Abstract

Sets of the nonionic polymers poly(N-vinyl isobutyramide) (pNVIBAm) and poly(N-isopropyl methacrylamide) (pNIPMAm) are synthesized by radical polymerization covering the molar mass range from about 20,000 to 150,000 kg mol−1, and their thermoresponsive and solvent-responsive behaviors in aqueous solution are studied. Both polymers feature a lower critical solution temperature (LCST) apparently of the rare so-called type II, as characteristic for their well-studied analogue poly(N-isopropyl acrylamide) (pNIPAm). Moreover, in analogy to pNIPAm, both polymers exhibit co-nonsolvency behavior in mixtures of water with several co-solvents, including short-chain alcohols as well as a range of polar aprotic solvents. While the cloud points of the aqueous solutions are a few degrees higher than those for pNIPAm and increase in the order pNIPAm < pNVIBAm < pNIPMAm, the co-nonsolvency behavior becomes less pronounced in the order pNIPAm > pNVIBAm > pNIPMAm. Exceptionally, pNIPMAm does not show co-nonsolvency in mixtures of water and N,N-dimethylformamide.

Graphical Abstract

Similar content being viewed by others

Introduction

The interest in the thermoresponsive behavior of polymers in aqueous solution has been mostly focused on the occurrence of a lower critical solution temperature (LCST) and a miscibility gap at elevated temperatures, implying a coil-to-globule transition of the solvated polymer chain when passing the phase boundary [1,2,3]. In fact, LCST behavior is widespread among nonionic polymers in aqueous solution [4, 5]. The precise transition temperature of a given system depends on a number of molecular features, first of all on the chemical structure of the monomer and the resulting constitutional repeat unit (CRU) [4, 6, 7], or in the case of statistical copolymers, on their composition [8,9,10,11,12]. Moreover, it is modulated by various additional molecular parameters, such as the polymer molar mass, end groups [13, 14], and tacticity [15,16,17]. Further, the transition temperature depends on numerous physical parameters of the system studied, including the polymer concentration or the pressure [18,19,20,21], and can be modulated by the presence of low molar mass additives, such as electrolytes, H-bond modifiers, osmolytes, or organic co-solvents [22,23,24,25].

While numerous nonionic water-soluble polymers exhibit a lower consolute boundary with a LCST in aqueous systems, on a closer view, type I and type II LCST behaviors can be distinguished [26, 27]. The former is the standard case and characterized by Flory–Huggins-like phase behavior, for which, e.g., the phase transition temperature changes sensitively with the polymer’s concentration and molar mass. Characteristically, the polymer concentration of the critical point approaches the value of 0 with increasing molar mass. When heating across the transition temperature, such polymers undergo a marked, but continuous desolvation, or a gradual shrinking in the case of hydrogels. Type I behavior is advantageous, for instance, for applications where the LCST transition is translated into quantitative signals or effects, which change markedly, though continuously within a certain temperature interval. This behavior is typically aspired for, e.g., sensors or molecular thermometers [28,29,30,31,32]. A characteristic feature of the exceptional type II behavior is the existence of an off-zero liquid–liquid critical composition for a hypothetical polymer of infinite molar mass [27, 33, 34]. This means that even at high molar masses, the polymer concentration at the critical point approaches a fixed value, but does not become zero. Typically, the phase transition temperature changes only weakly with the polymer’s molar mass when exceeding a value of about 20 kDa, and with its concentration over a large concentration range [35]. When heating beyond the transition temperature, such polymers undergo a rather abrupt desolvation or shrinking [26, 27], while gels show a discontinuous swelling transition [36, 37]. These features are typically advantageous for applications where the LCST transition is to be translated into a threshold value, as, e.g., for switches, actuators, valves, alarming devices, or controlled delivery purposes [38,39,40,41,42,43,44].

The prototype of polymers with LCST type II behavior in aqueous media is poly(N-isopropyl acrylamide) (pNIPAm), in which LCST is conveniently located around 30 °C [4, 27, 45,46,47]. Furthermore, pNIPAm shows also a rich co-nonsolvency behavior, i.e., insolubility in specific mixtures of good solvents, namely for mixtures of water and numerous water-miscible organic solvents [48,49,50]. Though studied intensely since long, many open questions remain on the behavior of pNIPAm [27], including, e.g., the uniqueness of pNIPAm’s behavior in solution. To clarify this aspect, we studied two chemically close analogs of pNIPAm, namely, the polymers poly(N-vinyl isobutyramide) (pNVIBAm) and poly(N-isopropyl methacrylamide) (pNIPMAm) (Fig. 1), which both share the secondary amide moiety as a hydrophilic key motif, investigating the impact of their modified molecular structures on the stimuli-responsive behavior.

The CRU of pNVIBAm represents a structural isomer of pNIPAm, with the only difference that the orientation of the amide moiety relative to the polymer backbone is inverted. Accordingly, when judging on an incremental base, both polymers pNVIBAm and pNIPAm are characterized by the identical hydrophilic–hydrophobic balance. However, literature reported an LCST value of around 40 °C for pNVIBAm [18, 51,52,53,54,55], contrasting with the LCST value of around 30 °C typically reported for pNIPAm [1, 27, 45]. The reasons for this difference are not clear so far. Anyhow, the number of reports on pNVIBAm and its phase behavior in aqueous solution is very limited, in flagrant contrast to the myriad reports on pNIPAm. Moreover, many of the few reports using NVIBAm as building block deal with chemically cross-linked hydrogels [56,57,58] or with copolymers [58,59,60,61], rather than with soluble homopolymers. Nevertheless, the few studies available suggest the exceptional type II LCST behavior for pNVIBAm [56] and mention, at least briefly, co-nonsolvency behavior in one system, namely in ethanol–water mixtures [62, 63].

The polymer pNIPMAm can be considered a homologue of pNIPAm bearing an additional methyl group on the polymer backbone. Although reports on pNIPMAm and its phase behavior in aqueous solution have been less rare than reports on pNVIBAm, the literature has remained quite scarce up to now, too. Notwithstanding, the structural similarity of pNIPMAm to pNIPAm has incited studies on its phase behavior in aqueous solution from the very beginning [35, 64, 65]. Remarkably, the LCST of pNIPMAm is not lower than the LCST of pNIPAm, as might have been expected due to the additional—a priori hydrophobic—methyl group of the repeat unit, but it is about 40–45 °C and thus higher [7, 64, 66,67,68,69]. Proposed explanations of this comparably high value include the sterically more crowded backbone weakening intrapolymer interactions [69,70,71,72,73,74], and an increased residence time of hydration water on the polymers [75]. Although the aqueous solution behavior of pNIPMAm shows some particularities [69, 76], it seems also to be of LCST type II [69]. Similar to pNVIBAm, only few studies mentioned co-nonsolvency behavior of pNIPMAm up to now, namely for aqueous mixtures of methanol [77], ethanol [78, 79], and acetone [44, 80].

In our study, we synthesized sets of varying molar masses for both pNVIBAm and pNIPMAm and investigated the effects of the varied molecular structures on the stimuli-responsive behavior. We studied, in particular, the phase transition temperature in pure water and in mixtures of water with a series of fully water-miscible organic solvents, comprising the protic solvents methanol, ethanol, n-propanol, and iso-propanol, as well as the aprotic solvents N,N-dimethylformamide (DMF), dimethylsulfoxide (DMSO), acetone, tetrahydrofuran (THF), and 1,4-dioxane.

Experimental

The chemicals and solvents used, as well as the monomer syntheses following literature procedures [81, 82], are specified in detail in the Supplementary Information.

Polymerizations

Conventional free radical polymerizations were performed to obtain pNIPMAm and pNVIBAm homopolymers. A typical procedure is presented in the following. Complete lists of all conventional free radical polymerizations along with the specific reaction parameters are provided in Tables 1 and 2.

N-Isopropyl methacrylamide (NIPMAm, 1.00 g, 7.86 mmol) was placed in a round-bottom flask equipped with a magnetic stirring bar. Initiator 2,2′-azobis(isobutyronitrile) (AIBN, 0.50 mg, 0.0031 mmol) was added, followed by additional benzene (total 2.66 mL), to achieve an overall concentration of 30 wt%. The flask was closed with a silicone septum and degassed with argon for 15 min, after which the flask was immersed in an oil bath of 65 °C. The reaction was allowed to proceed for 18 h, and then quenched by exposure to air and cooling to room temperature. The polymer was dissolved in acetone and precipitated into a tenfold volume of 2:1 diethyl ether/pentane. The precipitate was collected by filtration, and precipitation was repeated, if necessary, until no residual monomer was present, as evidenced by 1H NMR analysis. Finally, the polymer was dissolved in water and lyophilized to yield a colorless, hygroscopic powder.

Methods and equipment

1H NMR and 13C NMR spectra were recorded at ambient temperature in deuterated solvents, using a Bruker Avance 300 (300 MHz/75 MHz), Bruker Avance NEO 400 (400 MHz/101 MHz), Bruker Avance Neo 500 (500 MHz/126 MHz), or Bruker AVANCE III (600 MHz/151 MHz) spectrometer, depending on the resolution and sensitivity needed. Polymer concentrations were around 40 g L−1.

Size exclusion chromatography (SEC) of the polymers was performed at 25 °C in NMP with 0.5 wt% of LiBr added as an eluent, using a TSP P1000 isocratic pump (Thermo Fisher Scientific, Dreieich, Germany), a Shimadzu RID-6A refractive index detector (Shimadzu Corporation, Kyoto, Japan), and a PSS GRAM column (7 μm, 8 × 300 mm) (PSS GmbH, Mainz, Germany). The SEC setup was calibrated using narrowly distributed poly(methyl methacrylate) (PMMA) standards (PSS GmbH, Mainz, Germany).

Cloud points (TCP) of the polymers were determined by turbidimetry using a Varian Cary 5000 UV–Vis-NIR spectrophotometer, equipped with 6 + 6 cell Peltier thermostated cell holders, using quartz cuvettes with an optical path length of 10 mm. Measurements were performed at a wavelength (λ) of 500 nm, with heating and cooling rates of 0.5 K min−1. Measured transmission values were normalized to the maximum value in each sample’s measurement. Cloud points were determined from the heating run, using the onset temperature of the transmission decay. Polymer solutions in mixed solvents (water + co-solvent) were prepared by first dissolving the polymer with the target concentration in water as well as in the pure co-solvent and subsequently combining the desired proportions of the polymer solutions in water and the co-solvent, respectively.

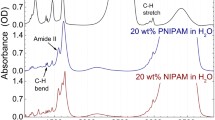

Fourier transform infrared spectroscopy (FTIR) spectra of powders were recorded using a Nicolet Avatar 370 FT-IR spectrometer equipped with an ATR Smart Performer element and AMTIR crystal.

Elemental analysis (EA) used a FlashEA 1112 CHNS/O Automatic Elemental Analyzer with a MAa2O6R autosampler (Thermo Scientific).

Thermogravimetric analysis (TGA) was conducted using a Mettler Toledo TGA/SDTA851e apparatus, under N2 atmosphere (20 mL min−1) in the temperature range from 25 to 900 °C, with a heating rate of 10 K min−1. Differential scanning calorimetry (DSC) analyses were performed with a Mettler Toledo DSC822e device, under N2 atmosphere (20 mL min−1) at temperatures ranging from 0 to 230 °C in four subsequent heating–cooling cycles. Heating and cooling rates were 10 K min−1 during the first and second cycles and 30 K min−1 during the third and fourth cycles. Glass transition temperatures were derived from the second heating curve, at the mid-point (half height) of the transition step.

Results and discussion

Polymer synthesis and characterization

The polymer pNVIBAm can be obtained by conventional radical polymerization of its monomer NVIBAm in solution [56, 63, 83] using azo initiators. Still, the originally reported synthesis of the monomer is cumbersome, implying a pyrolysis step [83]. Therefore, pNVIBAm was prepared alternatively by post-polymerization modification via a complex three-step sequence. Polymerizing the commercially available monomers N-vinyl formamide and N-vinylacetamide first, the amide moieties of the precursor polymer obtained were subsequently hydrolyzed to produce poly(vinylamine) as intermediate, which finally was converted to pNVIBAm by reforming the amide moieties with isobutyric acid [84, 85]. As inherently, this pathway may suffer from incomplete functionalization or side reactions, the exact structure of such pNVIBAm samples can deviate from the ideal structure, and therefore, the accuracy of the determined phase transition temperatures (of about 41 °C) can be questioned. The situation improved considerably with the much simpler synthesis procedure for monomer NVIBAm reported recently [81], which was adapted by us (see the Supplementary Information). In analogy to early reports [83], we employed benzene as solvent for the polymerizations that is highly inert against radical attack. As vinylamides belong to the group of “less activated monomers” [86], the propagating radicals of their polymers are less stabilized and thus, much more reactive and prone to side reactions (such as chain transfer to the solvent), which we wanted to minimize. Also, we tested the use of two different azo initiators, namely AIBN and MAIB (Fig. 2), which feature a very similar thermal decomposition profile, but showed remarkably different initiation efficiencies for the polymerization of monomers that are difficult to polymerize [87,88,89]. Moreover, NVIBAm was polymerized in the presence of chain transfer agent S-cyanomethyl N-methyl-N-phenyl-carbamodithioate (CTA-X), which was reported to efficiently control the radical addition fragmentation chain transfer polymerization (RAFT) of “less activated monomers” such as vinylamides [90], to prepare a pNVIBAm sample of low molar mass. Table 1 summarizes key reaction conditions and parameters of the polymers produced.

The data compiled in Table 1 are not surprising. The conventional radical polymerization of NVIBAM is rather fast (but considerably slowed down in the case of the RAFT process; see entry 6), gives reasonable yields, and delivers a certain spread of polymer molar masses in the range of 30 to 120 kg mol−1 for the number average (Mn). The rather moderate values of the dispersity (Ð) for a conventional free radical polymerization up to high conversions are explained by the purification of the polymers by dialysis and/or precipitation, thus cutting off the low molar mass fraction. The use of either AIBN or MAIB as an initiator did not result in significant differences.

As only very few molecular analytical data on pNVIBAm have been published [58], exemplary 1H and 13C NMR spectra are shown in Fig. 3 (see also Supplementary Information Figs. S4–S8). Presumably, the complex form of the broad signal between 1.4 and 1.9 ppm (Fig. 3a, signal a), which is characteristic for the methylene protons on the backbone, is due to the polymer’s tacticity. Analogously, tacticity effects may also explain the width and complexity of the corresponding signal between 37 and 42 ppm in the 13C spectrum, which required extended sampling to be distinguishable from the background noise (Fig. 3b; see also Supplementary Information Fig. S6). Though the effects are less pronounced in the spectra, the same consideration applies to the complex form of the signal between 2.3 and 2.6 ppm in the 1H spectrum (Fig. 3a, signal d) that is characteristic for the methine proton of the isobutyramide moiety of the side chain. Also in this case, the corresponding signal group between 35 and 35.5 ppm in the 13C spectrum consists of at least two only partially resolved signals (see Supplementary Information Fig. S5). Furthermore, the broadened signal b around 3.8 ppm of the backbone methine groups and signal e around 1.1 ppm of the methyl groups being part of the isobutyramide moiety in the side chain in the 1H spectrum have complex signal counterparts in the 13C spectrum (see Supplementary Information Figs. S4 and S7). Moreover, signal c around 180 ppm of the carbonyl group shows a complex fine structure at a closer look (see Supplementary Information Fig. S8). All these observations support the view that stereochemical effects in the backbone are responsible for the complex spectral details. However, to our knowledge, literature reports elucidating the influence of the tacticity on the form of the 1H spectra of pNVIBAm are missing yet. Hence, we could not attribute the stereochemistry of the pNVIBAm samples from the simple analysis of the 1H NMR spectra. Nevertheless, their very similar forms indicate that all the samples have virtually the same stereochemistry. Thus, any possible differences of the phase transition temperature in aqueous media (vide infra) cannot be explained by differing tacticities of the polymer samples.

Thermal analysis by thermogravimetry and DSC revealed that pNVIBAm becomes instable above 300 °C (Fig. 4), but there is no indication for a catastrophic decomposition at 200 °C (which is difficult to rationalize, considering the polymer’s chemical structure lacking thermally labile groups) as was reported before [91]. The gradual, limited mass loss occurring largely in the range up to 120 °C results from the evaporation of water bound due to the polymer’s marked hygroscopy. After removing the water during the first heating cycle, DSC shows a stable glass transition at about 152 °C (Figs. 4b and S12), considerably higher than the value of 133 °C reported in the aforementioned study [91]. Interestingly, the value of 152 °C is higher than that of its “structural isomer” atactic pNIPAm of about 130–140 °C [46, 92,93,94], suggesting that the interaction between the polymer chains is somewhat stronger in the case of atactic pNVIBAm.

In contrast to NVIBAm, the methacrylamide NIPMAm belongs to the group of “more activated monomers,” and thus, its radical polymerization is expected to be less sensitive to side reactions than the one of the vinylamide NVIBAm. Still, a survey of the (surprisingly limited) previous reports on the conventional radical polymerization of NIPMAm reveals that mostly, polymers with low molar masses, i.e., well below 50 × 103 Da, have been produced [28, 64, 65, 74, 95,96,97,98,99,100]. This includes our previous reported syntheses of pNIPMAm by conventional radical polymerization in THF [69, 101]. In line with these observations, the molar mass of statistical copolymers of NIPAm and NIPMAm drastically decreases with increasing NIPMAm content in the polymerization system [66]. Higher molar masses were typically reported only for aqueous polymerizations using peroxide initiators [70, 102]. Such conditions, however, favor chain transfer to the polymer and cross-linking side reactions via the methine moiety in the side chain that is particularly vulnerable to radical attack, as exploited in the synthesis of microgels from NIPAm and NIPMAm [103].

In order to obtain a set of pNIPMAm samples covering also the high molar mass range (> 105 Da), we varied largely the polymerization conditions with respect to the reaction solvent, monomer concentration, and concentration and type of initiator (cf. Figure 2). The reaction temperatures were chosen such that the half-life times of the respective initiators used were in the order of 10 h (Table 2).

Compared to the polymerization of NVIBAm, the polymerization of NIPMAm was much more sluggish. Also, we noted that the outcome of the polymerizations with respect to conversion/yield and molar mass obtained was difficult to reproduce, and results varied substantially, in particular when aiming at high molar masses by engaging only minute amounts of initiator. Still, there is a clear trend that high molar masses require rather high monomer concentrations (≥ 30 wt%) and low initiator concentrations (≤ 0.1 mol% relative to monomer), rendering these reactions highly sensitive to the presence of trace impurities. Also, it appears that the use of solvent benzene or trifluoroethanol (TFE), which are highly inert to the attack by carbon-centered radicals, favors high molar masses. None of these specific findings seems surprising, whereas the general troublesomeness to obtain elevated molar masses for pNIPMAm is. Possibly, this behavior is due to a slow propagation rate, rendering the homopolymerization vulnerable against side reactions. A clarification of this hypothesis by detailed kinetic studies seems interesting, but was beyond the scope of our study. In any case, we produced a large set of pNIPMAm samples in this way with molar masses (Mn) between 7 and 150 × 103 Da.

The 1H NMR spectra of the various pNIPMAm samples synthesized looked very similar (Fig. 5a), corresponding closely to the ones in the literature of samples also prepared by conventional radical polymerization in solution [66, 79]. Unfortunately, the complex signal group of the protons of the methyl moieties between about 0.85 and 1.3 ppm, which is directly attached to the polymer backbone and sensitive to the polymer’s tacticity [95, 104], and the intense signal group of the methyl protons of the isopropyl moiety are superposed. As the different signals could not be resolved, the 1H NMR spectra do not enable the absolute quantification of the relative frequency of the mm, mr, and rr triades, as had been done, e.g., for the analogue poly(N-methyl methacrylamide) [104]. Thus, precise tacticity attributions reported in the past were based on quantitative 13C NMR spectra [95, 104], however, without disclosing any spectra or details. Still, the published 13C NMR spectra of poly(N-methyl methacrylamide) of varying stereochemistry presumably provide a good guideline to diade and triade configurational attributions [105], as the high-resolution 13C NMR spectra of pNIPMAm exhibit various details (Fig. 5b, see also Supplementary Information Figs. S9–S11) in particular when recording 1H–13C correlation spectra (Fig. 5c). Accordingly, the signals of the backbone attached methyl group at 16.7 ppm and 17.9 ppm probably belong to the rr and mr triades, respectively. Analogously, the signals of the carbonyl group at 178.0 ppm and 178.2 ppm may be assigned to the rr and mr triades, respectively, while the signals of the methylene group in the backbone at 51.9 ppm and 54.5 ppm probably reflect the m and the r diades, respectively.

Also in the 1H spectra of the samples (Fig. 5a), the pronounced shoulder at 0.85–1.05 ppm with a secondary maximum at about 0.95 ppm is indicative of the predominance of rr triades, i.e., of syndiotactic diades in all polymers, in agreement with the correlation peaks visible in Fig. 5c. These deductions concur with the findings on the NMR model compound poly(N-methyl methacrylamide), for which the samples that were polymerized under comparable conditions (20 wt% in methanol solution at 60 °C, initiated by AIBN) were also atactic with the dominating syndiotactic triades [104].

Even without being able to derive precise values for the different configurations, the very similar forms of the spectra indicate that the tacticities of all our samples are about the same, independent of the reaction temperatures and solvents employed. Importantly, this implies that any possible differences of the phase transition temperature in aqueous media (vide infra) cannot be explained by different tacticities of the pNIPMAm samples compared.

Similarly as found for NVIBAm, analysis by TGA and by DSC (see Supplementary Information Fig. S13) revealed that pNIPMAm becomes instable above 275 °C, also showing some gradual, limited mass loss largely in the range up to 120 °C characteristic for the loss of bound water due to the polymer’s hygroscopy. After removing the water by annealing, DSC shows a glass transition at about 172 °C (see Supplementary Information Fig. S12), corroborating previous studies of atactic pNIPMAm samples [91, 106].

Thermal behavior of aqueous solutions

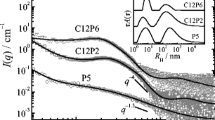

The thermoresponsive behavior of dilute and semi-dilute aqueous solutions of pNVIBAm and pNIPMAm was screened by turbidimetry in the concentration range up to 50 g L−1, and in the temperature range between 14 and 60 °C (Figs. 6, 7, 8, 9, and 10).

Effect of molar mass and end groups on the cloud point of pNIPMAm (10 g L−1 in water, λ = 500 nm), using the initiators MAIB in benzene (white circle), AIBN in benzene (white triangle), AIBN in THF (white upside-down triangle), AIBN in TFE (filled triangle), AIBAH in TFE (filled upside-down triangle), and AMODMV in ethanol (filled diamond) or using a chain transfer agent bearing a hydrophobic dye (X, data taken from ref. [68])

Typical transmittance curves of solutions of pNVIBAm in dependence on temperature are exemplified for the high molar mass sample NVIBAm1069 in Fig. 6a. Upon heating, the polymers feature a sharp clouding transition at about 39 °C, whereas the cloud point shows a continuous small but significant decrease with increasing concentration up to at least 50 g L−1 even for the highest molar masses studied of about 120 kg mol−1 (Fig. 6b; see also Supplementary Information Figs. S14 and S15). This behavior contrasts with the concentration effects on polymers with typical LCST type I behavior such as poly(N-vinylcaprolactam) [107], poly(N,N-diethylacrylamide [108], poly(methoxyethoxyethyl acrylate) [109], or poly(N,N-bis(2-methoxyethyl)acrylamide) [110], for which the minimum of the cloud point continuously shifts to lower concentration with increasing molar mass, thus approaching finally the value of 0 at infinitely high molar masses.

Moreover, for a given concentration, the cloud point temperature (TCP) seems not to vary significantly within the accuracy of the measurements for different molar masses when a value of 20 kg mol−1 is exceeded (Fig. 7). All these findings are in agreement with an LCST behavior of type II, corroborating a previous report on pNVIBAm-based hydrogels [56]. Also, no significant difference was found for polymer samples which were prepared using the different initiators (AIBN or MAIB or RAFT agent), thus resulting in end groups of somewhat differing polarities/hydrophilicities.

The thermoresponsive behavior of dilute and semi-dilute aqueous solutions of pNIPMAm is exemplified in Figs. 8, 9, and 10. It shows many similarities to the behavior of pNVIBAm. Nevertheless, it should be kept in mind that the solubility–insolubility phase transition of pNIPMAm in aqueous solution features some particularities compared to the classical case of, e.g., pNIPAm [76]. The transition temperatures of pNIPMAm determined by different methods may deviate significantly, e.g., when studied by turbidimetry or by calorimetry, where TCP is systematically lower than calorimetric transition temperature (TDSC) [69]. Also, the clouding transition is prone to a more marked hysteresis between the heating (resulting in clouding) and cooling (resulting in clearing) runs [69, 76], but this seems also true for pNVIBAm. The hysteresis behavior is illustrated for the high molar mass samples pNVIBAM1069 and pNIPMAm956 in Fig. 8. Further, pNIPMAm tends to sediment/precipitate rapidly once heated above the cloud point (cf. the apparent increase in transmittance upon continuous heating in Fig. 9 that results from colloid sedimentation), whereas colloids of collapsed pNVIBAm above the cloud point tend to stay dispersed for much longer periods, forming so-called mesoglobules, as they are well-established in the case of pNIPAm [4].

As the majority of the reports on the thermal behavior of pNIPMAm have focused on turbidimetric studies of the clouding upon heating, we also confined our screening of the thermal behavior of pNIPMAm solutions to the clouding transition by turbidimetry (Figs. 9 and 10). Figure 9a displays typical transmittance curves in dependence on the temperature for the high molar mass sample pNIPMAm956. The polymers feature a sharp clouding transition upon heating at about 44 °C, which exhibits a continuous small but significant decrease with increasing concentration of up to at least 50 g L−1 even for the highest molar masses studied (Fig. 9b, see also Supplementary Information Figs. S14 and S16).

Furthermore, for a given concentration, the cloud point does not vary significantly within the accuracy of the measurements for different molar masses, at the least when a value of 20 kg mol−1 is exceeded (Fig. 10), and takes a value of about 44.5 °C, with the notable exception of the samples prepared with the initiator AMODMV/V70. The latter group shows also a cloud point independent of the molar mass, but at about 41 °C, i.e., 3–4 °C lower than for the other pNIPMAm samples.

One possible reason for this difference could be that the lower polymerization temperature of these samples and/or that the choice of ethanol as reaction medium changes the stereochemistry of pNIPMAm and induces, for instance, a higher degree of isotactic triades [95]. However, such an explanation is not compatible with the close similarity of all NMR spectra of the various pNIPMAm made (see above). It would be also difficult to reconcile with the reports that notable differences in the stereochemistry for poly(meth)acrylamides such as pNIPAm or poly(N-methyl methacrylamide) produced by radical polymerization are only obtained, if conducted at considerably lower temperatures than employed in our study and in highly fluorinated solvents [105, 111], or when complexing agents are specifically added [95, 104]. This is not the case here. Therefore, in analogy to previous reports on the lowering of the cloud point of pNIPMAm when attaching hydrophobic end groups of intermediate size [68], we putatively attribute the relatively low cloud points to the end groups derived from the initiator fragments. These are considerably more hydrophobic in the case of initiator AMODMV than in the case of initiators AIBN, MAIB, and AIBAH (cf. Figure 2). Anyhow, as observed for pNVIBAm, all findings support the view that also pNIPMAm exhibits LCST behavior of type II.

Co-nonsolvency behavior in mixtures of water and organic solvents

The co-nonsolvency of pNIPAM in mixed aqueous solutions is well established, with the focus on the solvent system water–methanol [50, 112,113,114,115,116,117,118,119,120]. Occasionally, co-nonsolvency behavior was also reported for other organic co-solvents. Presumably, the broadest study of co-nonsolvency in various co-solvents is that by Costa and Freitas [121], where co-nonsolvency of pNIPAM with the co-solvents methanol, ethanol, isopropyl alcohol, n-propanol, acetone, DMSO, and DMF was compared. Further, acetonitrile, glycerol, oligoethyleneglycols, THF, and 1,4-dioxane were reported to show co-nonsolvency for pNIPAM [22, 122, 123]. Still, the reasons for the occurrence of co-nonsolvency are not clear yet, including a debate whether or not co-nonsolvency is a generic phenomenon, which does not depend on the specific interactions between the components of the system [124, 125]. Importantly, two contrasting patterns of co-nonsolvency have been reported for pNIPAm [121]. In the first pattern, the LCST transition passes through a minimum value with an increasing fraction of co-solvent. This is the case for the co-solvents methanol, acetone, THF, and dioxane. In the second pattern, the LCST transition decreases continuously until it falls below the melting point of the solvent mixtures, but does not recover for high fractions of co-solvent. Instead, the increasing fraction of co-solvent causes the UCST transition to decline steeply, until solubility is regained for a given temperature [126]. The latter scenario seems to be the more frequent one [121], applying to most other alcohols studied as well as to DMF and DMSO as co-solvent. However, many studies that have dealt with the swelling of gels in mixed aqueous media could not distinguish these two scenarios, e.g., when just following the reentrant swelling effect at a constant temperature as frequently done. In view of these observations, we screened the possible co-nonsolvency behavior in mixed aqueous solutions for a variety of co-solvents up to a molar fraction of 0.3 for pNIPMAm and pNVIBAm and compared their behaviors to that of their analogue pNIPAM using data from the literature (Figs. 11, 12, and 13), within the temperature window of 14 to 60 °C accessible by our experimental set-up.

Co-nonsolvency in mixtures of water and lower alcohols (methanol (MeOH, blue), ethanol (EtOH, red), iso-propanol (i-PrOH, green), and n-propanol (PrOH, black): a) of pNVIBAm (full symbols: blue, red, green, and black triangles); b) of pNIPMAm (full symbols: blue, red, green, and black circles), followed by the cloud point (λ = 500 nm, heating rate 0.5 K min−1). The dashed curves are meant as a guide to the eye. For comparison, the corresponding solutions of pNIPAm are shown (open symbols: blue, red, green, and black upside-down triangles) with data from reference [121]. The horizontal broken black line indicates the lower temperature limit of the experimental set-up used

Co-nonsolvency in mixtures of water and dipolar aprotic solvents (DMSO (cyan), DMF (brown), and acetone (magenta)): a) of pNVIBAm (full symbols: cyan, brown, and magenta triangles); b) of pNIPMAm (full symbols: cyan, brown, and magenta circles), followed by the cloud point (λ = 500 nm, heating rate 0.5 K min−1). The dashed curves are meant as a guide to the eye. For comparison, the corresponding solutions of pNIPAm are shown (open symbols: cyan, brown, and magenta upside-down triangles) with data from reference [121]. The horizontal broken black line indicates the lower temperature limit of the experimental set-up used

Co-nonsolvency in mixtures of water and dipolar aprotic solvents (THF (blue) and dioxane (black)): a) of pNVIBAm (full symbols: black and blue triangles); b) of pNIPMAm (full symbols: black and blue circles), followed by the cloud point (λ = 500 nm, heating rate 0.5 K min−1). The dashed curves are meant as a guide to the eye. For reference, the corresponding solutions of pNIPAm are shown (open symbols: black and blue upside-down triangles) using data from reference [122]. The horizontal broken black line indicates the lower temperature limit of the experimental set-up used

Figure 11 illustrates the effect of lower alcohols as co-solvents, namely of methanol, ethanol, iso-propanol, and n-propanol, on the cloud points of pNVIBAm (Fig. 11a) and pNIPMAm (Fig. 11b) in comparison to pNIPAm. All three polymers show qualitatively a similar behavior in the particular water–alcohol mixtures, and for a specific concentration and mixture, the transition temperatures always decrease in the order pNIPMAm > pNVIBAm > pNIPAm. Throughout, the extent of the co-nonsolvency effect, i.e., the magnitude of the decrease of TCP, increases with the decrease of the alcohol’s polarity. Methanol produces the mildest effects, while n-propanol provokes the strongest ones. In the case of methanol, a minimum for TCP is attained at about 30 mol% of co-solvent in water, beyond which the coexistence line increases rather steeply and the solubility window re-opens (scenario 1). Looking in more detail, the reduction of TCP is considerably more prominent for pNIPAm than for pNVIBAm and pNIPMAm, which show comparable strengths of the effect. We also note that the amount of methanol in the mixtures, at which the cloud point is minimum, decreases from about 35 mol% for pNIPAm via about 31 mol% for pNVIBAm to about 29 mol% for pNIPMAm. For ethanol, iso-propanol, and n-propanol, no increase of TCP could be observed at intermediate alcohol contents in the concentration and temperature window studied, suggesting a behavior according to pattern 2 (change from LCST to UCST transition). In any case, all three polymers become soluble at room temperature in alcohol-rich aqueous solutions.

Figure 12 illustrates the effect of aprotic polar co-solvents, namely DMF, DMSO, and acetone, on the cloud points of pNIPMAm and pNVIBAm. Acetone imparts on both pNIPMAm and pNVIBAm a similar behavior as methanol does, following co-nonsolvency pattern 1, albeit with a more pronounced effect on TCP (shift to lower temperatures). For pNVIBAm, DMSO and DMF have a similar impact on the transition temperatures as what was reported for pNIPAm (Fig. 12a). DMSO shows little impact when present in low fractions but causes TCP to drop more strongly as the fraction of co-solvent increases. The effect of DMF looks similar at a first view. However, low fractions of the co-solvent induce a slight increase of TCP, up to a molar fraction of about 0.07, corroborating previous observations [22, 121], above which TCP starts to fall continuously. The behavior of pNIPMAm in aqueous mixtures with DMSO and DMF, however, shows particularities. Most prominently, the addition of DMF makes TCP to rise continuously with no sign of co-nonsolvency behavior. The addition of DMSO results in a complicated behavior. Initially, it results in a slight increase of the transition temperature of pNIPMAm up to a molar fraction of ca. 0.025, only beyond which TCP decreases in the typical co-nonsolvency fashion. Interestingly, while Costa and Freitas [121] did not report a similar effect, Yamauchi and Maeda [127] observed an analogous behavior for pNIPAm with a small maximum of TCP at a comparably small molar fraction of DMSO before inducing co-nonsolvency at higher fractions.

The effect of adding the cyclic ethers THF and dioxane on the cloud points of pNIPMAm and pNVIBAm is illustrated in Fig. 13. For both pNIPAm and pNVIBAm, already small THF contents in water cause a very sharp drop of the transition temperature (Fig. 13a). For pNIPMAm, a first small, and then increasingly marked increase of TCP is observed when the molar fraction of THF exceeds 0.1 (Fig. 13b). The analogous behavior was observed for pNVIBAm, though the lowest transition temperatures were outside of the measuring range of our experimental setup.

Finally, co-nonsolvency of pNIPMAm and pNVIBAm in water–dioxane mixtures was evaluated, for which only weak co-nonsolvency behavior has been reported for pNIPAm [122, 128]. For both pNVIBAm and pNIPMAm, an even weaker, nearly plateau-like effect of lowering TCP is observed in mixtures with dioxane molar fractions below 0.1 (Fig. 13). The effect is small for pNIPMAm (for which TCP is reduced by about 2 °C at maximum at a molar fraction of 0.08, Fig. 13b) and even marginal for pNVIBAm (for which TCP is reduced by 0.7 °C at maximum for a molar fraction of 0.05, Fig. 13a), while TCP increases steeply for both polymers when the molar fraction of dioxane is further increased. This behavior may be interesting from a practical point of view when amphiphilic block copolymers combining thermoresponsive blocks of pNIPAm, PNVIBAm, or pNIPMAm and a hydrophobic block such as polystyrene are to be dispersed in water to form small micellar entities or nanoparticles, by continuously diluting a solution of the block copolymer in a nonselective, water-miscible solvent with water [129, 130]. With dioxane being a good solvent for many polymers, the homogeneous solutions of such block copolymers in dioxane can be continuously diluted at ambient temperature to make the hydrophobic block micro-phase separate without the interfering intermediate precipitation and aggregation of both the hydrophobic and the thermoresponsive hydrophilic blocks, as encountered for most fully water-miscible organic solvents.

Overall, the co-nonsolvency behaviors of pNIPMAm and pNVIBAm appear qualitatively comparable to that of pNIPAm, but are quantitatively less pronounced, with transition temperatures consistently following the trend of pNIPAm < pNVIBAm < pNIPMAm. Nevertheless, some differences were identified. The most remarkable one seems that DMF does not cause co-nonsolvency for pNIPMAm (Fig. 12b), contrary to the marked co-nonsolvency effect encountered for both pNIPAM and pNVIBAm (Fig. 12a). Whereas the rather close similarities of the overall co-nonsolvency behaviors of the “isomeric” polymers pNIPAM and pNVIBAm are not self-evident but seem intuitively comprehensible, this is less obvious for the case of pNIPMAm. As already the interaction with water differs notably, resulting in a considerably higher LCST for pNIPMAm despite a formally lower hydrophilic-lipophilic balance of the repeat unit (see “Introduction”), more differences in the co-nonsolvency behavior than the few observed might have been expected. As, however, our understanding of the co-nonsolvency phenomenon is quite limited (and disputed) yet, a convincing explanation has to be awaited for.

Conclusions

Both analogues of poly(N-isopropyl acrylamide) (pNIPAm), namely poly(N-vinyl isobutyramide) (pNVIBAm) and poly(N-isopropyl methacrylamide) (pNIPMAm), feature an upper miscibility gap in aqueous solution, for which the phase transition temperatures hardly evolve above molar masses of 20 kg mol−1. As, furthermore, the phase transition temperatures decrease still gradually with increasing polymer concentration up to a concentration of at least 50 g L−1 even for high molar masses, both polymers seem to feature the unusual LCST type II behavior that is characteristic for pNIPAm [26]. Overall, differences in the properties compared to pNIPAm seem somewhat more pronounced for pNIPMAm than for pNVIBAm. For a given polymer concentration, phase transition temperatures increase in the order pNIPAm < pNVIBAm < pNIPMAm, which cannot be intuitively rationalized simply by the relative hydrophilicities of the repeat units chemical structures. As known for pNIPAm, both pNVIBAm and pNIPMAm exhibit marked co-nonsolvency behavior with a large group of water-miscible organic solvents, including lower alcohols, as well as aprotic solvents of different polarities such as dimethylsulfoxide (DMSO), acetone, and tetrahydrofuran (THF). Both pNVIBAm and pNIPMAm show also co-nonsolvency in mixtures of water and dioxane, but the effects are marginal, even weaker than known for pNIPAm. Throughout, the co-nonsolvency behavior becomes less pronounced in the order pNIPAm > pNVIBAm > pNIPMAm. Exceptionally, pNIPMAm does not feature co-nonsolvency in mixtures of water and N,N-dimethylformamide (DMF). In contrast, pNVIBAm shows weak co-solvency at low, but marked co-nonsolvency at intermediate fractions of DMF in the mixtures, as reported for pNIPAm. In mixtures containing DMSO, co-nonsolvency behavior was observed for pNVIBAm for all fractions of the co-solvent, while pNIPMAm shows weak co-solvency at low, but notable co-nonsolvency at intermediate fractions of DMSO. In the light of the current theories about the origin of co-nonsolvency [48, 50, 131, 132], these observations are difficult to explain and might trigger further investigations and atomistic simulations. In any case, the many similarities of their thermoresponsive behaviors to the one of pNIPAm, together with the difference in the transition temperatures, render pNVIBAm and pNIPMAm interesting complements to pNIPAm as building blocks for smart polymers.

References

Aseyev V, Tenhu H, Winnik F (2006) Temperature dependence of the colloidal stability of neutral amphiphilic polymers in water. Adv Polym Sci 196:1–85

Tavagnacco L, Zaccarelli E, Chiessi E (2022) Modeling solution behavior of poly(N-isopropylacrylamide): a comparison between water models. J Phys Chem B 126:3778–3788. https://doi.org/10.1021/acs.jpcb.2c00637

Niebuur B-J, Chiappisi L, Zhang X, Jung F, Schulte A, Papadakis CM (2018) Formation and growth of mesoglobules in aqueous poly(N-isopropylacrylamide) solutions revealed with kinetic small-angle neutron scattering and fast pressure jumps. ACS Macro Lett 7:1155–1160. https://doi.org/10.1021/acsmacrolett.8b00605

Aseyev V, Tenhu H, Winnik F (2011) Non-ionic thermoresponsive polymers in water. Adv Polym Sci 242:29–89. https://doi.org/10.1007/12_2010_57

Roy D, Brooks WLA, Sumerlin BS (2013) New directions in thermoresponsive polymers. Chem Soc Rev 42:7214–7243. https://doi.org/10.1039/c3cs35499g

Zhao C, Ma Z, Zhu XX (2019) Rational design of thermoresponsive polymers in aqueous solutions: a thermodynamics map. Prog Polym Sci 90:269–291. https://doi.org/10.1016/j.progpolymsci.2019.01.001

Hannappel Y, Wiehemeier L, Dirksen M, Kottke T, Hellweg T (2021) Smart microgels from unconventional acrylamides. Macromol Chem Phys 222(2100067):2100061–2100013. https://doi.org/10.1002/macp.202100067

Priest JH, Murray SL, Nelson RJ, Hoffman AS (1987) Lower critical solution temperatures of aqueous copolymers of N-isopropylacrylamide and other N-substituted acrylamides. ACS Symp Ser 350:255–264. https://doi.org/10.1021/bk-1987-0350.ch018

Laschewsky A, Rekai ED, Wischerhoff E (2001) Tailoring of stimuli-responsive water-soluble acrylamide and methacrylamide polymers. Macromol Chem Phys 202:276–286. https://doi.org/10.1002/1521-3935(20010101)202:2%3c276::aid-macp276%3e3.0.co;2-1

Lutz J-F, Weichenhan K, Akdemir Ö, Hoth A (2007) About the phase transitions in aqueous solutions of thermoresponsive copolymers and hydrogels based on 2-(2-methoxyethoxy)ethyl methacrylate and oligo(ethylene glycol) methacrylate. Macromolecules 40:2503–2508. https://doi.org/10.1021/ma062925q

ten Brummelhuis N, Schlaad H (2011) Stimuli-responsive star polymers through thiol–yne core functionalization/crosslinking of block copolymer micelles. Polym Chem 2:1180–1184. https://doi.org/10.1039/c1py00002k

Weiss J, Li A, Wischerhoff E, Laschewsky A (2012) Water-soluble random and alternating copolymers of styrene monomers with adjustable lower critical solution temperature. Polym Chem 3:352–361. https://doi.org/10.1039/c1py00422k

Furyk S, Zhang Y, Ortiz-Acosta D, Cremer PS, Bergbreiter DE (2006) Effects of end group polarity and molecular weight on the lower critical solution temperature of poly(N-isopropylacrylamide). J Polym Sci, Part A: Polym Chem 44:1492–1501. https://doi.org/10.1002/pola.21256

Xia Y, Burke NAD, Stöver HDH (2006) End group effect on the thermal response of narrow-disperse poly(N-isopropylacrylamide) prepared by atom transfer radical polymerization. Macromolecules 39:2275–2283. https://doi.org/10.1021/ma0519617

Isobe Y, Fujioka D, Habaue S, Okamoto Y (2001) Efficient Lewis acid-catalyzed stereocontrolled radical polymerization of acrylamides. J Am Chem Soc 123:7180–7181. https://doi.org/10.1021/ja015888l

Katsumoto Y, Etoh Y, Shimoda N (2010) Phase diagrams of stereocontrolled poly(N, N-diethylacrylamide) in water. Macromolecules 43:3120–3121. https://doi.org/10.1021/ma902673z

Nishi K, Hiroi T, Hashimoto K, Fujii K, Han Y-S, Kim T-H, Katsumoto Y, Shibayama M (2013) SANS and DLS study of tacticity effects on hydrophobicity and phase separation of poly(N-isopropylacrylamide). Macromolecules 46:6225–6232. https://doi.org/10.1021/ma401349v

Kunugi S, Takano K, Tanaka N, Suwa K, Akashi M (1997) Effects of pressure on the behavior of the thermoresponsive polymer poly(N-vinylisobutyramide) (PNVIBA). Macromolecules 30:4499–4501. https://doi.org/10.1021/ma961770r

Kirpach A, Adolf D (2006) High pressure induced coil-globule transitions of smart polymers. Macromol Symp 237:7–17. https://doi.org/10.1002/masy.200650502

Niebuur B-J, Claude K-L, Pinzek S, Cariker C, Raftopoulos KN, Pipich V, Appavou M-S, Schulte A, Papadakis CM (2017) Pressure-dependence of poly(N-isopropylacrylamide) mesoglobule formation in aqueous solution. ACS Macro Lett 6:1180–1185. https://doi.org/10.1021/acsmacrolett.7b00563

Niebuur B-J, Chiappisi L, Jung F, Zhang X, Schulte A, Papadakis CM (2019) Kinetics of mesoglobule formation and growth in aqueous poly(N-isopropylacrylamide) solutions: pressure Jumps at low and at high pressure. Macromolecules 52:6416–6427. https://doi.org/10.1021/acs.macromol.9b00937

Panayiotou M, Garret-Flaudy F, Freitag R (2004) Co-nonsolvency effects in the thermoprecipitation of oligomeric polyacrylamides from hydro-organic solutions. Polymer 45:3055–3061. https://doi.org/10.1016/j.polymer.2004.02.046

Hofmann C, Schönhoff M (2009) Do additives shift the LCST of poly (N-isopropylacrylamide) by solvent quality changes or by direct interactions? Colloid Polym Sci 287:1369–1376. https://doi.org/10.1007/s00396-009-2103-3

Zhang Y, Cremer PS (2010) Chemistry of Hofmeister anions and osmolytes. Annu Rev Phys Chem 61:63–83. https://doi.org/10.1146/annurev.physchem.59.032607.093635

Umapathi R, Reddy PM, Rani A, Venkatesu P (2017) Influence of additives on thermoresponsive polymers in aqueous media: a case study of poly(N-isopropylacrylamide). Phys Chem Chem Phys 20:9717–9744. https://doi.org/10.1039/c7cp08172c

Afroze F, Nies E, Berghmans H (2000) Phase transitions in the system poly(N-isopropylacrylamide)/water and swelling behaviour of the corresponding networks. J Mol Struct 554:55–68. https://doi.org/10.1016/s0022-2860(00)00559-7

Halperin A, Kröger M, Winnik FM (2015) Poly(N-isopropylacrylamide) phase diagrams: fifty years of research. Angew Chem Int Ed 54:15342–15367. https://doi.org/10.1002/anie.201506663

Uchiyama S, Matsumura Y, de Silva AP, Iwai K (2003) Fluorescent molecular thermometers based on polymers showing temperature-induced phase transitions and labeled with polarity-responsive benzofurazans. Anal Chem 75:5926–5935. https://doi.org/10.1021/ac0346914

Couturier J-P, Sütterlin M, Laschewsky A, Hettrich C, Wischerhoff E (2015) Responsive inverse opal hydrogels for the sensing of macromolecules. Angew Chem Int Ed 54:6641–6644. https://doi.org/10.1002/anie.201500674

Couturier J-P, Wischerhoff E, Bernin R, Hettrich C, Koetz J, Sütterlin M, Tiersch B, Laschewsky A (2016) Thermoresponsive polymers and inverse opal hydrogels for the detection of diols. Langmuir 32:4333–4345. https://doi.org/10.1021/acs.langmuir.6b00803

Enzenberg A, Laschewsky A, Boeffel C, Wischerhoff E (2016) Influence of the near molecular vicinity on the temperature regulated fluorescence response of poly(N-vinylcaprolactam). Polymers 8(109):101–127. https://doi.org/10.3390/polym8040109

Wei M, Gao Y, Lia X, Serpe MJ (2017) Stimuli-responsive polymers and their applications. Polym Chem 8:127–143. https://doi.org/10.1039/c6py01585a

Schäfer-Soenen H, Moerkerke R, Berghmans H, Koningsveld R, Dušek K, Šolc K (1997) Zero and off-zero critical concentrations in systems containing polydisperse polymers with very high molar masses. 2. The system water–poly(vinyl methyl ether). Macromolecules 30:410–416. https://doi.org/10.1021/ma960114o

Han J, Takahashi R, Kuang C, Sato T (2022) Phase Separation behavior of aqueous poly(N-isopropylacrylamide) solutions studied by scattering experiments. Langmuir 38:5089–5097. https://doi.org/10.1021/acs.langmuir.1c01917

Fujishige S, Kubota K, Ando I (1989) Phase transition of aqueous solutions of poly(N-isopropylacrylamide) and poly(N-isopropylmethacrylamide). J Phys Chem 93:3311–3313. https://doi.org/10.1021/j100345a085

Inomata H, Goto S, Saito S (1990) Phase transition of N-substituted acrylamide gels. Macromolecules 23:4887–4888. https://doi.org/10.1021/ma00224a023

Kojima H, Tanaka F (2010) Cooperative hydration induces discontinuous volume phase transition of cross-linked poly(N-isopropylacrylamide) gels in water. Macromolecules 43:5103–5113. https://doi.org/10.1021/ma100588f

Liu R, Fraylich M, Saunders BR (2009) Thermoresponsive copolymers: from fundamental studies to applications. Colloid Polym Sci 287:627–643. https://doi.org/10.1007/s00396-009-2028-x

Döring A, Birnbaum W, Kuckling D (2013) Responsive hydrogels – structurally and dimensionally optimized smart frameworks for applications in catalysis, micro-system technology and material science. Chem Soc Rev 42:7391–7420. https://doi.org/10.1039/c3cs60031a

Laschewsky A, Müller-Buschbaum P, Papadakis CM (2013) Thermo-responsive amphiphilic di- and triblock copolymers based on poly(N-isopropylacrylamide) and poly(methoxy diethylene glycol acrylate): aggregation and hydrogel formation in bulk solution and in thin films. Prog Colloid Polym Sci 140:15–34. https://doi.org/10.1007/978-3-319-01683-2_2

Kim Y-J, Matsunaga YT (2017) Thermo-responsive polymers and their application as smart biomaterials. J Mater Chem B 5:4307–4321. https://doi.org/10.1039/c7tb00157f

Hu L, Zhang Q, Li X, Serpe MJ (2019) Stimuli-responsive polymers for sensing and actuation. Mater Horiz 6:1774–1793. https://doi.org/10.1039/c9mh00490d

Cook MT, Haddow P, Kirton SB, McAuley WJ (2021) Polymers exhibiting lower critical solution temperatures as a route to thermoreversible gelators for healthcare. Adv Funct Mater 31(2008123):2008121–2008125. https://doi.org/10.1002/adfm.202008123

Geiger C, Reitenbach J, Henschel C, Kreuzer LP, Widmann T, Wang P, Mangiapia G, Moulin J-F, Papadakis CM, Laschewsky A, Müller-Buschbaum P (2021) Ternary nanoswitches realized with multiresponsive PMMA-b-PNIPMAM films in mixed water/acetone vapor atmospheres. Adv Eng Mater 23(2100191):2100191–2100112. https://doi.org/10.1002/adem.202100191

Schild HG (1992) Poly(N-isopropylacrylamide): experiment, theory and application. Prog Polym Sci 17:163–249

Van Durme K, Van Assche G, Van Mele B (2004) Kinetics of demixing and remixing in poly(N-isopropylacrylamide)/water studied by modulated temperature DSC. Macromolecules 37:9596–9605. https://doi.org/10.1021/ma048472b

Luo G-F, Chen W-H, Zhang X-Z (2020) 100th anniversary of macromolecular science viewpoint: poly(N-isopropylacrylamide)-based thermally responsive micelles. ACS Macro Lett 9:872–881. https://doi.org/10.1021/acsapm.0c00348

Mukherji D, Marques CM, Kremer K (2020) Smart responsive polymers: fundamentals and design principles. Annu Rev CondensMatter Phys 11:271–299. https://doi.org/10.1146/annurev-conmatphys-031119-050618

Yong H, Sommer J-U (2022) Cononsolvency effect: when the hydrogen bonding between a polymer and a cosolvent matters. Macromolecules 55:11034–11050. https://doi.org/10.1021/acs.macromol.2c01428

Bharadwaj S, Niebuur B-J, Nothdurft K, Richtering W, van der Vegt N, Papadakis CM (2022) Cononsolvency of thermoresponsive polymers: where we are now and where we are going. Soft Matter 18:2884–2909. https://doi.org/10.1039/d2sm00146b

Müller M, Rieser T, Dubin PL, Lunkwitz K (1998) Effects of salt on the temperature and pressure responsive properties of poly(N-vinylisobutyramide) aqueous solutions. Colloid Polym Sci 276:529–533. https://doi.org/10.1007/s003960050276

Serizawa T, Chen M-Q, Akashi M (1998) Graft copolymers having hydrophobic backbone and hydrophilic branches. XVIII. Poly(styrene) nanospheres with novel thermosensitive poly(N-vinylisobutyramide)s on their surfaces. J Polym Sci, Part A: Polym Chem 36:2581–2587. https://doi.org/10.1002/(sici)1099-0518(199810)36:14%3c2581::aid-pola17%3e3.0.co;2-e

Suwa K, Yamamoto K, Akashi M, Takano K, Tanaka N, Kunugi S (1998) Effects of salt on the temperature- and pressure-responsive properties of poly(N-vinylisobutyramide) aqueous solutions. Colloid Polym Sci 276:529–533. https://doi.org/10.1007/s003960050276

Kishida A, Kikunaga Y, Akashi M (1999) Synthesis and functionality of poly(N-vinylalkylamide). X. A novel aqueous two-phase system based on thermosensitive polymers and dextran. J Appl Polym Sci 73:2545–2548. https://doi.org/10.1002/(SICI)1097-4628(19990923)73:13%3c2545::AID-APP1%3e3.0.CO;2-1

Kunugi S, Tada T, Tanaka N, Yamamoto K, Akashi M (2002) Microcalorimetric study of aqueous solution of a thermoresponsive polymer, poly(N-vinylisobutyramide) (PNVIBA). Polym J (Jpn) 34:383–388. https://doi.org/10.1295/polymj.34.383

Patra L, Messman JM, Toomey R (2013) On the nature of volume-phase transitions in photo-cross-linked poly(cyclopropylacrylamide) and poly(N-vinylisobutyramide) coatings. Soft Matter 9:4349–4356. https://doi.org/10.1039/c3sm26962k

Kan K, Ajiro H (2018) Switchable thermal responsive interpenetrated polymer network gels of poly(N-vinylacetamide) and poly(N-vinylisobutyramide). Chem Lett 47:591–593. https://doi.org/10.1246/cl.171191

Yoshida H, Furumai H, Ajiro H (2022) Preparation and characterization of thermoresponsive poly(N-vinylisobutyramide) microgels. Langmuir 38:5269–5274. https://doi.org/10.1021/acs.langmuir.1c02676

Kunugi S, Tada T, Yamazaki Y, Yamamoto K, Akashi M (2000) Thermodynamic studies on coil–globule transitions of poly(N-vinylisobutyramide-co-vinylamine) in aqueous solutions. Langmuir 16:2042–2044. https://doi.org/10.1021/la991041f

Yamamoto K, Serizawa T, Muraoka Y, Akashi M (2000) Synthesis and functionalities of poly(N-vinylalkylamide). XII. Synthesis and thermosensitive property of poly(vinylamine) copolymer prepared from poly(N-vinylformamide-co-N-vinylisobutyramide). J Polym Sci, Part A: Polym Chem 38:3674–3681. https://doi.org/10.1002/1099-0518(20001001)38:19%3c3674::aid-pola210%3e3.0.co;2-n

Yamamoto K, Serizawa T, Muraoka Y, Akashi M (2001) Synthesis and functionalities of poly(N-vinylalkylamide). 13. Synthesis and properties of thermal and pH stimuli-responsive poly(vinylamine) copolymers. Macromolecules 34:8014–8020. https://doi.org/10.1021/ma0102969

Chen C-W, Tano D, Akashi M (1999) Synthesis of platinum colloids sterically stabilized by poly(N-vinylformamide) or poly(N-vinylalkylamide) and their stability towards salt. Colloid Polym Sci 277:488–493. https://doi.org/10.1007/s003960050414

Chen C-W, Takezako T, Yamamoto K, Serizawa T, Akashi M (2000) Poly(N-vinylisobutyramide)-stabilized platinum nanoparticles: synthesis and temperature-responsive behavior in aqueous solution. Coll Surf A 169:107–116. https://doi.org/10.1016/S0927-7757(00)00422-2

Ito S (1989) Phase transition of aqueous solutions of poly(N-alkylacrylamide) derivatives. Effects of side chain structure. Kobunshi Ronbunshu 46:437–443. https://doi.org/10.1295/koron.46.437

Tiktopulo EI, Uversky VN, Lushchik VB, Klenin SI, Bychkova VE, Ptitsyn OB (1995) “Domain” coil-globule transition in homopolymers. Macromolecules 28:7519–7524. https://doi.org/10.1021/ma00126a032

Djokpé E, Vogt W (2001) N-Isopropylacrylamide and N-isopropylmethacrylamide: cloud points of mixtures and copolymers. Macromol Chem Phys 202:750–757. https://doi.org/10.1002/1521-3935(20010301)202:5%3c750::AID-MACP750%3e3.0.CO;2-8

Berndt I, Richtering W (2003) Doubly temperature sensitive core-shell microgels. Macromolecules 36:8780–8785. https://doi.org/10.1021/ma034771+

Vishnevetskaya NS, Hildebrand V, Niebuur B-J, Grillo I, Filippov SK, Laschewsky A, Müller-Buschbaum P, Papadakis CM (2017) “Schizophrenic” micelles from doubly thermoresponsive polysulfobetaine-b-poly(N-isopropylmethacrylamide) diblock copolymers. Macromolecules 50:3985–3999. https://doi.org/10.1021/acs.macromol.7b00356

Ko C-H, Claude K-L, Niebuur B-J, Jung FA, Kang J-J, Schanzenbach D, Frielinghaus H, Barnsley LC, Wu B, Pipich V, Schulte A, Müller-Buschbaum P, Laschewsky A, Papadakis CM (2020) Temperature-dependent phase behavior of the thermoresponsive polymer poly(N-isopropylmethacrylamide) in an aqueous solution. Macromolecules 53:6816–6827. https://doi.org/10.1021/acs.macromol.0c01256

Kubota K, Hamano K, Kuwahara N, Fujishige S, Ando I (1990) Characterization of poly(N-isopropylmethacrylamide) in water. Polym J (Jpn) 22:1051–1057. https://doi.org/10.1295/polymj.22.1051

Dybal J, Trchová M, Schmidt P (2009) The role of water in structural changes of poly(N-isopropylacrylamide) and poly(N-isopropylmethacrylamide) studied by FTIR, Raman spectroscopy and quantum chemical calculations. Vibr Spectrosc 51:44–51. https://doi.org/10.1016/j.vibspec.2008.10.003

Kano M, Kokufuta E (2009) On the temperature-responsive polymers and gels based on N-propylacrylamides and N-propylmethacrylamides. Langmuir 25:8649–8655. https://doi.org/10.1021/la804286j

Pang J, Yang H, Ma J, Cheng R (2011) Understanding different LCST levels of poly(N-alkylacrylamide)s by molecular dynamics simulations and quantum mechanics calculations. J Theor Comp Chem 10:359–370. https://doi.org/10.1142/s0219633611006505

Kokufuta MK, Sato S, Kokufuta E (2012) LCST behavior of copolymers of N-isopropylacrylamide and N-isopropylmethacrylamide in water. Colloid Polym Sci 290:1671–1681. https://doi.org/10.1007/s00396-012-2706-y

Ortiz de Solorzano I, Bejagam KK, An Y, Singh SK, Deshmukh SA (2020) Solvation dynamics of N-substituted acrylamide polymers and the importance for phase transition behavior. Soft Matter 16:1582–1593. https://doi.org/10.1039/c9sm01798d

Netopilík M, Bohdanecký M, Chytrý V, Ulbrich K (1997) Cloud point of poly(N-isopropylmethacrylamide) solutions in water: is it really a point? Macromol Rapid Commun 18:107–111. https://doi.org/10.1002/marc.1997.030180206

Kreuzer LP, Lindenmeir C, Geiger C, Widmann T, Hildebrand V, Laschewsky A, Papadakis CM, Müller-Buschbaum P (2021) Poly(sulfobetaine) versus poly(N-isopropylmethacrylamide): co-nonsolvency-type behavior of thin films in a water/methanol atmosphere. Macromolecules 54:1548–1556. https://doi.org/10.1021/acs.macromol.0c02281

Alenichev I, Sedláková Z, Ilavský M (2007) Swelling and mechanical behavior of charged poly(N-isopropylmethacrylamide) and poly(N-isopropylacrylamide) networks in water/ethanol mixtures. Cononsolvency effect Polym Bull 58:191–199. https://doi.org/10.1007/s00289-006-0586-3

Kouřilová H, Hanyková L, Spěváček J (2009) NMR study of phase separation in D2O/ethanol solutions of poly(N-isopropylmethacrylamide) induced by solvent composition and temperature. Eur Polym J 45:2935–2941. https://doi.org/10.1016/j.eurpolymj.2009.06.011

Wang P, Geiger C, Kreuzer LP, Widmann T, Reitenbach J, Liang S, Cubitt R, Henschel C, Laschewsky A, Papadakis CM, Müller-Buschbaum P (2022) Poly(sulfobetaine)-based diblock copolymer thin films in water/acetone atmosphere: modulation of water hydration and co-nonsolvency-triggered film contraction. Langmuir 38:6934–6948. https://doi.org/10.1021/acs.langmuir.2c00451

Tu S, Zhang C (2015) Facile preparation of N-vinylisobutyramide and N-vinyl-2-pyrrolidinone. Org Process Res Dev 19:2045–2049. https://doi.org/10.1021/acs.oprd.5b00303

Zhang J, Wang Z, Lin W, Chen S (2014) Gene transfection in complex media using PCBMAEE-PCBMA copolymer with both hydrolytic and zwitterionic blocks. Biomater 35:7909–7918. https://doi.org/10.1016/j.biomaterials.2014.05.066

Suwa K, Wada Y, Kikunaga Y, Morishita K, Kishida A, Akashi M (1997) Synthesis and functionalities of poly(N-vinylalkylamide). IV. Synthesis and free radical polymerization of N-vinylisobutyramide and thermosensitive properties of the polymer. J Polym Sci, Part A: Polym Chem 35:1763–1768. https://doi.org/10.1002/(SICI)1099-0518(19970715)35:9%3c1763::AID-POLA17%3e3.0.CO;2-3

Akashi M, Nakano S, Kishida A (1996) Synthesis of poly(N-vinylisobutyramide) from poly(N-vinylacetamide) and its thermosensitive property. J Polym Sci, Part A: Polym Chem 34:301–303. https://doi.org/10.1002/(sici)1099-0518(19960130)34:2%3c301::aid-pola16%3e3.0.co;2-u

Chua PC, Kelland MA, Ajiro H, Sugihara F, Akashi M (2013) Poly(vinylalkanamide)s as kinetic hydrate inhibitors: comparison of poly(N-vinylisobutyramide) with poly(N-isopropylacrylamide). Energy Fuels 27:183–188. https://doi.org/10.1021/ef301703w

Benaglia M, Chiefari J, Chong YK, Moad G, Rizzardo E, Thang SH (2009) Universal (switchable) RAFT agents. J Am Chem Soc 131:6914–6915. https://doi.org/10.1021/ja901955n

Yoshioka M, Otsu T (1992) Reactivity of primary radicals in the radical polymerization of dialkyl fumarates initiated with dimethyl 2,2′-azobis(isobutyrate) and 2,2′-azobis(isobutyronitrile). Macromolecules 25:2599–2602. https://doi.org/10.1021/ma00036a006

Sato T, Shimooka S, Seno M, Tanaka H (1995) Radical polymerization behavior of ethyl ortho-formylphenyl fumarate involving intramolecular hydrogen abstraction. J Polym Sci, Part A: Polym Chem 33:2865–2873. https://doi.org/10.1002/pola.1995.080331702

Cochin D, Laschewsky A, Pantoustier N (2000) New substituted polymethylenes by free radical polymerization of bulky fumarates and their properties. Polymer 41:3895–3903. https://doi.org/10.1016/S0032-3861(99)00650-3

Keddie DJ, Moad G, Rizzardo E, Thang SH (2012) RAFT agent design and synthesis. Macromolecules 45:5321–5342. https://doi.org/10.1021/ma300410v

Ruiz-Rubio L, Vilas JL, Rodríguez M, León LM (2014) Thermal behaviour of H-bonded interpolymer complexes based on polymers with acrylamide or lactame groups and poly(acrylic acid): influence of N-alkyl and a-methyl substitutions. Polym Degrad Stab 109:147–153. https://doi.org/10.1016/j.polymdegradstab.2014.07.012

Li J-J, Zhou Y-N, Luo Z-H (2014) Thermal-responsive block copolymers for surface with reversible switchable wettability. Ind Eng Chem Res 53:18112–18120. https://doi.org/10.1021/ie503610n

Nuopponen M, Kalliomäki K, Laukkanen A, Hietala S, Tenhu H (2008) A-B–A stereoblock copolymers of N-isopropylacrylamide. J Polym Sci, Part A: Polym Chem 46:38–46. https://doi.org/10.1002/pola.22355

Biswas CS, Patel VK, Vishwakarma NK, Tiwari VK, Maiti B, Maiti P, Kamigaito M, Okamoto Y, Ray B (2011) Effects of tacticity and molecular weight of poly(N-isopropylacrylamide) on its glass transition temperature. Macromolecules 44:5822–5824. https://doi.org/10.1021/ma200735k

Suito Y, Isobe Y, Habaue S, Okamoto Y (2002) Isotactic-specific radical polymerization of methacrylamides in the presence of Lewis acids. J Polym Sci, Part A: Polym Chem 40:2496–2500. https://doi.org/10.1002/pola.10337

Isobe Y, Suito Y, Habaue S, Okamoto Y (2003) Stereocontrol during the free-radical polymerization of methacrylamides in the presence of Lewis acids. J Polym Sci, Part A: Polym Chem 41:1027–1033. https://doi.org/10.1002/pola.10647

Liu G, Zhou W, Zhang J, Zhao P (2012) Polymeric temperature and pH fluorescent sensor synthesized by reversible addition–fragmentation chain transfer polymerization. J Polym Sci, Part A: Polym Chem 50:2219–2226. https://doi.org/10.1002/pola.25995

Kouřilová H, Spěváček J, Hanyková L (2013) 1H NMR study of temperature-induced phase transitions in aqueous solutions of poly(N-isopropylmethacrylamide)/poly(N-vinylcaprolactam) mixtures. Polym Bull 70:221–235. https://doi.org/10.1007/s00289-012-0831-x

Ding Z, Wang C, Feng G, Zhang X (2018) Thermo-responsive fluorescent polymers with diverse LCSTs for ratiometric temperature sensing through FRET. Polymers 10(283):281–210. https://doi.org/10.3390/polym10030283

Ree LHS, Opsahl E, Kelland MA (2019) N-Alkyl methacrylamide polymers as high performing kinetic hydrate inhibitors. Energy Fuels 33:4190–4201. https://doi.org/10.1021/acs.energyfuels.9b00573

Reitenbach J, Geiger C, Wang P, Vagias A, Cubitt R, Schanzenbach D, Laschewsky A, Papadakis CM, Müller-Buschbaum P (2023) Effect of magnesium salts with chaotropic anions on the swelling behavior of PNIPMAM thin films. Macromolecules 56:567–577. https://doi.org/10.1021/acs.macromol.2c02282

Ruiz-Rubio L, Álvarez V, Lizundia E, Vilas JL, Rodríguez M, León LM (2015) Influence of α-methyl substitutions on interpolymer complexes formation between poly(meth)acrylic acids and poly(N-isopropyl(meth)acrylamide)s. Colloid Polym Sci 293:1447–1455. https://doi.org/10.1007/s00396-015-3529-4

Brugnoni M, Nickel AC, Kröger LC, Scotti A, Pich A, Leonhard K, Richtering W (2019) Synthesis and structure of deuterated ultra-low cross-linked poly(N-isopropylacrylamide) microgels. Polym Chem 10:2397–2405. https://doi.org/10.1039/C8PY01699B

Habaue S, Isobe Y, Okamoto Y (2002) Stereocontrolled radical polymerization of acrylamides and methacrylamides using Lewis acids. Tetrahedron 58:8205–8209. https://doi.org/10.1016/S0040-4020(02)00969-9

Zhang J, Liu W, Nakano T, Okamoto Y (2000) Stereospecific radical polymerization of N-methyl methacrylamide. Polym J (Jpn) 32:694–699. https://doi.org/10.1295/polymj.32.694

Salmerón Sánchez M, Hanyková L, Ilavský M, Monleón Pradas M (2004) Thermal transitions of poly(N-isopropylmethacrylamide) in aqueous solutions. Polymer 45:4087–4094. https://doi.org/10.1016/j.polymer.2004.04.020

Meeussen F, Nies E, Berghmans H, Verbrugghe S, Goethals E, Du Prez F (2000) Phase behaviour of poly(N-vinyl caprolactam) in water. Polymer 41:8597–8602. https://doi.org/10.1016/s0032-3861(00)00255-x

Lessard DG, Ousalem M, Zhu XX (2001) Effect of the molecular weight on the lower critical solution temperature of poly(N, N-diethylacrylamide) in aqueous solutions. Can J Chem 79:1870–1874. https://doi.org/10.1139/v01-180

Miasnikova A, Laschewsky A (2012) Influencing the phase transition temperature of poly(methoxy diethylene glycol acrylate) by molar mass, end groups, and polymer architecture. J Polym Sci, Part A: Polym Chem 50:3313–3323. https://doi.org/10.1002/pola.26116

Hechenbichler M, Laschewsky A, Gradzielski M (2021) Poly(N, N-bis(2-methoxyethyl)acrylamide), a thermoresponsive non-ionic polymer combining the amide and the ethyleneglycolether motifs. Colloid Polym Sci 299:205–219. https://doi.org/10.1007/s00396-020-04701-9

Hirano T, Kamikubo T, Okumura Y, Sato T (2007) Heterotactic poly(N-isopropylacrylamide) prepared via radical polymerization in the presence of fluorinated alcohols. Polymer 48:4921–4925. https://doi.org/10.1016/j.polymer.2007.06.059

Amiya T, Hirokawa Y, Hirose Y, Li Y, Tanaka T (1987) Reentrant phase transition of N-isopropylacrylamide gels in mixed solvents. J Chem Phys 86:2375–2379. https://doi.org/10.1063/1.452740

Winnik FM, Ringsdorf H, Venzmer J (1990) Methanol-water as a co-nonsolvent system for poly(N-isopropylacrylamide). Macromolecules 23:2415–2416. https://doi.org/10.1021/ma00210a048

Scherzinger C, Schwarz A, Bardow A, Leonhard K, Richtering W (2014) Cononsolvency of poly-N-isopropyl acrylamide (PNIPAM): microgels versus linear chains and macrogels. Curr Opin Coll Interface Sci 19:84–94. https://doi.org/10.1016/j.cocis.2014.30.011

Kyriakos K, Philipp M, Lin C-H, Dyakonova M, Vishnevetskaya N, Grillo I, Zaccone A, Miasnikova A, Laschewsky A, Müller-Buschbaum P, Papadakis CM (2016) Quantifying the interactions in the aggregation of thermoresponsive polymers: the effect of cononsolvency. Macromol Rapid Commun 37:420–425. https://doi.org/10.1002/marc.201500583

Xue N, Qiu X-P, Aseyev V, Winnik FM (2017) Nonequilibrium liquid–liquid phase separation of poly(N-isopropylacrylamide) in water/methanol mixtures. Macromolecules 50:4446–4453. https://doi.org/10.1021/acs.macromol.7b00407

Raftopoulos KN, Kyriakos K, Nuber M, Niebuur B-J, Holderer O, Ohl M, Ivanova O, Pasini S, Papadakis CM (2020) Co-nonsolvency in concentrated aqueous solutions of PNIPAM: effect of methanol on the collective and the chain dynamics. Soft Matter 16:8462–8472. https://doi.org/10.1039/d0sm01007c

Ko C-H, Henschel C, Meledam GP, Schroer MA, Guo R, Gaetani L, Müller-Buschbaum P, Laschewsky A, Papadakis CM (2021) Co-nonsolvency effect in solutions of poly(methyl methacrylate)-b-poly(N-isopropylacrylamide) diblock copolymers in water/methanol mixtures. Macromolecules 54:5825–5837. https://doi.org/10.1021/acs.macromol.1c00512

Niebuur B-J, Lohstroh W, Ko C-H, Appavou M-S, Schulte A, Papadakis CM (2021) Pressure dependence of water dynamics in concentrated aqueous poly(N-isopropylacrylamide) solutions with a methanol cosolvent. Macromolecules 54:4387–4400. https://doi.org/10.1021/acs.macromol.1c00111

Niebuur B-J, Deyerling A, Höfer N, Schulte A, Papadakis CM (2022) Cononsolvency of the responsive polymer poly(N-isopropylacrylamide) in water/methanol mixtures: a dynamic light scattering study of the effect of pressure on the collective dynamics. Colloid Polym Sci 300:1269–1279. https://doi.org/10.1007/s00396-022-04987-x

Costa ROR, Freitas RFS (2002) Phase behavior of poly(N-isopropylacrylamide) in binary aqueous solutions. Polymer 43:5879–5885. https://doi.org/10.1016/S0032-3861(02)00507-4

Schild HG, Muthukumar M, Tirrell DA (1991) Cononsolvency in mixed aqueous solutions of poly(N-isopropylacrylamide). Macromolecules 4:948–952. https://doi.org/10.1021/ma00004a022

Mukae K, Sakurai M, Sawamura S, Makino K, Kim SW, Ueda I, Shirahama K (1994) Swelling of poly(N-isopropylacrylamide) gels in water-aprotic solvent mixtures. Colloid Polym Sci 272:655–663. https://doi.org/10.1007/bf00659279

Bharadwaj S, van der Vegt NFA (2019) Does Preferential adsorption drive cononsolvency? Macromolecules 52:4131–4138. https://doi.org/10.1021/acs.macromol.9b00575

Mukherji D, Marques CM, Kremer K (2014) Polymer collapse in miscible good solvents is a generic phenomenon driven by preferential adsorption. Nat Commun 5(4882):4881–4886. https://doi.org/10.1038/ncomms5882

Hore MJA, Hammouda B, Li Y, Cheng H (2013) Co-nonsolvency of poly(N-isopropylacrylamide) in deuterated water/ethanol mixtures. Macromolecules 46:7894–7901. https://doi.org/10.1021/ma401665h

Yamauchi H, Maeda Y (2007) Co-nonsolvency effect of thermosensitive N-isopropylacrylamide nanometer-sized gel particles in water–PEG systems. J Phys Chem 111:12964–12968. https://doi.org/10.1021/jp072438s

Pagonis K, Bokias G (2006) Simultaneous lower and upper critical solution temperature-type co-nonsolvency behaviour exhibited in water–dioxane mixtures by linear copolymers and hydrogels containing N-isopropylacrylamide and N, N-dimethylacrylamide. Polym Int 55:1254–1258. https://doi.org/10.1002/pi.2072

Cameron NS, Corbierre MK, Eisenberg A (1999) Asymmetric amphiphilic block copolymers in solution: a morphological wonderland. Can J Chem 77:1311–1326. https://doi.org/10.1139/v99-141

Bivigou-Koumba AM, Kristen J, Laschewsky A, Müller-Buschbaum P, Papadakis CM (2009) Synthesis of symmetrical triblock copolymers of styrene and N-isopropylacrylamide using bifunctional bis(trithiocarbonate)s as RAFT agents. Macromol Chem Phys 210:565–578. https://doi.org/10.1002/macp.200800575

Yong H, Merlitz H, Fery A, Sommer J-U (2020) Polymer brushes and gels in competing solvents: the role of different interactions and quantitative predictions for poly(N-isopropylacrylamide) in alcohol–water mixtures. Macromolecules 53:2323–2335. https://doi.org/10.1021/acs.macromol.0c00033

Grinberg VY, Burova TV, Grinberg NV, Moskalets AP, Dubovik AS, Plashchina IG, Khokhlov AR (2020) Energetics and mechanisms of poly(N-isopropylacrylamide) phase transitions in water–methanol solutions. Macromolecules 53:10765–10772. https://doi.org/10.1021/acs.macromol.0c02253

Acknowledgements

The authors acknowledge the support for SEC analysis by S. Prenzel and H. Schlaad, the support for thermal analysis by A. Taubert, and the support for NMR spectroscopy by A. Krtitschka and H. Möller (all University of Potsdam).

Funding

Open Access funding enabled and organized by Projekt DEAL. This study received financial support from the Deutsche Forschungsgemeinschaft DFG (grants LA 611/16–1, MU 1487/29–1, and PA 771/20–1).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

396_2023_5083_MOESM1_ESM.pdf

Supplementary file1 Contents: monomer synthesis and characterization. Details of polymer NMR spectra, thermal analysis and thermo-responsive behavior in aqueous solution. (PDF 796 KB)

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Henschel, C., Schanzenbach, D., Laschewsky, A. et al. Thermoresponsive and co-nonsolvency behavior of poly(N-vinyl isobutyramide) and poly(N-isopropyl methacrylamide) as poly(N-isopropyl acrylamide) analogs in aqueous media. Colloid Polym Sci 301, 703–720 (2023). https://doi.org/10.1007/s00396-023-05083-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-023-05083-4