Abstract

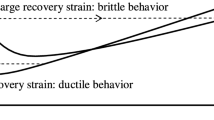

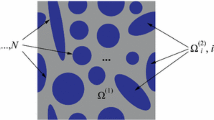

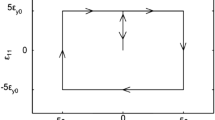

The strong dependent behavior of semi-crystalline polymers can lead to the use of simplified material laws in finite element structural calculations for reasons of robustness to the detriment of the quantitative response of the models. This work focuses on numerical integration methods as a solution to overcome the possible convergence and robustness limitations of mean-stress dependent elastoviscoplastic material laws, typical of the semi-crystalline polymers’ mechanical behavior. What is proposed here is a rational application of three explicit integration methods (fourth- and second-order Runge–Kutta method, a hybrid schema between Runge–Kutta, and Euler method) in engineering structural calculations, which provide a reliable solution for constitutive models of semi-crystalline polymer. These methods are examined for structure creep test and tensile test, in comparison with experimental data. The investigations have been done in terms of the stability toward convergence, the accuracy of results, the plastic consistency, and CPU time efficiency. This work, proposes an easy implementation of integration methods in any computational finite element code. It also provides a flexible modular implementation which is applicable to any different constitutive equations. An integration step sub-division technique is recommended. It is a powerful technique to improve the convergence of solution and accuracy of result by damping oscillation around stress Gauss point integration solution. The results obtained illustrate the effect of numerical integration schemas on structural analysis and provide an insight into select suitable method.

Similar content being viewed by others

References

Zhang C, Moore ID (1997) Nonlinear mechanical response of high-density polyethylene. Part II: uniaxial constitutive modeling. Polym Eng Sci 37:413–420

Seguela R, Gaucher-Miri V, Elkoun S (1998) Plastic deformation of polyethylene and ethylene copolymers. Part I homogeneous crystal slip and molecular mobility. J Mater Sci 33:1273–1279

Cangémi L, Meimon Y (2001) A two-phase model for the mechanical behaviour of semicrystalline polymers. Oil Gas Sci Technol Rev IFP 56(6):555–580

Bergström JS, Rimnac CM, Kurtz SM (2004) An augmented hybrid constitutive model for simulation of unloading and cyclic loading behavior of conventional and highly crosslinked UHMWPE. Biomaterials 25(11):2171–2178. https://doi.org/10.1016/j.biomaterials.2003.08.065

Nikolov S, Doghri I, Pierard O, Zealouk L, Goldberg A (2002) Multi-scale constitutive modeling of the small deformations of semi-crystalline polymers. J Mech Phys Solids 50(11):2275–2302. https://doi.org/10.1016/S0022-5096(02)00036-4

Challier M, Besson J, Laiarinandrasana L, Piques R (2006) Damage and fracture of polyvinylidene fluoride (PVDF) at 20°C: experiments and modelling. Eng Fract Mech 73:79–90. https://doi.org/10.1016/j.engfracmech.2005.06.007

Ahzi S, Makradi A, Gregory RV, Edie DD (2003) Modeling of deformation behavior and strain-induced crystallization in poly(ethylene terephthalate) above the glass transition temperature. Mech Mater 35(12):1139–1148. https://doi.org/10.1016/S0167-6636(03)00004-8

Khan F, Krempl E (2006) Amorphous and semicrystalline solid polymers: experimental and modeling studies of their inelastic deformation behaviors. J Eng Mater Technol 128:64–72

Zaïri F, Aour B, Gloaguen JM, Naït-Abdelaziz M, Lefebvre JM (2006) Numerical modelling of elastic–viscoplastic equal channel angular extrusion process of a polymer. Comput Mater Sci 38(1):202–216. https://doi.org/10.1016/j.commatsci.2006.02.008

Ben Hadj Hamouda H, Laiarinandrasana L, Piques R (2007) Viscoplastic behaviour of a medium density polyethylene (MDPE): constitutive equations based on double nonlinear deformation model. Int J Plast 23(8):1307–1327. https://doi.org/10.1016/j.ijplas.2006.11.007

Brusselle-Dupend N, Cangémi L (2008) A two-phase model for the mechanical behaviour of semicrystalline polymers. Part I: Large strains multiaxial validation on HDPE. Mech Mater 40(9):743–760. https://doi.org/10.1016/j.mechmat.2008.03.011

Dusunceli N, Colak OU (2008) Modelling effects of degree of crystallinity on mechanical behavior of semicrystalline polymers. Int J Plast 24(7):1224–1242. https://doi.org/10.1016/j.ijplas.2007.09.003

Boulahia R, Gloaguen JM, Zaïri F, Naït-Abdelaziz M, Seguela R, Boukharouba T, Lefebvre JM (2009) Deformation behaviour and mechanical properties of polypropylene processed by equal channel angular extrusion: effects of back-pressure and extrusion velocity. Polymer 50(23):5508–5517. https://doi.org/10.1016/j.polymer.2009.09.050

Ayoub G, Zaïri F, Fréderix C, Gloaguen JM, Naït-Abdelaziz M, Seguela R, Lefebvre JM (2011) Effects of crystal content on the mechanical behaviour of polyethylene under finite strains: experiments and constitutive modelling. Int J Plast 27(4):492–511

Bartczak Z, Galeski A (2010) Plasticity of semicrystalline polymers. Macromol Symp 294(1):67–90. https://doi.org/10.1002/masy.201050807

Zeng F, Le Grognec P, Lacrampe MF, Krawczak P (2010) A constitutive model for semi-crystalline polymers at high temperature and finite plastic strain: application to PA6 and PE biaxial stretching. Mech Mater 42(7):686–697

Drozdov AD, Klitkou R, Christiansen J (2013) Cyclic viscoplasticity of semicrystalline polymers with finite deformations. Mech Mater 56:53–64. https://doi.org/10.1016/j.mechmat.2012.09.005

Rozanski A, Galeski A (2013) Plastic yielding of semicrystalline polymers affected by amorphous phase. Int J Plast 41:14–29. https://doi.org/10.1016/j.ijplas.2012.07.008

Uchida M, Tada N (2013) Micro-, meso- to macroscopic modeling of deformation behavior of semi-crystalline polymer. Int J Plast 49:164–184. https://doi.org/10.1016/j.ijplas.2013.03.007

Shojaei A, Li G (2013) Viscoplasticity analysis of semicrystalline polymers: a multiscale approach within micromechanics framework. Int J Plast 42:31–49. https://doi.org/10.1016/j.ijplas.2012.09.014

Abdul-Hameed H, Messager T, Ayoub G, Zaïri F, Naït-Abdelaziz M, Qu Z (2014) A two-phase hyperelastic–viscoplastic constitutive model for semi-crystalline polymers: application to polyethylene materials with a variable range of crystal fractions. J Mech Behav Biomater 37:323–332. https://doi.org/10.1016/j.jmbbm.2014.04.016

Abdul-Hameed H, Messager T, Zaïri F, Naït-Abdelaziz M (2014) Large-strain viscoelastic–viscoplastic constitutive modeling of semi-crystalline polymers and model identification by deterministic/evolutionary approach. Comput Mater Sci 90:241–252. https://doi.org/10.1016/j.commatsci.2014.03.043

Hachour K, Zaïri F, Naït-Abdelaziz M, Gloaguen JM, Aberkane M, Lefebvre JM (2014) Experiments and modeling of high-crystalline polyethylene yielding under different stress states. Int J Plast 54:1–18. https://doi.org/10.1016/j.ijplas.2013.06.004

Popa CM, Fleischhauer R, Schneider K, Kaliske M (2014) Formulation and implementation of a constitutive model for semicrystalline polymers. Int J Plast 61:128–156. https://doi.org/10.1016/j.ijplas.2014.05.010

Haouala S, Doghri I (2015) Modeling and algorithms for two-scale time homogenization of viscoelastic–viscoplastic solids under large numbers of cycles. Int J Plast 70:98–125. https://doi.org/10.1016/j.ijplas.2015.03.005

Torres JP, Frontini PM, Machado M, Major Z (2016) Deformation and failure of semicrystalline polymers under dynamic tensile and biaxial impact loading. Int J Impact Eng 98:52–61. https://doi.org/10.1016/j.ijimpeng.2016.08.004

Garcia-Gonzalez D, Zaera R, Arias A (2017) A hyperelastic–thermoviscoplastic constitutive model for semi-crystalline polymers: application to PEEK under dynamic loading conditions. Int J Plast 88:27–52. https://doi.org/10.1016/j.ijplas.2016.09.011

Makki M, Ayoub G, Abdul-Hameed H, Zaïri F, Mansoor B, Naït-Abdelaziz M, Ouederni M (2017) Mullins effect in polyethylene and its dependency on crystal content: a network alteration model. J Mech Behav Biomater 75:442–454. https://doi.org/10.1016/j.jmbbm.2017.04.022

Büttner J, Simeon B (2002) Runge-Kutta methods in elastoplasticity. Appl Numer Math 41(4):443–458. https://doi.org/10.1016/S0168-9274(01)00133-7

Hiley RA, Rouainia M (2008) Explicit Runge–Kutta methods for the integration of rate-type constitutive equations. Comput Mech 42(1):53–66. https://doi.org/10.1007/s00466-007-0234-2

Liu CS, Liu LW, Hong HK (2016) A scheme of automatic stress-updating on yield surfaces for a class of elastoplastic models. Int J Non Linear Mech 85:6–22. https://doi.org/10.1016/j.ijnonlinmec.2016.05.006

Scalet G, Auricchio F (2017) Computational methods for elastoplasticity: an overview of conventional and less-conventional approaches. Arch Computat Methods Eng 18(11–12):733. https://doi.org/10.1007/s11831-016-9208

Besson J (2009) Continuum models of ductile fracture: a review. Int J Damage Mech 19(1):3–52. https://doi.org/10.1177/1056789509103482

Rezaiee-Pajand M, Sharifian M, Sharifian M (2011) Accurate and approximate integrations of Drucker–Prager plasticity with linear isotropic and kinematic hardening. Eur J Mech A Solids 30(3):345–361

Sloan SW (1987) Substepping schemes for the numerical integration of elastoplastic stress–strain relations. Int J Numer Methods Eng 24(5):893–911. https://doi.org/10.1002/nme.1620240505

Ashour SS, Hanna OT (1990) A new very simple explicit method for the integration of midly stiff ordinary differential equations. Comput Chem Eng 14(3):267–272

Hairer E, Nørsett SP, Wanner G (2008) Solving ordinary differential equations I: Nonstiff problems, 2nd edn. Springer, New York, p 528

Lee EH (1969) Elastic–plastic deformation at finite strains. J Appl Mech 36(1):1. https://doi.org/10.1115/1.3564580

Coussy O (1995) Mechanics of porous continua. Wiley, London

Baudet C, Grandidier JC, Cangemi L (2011) A damage model for the blistering of polyvinylidene fluoride subjected to carbon dioxide decompression. J Mech Phys Solids 59:1909–1926

Halsey G, White HJ, Eyring H (1945) Polymeric and inorganic fibers. Text Res J 15:295

Diffuso-mechanical modelling of semicrystalline polymer under water pressure, French Thesis IFPEN/Institut P’ ENSMA, Camilo Castro Lopez (2015)

Fragilisation mécanique du polyamide 11 en condition d’hydrolyse: mécanismes et modélisation, French Thesis IFPEN/Institut P’ ENSMA, Sofiane Maiza (2017)

Press WH, Flannery BP, Teukolsky SA, Vetterling WT (2007) Numerical recipes in C: the art of scientific computing (Fortran version), 2nd edn. Cambridge University Press, Cambridge, p 994

Hairer E, Wanner G (2010) Solving ordinary differential equations II: stiff and differential-algebraic problems, 2nd edn. Springer, Heidelberg, p 614

ABAQUS/Standard, Version 6.14 (2014) Theory and user’s manuals. HKS Inc., Pawtucket

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Abdul-Hameed, H., Roguet, E., Brusselle-Dupend, N. et al. Explicit integration methods for constitutive equations of a mean-stress dependent elastoviscoplastic model: impact on structural finite element analyses. Engineering with Computers 37, 57–75 (2021). https://doi.org/10.1007/s00366-019-00809-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00366-019-00809-x