Abstract

The present study investigated the influence of a created radial flow upstream of the extrusion die and the average molecular weight on the processibility of polymer melts. Two linear polydimethylsiloxanes (PDMS) of different molecular weights were considered. A convergent radial flow was created at the entrance zone by imposing a rod upstream the capillary die. The flow of the tested PDMSs has been studied using capillary rheometry and particle image velocimetry (PIV). The obtained experimental results revealed a transition zone, on the flow curves (associated to the two PDMSs), located between the end of the surface instability zone and the onset of the gross melt fracture. The morphology of the associated extrudate strand is changed. Furthermore, the PIV recording under the unstable flow shows a new flow pattern in the front of the die due to the created radial flow. The possible origin of the new flow instability was discussed.

Similar content being viewed by others

References

Adewale KEP, Olabisi O, Oyediran AA, Olunloyo VOS (2013) A stick-slip problem related to melt fracture in polymer processing operations. Int Polym Proc 30(6):195–198

Agassant JF, Arda, Combeaud C, Merten A, Munstedr H, Mackley MR, L Robert, Vergne B (2006) Polymer processing extrusion instabilities and methods for their elimination or minimization. International polymer processing XXI 3.

Allal A, Lavernhe A, Vergnes B, Marin G (2006) Relationships between molecular structure and sharkskin defect for linear polymers. J Non Newtonian Fluid Mech 134:127–135

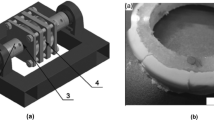

Ayadi A, Elgasri S, Mezghani A, Castro M, Elhaouani F (2011) Effect of radial flow in the die entrance region on gross melt fracture of PDMS extrudate. J Non Newtonian Fluid Mech 166:661–666

Bagley EB, Schreiber HP (1961) Effect of die entry geometry on polymer melts fracture and extrudate distortion. Trans Soc Rheol 5:341–353

Batchelor GK (1985) An introduction to fluid dynamics. Cambridge University Press, Cambridge, UK

Blyler LL, Hart AC (1970) Capillary flow instability of ethylene polymer melts. Polym Eng Sci 10:193–203

Boger DV, Walters K (2000) Experimental dilemmas in non-Newtonian fluid mechanics and their theoretical resolution. Korea-Aust Rheol J 12(1):27–38

Combeaud C (2004) Study of volume instabilies inextrusion of polypropylene and polystyrene, PHD, University of Mines.

Den Otter JL (1970) Mechanisms of melt fracture. Plast Polym:155–168.

Done DS, Baird DG, Average AE (1983) The influence of porous media on the flow of polymer melts in capillaries. Chem Eng Commun 21:293–309

Elgasri S, Ayadi A, Elhaouani F (2011) Effect of die geometry on helical defect during extrusion of PDMS across a radial flow upstream the contraction. J Non Newtonian Fluid Mech 166:1415–1420

Elkissi N, Piau JM (1996) Stability phenomena during polymer melt extrusion. In: Piau JM, Agassant JF (eds) Rheology for polymer melts processing. Elsevier, Amsterdam

Elkissi N, Léger L, Piau JM, Mezghani A (1994) Effect of surface properties on polymer melt slip and extrusion defects. J Non-Newtonian Fluid Mech 52:249–261

Elkissi N, Piau JM, Toussaint F (1997) Sharkskin and cracking of polymer melt extrudates. J Non Newtonian Fluid Mech 68(2–3):271–290

Faure Th, Sato M, Lecocq Y (2003) Mesures PIV par flot optique dans deux types d’écoulements turbulents. Notes et documents LIMSI N :17–18.

Fernandez M, Vega J, Santamaria A, Munoz-Escalona A, Lafuente P (2000) The effect of chain architecture on “sharkskin” of metallocene polyethylenes. Macromol Rapid Commun 21:973–978

Fuller G, Yim KS, Brooks C, Olson D, Frank C (1999) The rheology of two dimensional systems. Korea-Australia Rheology 11(4):321–328

Goyal S, Kazatchkov I, Bohnet N, Hatzikiriakos SG (1997) Influence of molecular weight distribution on the rheological behavior of LLDP resins. Antec’97- Plastics saving earth, Conference Proceeding 1(3):1076

Goutille Y, Guillet J (2002) Influence of filters in the die entrance region on gross melt fracture: extrudate and flow visualization. J Non Newtonian Fluid Mech 102:19–36

Goutille Y, Guillet J (2002) Disentanglement of polymer melts flowing through porous medium before entering a capillary die. J Rheol 46:1307–1323

Goutille Y, Majesté JC, Tassin JF, Guillet J (2003) Molecular structure and gross melt fracture triggering. J Non-Newtonian Fluid Mech 111:175–198

Ketata M, Ayadi A, Elkissi N, Bradai Ch (2017) Effect of rheological and physical properties on mitigation of melt fracture instability during extrusion of polymer melts through a radial flow die. Rheol Acta 56:341

Ketata M, Ayadi A, Bradai Ch, Abid MS (2020) Effect of a radial flow foregoing a capillary die on the behavior of extruded PDMS: velocity field–distorted strand correlation. Rheol Acta 59:425–434

Koopmans R (2002) Engineering techniques, processed plastics and composites, AM3657.

Koopmans R, Molenaar J (1998) The “sharkskin effect” in polymer extrusion. Polym Eng Sci 38:101–107

Kurtz SJ (1992) The dynamics of sharkskin melt fracture: effect of die geometry. Theoretical and Applied Rheology 1:377–379

Legrand F, Piau JM (1998) Spatially resolved stress birefringence and flow visualization in the flow instabilities of a polydimethylsyloxane extruded through a slit die. J Non-Newtonian Fluid Mech 77:123–150

Meh M (1997) Private communication.

Muller R, Vergnes B (1996) Validity of the stress optical law and application of birefringence to polymer complex flows. In: Piau JM, Agassant JF (Eds.) Rheology for polymer processing, Elsevier.

Nigen S, El Kissi N, Piau JM, Sadun S (2003) Velocity field for polymer melts extrusion using particle image velocimetry stable and unstable flow regimes. J Non Newton Fluid Mech 112:177–202

Petrie C, Denn M (1976) Instabilities in polymer processing. AIChE 22: 209-236

Piau JM, El Kissi N, Tremblay B (1990) Influence of upstream instabilities and wall slip on melt fracture and sharkskin phenomena during silicones extrusion through orifice dies. J Non-Newtonian Fluid Mech 34:145–180

Piau JM, ElKissi N, Mezghani A (1995) Slip flow of polybutadiene through fluorinated dies. J Non-Newtonian Fluid Mech 59:11–30

Piau JM, ElKissi N, Toussaint F, Mezghani A (1995) Distortions of polymer melt extrudates and their elimination using slippery surfaces. Rheol Acta 34:40–57

Piau JM, Nigen S, ElKissi N (2000) Effect of die entrance filtering on mitigation of upstreaminstability during extrusion of polymermelts. J Non-Newtonian Fluid Mech 91:37–57

Ramamurthy A (1988) Extrudate irregularities and the polymer-metal interface connection. Xth International Congress on Rheology, Sydney, Australia, pp 85–90

Rothstein JR, McKinley GH (2001) The axisymmetric contraction expansion: the role of extensional rheology on vortex growth dynamics and the enhanced pressure drop. J Non-Newtonian Fluid Mech 98:33–63

Vega J, Fernandez M, Santamaria A, Munoz-Escalona A, Lafuente P (1999) Rheological criteria to characterize metallocene catalyzed polyethylenes. Chem Phys 200:2257–2268

Vlachopoulos J, Alam M (1972) Critcal stress and recoverable shear for polymer melt fracture. Polym Eng Sci 12(3):184–192

Vergnes B (2015) Extrusion defects and flow instabilities of molten polymers. Int Polym Proc 30(1):3–28

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ketata, M., Ayadi, A. & Bradai, C. The upstream region radial flow and average molecular weight effect on the molten PDMS processibility. Rheol Acta 60, 775–785 (2021). https://doi.org/10.1007/s00397-021-01311-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00397-021-01311-2