Abstract

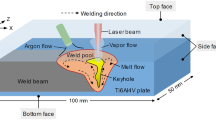

A multi-phase and multi-physics coupling model was proposed and experimentally verified. The simulation of keyhole and weld pool dynamics was conducted during the pulsed laser beam welding (PLBW) of Ti6Al4V titanium alloy. Different pulse frequencies were employed in numerical cases to investigate the influences on thermal transfer and fluid flow behavior and the resultant weld pool dimensions. The calculation results reveal that the welding dynamics go through three stages, that is, keyhole formation/rebuilding, keyhole shrinking, and keyhole collapsing, within a typical laser pulse period. Keyhole collapsing always induces porosities in the lower weld pool, which can be non-contact with a rising-up tendency or captured by the liquid-solid interface unilaterally or multilaterally. Compensation flows are commonly observed near the concaves at keyhole shrinking stage, and then evolve to circulations between porosity and collapsed keyhole. Besides, the keyhole and weld pool show an oscillatory growth on depth values with the oscillation amplitude of keyhole being much higher. A reduced laser pulse frequency can increase the initial weld pool dimensions, obviously, while having little impact on the final welding penetration. The configuration of pulse frequency should be critical to a desirable welding formation in terms of continuity and homogeneity.

Similar content being viewed by others

References

E. Akman, A. Demir, T. Canel, T. Sınmazçelik, J. Mater. Process. Technol. 209, 3705 (2009)

P. Kumar, A.N. Sinha, Weld. World 63, 673 (2019)

Z. Mohid, N.H. Rafai, R. Ibrahim, E.A. Rahim, Mater. Sci. Forum 882, 8 (2017)

F. Caiazzo, V. Alfieri, A. Astarita, A. Squillace, G. Barbieri, Adv. Mech. Eng. 9, 168781401668554 (2016)

X. Gao, J. Liu, L. Zhang, J. Zhang, Mater. Charact. 93, 136 (2014)

J. Liu, X. Gao, J. Zhang, J. Mater. Eng. Perform. 25, 5109 (2016)

P. Xu, Trans. Nonferrous Met. Soc. China 22, 2118 (2012)

H. Heydari, M. Akbari, Infrared Phys. Techn. 106, 103267 (2020)

S. Chatterjee, S.S. Mahapatra, V. Bharadwaj, B.N. Upadhyaya, K.S. Bindra, Laser Eng. 46, 111 (2020)

Y. Zhang, D. Sun, X. Gu, H. Li, Int. J. Adv. Manuf. Tech. 94, 1073 (2018)

B.C. Kim, T.H. Kim, J.S. Kim, K.B. Kim, H.Y. Lee, 20th ICALEO. Congress Proceedings 92–93, 465 (2001)

T. Arai, Materialwiss. Werkstofftech. 44, 462 (2013)

K.S. Kumar, Materials Today: Proceedings 2, 2256 (2015)

G. Satyanarayana, K.L. Narayana, B.N. Rao, M.S. Slobodyan, M.A. Elkin, A.S. Kiselev, Therm. Eng. 66, 210 (2019)

H. Tan, Y. Zhang, Y. Liu, X. Fu, Infrared Phys. Techn. 98, 334 (2019)

F. Lange, A. Artinov, M. Bachmann, M. Rethmeier, K. Hilgenberg, Procedia CIRP 74, 6792 (2018)

A. Bagchi, S. Saravanan, K.G. Shanthos, G. Murugan, K. Raghukandan, Optik 146, 80 (2017)

Z.M. Beiranvand, F.M. Ghaini, H.N. Moosavy, M. Sheikhi, M.J. Torkamany, Metall. Mater. Trans. B Process Metall. Mater. Process. Sci. 49, 2896 (2018)

Z.M. Beiranvand, F.M. Ghaini, H.N. Moosavy, M. Sheikhi, M.J. Torkamany, M. Moradi, Opt. Laser Technol. 128, 106170 (2020)

X. Jin, P. Berger, T. Graf, J. Phys. D. Appl. Phys. 39, 4703 (2006)

S. Katayama, Y. Kawahito, Proc. SPIE 7195, 71951R (2009)

A.D. Brent, V.R. Voller, K.J. Reid, Numerical Heat Transfer 13, 297 (1988)

H. Ki, P.S. Mohanty, J. Mazumder, J. Phys. D. Appl. Phys. 34, 364 (2001)

S. Pang, L. Chen, J. Zhou, Y. Yin, T. Chen, J. Phys. D. Appl. Phys. 44, 025301 (2011)

W.H. Lee, Math. Model. C3, 406 (1979)

J.H. Cho, S.J. Na, J. Phys. D. Appl. Phys. 39, 5372 (2006)

H. Ki, J. Mazumder, P.S. Mohanty, Metall Mater Trans A 33, 1817 (2002)

M. Sussman, E.G. Puckett, J. Comput. Phys. 162, 301 (2000)

H. Ding, P.D.M. Spelt, C. Shu, J. Comput. Phys. 226, 2078 (2007)

H. Ren, X. Zhuang, T. Rabczuk, CMES-Comp. Model. Eng. 121, 353 (2019)

L. Qian, Y. Wei, F. Xiao, J. Comput. Phys. 373, 284 (2018)

J.U. Brackbill, D.B. Kothe, C. Zemach, J. Comput. Phys. 100, 335 (1992)

X. Gao, J. Liu, L. Zhang, Int. J. Adv. Manuf. Tech. 94, 3937 (2018)

W.I. Cho, S.J. Na, C. Thomy, F. Vollertsen, J. Mater. Process. Tech. 212, 262 (2012)

M. Courtois, M. Carin, M.P. Le, S. Gaied, M. Balabane, J. Laser. Appl. 26, 042001 (2014)

L. Huang, X. Hua, D. Wu, Y. Ye, Int. J. Adv. Manuf. Tech. 103, 913 (2019)

E.H. Amara, A. Bendib, J. Phys. D. Appl. Phys. 35, 272 (2002)

B. Chang, C. Allen, J. Blackburn, P. Hilton, D. Du, Metall. Mater. Trans. B. 46, 906 (2015)

Acknowledgments

The authors gratefully acknowledged a project funded by the Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD) and China Postdoctoral Science Foundation No. 2020M671479.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declared that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chen, J., Chen, X., Liu, X. et al. Numerical investigation on keyhole collapsing and rebuilding behavior during pulsed laser beam welding of Ti6Al4V titanium alloy under various pulse frequencies. Appl. Phys. A 128, 140 (2022). https://doi.org/10.1007/s00339-021-05006-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-021-05006-6