Abstract

This paper presents the experimental observations, theoretical analysis and machine learning model of plastic anisotropy of rolling AA7075-T6. Compression responses have been discussed by obtaining the instantaneous stress–strain relationship. The analytical solution of anisotropic initial yielding and hardening has been derived through generalizing the J2 flow theory and applying the evolutive constitutive parameters. In addition, a machine learning model consisting of artificial neural network optimized by genetic algorithm (GA-ANN) is utilized to simulate the plastic anisotropy of AA7075-T6. According to the comparisons among experimental, theoretical and predicted (GA-ANN) results, the machine learning model provides flexible application and is found easy to be generalized for solving such mechanical problems, but with difficultly in assessment of the model’s reliability. Multi-index estimation is a feasible approach to ensure the objective of evaluation in machine learning model.

Similar content being viewed by others

Data availability statement

Data available on request from the authors.

References

H. Badreddine, K. Saanouni, C. Labergère, J.-L. Duval, Effect of the kinematic hardening on the plastic anisotropy parameters for metallic sheets. Comptes Rendus Mécanique 346, 678–700 (2018)

M. Fourmeau, T. Børvik, A. Benallal, O.S. Hopperstad, Anisotropic failure modes of high-strength aluminium alloy under various stress states. Int. J. Plast 48, 34–53 (2013)

J. Ha, M. Baral, Y.P. Korkolis, Plastic anisotropy and ductile fracture of bake-hardened AA6013 aluminum sheet. Int. J. Solids Struct. 155, 123–139 (2018)

A. Jenab, I. Sari Sarraf, D.E. Green, T. Rahmaan, M.J. Worswick, The use of genetic algorithm and neural network to predict rate-dependent tensile flow behaviour of AA5182-O sheets. Mater Design 94, 262–273 (2016)

M. Safaei, M.-G. Lee, S.-L. Zang, W. De Waele, An evolutionary anisotropic model for sheet metals based on non-associated flow rule approach. Comput. Mater. Sci. 81, 15–29 (2014)

H. Huh, Y. Lou, G. Bae, C. Lee, F. Barlat, Y.H. Moon, M.G. Lee, Accuracy Analysis of Anisotropic Yield Functions based on the Root-Mean Square Error, (2010) 739–746.

X. Zhou, J. Wang, L. Jing, Coupling effects of strain rate and fatigue damage on wheel-rail rolling contact behaviour: a dynamic finite element simulation. Int. J. Rail Transport. 0(0), 1–22 (2022)

L. Jing, X. Su, F. Yang, H. Ma, L. Zhao, Compressive strain rate dependence and constitutive modeling of closed-cell aluminum foams with various relative densities. J. Mater. Sci. 53, 14739–14757 (2018)

X. Su, L. Zhou, L. Jing, H. Wang, Experimental investigation and constitutive description of railway wheel/rail steels under medium-strain-rate tensile loading. J. Mater. Eng. Perform. 29, 2015–2025 (2020)

X. Li, R. Xu, X. Zhang, H. Zhang, J. Yang, Inner blast response of fiber reinforced aluminum tubes. Int. J. Impact Eng 172, 104416 (2023)

O. Cazacu, A criterion for description of anisotropy and yield differential effects in pressure-insensitive metals. Int. J. Plast 20, 2027–2045 (2004)

F. Barlat, D.J. Lege, J.C. Brem, A six-component yield function for anisotropic materials. Int. J. Plast 7, 693–712 (1991)

F. Barlat, J.W. Yoon, O. Cazacu, On linear transformations of stress tensors for the description of plastic anisotropy. Int. J. Plast 23, 876–896 (2007)

O. Cazacu, F. Barlat, Generalization of Drucker’s yield criterion to orthotropy. Math. Mech. Solids 6, 613–630 (2001)

O. Cazacu, F. Barlat, Application of the theory of representation to describe yielding of anisotropic aluminum alloys. Int. J. Eng. Sci. 41, 1367–1385 (2003)

L. Jing, X. Su, C. Feng, L. Zhou, Strain-rate dependent tensile behavior of railway wheel/rail steels with equivalent fatigue damage: experiment and constitutive modeling. Eng. Fract. Mech. 275, 108839 (2022)

D.W. Abueidda, M. Almasri, R. Ammourah, U. Ravaioli, I.M. Jasiuk, N.A. Sobh, Prediction and optimization of mechanical properties of composites using convolutional neural networks. Compos. Struct. 227, 111264 (2019)

D.W. Abueidda, S. Koric, N.A. Sobh, H. Sehitoglu, Deep learning for plasticity and thermo-viscoplasticity. Int. J. Plast 136, 102852 (2021)

M.S. Al-Haik, M.Y. Hussaini, H. Garmestani, Prediction of nonlinear viscoelastic behavior of polymeric composites using an artificial neural network. Int. J. Plast 22, 1367–1392 (2006)

U. Ali, W. Muhammad, A. Brahme, O. Skiba, K. Inal, Application of artificial neural networks in micromechanics for polycrystalline metals. Int. J. Plast 120, 205–219 (2019)

M.A. Bessa, R. Bostanabad, Z. Liu, A. Hu, D.W. Apley, C. Brinson, W. Chen, W.K. Liu, A framework for data-driven analysis of materials under uncertainty: countering the curse of dimensionality. Comput. Methods Appl. Mech. Eng. 320, 633–667 (2017)

A.L. Frankel, R.E. Jones, C. Alleman, J.A. Templeton, Predicting the mechanical response of oligocrystals with deep learning. Comput. Mater. Sci. 169, 109099 (2019)

M.B. Gorji, D. Mohr, Towards neural network models for describing the large deformation behavior of sheet metal. IOP Conf. Ser. Mater. Sci. Eng. 651, 012102 (2019)

M.B. Gorji, M. Mozaffar, J.N. Heidenreich, J. Cao, D. Mohr, On the potential of recurrent neural networks for modeling path dependent plasticity. J. Mech. Phys. Solids 143, 103972 (2020)

X. Liu, C.E. Athanasiou, N.P. Padture, B.W. Sheldon, H. Gao, A machine learning approach to fracture mechanics problems. Acta Mater. 190, 105–112 (2020)

U. Reuter, A. Sultan, D.S. Reischl, A comparative study of machine learning approaches for modeling concrete failure surfaces. Adv. Eng. Softw. 116, 67–79 (2018)

J. Wen, Q. Zou, Y. Wei, Physics-driven machine learning model on temperature and time-dependent deformation in lithium metal and its finite element implementation. J. Mech. Phys. Solids 153, 104481 (2021)

B. Jordan, M.B. Gorji, D. Mohr, Neural network model describing the temperature- and rate-dependent stress-strain response of polypropylene. Int. J. Plast 135, 102811 (2020)

M. Mozaffar, R. Bostanabad, W. Chen, K. Ehmann, J. Cao, M.A. Bessa, Deep learning predicts path-dependent plasticity. Proc Natl Acad Sci USA (2019). https://doi.org/10.1073/pnas.1911815116

E. Samaniego, C. Anitescu, S. Goswami, V.M. Nguyen-Thanh, H. Guo, K. Hamdia, X. Zhuang, T. Rabczuk, An energy approach to the solution of partial differential equations in computational mechanics via machine learning: concepts, implementation and applications. Comput. Methods Appl. Mech. Eng. 362, 112790 (2020)

V.M. Nguyen-Thanh, C. Anitescu, N. Alajlan, T. Rabczuk, X. Zhuang, Parametric deep energy approach for elasticity accounting for strain gradient effects. Comput. Methods Appl. Mech. Eng. 386, 114096 (2021)

S. Goswami, C. Anitescu, S. Chakraborty, T. Rabczuk, Transfer learning enhanced physics informed neural network for phase-field modeling of fracture. Theoret. Appl. Fract. Mech. 106, 102447 (2020)

T.B. Stoughton, J.W. Yoon, Anisotropic hardening and non-associated flow in proportional loading of sheet metals. Int. J. Plast 25, 1777–1817 (2009)

H. Wang, M. Wan, X. Wu, Y. Yan, The equivalent plastic strain-dependent Yld 2000–2d yield function and the experimental verification. Comput. Mater. Sci. 47, 12–22 (2009)

Y.S. Lou, H. Huh, J.W. Yoon, Consideration of strength differential effect in sheet metals with symmetric yield function. Int. J. Mech. Sci. 66, 214–213 (2013)

J.W. Yoon, Y. Lou, J. Yoon, M.V. Glazoff, Asymmetric yield function based on the stress invariants for pressure sensitive metals. Int. J. Plast 56, 184–202 (2014)

Q. Hu, X. Li, X. Han, H. Li, J. Chen, A normalized stress invariant-based yield criterion: Modeling and validation. Int. J. Plast 99, 248–273 (2017)

S. Nikbakht, C. Anitescu, T. Rabczuk, Optimizing the neural network hyperparameters utilizing genetic algorithm. J. Zhejiang Univ. Sci. A 22, 407–426 (2021)

K. Srinivasann, A.K. Cherukuri, D.R. Vincent, A.C. Garg, B.-Y. Chen, An efficient implementation of artificial neural networks with K-fold cross-validation for process. J. Internet Technol. 20, 1213–1225 (2019)

H. Li, X. Hu, H. Yang, L. Li, Anisotropic and asymmetrical yielding and its distorted evolution: Modeling and applications. Int. J. Plast 82, 127–158 (2016)

Funding

The Natural Science Foundation of Zhejiang Province (Grant number LQ23A020007), National Natural Science Foundation of China (Grant number 11802199), and University-enterprise cooperation Project of visiting Engineer of universities (Grant number FG2021035) supported this work by providing the financial contributions.

Author information

Authors and Affiliations

Contributions

LL: writing—original draft, investigation. WWL: conceptualization, investigation, project administration. HL: investigation, funding acquisition, software. All the authors contributed to the scientific discussion and editing the paper. TJ: conceptualization, funding acquisition, methodology.

Corresponding author

Ethics declarations

Conflict of interest

The authors confirm that there are no conflicts of interest and that the manuscript has not been published elsewhere, is not under editorial review for publication elsewhere, and is not being submitted simultaneously to another journal.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

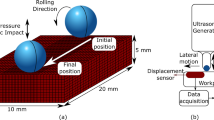

Appendix 1: Shear test of AA7075-T6 in in-plane direction and validation of constitutive model based on stress integral algorithm

Figure 19 shows the geometric schematic of in-plane shear specimen. The shear stress state can be obtained through stretching short edge of specimen along RD direction. Then, the shear stress can be calculated by dividing the cross-sectional area into force and the shear strain also obtained through DIC method. The complete responses of AA7075-T6 under shear are shown in Fig. 20 and the combined Voce–Hockett–Sherby hardening model was utilized to fit such responses:

In addition, the hardening parameters are listed in Table 8. Based on Eq. 31, the equivalent stress at four different levels of equivalent strain can be obtained as displayed in Table 9. It should be point out that the fracture failure has occurred when \(\varepsilon_{{{\text{eq}}}}^{p}\) reaches 0.2 and the corresponding \(\sigma_{{{\text{eq}}}}\) is extrapolated through Eq. 31. Then, the plastic work of in-plane shear can be integrated and cubic polynomial was adopted to guarantee the continuous description:

where \(W_{{{\text{eq}}}}^{p}\) is equivalent plastic work.

In order to validate the accuracy of the constitutive model used in this paper, the return mapping algorithm and implicit integration algorithm are applied to carry out stress update at the level of integration point with the assumption of associated flow rule (AFR). Based on above considerations, the integration algorithm can be written as (Fig. 21)

where \(\lambda\), \({\mathbf{g}}\), \({\mathbf{q}}\), \({\mathbf{h}}\), \({\mathbf{C}}\) and n denote the plastic multiplier, flow direction, internal variables, hardening parameters, elastic modulus tensor and time step. Ignoring the subscript n + 1, the following equations can be obtained [40]:

Based on Taylor expansion, the linearized equation system can be obtained (k denotes the iterative step):

Therefore, the following equation system can be built:

Considering the combination of anisotropic hardening and isotropic hardening, the internal variables \({\mathbf{q}}\) only involve hardening parameters:

Based on AFR, the increase of plastic multiplier equals to the increase of equivalent plastic strain:

Then, the equation system B4 can be rewritten as

Through solving above equations, the updated stresses satisfy the consistency condition which confirms that the stress loci are located on the yield surface.

It should be point out that the two-dimension stress state is considered, and the isotropic elastic relation can be written as

where

The flow directions can be expressed as

Based on above descriptions, the comparisons between experimental results and constitutive model of compression responses at loading angle of 0° and 90° are presented in Fig. 22. In 0° direction, the predicted values of model agree well with experimental results while that predicted values are slightly higher than experimental results as the loading angle equals to 90°.

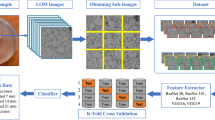

Appendix 2: Determination of number of neurons and fitness histories with generations of GA

Figures 23, 24, 25, 26, 27 and 28 show the determination of number of neurons of ANN and fitness histories versus generations of GA with different datasets of case 1, case 2 and case 3. The number of neurons can be determined through finding the neurons whose MSE is minimum. Fitness curves that also can be found are convergent to small values with the increasing generation which indicates the reliable optimization of the initial \(\omega_{ij}\), \(\omega_{ki}\), \(b_{i}\),\(b_{k}\) in ANN.

Appendix 3: Performance and training histories of ANN

Figures 29, 30, 31, 32, 33, and 34 show the performance and training histories of ANN with datasets of case 1, case 2 and case 3. For case 1, the R of training set, validation set, test set and total dataset are 0.99991, 0.99985, 0.9998 and 0.99989, respectively. The best validation performance is 4.94e−5 at epoch 277. For case 2, the R of training set, validation set, test set and total dataset are 0.99619, 0.99739, 0.99529 and 0.99621, respectively and the best validation performance 8.396e−4 is found at epoch 39. In addition, the R of training set, validation set, test set and total dataset are 0.99929, 0.99917, 0.99876 and 0.9992, respectively, as the dataset turned into case 3. The corresponding best validation performance is 2.509e−4 at epoch 152.

Appendix 4: Weights and bias of ANN with different datasets of case 1, case 2 and case 3 optimized by GA

Tables 10, 11 and 12 list the optimized initial values of weight and bias of ANN with different dataset of case 1, case 2 and case 3 by GA.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lv, L., Lee, W.W., Lin, H. et al. Plastic anisotropy of AA7075-T6 alloy under quasi-static compression: experiments, classical plasticity and artificial neural networks modeling. Appl. Phys. A 129, 209 (2023). https://doi.org/10.1007/s00339-023-06476-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-023-06476-6