006a).

EBSD measurements

Crystal orientation maps were obtained on uncoated samples using Oxford Instruments HKL Channel 5 software and Nordlys CCD camera integrated with a Philips XL30 SFEG scanning electron microscope (SEM) operating at 20 mm working distance, ~2 nA beam current and 12 kV accelerating voltage. Samples were tilted to an angle of 70° with respect to the electron beam for EBSD analysis. The sample tilt and scan rotation of the instrument were adjusted to within 0.1° using a silicon crystal calibration grid to correct foreshortening in the mapped area and to ensure alignment of the beam maps with the stage movement. The step size used for mapping needed to be small enough to give a reasonable trace of the grain boundaries (Wright and Larsen 2002). For an average grain size of ~300 μm, a 20 μm step size was used. Maps were obtained by combining beam scanning (1,500 × 1,100 μm area) with stage movements and stitching together the beam maps. Occasionally contiguous beam maps did not match up, possibly because local charging deflected the beam; boundary data across poorly matched regions was not used. In total an area of ~12 cm2 was mapped.

The indexing success of EBSD maps was typically around 98%. Spurious and non-indexed pixels, and small grains of less than two pixels diameter, were all replaced with neighbouring grain orientations. A few misindexed pixels occurred with 45° rotation about 〈100〉 with respect to their neighbouring pixels. These pixels were manually replaced by a neighbouring pixel orientation to avoid loss of information from real grain boundaries with the same misorientation.

The orientations determined from the HKL software (square grid mapping) were imported into EDAX TSL OIM software (hexagonal grid format) before further processing with software developed by the group at Carnegie Mellon University. Grains were defined with a boundary misorientation of more than 3°, to ensure that the fraction of low angle grain boundaries, which were recognized from the grain shape in forescatter images, were included in the data set. Other low misorientation deformation induced boundaries within the grain were examined to assess their contribution to the plane distribution. Internal “island” grains were ignored in the analysis. Nearly 21,000 grains were used in the data set.

Each grain was assigned its average orientation value. Boundary line segment traces were extracted using the method developed by Wright and Larsen (2002) (Fig. 2) to give a total of 65,000 grain boundary line segments. A large statically recrystallized grain, that developed during long term storage of the sample, contributed a very small fraction, less than 0.1%, of the total number of grain segments: as these segment were spread over all misorientations, they are not expected to influence distributions of individual plots about a specific misorientation. For each plot the probability of finding a plane normal was expressed as multiples of a random distribution (MRD) and plotted in stereographic projection. Data were partitioned into 10° cells, so the angular resolution of the grain boundary planes was about 10°. The resolution of the measured misorientation angle was better than 1° (Pennock et al. 2002).

Sketch showing how an EBSD mapped grain boundary trace (continuous line) is reconstructed into segments (dashed line). Triple junctions are identified, and a straight line is drawn between them. These line segments are dissected into shorter segments until the tolerance (arrow) between the reconstructed line and the actual grain boundary is less than twice the step size used for mapping (adapted from Wright and Larsen 2002)

Results

Before presenting the results on the grain boundary plane analysis the microstructures are examined to determine the range of deformation related subgrain boundaries present. The very low angle subgrain boundaries, less than 3°, were not included in the grain boundary trace analysis. The frequency distribution of misorientations angles more than 3° between pixels (Fig. 3) shows that low angle misorientations represented a significant fraction of the total boundary length. Misorientation rotation axes over all possible misorientation angles are shown in Fig. 4. The distributions show that the axes were very uniformly spread and have no preferred orientation. The absence of any preferred orientation in the distribution of the misorientation rotation axes suggests that the boundary population in a single section analysis is adequately represented, as required for the five-parameter analysis (Saylor et al. 2003a). The microstructure of low and high angle boundaries is shown in Fig. 5. For one mapped area (3,000 grains) the average misorientation within grains based on random pixel pairs, was 1.8°, with a standard error of 0.02°. Several boundary misorientations, in the range 3°–10°, define boundaries between grain shaped domains and are clearly low angle boundaries between grains, as opposed to deformation induced subgrains. However, most low angle misorientations are deformation related, or arise from scratches and poorly indexed regions. The majority of them have short segments that were not confined between two triple junctions that were used to define the boundary segments, as shown in Fig. 2. Therefore, the majority of the deformation induced boundaries were not included in the grain boundary plane algorithm. Boundaries with a common 〈100〉 axis, about 2% of the total boundary length (Table 1), are shown in red (Fig. 5).

Graph showing the relative frequency distribution of misorientations after 0.07 strain. (The distribution is of orientation gradients, as the 20 μm step size accumulates misorientations across some subgrain boundaries). Low angle misorientations, <10°, constitute a significant fraction of the total boundary length. The random distribution is shown as a solid line

Distribution of axes is shown about all possible misorientation angles. Data are contoured in one-times-unit multiples of uniform density. The allowable limits for the axes, using the minimum misorientation angle, are shown for the higher angle ranges. Note that the contouring algorithm does not take into account the nonuniform distribution of axes at higher misorientation angles; there is therefore no texture in the rotation axes

EBSD microstructures (montage of beam maps), showing the distribution of low and high angle boundaries. Boundaries about a 〈100〉 axis are shown as red lines, 3–10° misorientation are shown as green lines and >10° misorientations as black lines, and a non-indexed patch in purple. A low angle boundary between two grains is arrowed. Variations in the orientation of the 〈111〉 axes with respect to the compression axis (vertical) are shaded in grey, see legend

Grain boundary traces were examined using light microscopy on an untilted surface to determine whether any distortion in the image occurred because of the 70° tilt used for EBSD mapping (Fig. 6a). EBSD maps of the same area imaged at 70° tilt have the same aspect ratio and match up well across individual boundaries (Fig. 6b). The microstructure after assigning an average orientation value to each grain and after reconstructing the boundaries is shown in Fig. 6c. The reconstructed boundaries (Fig. 6c) are in good agreement with the microstructure, even in the triple junction region where the boundary trace is rather convoluted. Higher magnifications show that the majority of grain boundaries surrounding square shaped grains were straight after 0.07 strain, although fine scale variations of the boundary trace (Fig. 7) was not resolved in EBSD maps (Fig. 7).

Correlation between a light microscopy, b EBSD and c reconstructed microstructures. The location of the borders between EBSD maps is shown by three small arrows. Colour legend in b is the same as given for Fig. 5. In c, the square grid map is reconstructed with an hexagonal grid and each grain is given a single average orientation value, represented as a random colour; grain boundary line segments used in the analysis are shown as black lines. A small island grain and a low angle peninsular grain (arrows in b) are ignored in the reconstructed microstructure, otherwise the correlation is good

Boxed region, Fig. 6a, showing finer scale detail of an etched grain boundary. The spots in the upper grain are damage pits, caused by the electron beam during mapping with a 20 μm grid

The results from the grain boundary plane analysis are now presented. Figure 8 shows all of the grain boundary plane normals, for all misorientations, plotted in stereographic projection. The distribution shows peaks in frequency on {100} planes at about twice the random frequency. This means that the {100} planes are the most favoured planes whereas the probability of {111} planes is only half that for a random frequency.

Grain boundary distribution for all grain boundary planes averaged over all misorientations, both axes and angles, plotted in stereographic projection, with the location of the (100) and (010) poles shown as dots and the (111) pole as a triangle. The populations are colour coded in terms of multiples of a random distribution (MRD)

A selection of the grain boundary populations within the five-parameter space, plotted in stereographic projection for several misorientation axes and angles, is shown in Figs. 9, 10, 11 and 12. The locations of the misorientation axes are shown with a dot in the plot with the lowest misorientation angle. Twist boundaries have normals parallel to the misorientation axis whereas the locations of tilt boundaries, with normals perpendicular to the misorientation axis, are shown by a thick line. The three lowest index misorientation axes [100], [110] and [111], plus one general misorientation axis, [123], were chosen for plotting. In all of the plots, the variations for each distribution are given in a key: maximum MRD values differ for each plot, to emphasize the subtle changes in each distribution. An MRD less than one is generally red in colour; general {hkl} category of boundary is predominantly green and has MRD greater than 1 and peaks in the distribution of the more favoured grain boundary planes tend towards a blue colour.

Probability distributions of grain boundary plane normals plotted in 001 stereographic projection and coloured as MRD showing only data for the [100] misorientation axis (black dot) and at misorientation angles ranging from 5° to 45°, including the Σ5 CSL misorientation angle. The location of tilt boundaries is shown with a thick line

Probability distributions of grain boundaries plotted for rotations about low index axes [110], [111] and [123] and at low angle misorientations, 5° and 10°. Black dots show the location for each misorientation axis and location of tilt boundaries are shown for each axis at 5° with a thick line. Planes vicinal to {100} are favoured and twist boundaries for these axes are not favoured

The percentages of the total grain boundary length for each axis shown in Figs. 9, 10, 11 and 12 are given in Table 1. The percentages in the upper half of the table cover the complete possible range of misorientation angles, 5°–62.5°. The partitioning of the boundary length, as a function of misorientation angle, is illustrated for the 〈123〉 axis and a 5° deviation about the misorientation angle: the percentages vary with misorientation angle, being highest at 45°–50°, which is consistent with the distribution for random boundaries shown in Fig. 3. Each misorientation angle plot contains a small fraction of this length.

In Fig. 9, the distribution of grain boundary plane normals is shown for a [100] misorientation axis and misorientation angles ranging from 5° to the maximum possible value, allowed by symmetry, of 45°, including the Σ5 CSL misorientation. At very low misorientations (5°) there are three dominant peaks (almost 4.5 MRD), showing the most favoured types of planes, which occur at, or near, (001) and (010) pole locations. These poles are tilt boundaries. Thus, if one grain boundary plane lies on (001), then the neighbouring plane normal has to be within 5° (the misorientation angle) of (001), which is not resolved in the plot, as the resolution of the grain boundary plane is 10°. The next highest MRD region in the distribution is close to the [100] misorientation axis, and shows that twist boundaries, made up of two {100} planes, are also favoured, with probabilities of about 3.5 MRD. At 10° misorientation angle, the tilt boundaries remains the most favoured type of plane, and have about 4MRD: the tilt boundaries have one plane on, or close to, a {100} type of plane and the second plane, {0kl}, is geometrically confined by the misorientation angle to be within 10° of {100}. These plane combinations, i.e., {100}{0kl}, are asymmetric tilt boundaries (see Fig. 1). General boundaries, with a [100] misorientation axis, have {hkl}{hkl} planes, are slightly less probable, but still favoured, with probabilities of about 3 MRD (green colour). Twist boundaries still have probabilities of 3.5 MRD. At 20° misorientation angle, {100} tilt and twist boundary types are equally favoured, with 3.5 MRD. Note that, as the misorientation angle increases, the maximum in the tilt plane normals shifts away from the exact (001) and (010) locations. The most favoured plane combinations are asymmetric tilt types of boundary, with {0kl} planes. The trend continues at higher misorientation angles; the probability of finding asymmetric tilt boundary decreases (to about 2.9 MRD at 30° misorientation), whereas the probability of finding a twist boundary remains the same (about 3.5 MRD) over the entire misorientation angle range. There are no additional favoured planes at the Σ5 CSL misorientation, such as symmetrical tilt planes (see Fig. 1), or other combinations that might be associated with high planar coincidence (Saylor et al. 2003b; Rohrer et al. 2004a). The trend continues for reduced occurrence of asymmetric tilt boundaries but, at 45° misorientation, these type of boundaries are still slightly more likely than general {hkl} type of boundaries. The reduced symmetry arising from the bicrystal symmetry no longer applies at higher misorientation angles and full symmetry is restored to the grain boundary plane distribution (Saylor et al. 2003a), as shown at 45° misorientation. Boundaries close to {111} are clearly not favoured at any misorientation angle, and this trend is seen for all misorientation axes (see also Figure 8). As the misorientation angle increases, the least favoured planes types are spread between {111} and {110} types of planes. More general boundary plane combinations, {hkl}{hkl} complete the distribution, with probabilities of about 2MRD.

The distribution probabilities of grain boundary planes for low misorientation angles about the [110], [111] and [123] misorientation axes are shown in Fig. 10. There is a low probability for planes in the location of the misorientation axes, which means that twist boundaries are unlikely for these misorientation axes, in contrast to the results for the [100] misorientation axis. Neither are there maxima in tilt boundary locations (shown by the thicker lines). Irrespective of the axes of misorientation, {100} planes are the preferred grain boundary planes, although the maxima are more spread away from exact {100} locations. General {hkl} types of boundary are favoured with an MRD of 1.5–2 and least favoured boundaries follow the same trend as seen for the 〈100〉 misorientation axes, namely, they form wide zones that spread between {111} and {110} types of planes as the misorientation angle increases.

Figure 11 shows higher misorientation angles for a [110] misorientation axis. The {100} planes have the higher probabilities, spreading along the 〈100〉 zones with increasing misorientation angle. The special misorientation angles associated with ∑27a and ∑9 CSLs are also shown. At these misorientations, asymmetric tilt grain boundaries occur, spreading away from the (001) pole along the [110] zone. Several other CSL relationships are also illustrated in the Figs. 9, 10, 11 and 12. In all cases studied there was no indication that the CSL relationship resulted in the occurrence of special grain boundary planes other than {100} type boundaries [A more complete analysis of CSL planes is given by Rohrer et al. (2004a) and Saylor et al. (2003b).]. Peaks in the distribution also occur for {100} planes at higher angle misorientations about the [111] rotation axis (Fig. 12). The peaks become increasingly spread with increasing misorientation angle, consistent with a rotation around [111] axis. The same trend is seen for the higher angle misorientations about the more general [123] axis.

Discussion

The microstructure in this deformed sample (larger grain size, convoluted grain boundary traces and presence of subgrains) differs from that in most other studies, which were on annealed materials. Average orientation values were used to reconstruct grains and subgrains contributed an average error of 1.8° to grain orientations, but this error is small in comparison to the accuracy of the technique, which is 10°. The larger grain size, (300 μm) was mapped with a larger step size, although, for each microscope system there are limits to the size of both beam maps and stage movements. However, the time to collect data sets for larger grained material increases with the number of stage movements and the number of sample section needed for the analysis. Whereas EBSD offers good statistics, universal stage measurements may be a more appropriate method for collecting grain boundary plane information for very large grain size, transparent materials, and provides site specific information that is not available with the single section method. However, for fully annealed materials, grain orientation and grain boundary traces can be defined with fewer measurements, using images to define the grain boundary traces (Saylor et al. 2003a).

The single section method of analysing grain boundary plane populations assumes that there is no strong microstructural alignment of the grain boundary planes in the section (Saylor et al. 2004b). A few, larger grains tended to develop square shapes during deformation and this subset of grains was very weakly aligned with the 〈111〉 axis parallel to the compression axis (Pennock et al. 2006a). These grains represented a maximum of 25% of the mapped area, 13% of all grains, and include several grains in which only two of the grain boundaries, that surrounded the grains, developed a facet. The application of the single section analysis method is still expected to be valid, as reasonable results were reported if at least 60% of each grain boundary type were randomly distributed (Saylor et al. 2004b).

In all sections examined, grain boundary plane distributions have shown that boundaries on {100} planes are favoured in wet NaCl. These {100} planes occur at general boundary misorientations, including CSL misorientations. Other low index planes, that are associated with high coincident density at CSL misorientations, are not favoured in NaCl. These results confirm suggestions from our earlier study in which two dimensional trace analyses on a limited number of grain boundaries were measured in a wide range of synthetic NaCl polycrystals (Pennock et al. 2006b). From the grain boundary character distributions, three types of grain boundary were identified to have densities greater than one times a random distribution, namely {100} twist boundaries, boundaries with {100} in one grain parallel to {hkl} in the neighbouring grain, including asymmetrical tilt boundaries, {001} {0kl}, and vicinal twist boundaries, ~{001}{001}, and general boundaries with {hkl} in one grain parallel to {hkl} in the neighbouring grain. The {100} boundary planes were the most favoured type of boundary, having at least twice random densities for all misorientations about the axes examined. The spread of boundaries, away from the {100} plane, agrees with our earlier study in which many of the boundary traces deviated by up to 12° from the trace of {100} (Pennock et al. 2006b). The spread indicates a vicinal character to the grain boundary plane, that is, a boundary vicinal to {100} can be thought of as a {100} plane with steps, or line defects (Sutton and Balluffi 1995).

Severe deformation during preparation of synthetic ceramics, can influence the grain shape, and may influence the grain boundary distribution if there is an LPO (Vonlanthen and Groberty 2008). For synthetic NaCl, both the starting powder and the cold pressing stage produce a large number of {100} faces that may influence the grain boundary distribution. However, during annealing, densification of the powder only occurs if water is present, which enables fluid assisted grain boundary migration. After annealing, the LPO is random and most of the grains are not square shaped. Therefore, the population of the {100} grain boundaries in the synthetic sample in this study are not inherited from the sample preparation.

NaCl and MgO have the same crystal symmetry, and structure (space group \( Fm\bar{3}m), \) which has a minimum surface energy for {100} planes (Hartman 1973; Saylor et al. 2000). The grain boundary plane populations for NaCl found in this study are very similar to those reported for magnesia (MgO) (Saylor et al. 2003a): both materials show a preference for {100} planes when plane normals are averaged over all misorientations. A significant difference between the MgO and NaCl data sets is seen in the plot for very low misorientations, 5°, about the [110] rotation axis: whereas MgO shows peaks in the distribution for {110} symmetric tilt boundaries (more than 20 times random) these boundaries have much lower densities in NaCl (about twice random) and distributions in NaCl show peaks for vicinal {100} planes. Both NaCl and MgO have the same easy slip system, {110} \( \left\langle {1\bar{1}0} \right\rangle \) (Frost and Ashby 1982), and polygonise dislocations on {110} tilt boundaries. The presence of {110} planes in the 5° about [110] distribution in the MgO study suggests that these boundary planes are low energy dislocation tilt walls (Saylor et al. 2003a, b). The majority of the deformation induced low angle boundaries in the NaCl sample did not contribute to the boundary reconstruction algorithm so these boundaries do not influence any of the distributions. The differences in the 5° about [110] distributions may be caused by variations in the sample preparation for the two materials. The MgO sample was hot pressed (0.63 Tm), and annealed at 0.54 Tm, whereas the NaCl sample was cold pressed (0.27 Tm), and annealed at 0.4 Tm before straining. It is likely that plastic deformation was more important in the hot pressed MgO compared to the cold pressed NaCl sample in controlling the low angle grain boundary populations about the [110] axis.

The occurrence of grain boundaries parallel to a low energy growth form is common in natural rocks (Urai 1983; Drury and van Roermund 1989; Vernon 2004). In a material that is not strongly anisotropic, like NaCl, the development of facetted grain boundaries, often forming square shaped grains in NaCl, is taken as evidence for the presence of intergranular fluids (Urai 1983; Spiers et al. 1986), although some highly anisotropic minerals, like micas, always have facetted grain boundaries (Vernon 2004). The NaCl sample contained about 32 ppm of water and the MgO sample studies by Saylor et al. (2000), about 0.3% of impurities. Water and impurities predominantly segregate at grain boundaries (Yan et al. 1983; ter Heege et al. 2004), although the main impurity in MgO, calcium, is reported to show anisotropic segregation, with the most frequently observed boundaries showing the least calcium accumulation (Saylor et al. 2003b). The presence of fluids, or an amorphous phase, at grain boundaries is likely to be of significance in enabling the formation of boundaries with a low energy growth form in both NaCl and MgO materials, rather than the CSL related boundaries.

The population of {100} grain boundaries in the NaCl sample was not significantly different at CSL misorientations compared to other misorientations. Both CSL related boundaries and general boundaries appear to migrate and show similar microstructures, which suggests that water was present along the majority of boundaries in NaCl (Pennock et al., 2006b), in agreement with transmitted light microscopy studies of the undeformed material (Ter Heege et al. 2005). Although in some materials boundaries with impurity segregation can still be semi coherent (Sickafus and Sass 1987; Bons et al. 1990), the presence of intergranular fluids could explain the absence of CSL boundary planes in the NaCl sample studied. Several studies of grain boundary populations in naturally deformed rocks have shown that, apart from the occurrence of low Σ CSL boundaries, corresponding to well known twin boundaries, other CSLs in many natural rocks are not preferentially occupied (Faul and Fitz Gerald 1999; Fliervoet et al. 1999; Lloyd 2004; Kuntcheva et al. 2006), that is, only those CSLs expected from a random combination of the population of grain orientations, defined by the LPO, occur. Like NaCl and MgO, a possible reason why CSLs are not common in rocks is the presence of intergranular fluids and segregation of impurities, which would cause a loss of structural integrity and interplay between grains, and would therefore favour boundaries with a low energy plane.

In low stacking fault metals, the coherent Σ3 twin is prolific, but when these twins were removed from the grain boundary plane data for brass, the population was indistinguishable to aluminium, and both metals showed a preference for low index, low energy planes (Rohrer et al. 2006). The occurrence of low index, low energy planes in grain boundaries of metals might also be explained by a decoupling of the grain misorientation by segregation of impurities at the grain boundary, or by some disordering of the grain boundary at high homologous temperature. Recent molecular dynamic modelling has shown that even pure materials, including metals, general high angle grain boundaries may show a structural transition to a disordered structure at temperatures of 0.6 Tm (Keblinski et al. 1997; Wolf et al. 2001), although there is currently no experimental confirmation of these theoretical models. Calculated grain boundary populations, based on the energy of the interfaces, less a binding energy, show a good inverse correlation with the experimental preferred boundary population in MgO (Saylor et al. 2003b). A similar result, based on total energy calculations, was found for the tetragonal material, TiO2 (Pang and Wynblatt 2006). These results suggests that surface energy alone is a sufficient reason for the occurrence of the preferred planes, although the grain boundary population may be modified by impurity segregation (Pang and Wynblatt 2006). Because crystallographic controlled, low index planes are favoured in relatively pure metals, where intergranular fluids (generally) do not occur, the occurrence of similar grain boundaries in ceramic and rocks should not be taken as evidence for fluid along a grain boundary. In the present study, intergranular fluid is present, and we have argued that most boundaries are wetted because, in the absence of water, boundary migration in NaCl does not occur until much higher temperatures of about 500°C (0.7 Tm) (Guillopé and Poirier 1979; Franssen 1993).

The current study investigated a deformed microstructure, so driving forces for grain growth and migration is more complex than in studies on grain boundary populations in which samples were fully annealed. The microstructure in the low strain NaCl sample changed significantly compared to the annealed state, and compared to the dry deformed state (see Fig. 2 in Pennock et al. 2006a). Some grain growth occurred during deformation, and more square shaped grains developed, probably because of strain energy driven growth (Pennock et al. 2006a). The square shape of the grains suggests that the grain boundary mobility is anisotropic (Pennock et al. 2006a, b). Fluid assisted grain boundary migration in NaCl could be diffusion controlled, or interface reaction controlled, and both cases can be anisotropic (De Meer et al. 2005; Van Noort et al. 2007). Therefore, the {100} grain boundary planes in the current study are present because they have low mobility compared to other orientations. As in crystal growth, anisotropic grain boundary mobility results in the development of faces with the slowest migrating boundaries. Note that, in NaCl and many other materials, low energy boundaries will also be of low mobility.

The effect that the grain boundary population has on the physical properties of NaCl polycrystals will depend on the properties of the three main types of grain boundary identified in the grain boundary population. Bicrystal studies show that {100} twists have a smooth, possibly fluid free, boundary and are susceptible to contact healing rather than pressure solution (Hickman and Evans 1992; Van Noort et al. 2007) whereas {100}{hkl} boundaries develop a dynamic, rough structure, enabling rapid pressure solution to occur (Schutjens and Spiers 1999). Furthermore, De Meer et al. (2005) have shown that the average thickness of rough grain boundary films, along NaCl–CaF2 interfaces, depend on crystal orientation. On the basis of these results, we expect that {100}{hkl} boundaries may be less rough than {hkl}{hkl} boundaries. Thus the transport and creep properties of NaCl polycrystals will depend on the fraction of the different boundary types. In the current sample, {100} twist boundaries form only a fraction of the possible boundaries about 〈100〉. However, a 〈100〉 texture develops during dynamic and static recrystallization of wet NaCl, in synthetic samples and in salt domes (Skrotzki and Welch 1983; Trimby et al. 2000; Pennock et al. 2006a). The proportion of {100} twist boundaries is expected to be greater in materials with a stronger texture. The actual plane of the grain boundary, that is, the twist nature, is determined by the microstructure. The combination of strong 〈100〉 textures and square shaped grains, which have neighbouring square shaped grains, can produce many twist boundaries. This type of microstructure is seen in extruded wet NaCl (Skrotzki and Welch 1983), and could be particularly resistant to pressure solution.

Conclusions

The grain boundary plane population have been determined using EBSD in slightly deformed, synthetic NaCl. The {100} boundaries were the most favoured type of boundary having at least twice random densities in all misorientations about the axes examined. Three types of grain boundary were found to have densities greater than one times a random distribution: {100} twist boundaries, boundaries with {100} in one grain parallel to {hkl} in the neighbouring grain and general boundaries with {hkl} in one grain parallel to {hkl} in the neighbouring grain. Other boundary planes, for instance those associated with CSL lattice misorientations, are not favoured in NaCl. The grain boundary plane distribution found in NaCl were largely similar to that reported for MgO; the low angle {110} boundaries found in MgO were absent in NaCl, probably because of differences in the processing history for the two samples. We expect that the transport and creep properties of wet NaCl polycrystals will be influenced by the grain boundary populations.

References

Bons AJ, Drury MR, Schrijvers D, Zwart HJ (1990) Implications for mass transport processes during low temperature metamorphism. Phys Chem Miner 17:402–408. doi:10.1007/BF00212208

Breunese JN, Van Eijs RMHE, De Meer S, Kroon IC (2003) Observation and prediction of the relation between salt creep and land subsidence in solution mining—the Barradeel case. Solution Mining Research Institute, Conference, Chester, pp 38–57

Carter NL, Kronenberg AK, Ross JV, Wiltschko DV (1990) Control of fluids on deformation of rocks. In: Knipe RJ, Rutter EH (eds) Deformation mechanisms, rheology and tectonics, vol 54. The Geological Society, London, Special Publication, Leeds, pp 1–13

De Meer S, Spiers CJ, Nakashima S (2005) Structure and diffusive properties of fluid-filled grain boundaries: an in-situ study using infrared (micro) spectroscopy. Earth Planet Sci Lett 232(3–4):403–414. doi:10.1016/j.epsl.2004.12.030

Drury MR, van Roermund HLM (1989) Fluid assisted recrystallization in upper mantle peridotite xenoliths from kimberlites. J Petrol 30:133–152

Faul UH, Fitz Gerald JD (1999) Grain misorientations in partially molten aggregates: an electron backscattere diffraction study. Phys Chem Miner 26(3):187–198. doi:10.1007/s002690050176

Fliervoet TF, Drury MR, Chopra PN (1999) Crystallographic preferred orientations and misorientations in some olivine rocks deformed by diffusion or dislocation creep. Tectonophys 303:1–27. doi:10.1016/S0040-1951(98)00250-9

Franssen RCMW (1993) Rheology of synthetic rocksalt. PhD Thesis, Nr. 113, Utrecht University, Utrecht, pp 221

Frost HJ, Ashby MF (1982) Deformation mechanism maps. The plasticity and creep of metals and ceramics. Pergamon, New York, pp 166

Guillopé M, Poirier JP (1979) Dynamic recrystallization during creep of single crystalline halite: an experimental study. J Geophys Res 84:5557–5567. doi:10.1029/JB084iB10p05557

Hartman P (1973) Structure and morphology. In: Hartman P (ed) Crystal growth: an introduction, vol 1. North Holland Publishing Company, Amsterdam, pp 367–402

Hickman SH, Evans B (1992) Growth of grain contacts in halite by solution transfer: implications for diagenesis, lithification and strength recovery. In: Evans B, Wong TF (eds) Fault mechanics and transport properties of rocks. Academic press, San Diego, pp 253–280

Keblinski P, Wolf D, Philpot SR, Gleiter H (1997) Continuous thermodynamic-equilibrium glass transition in high-energy grain boundaries? Philos Mag 76(3):143–151. doi:10.1080/095008397179093

Kuntcheva B, Kruhl JH, Kunze K (2006) Crystallographic orientations of high-angle grain boundaries in dynamically recrystallized quartz: first results. Tectonophysics 421(3–4):331–346. doi:10.1016/j.tecto.2006.05.007

Larsen RJ, Adams BL (2004) New stereology for the recovery of grain-boundary plane distributions in the crystal frame. Metall Mater Trans A 35(7):1991–1998. doi:10.1007/s11661-004-0148-y

Lloyd GE (2004) Microstructural evolution in a mylonitic quartz simple shear zone: the significant roles of dauphine twinning and misorientation. In: Alsop GI, Holdsworth RE, McCaffrey KJW, Hand M (eds) Flow processes in faults and shear zones, vol 224. Geological Society London, Special Publication, pp 39–61

McLaren AC (1986) Some speculations on the nature of high-angle grain boundaries in quartz rocks. In: Hobbs BE, Heard HC (eds) Mineral and rock deformation: laboratory studies, the Paterson volume, Washington, DC. American Geophysical Union. Geophysics Monograph, vol 36, pp 233–247

Pang Y, Wynblatt P (2006) Effects of Nb doping and segregation on the grain boundary plane distribution in TiO2. J Am Ceram Soc 89(2):666–671

Peach CJ, Spiers CJ (1996) Influence of crystal plastic deformation on dilatancy and permeability development in synthetic salt rock. Tectonophysics 256:101–128. doi:10.1016/0040-1951(95)00170-0

Pennock GM, Drury MR, Trimby PW, Spiers CJ (2002) Misorientation distributions in hot deformed NaCl using electron backscattered diffraction. J Microsc 205(3):285–294

Pennock GM, Drury MR, Peach CJ, Spiers CJ (2006a) The influence of water on deformation microstructures and textures in synthetic NaCl measured using EBSD. J Struct Geol 28(4):588–601. doi:10.1016/j.jsg.2006.01.014

Pennock GM, Drury MR, Spiers CJ (2006b) Grain boundary populations in wet and dry NaCl. Mater Sci Tech 22(11):1307–1315. doi:10.1179/174328406X130975

Pennock GM, Zhang X, Peach CJ, Spiers CJ (2007). Microstructural study of reconsolidated salt. The mechanical behaviour of salt-understanding of THMC in salt, Hannover, Germany. Taylor and Francis Group, London, pp 231–237

Randle V (1992) Microtexture determination and its applications. Lond Inst Mater, vol. 510, pp 174

Randle V (1993) The measurement of grain boundary geometry. In: Cantor B, Goringe MJ (eds) Electron microscopy in material science series. Institute of Physics Publishing, Bristol and Philadelphia, pp 169

Randle V (2006) ‘Five-parameter’ analysis of grain boundary networks by electron backscatter diffraction. J Microsc 222:69–75. doi:10.1111/j.1365-2818.2006.01575.x

Randle V, Davies PA (2001) A comparison between three dimensional and two dimensional grain boundary plane analysis. Ultramic 90(2–3):153–162. doi:10.1016/S0304-3991(01)00137-1

Rohrer GS, El Dasher BS, Miller HM, Rollett AD, Saylor DM (2004a) Distribution of grain boundary planes at coincident lattice misorientations. Mater Res Symp Proc 819:265–275 Materials Research Society

Rohrer GS, Saylor DM, Dasher BE, Adams BL, Rollett AD, Wynblatt P (2004b) The distribution of internal interfaces in polycrystals. Z Metallk 95(4):1–18

Rohrer GS, Randle V, Kim CS, Hu Y (2006) Changes in the five-parameter grain boundary character distribution in α-brass brought about by iterative thermomechanical processing. Acta Mater 54(17):4489–4502. doi:10.1016/j.actamat.2006.05.035

Saylor DM, Mason DE, Rohrer GS (2000) Experimental method for determining surface energy anisotropy and its application to magnesia. J Am Ceram Soc 83(5):1226–1232

Saylor DM, Morawiec M, Rohrer GS (2003a) Distribution of grain boundaries in magnesia as a function of five macroscopic parameters. Acta Mater 51:3663–3674. doi:10.1016/S1359-6454(03)00181-2

Saylor DM, Morawiec M, Rohrer GS (2003b) The relative free energies of grain boundaries in magnesia as a function of five macroscopic parameters. Acta Mater 51:3675–3686. doi:10.1016/S1359-6454(03)00182-4

Saylor DM, Dasher BE, Pang Y, Miller HM, Wynblatt P, Rollett AD, Rohrer GS (2004a) Habits of grains in dense polycrystalline solids. J Am Ceram Soc 87(4):724–726. doi:10.1111/j.1551-2916.2004.00724.x

Saylor DM, El-Dasher BS, Adams BL, Rohrer GS (2004b) Measuring the five-parameter grain-boundary distribution from observations of planar sections. Metall Mater Trans A 35A(7):1981–1989

Saylor DM, El-Dasher B, Sano T, Rohrer GS (2004c) Distribution of grain boundaries in SrTiO3 as a function of five macroscopic parameters. J Am Ceram Soc 87(4):670–676. doi:10.1111/j.1551-2916.2004.00670.x

Saylor DM, El Dasher BS, Rollett AD, Rohrer GS (2004d) Distribution of grain boundaries in aluminium as a function of five macroscopic parameters. Acta Mater 52:3649–3655. doi:10.1016/j.actamat.2004.04.018

Saylor DM, Fridy J, El-Dasher BS, Jung KY, Rollett AD (2004e) Statistically representative three-dimensional microstructures based on orthogonal observation sections. Metall Mater Trans A 35(7):1969–1979. doi:10.1007/s11661-004-0146-0

Schenk O, Urai JL (2004) Microstructural evolution and grain boundary structure during static recrystallization in synthetic polycrystals of sodium chloride containing brine. Contrib Mineral Petrol 146:671–682. doi:10.1007/s00410-003-0522-6

Schenk O, Urai JL, Piazolo S (2006) Structure of grain boundaries in wet synthetic polycrystalline, statically recrystallizing halite—evidence from cryo-SEM observations. Geofluids 6:93–104. doi:10.1111/j.1468-8123.2006.00134.x

Schutjens PMTM, Spiers CJ (1999) Intergranular pressure solution in NaCl: Grain-to-grain contact experiments under the optical microscope. Oil Gas Sci Technol 54(6):729. doi:10.2516/ogst:1999062

Sickafus KE, Sass SL (1987) Grain boundary structural transformations induced by solute segregation. Acta Mater 35(1):69–79. doi:10.1016/0001-6160(87)90214-8

Skrotzki W, Welch P (1983) Development of texture and microstructure in extruded ionic polycrystalline aggregates. Tectonophysics 99:47–61. doi:10.1016/0040-1951(83)90169-5

Spiers CJ, Carter NL (1996) Microphysics of rocksalt flow in nature. In: Fourth conference on the mechanical behaviour of salt. Pennsylvania State University, Trans Tech Publications, pp 115–128

Spiers CJ, Urai JL, Lister GS, Boland JN, Zwart HJ (1986) The influence of rock–fluid interaction on the rheological and transport properties of dry and wet salt rocks, European Communities Commission. Nucl Sci Technol Ser Luxemb EUR 10399: pp 132

Spiers CJ, Peach CJ, Brzesowsky RH, Schutjens PMTM, Liezenberg JL, Zwart HJ (1989) Long term rheological and transport properties of dry and wet salt rocks. Nuclear Science and Technology, EUR E. Nuclear Science and Technology, Office for Official Publications of the European Communities, Luxembourg. 11848 EN, pp 161

Sutton AP, Balluffi RW (1995) Interfaces in crystalline materials, vol. 961 51. Oxford Science Publication, Clarendon, pp 819

ter Heege J, de Bresser JHP, Spiers CJ (2004) Dynamic recrystallization of dense polycrystalline NaCl: dependence of grain size distribution on stress and temperature. Mater Sci Forum 467–470:1187–1192

Ter Heege JH, De Bresser JHP, Spiers CJ (2005) Dynamic recrystallization of wet synthetic polycrystalline halite: dependence of grain size distribution on flow stress, temperature and strain. Tectonophysics 396:35–57. doi:10.1016/j.tecto.2004.10.002

Trimby PW, Drury MR, Spiers CJ (2000) Recognising the crystallographic signature of recrystallization processes in deformed rocks: a study of experimentally deformed rocksalt. J Struct Geol 22(11–12):1609–1620. doi:10.1016/S0191-8141(00)00059-6

Urai JL (1983) Water assisted dynamic recrystallization and weakening in polycrystalline bischovite. Tectonophysics 96:125–157. doi:10.1016/0040-1951(83)90247-0

Urai JL, Spiers CJ, Peach CJ, Franssen RCMW, Liezenberg JL (1987) Deformation mechanisms operating in naturally deformed halite rocks as deduced from microstructural investigations. Geol Mijnb 66:165–176

Van Noort R, Spiers CJ, Peach CJ (2007) Effects of orientation on the diffusive properties of fluid-filled grain boundaries during pressure solution. Phys Chem Miner 34(2):95–112. doi:10.1007/s00269-006-0131-9

Vernon RH (2004) A practical guide to rock microstructures. Cambridge University Press, Cambridge, pp 594

Vonlanthen P, Groberty B (2008) CSL grain boundary distribution in alumina and zirconia ceramics. Ceram Int 34:1459–1472. doi:10.1016/j.ceramint.2007.04.006

Watanabe T, Peach CJ (2002) Electrical impedance measurement of plastically deforming halite rocks at 125°C and 50 MPa. J Geophys Res 107 (B1)(ECV2):1–12

Wolf D, Lutsko JF (1989) On the geometrical relationship between tilt and twist grain boundaries. Z Krystall 189:239–262

Wolf D, Yamakov V, Keblinski P, Phillpot SR, Gleiter H (2001). High-temperature structure and properties of grain boundaries by molecular-dynamic simulation. In: Recrystallization and grain growth, proceedings of the first joint international conference RWTH Aachen, Springer, Heidelberg, pp 61–72

Wright SI, Larsen RJ (2002) Extracting twins from orientation imaging microscopy scan data. J Microsc 205(3):245–252. doi:10.1046/j.1365-2818.2002.00992.x

Yan MF, Cannon RM, Bowen HK (1983) Space charge, elastic field, and dipole contributions to equilibrium solute segregation at interfaces. J Appl Phys 54(2):764–778. doi:10.1063/1.332035

Zhang X, Grupa J, Spiers CJ, Peach CJ (2007) Stress relaxation experiments on compacted polycrystalline salt. The mechanical behaviour of salt, Hannover, Germany. Taylor and Francis Group, London, pp 159–166

Acknowledgments

Karsten Kunze and an anonymous reviewer are both thanked for their constructive reviews that have helped to improve this article. One of the authors (Pennock) was funded by The Netherlands Organisation for Scientific Research (Nederlandse Orginsatie voor Wetenschappelijk Onderzoek, NWO). John Wheeler, Reinier van Noort, Colin Peach and Chris Spiers are thanked for useful discussions and Colin Peach is thanked for providing the sample for the analysis.

Open Access

This article is distributed under the terms of the Creative Commons Attribution Noncommercial License which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

Author information

Authors and Affiliations

Corresponding author

Additional information

Communicated by M. W. Schmidt.

Rights and permissions

Open Access This is an open access article distributed under the terms of the Creative Commons Attribution Noncommercial License (https://creativecommons.org/licenses/by-nc/2.0), which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

About this article

Cite this article

Pennock, G.M., Coleman, M., Drury, M.R. et al. Grain boundary plane populations in minerals: the example of wet NaCl after low strain deformation. Contrib Mineral Petrol 158, 53–67 (2009). https://doi.org/10.1007/s00410-008-0370-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00410-008-0370-5