Abstract

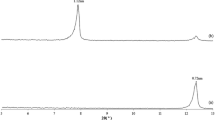

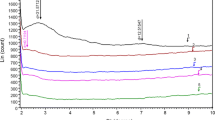

Preparation of polystyrene nanocomposites containing flame retardants is difficult to achieve in one step by suspension polymerization. Styrene suspension polymerization was studied to determine the effects of the flame retardant on the polymerization process and properties of polystyrene beads. Triphenyl phosphate (TPP) was used in this work, which can dissolve completely in styrene monomers. The results showed that TPP were nanosized spherical particles, distributed homogenously and uniformly in a polystyrene (PS) matrix, and the formation mechanism of TPP nanoparticles was also investigated. In addition, the effects of TPP on the styrene polymerization process were investigated. With TPP amount increasing, the polymerization time increased significantly; molecular weight of PS nanocomposites also decreased and molecular weight distribution became wide; the particle size distribution (PSD) of the PS nanocomposites became wider than pure PS slightly as the particle size decreased. PS/TPP nanocomposites obtained good flame retardance because of nanodispersed TPP particles in its matrix. In a word, the suspension polymerization method provides a facile approach to prepare PS/TPP nanocomposites with better properties.

Similar content being viewed by others

References

Levchik SV, Weil ED (2008) New developments in flame retardancy of styrene thermoplastics and foams. Polym Int 57:431–448

Tai QL, Chen LJ, SongL NSB, Hu Y, Yuen RKK (2010) Preparation and thermal properties of a novelflame retardant copolymer. Polym Degrad Stab 95:830–836

Utevski L, Scheinker M, Georlette P, Lach S (1997) Flame retardancy in UL-94 V-0 and in UL-94 5VA high impact polystyrene. J Fire Sci 15:375–389

Chen L, Wang YZ (2010) A review on flame retardant technology in China. Part I: development of flame retardants. Polym Adv Techno 21:1–26

Liu YY, Wang SJ, Xiao M, Meng YZ (2007) Halogen-free polymeric flame-retardants for common resins. Res J Chem Environ 11:84–103

Bourbigot S, Duquesne S (2007) Fire retardant polymers: recent developments and opportunities. J Mater Chem 17:2283–2300

Zhou KQ, Zhang QJ, Liu JJ, Wang B, Jiang SH, Shi YQ, Hu Y, Gui Z (2014) Synergetic effect of ferrocene and MoS2 in polystyrene composites with enhanced thermal stability, flame retardant and smoke suppression properties. RSC Adv 4:13205–13214

Liu JC, Yu ZL, Chang HB, Zhang YB, Shi YZ, Luo J, Pan BL, Lu C (2014) Thermal degradation behavior and fire performance of halogen-free flame-retardant high impact polystyrene containing magnesium hydroxide and microencapsulated red phosphorus. Polym Degrad Stab 103:83–95

Yan YW, Chen L, Jian RK, Kong S, Wang YZ (2012) Intumescence: an effect way to flame retardance and smoke suppression for polystyrene. Polym Degrad Stab 97:1423–1431

Braun U, Schartel B (2004) Flame retardant mechanisms of red phosphorus and magnesium hydroxide in high impact polystyrene. Macromol Chem Phys 205:2185–2196

Cze’ge’ny Z, Blazso´ M (2008) Effect of phosphorous flame retardants on the thermal decomposition of vinyl polymers and copolymers. J Anal Appl Pyrolysis 81: 218–224.

Cui WG, Guo F, Chen JF (2007) Preparation and properties of flame retardant high impact polystyrene. Fire Safety J 42:232–239

Yan YW, Huang JQ, Guan YH, Shang K, Jian RK, Wang YZ (2014) Flame retardance and thermal degradation mechanism of polystyrene modified with aluminum hypophosphite. Polym Degrad Stab 99:35–42

Dowding PJ, Vincent B (2000) Suspension polymerisation to form polymer beads. Colloid Surface A 161:259–269

Schellenberg J (2008) Effects of styrene oligomers and polymers on the suspension polymerization behavior and properties of expandable polystyrene. J Appl Polym Sci 110:453–458

Park M (2006) Suspension polymerization with hydrophobic silica as a stabilizer II. Preparation of polystyrene composite particles containing carbon black. Polym-Korea 30:505–511

Bao YZ, Huang ZM, Weng ZX (2006) Preparation and characterization of poly(vinyl chloride)/layered double hydroxides nanocomposite via in situ suspension polymerization. J Appl Polym Sci 102:1471–1477

Zheng ZH, Li WJ, Sun HM, Cheng AQ, Yan JT, Wang HW, Cui XJ (2013) Preparation and characterization of polystyrene/modified carbon black composite beads via in situ suspension polymerization. Polym Comppos 34:1110–1118

Yan JT, Miao XJ, Zhang QY, Cui XJ, Li JF, Wang HY (2011) One-step preparation of black polystyrene particles via in situ suspension polymerization. Polym Eng Sci 51:294–301

Hwu JM, Ko TH, Yang WT, Lin JC, Jiang GJ, Xie W, Pan WP (2004) Synthesis and properties of polystyrene–montmorillonite nanocomposites by suspension polymerization. J Appl Polym Sci 91:101–109

Zhang CW, Li XM, Yang RJ (2015) Facile preparation and characterization of polystyrene/triphenyl phosphate nanocomposite via suspension polymerization. Chem Lett 44:1762–1764

Gonccalves OH, Nogueira AL, Araujo PHH, Machado RAF (2011) Effects of operational parameters on particle size distributions in methyl methacrylate suspension polymerization. Ind Eng Chem Res 50:9116–9122

Lee JN, Park C, Whitesides GM (2003) Solvent compatibility of poly(dimethylsiloxane)-based microfluidic devices. Anal Chem 75:6544–6554

Greenhalgh DJ, Williams AC, Timmins P, York P (1999) Solubility parameters as predictors of miscibility in solid dispersions. J Pharm Sci 88:1182–1190

Gupta J, Nunes C, Vyas S, Jonnalagadda S (2011) Prediction of solubility parameters and miscibility of pharmaceutical compounds by molecular dynamics simulations. J Phys Chem B 115:2014–2023

Brandrup J, Immergut EH, Grulke EA (2003) Polymer handbook(fourth edition). Wiley Interscience, New York

Lan YH, Li DH, Yang RJ, Liang WS, Zhou LX, Chen ZW (2013) Computer simulation study on the compatibility of cyclotriphosphazene containing aminopropylsilicone functional group in flame retarded polypropylene/ammonium polyphosphate composites. Compos Sci Technol 88:9–15

Yang JQ, Zhang XL, Gao P, Gong XD, Wang GX (2014) Molecular dynamics and dissipative particle dynamics simulations of the miscibility and mechanical properties of GAP/DIANP blending systems. RSC Adv 4:41934–41941

Ray SS, Okamoto K, Okamoto M (2003) Structure-property relationship in biodegradable poly(butylene succinate)/layered silicate nanocomposites. Macromolecules 36:2355–2367

Brooks BW (2010) Suspension polymerization processes. Chem Eng Technol 33:1737–1744

Gaan S, Sun G, Hutches K, Engelhard MH (2008) Effect of nitrogen additives on flame retardant action of tributyl phosphate: phosphoruse-nitrogen synergism. Polym Degrad Stab 93:99–108

Oliveira MAM, Melo JPA, Nele M, Pinto JC (2012) In situ incorporation of doxorubicin in copolymer particles during suspension polymerization. Macromol Symp 319:23–33

Alvarez J, Alvarez J, Hernández M (1994) A population balance approach for the description of particle size distribution in suspension polymerization reactors. Chem Eng Sci 49:99–113

Jahanzad F, Sajjadi S, Brooks BW (2004) On the evolution of particle size average and size distribution in suspension polymerization processes. Macromol Symp 206:255–262

Kaynak C, Sipahioglu BM (2013) Effects of nanoclays on the flammability of polystyrene with triphenyl phosphate-based flame retardants. J Fire Sci 31:339–355

Pawlowski KH, Schartel B (2007) Flame retardancy mechanisms of triphenyl phosphate, resorcinol bis(diphenyl phosphate) and bisphenol bis(diphenyl phopshate) in polycarbonate_acrylonitrile-butadiene-styrene blends. Polym Int 56:1404–1414

Schartel B (2010) Phosphorus-based flame retardancy mechanisms—old hat or starting point for future development? Materials 3:4710–4745

Wang Y, Jow J, Su K, Zhang J (2012) Dripping behavior of burning polymers under UL94 vertical test conditions. J Fire Sci 30:477–501

Babrauskas V, Peacock RD (1992) Heat release rate: the single most important variable in fire hazard. Fire Safety J 18:255–272

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Funding

This research received no specific grant from any funding agency in the public, commercial, or not-for-profit sectors.

Conflict of interest

The authors declare that they have no conflict of interest.

Electronic Supplementary Material

Rights and permissions

About this article

Cite this article

Zhang, C., Li, X., Yang, R. et al. Effects of triphenyl phosphate on styrene suspension polymerization process and flame retardance properties of polystyrene/triphenyl phosphate nanocomposite. Colloid Polym Sci 294, 1153–1163 (2016). https://doi.org/10.1007/s00396-016-3872-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-016-3872-0