Abstract

What strategies may insects use when controlling redundant degrees of freedom? We investigate this question in standing stick insects. Specifically, the question is addressed how the changes of the torques are coordinated that are produced by the 18 leg joints in a still standing animal. Using a generalization of the principal component analysis, three coordination rules have been identified. These rules are sufficient to describe more than half of the variation observed in the data. To move from a descriptive approach to hypotheses on how the neuronal system may be structured, two simulation approaches are proposed. In both cases, torques are decreased by randomly selected values. In the first simulation, the coordination rules derived from the principal components are used to produce changes in torques. In the second simulation, the individual joint torques are modified using a simple local approach. In both approaches, the resulting torques are re-adjusted by Integral controllers applied in each joint. The results show that the torque distribution problem can be solved by a local approach without requiring a body model.

Similar content being viewed by others

Abbreviations

- CORCONDIA:

-

Core consistency diagnostic

- DoFs:

-

Degrees of freedom

- mN:

-

Millinewton

- mNmm:

-

Millinewton millimeter

- mm:

-

Millimeter

- PARAFAC:

-

Parallel factor analysis

- PC:

-

Principal component

- PCA:

-

Principal component analysis

- PID controller:

-

Proportional integral derivative controller

- s:

-

Second

References

Alexandrov A, Frolov A, Massion J (1998) Axial synergies during human upper trunk bending. Exp Brain Res 118(2):210–220

Bernstein N (1967) the co-ordination and regulation of movements. Pergamon Press, Oxford

Bockemühl T, Dürr V, Troje N (2008a) Principal components as motor synergies of human catching movements

Bockemühl T, Meisterernst A, Schmitz J, Cruse H (2008b) Trajectory formation in human arm movements: a local approach: I. Experiments

Bro R, Kiers H (2003) A new efficient method for determining the number of components in parafac models. J Chemometr 17(5):274–286

Carroll J, Chang J (1970) Analysis of individual differences in multidimensional scaling via an n-way generalization of “eckart-young" decomposition. Psychometrika 35(3):283–319

Cruse H, Bartling C (1995) Movement of joint angles in the legs of a walking insect, carausius morosus. J Insect Physiol 41(9):761–771

Cruse H, Pflüger H (1981) Is the position of the femur-tibia joint under feedback control in the walking stick insect? ii. electrophysiological recordings. J Exp Biol 92(1):97–107

Cruse H, Schmitz J (1983) The control system of the femur-tibia joint in the standing leg of a walking stick insect carausius morosus. J Exp Biol 102(1):175–185

Cruse H, Kühn S, Park S, Schmitz J (2004) Adaptive control for insect leg position: controller properties depend on substrate compliance. J Comp Physiol 190(12):983–991

Ekeberg O, Blümel M, Büschges A (2004) Dynamic simulation of insect walking. Arthropod Struct Dev 33(3):287–300

Feldman A (1966a) Functional tuning of the nervous system with control of movement or maintenance of a steady posture: II. Controllable parameters of the muscle. Biophysics 11:565–578

Feldman A (1966b) Functional tuning of the nervous system with control of movement or maintenance of a steady posture: III. Mechanographic analysis of execution by man of the simplest motor task. Biophysics 11:766–775

Flash T, Hogan N (1985) The coordination of arm movements: an experimentally confirmed mathematical model. J Neurosci 5(7):1688–1703

Gottlieb G, Song Q, Hong D, GL Almeida DC (1996) Coordinating movement at two joints: a principle of linear covariance. J Neurophysiol 75:1760–1764

Harshman R (1970) Foundations of the parafac procedure: Models and conditions for an “explanatory" multi-mode factor analysis. UCLA Work Pap Phon 16:1–84

Kroonenberg P, DeLeeuw J (1980) Principal component analysis of three-mode data by means of alternating least squares algorithms. Psychometrika 45(1):69–97

Lacquaniti F, Terzuolo C, Viviani P (1983) The law relating the kinematic and figural aspects of drawing movements. Acta Psychol 54(1–3):115–130

Lafosse R (1989) Proposal for a generalized canonical analysis. In: Coppi R, Bolasco S (eds) Multiway data analysis. North Holland Publishing Co, Amsterdam, pp 269–276

Lafosse R, TenBerge J (2005) A simultaneous concor algorithm for the analysis of two portioned matrices. Comput Statist Data Anal 2529–2535(10):50

Lévy J, Cruse H (2008) Controling a system with redundant degrees of freedom: I. Torque distribution in still standing stick insects. J Comp Physiol A. doi:10.1007/s00359-008-0343-1

Manly B (2004) Multivariate statistical methods. Chapman and Hall, London

Morasso P (1983) Three dimensional arm trajectories. Biol Cybern 48:187–194

Rosenbaum D, Slotta J, Vaughan J, Plamondon R (1991) Optimal movement selection. Psychol Sci 2(2):86–91

Sanger T (2000) Human arm movements described by a low-dimensional superposition of principal components. J Neurosci 20(3):1066–1072

Schneider A, Cruse H, Schmitz J (2007a) Self-adjusting negative feedback joint controller for legs standing on moving substrates of unknown compliance. In: Bioengineered and bioinspired systems. SPIE

Schneider A, Cruse H, Schmitz J (2007b) A self-adjusting universal joint controller for standing and walking legs. In: The 10th international conference on climbing and walking robots. World Scientific, Singapore

Shemmell J, Hasan Z, Gottlieb G, Corcos D (2007) The effect of movement direction on joint torque covariation. Exp Brain Res 176(1):150–158

Todorov E, Jordan M (2002) Optimal feedback control as a theory of motor coordination. Nat Neurosci 5(11):1226–1235

Todorov E, Li W, Pan X (2005) From task parameters to motor synergies: a hierarchical framework for approximately optimal control of redundant manipulators. J Robot Syst 22(11):691–710

Tucker L (1963) Implications of a factor analysis of three-way matrices for measurement of change. In: Problems in measuring change. University of Wisconsin Press, Wisconsin

Tucker L (1966) Some mathematical notes on three-way mode factor analysis. Psychometrika 31(3):279–311

Vaughan J, Rosenbaum D, Diedrich F, Moore C (1996) Cooperative selection of movements: the optimal selection model. Psychol Res 58(4):254–273

Wang Y, Asaka T, Zatsiorsky V, Latash M (2006) Muscle synergies during voluntary body sway: combining across-trials and within a trial analyses. Exp Brain Res 174(4):679–693

Acknowledgments

This work was supported by the DFG grant no. Cr 58/11-1,2 and the Center of Excellence “Cognitive Interaction Technology” no. 277.

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

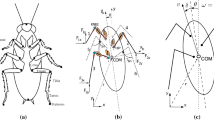

Modelling the body and position control

For the simulation using the Matlab interface Simulink, the animal was represented using measurements for masses and lengths taken from Ekeberg et al. (2004). The animal is represented by a rigid body with a mass concentrated at the center of gravity between middle leg coxae. It has three translational (body fixed coordinates) and three rotational (yaw, pitch and roll angles) degrees of freedom. Each one of the 18 leg joints is represented by a joint with one rotational degree of freedom, i.e., is considered as hinge joint. α-joints are connected to the body after being rotated using the values of the ψ and φ-angles. Coxa, femur and tibia are defined as rigid body segments with a mass concentrated at their center of gravity. Each leg is connected to the ground via a joint with three rotational degrees of freedom. These joints ensure that leg endpoints remain at fixed positions, but do not affect the workspace of the insect. Gravity force was set to act on the body.

α- β-, and γ-joints are supplied with a position controller that controls the size of the angle values. The P- (Proportional), I- (Integral), and D- (Derivative) components of the negative feedback controller were set manually. The P- and the D- parts are small. The I-part is large. The reason for this setting is to guarantee that the size of the individual joint angles and therefore the position of the insect remains constant during the complete simulation as was observed in the experiments.

Minimization of torques

Before starting the simulation run, the body model was given the position the insect has chosen in the experiment to be simulated. These 18 angle values are given as reference values to the PID joint controllers. At the beginning, the joint motors are provided with the torque values measured at the beginning of this experiment. Due to errors in the measurements these torque values do not exactly produce the position introduced. Therefore, torques were allowed to relax to a torque distribution that fits to the body position given. This torque distribution is determined by the PID controllers and is similar to the original torques values. After a stable situation is reached, i.e., a situation where torques match the given position, the actual simulation is started.

The simulation consists of a repetition of the following iteration process. First the torques are changed following one of the two given procedures as explained below. In general, the changed torques do not match the position constraint. Therefore, governed by the PID controller, the torque values are allowed to relax for 1,300 iterations until a new torque distribution is found that matches the angular reference values, i.e., the given body position. This is illustrated by Fig. 11, which shows two consecutive iteration procedures for one selected joint. As mentioned earlier, at the beginning of the first iteration process, torques are given a value (left upper panel, circle, about −45.68 mNmm). As the torques (in combination with the other 17 torques values and the rigid connection via the body and leg segments) do not match the desired body position which is maintained via the PID position controllers, the torque relaxes to adopt a new value (also the other 17 torques), in this example relaxes to −45.87 mNmm. After relaxation, in a next time step, the torque is changed again according one of the two procedures explained below (11, right upper panel, circle, new torque value is about −45.55 mNmm). Again the torques do not fit the position, and are allowed to relax during the iteration process. The two lower panels of Fig. 11 show the time courses of the deviation from the angular reference value, i.e., the error signal received by the PID controller, which approximate zero during the relaxation. Note that the deviations are very small in absolute terms.

In the following, the two procedures are explained that are used to simulate the minimization of torques.

Procedure 1: application of PCs

The first procedure that is applied to change the torques is based on the PARAFAC and on the correlation structure observed during the torque minimization process. Correctly weighted and added, the PCs correspond to a decrement of torques between the two time steps t i and t i+1. In the simulation, weights are taken at random from normal distributions whose parameters \(({\mu}_{a_{q}} ,{\sigma}_{a_{q}}^{2} ,{\mu}_{c_{q}} ,{\sigma}_{c_{q}}^{2})\) were estimated from the experimental data. Using the weighted PCs, the set of torques obtained at the end of an iteration process is changed and the new set of torques is used for the initiation of the new iteration. The minimization process between the two time steps t i and t i+1 is illustrated as follows:

‘X’ is the matrix containing the set of torques. ‘B’ is the PC-matrix, containing the three PCs calculated from the PARAFAC analysis and is the same for each simulation. ‘A’ is a score matrix whose entries are taken at random from a normal distribution for each time step t i . ‘C’ is another score matrix whose entries are taken at random from a normal distribution at the beginning of each simulation and stays the same for each time step.

Procedure 2: application of a local rule

The second procedure represents a local rule, which is not based on the PCs. In this simulation, each torque is reduced between two iteration processes proportionally to its actual size. These reduction factors \(({\hat{p}_{t_{i} j}})\) are not fixed, but, for each time step t i taken at random from normal distributions whose parameters \((\hat{\mu}{{_{p}}}_{\tau},{\hat{\sigma}{{_{p}}}_{\tau}}^{2})\) depend on the absolute sum of all torques, denoted by τ in Table 5. The minimization process between the two time steps t i and t i+1 is illustrated as follows:

The parameters \(\hat{\mu}{{_{p}}}_{\tau}\) and \({\hat{\sigma}{{_{p}}}_{\tau}}^{2}\) were estimated in a way that the amount of torque decrease and variation was large for a high sum of absolute torques but became smaller when the sum of absolute torques decreases.

Rights and permissions

About this article

Cite this article

Lévy, J., Cruse, H. Controlling a system with redundant degrees of freedom: II. Solution of the force distribution problem without a body model. J Comp Physiol A 194, 735–750 (2008). https://doi.org/10.1007/s00359-008-0348-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00359-008-0348-9