Abstract

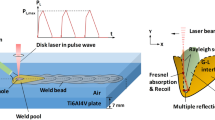

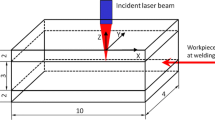

A three-dimensional (3D) transient numerical model is developed to simulate the keyhole dynamics, melt flow, and keyhole-induced porosity formation. The influence of the plate thickness on keyhole-induced porosity size and number is thoroughly investigated. The simulation results show that the average keyhole depth in plate thickness of 3, 6, and 10 mm is 2.07 mm, 1.89 mm, and 1.77 mm, respectively, and the value of keyhole depth reaching the quasi-steady state is 34 ms, 28 ms, and 14 ms, respectively. Compared to the thinner thickness plate, it is not easy to see the phenomenon of bubble amalgamation in the thickness of 10 mm under the parameter of low laser power and high welding speed. The less porosity in thicker plate laser welding is attributed to lower frequency of keyhole collapse, higher ratio of keyhole open after keyhole collapse to total keyhole collapse number, lower ratio of bubble number to total keyhole collapse number, higher ratio of bubble escape to the total bubbles number, and lower ratio of bubble amalgamation to the total.

Similar content being viewed by others

References

Wang J, Peng G, Li L, Si C, Meng S, Gong J (2019) 30 kW-level laser welding characteristics of 5A06 aluminum alloy thick plate under subatmospheric pressure. Opt Laser Technol 119:105668

Jiang Z, Hua X, Huang L, Wu D, Li F, Zhang Y (2018) Double-sided hybrid laser-MIG welding plus MIG welding of 30-mm-thick aluminum alloy. Int J Adv Manuf Technol 97(1–4):903–913

Huang L, Hua X, Wu D, Jiang Z, Li F, Wang H, Shi S (2017) Microstructural characterization of 5083 aluminum alloy thick plates welded with GMAW and twin wire GMAW processes. Int J Adv Manuf Technol 93:1809–1817

Li R, Zhang F, Sun T, Liu B, Chen S, Tian Y (2019) Investigation of strengthening mechanism of commercially pure titanium joints fabricated by autogenously laser beam welding and laser-MIG hybrid welding processes. Int J Adv Manuf Technol 101:377–389

Li L, Mi G, Zhang X, Xiong L, Zhu Z, Wang C (2019) The influence of induction pre-heating on microstructure and mechanical properties of S690QL steel joints by laser welding. Opt Laser Technol 119:105606

Jiang M, Chen X, Chen Y, Tao W (2020) Mitigation of porosity defects in fiber laser welding under low vacuum. J Mater Process Tech 276:116385

Xu J, Rong Y, Huang Y, Wang P, Wang C (2018) Keyhole-induced porosity formation during laser welding. J Mater Process Tech 252:720–727

Ola O, Doern F (2015) Keyhole-induced porosity in laser-arc hybrid welded aluminum. Int J Adv Manuf Technol 80(1–4):3–10

Miyagi M, Kawahito Y, Kawakami H, Shoubud T (2017) Dynamics of solid-liquid interface and porosity formation determined through x-ray phase-contrast in laser welding of pure Al. J Mater Process Tech 250:9–15

Berger P, Hugel H, Graf T (2011) Understanding pore formation in laser beam welding. Phys Proc 12:241–247

Kawahito Y, Wang H (2018) In-situ observation of gap filling in laser butt welding. Scripta Mater 154:73–77

Bayat M, Thanki A, Mohanty S, AnnWitvrouw A, Yang S, Thorborg J, Tiedje N, Hattela J (2019) Keyhole-induced porosities in laser-based powder bed fusion (L-PBF) of Ti6Al4V: high-fidelity modelling and experimental validation. Addit Manuf 30:100835

Wang T, Yang Z, Shi C, Dong D (2017) Simulating effects of welding speed on melt flow and porosity formation during double-sided laser beam welding of AA6056-T4/AA6156-T6 aluminum alloy T-joint. J Alloy Compd 699:638–647

Huang L, Hua X, Wu D, Li F, Cai Y, Ye Y (2018) Effect of magnesium content on keyhole-induced porosity formation and distribution in aluminum alloys laser welding. J Manuf Process 33:43–53

Pang S, Chen W, Wang W (2014) A quantitative model of keyhole instability induced porosity in laser welding of titanium alloy. Metall Mater Trans A 45(6):2808–2818

Li L, Peng G, Wang J, Gong J, Meng S (2019) Numerical and experimental study on keyhole and melt flow dynamics during laser welding of aluminum alloys under subatmospheric pressures. Int J Heat Mass Tranf 133:812–816

Liu T, Mu Z, Hu R, Pang S (2019) Sinusoidal oscillating laser welding of 7075 aluminum alloy: hydrodynamics, porosity formation and optimization. Int J Heat Mass Tran 140:346–358

Li Z, Rostamc K, Panjehpour A, Akbar M, Karimipour A, Rostami S (2020) Experimental and numerical study of temperature field and molten pool dimensions in dissimilar thickness laser welding of Ti6Al4V alloy. J Manuf Process 49:438–446

Le K, Tang C, Wong C (2019) On the study of keyhole-mode melting in selective laser melting process. Int J Therm Sci 145:105992

Huang L, Hua X, Wu D, Jiang Z, Ye Y (2019) A study on the metallurgical and mechanical properties of a GMAW-welded Al-Mg alloy with different plate thicknesses. J Manuf Process 37:438–445

Chinnapat P, Bama P, Ward R, Nathanael T, Richard P, Jeffery W, Hector C (2017) Keyhole formation and thermal fluid flow-induced porosity during laser fusion welding in titanium alloys: experimental and modelling. Acta Mater 126:251–263

Meng X, Artinov A, Bachmann M, Rethmeier M (2019) Numerical and experimental investigation of thermo-fluid flow and element transport in electromagnetic stirring enhanced wire feed laser beam welding. Int J Heat Mass Tra 144:118663

Lin R, Wang H, Lu F, Solomon J, Carlson B (2017) Numerical study of keyhole dynamics and keyhole-induced porosity formation in remote laser welding of Al alloys. Int J Heat Mass Tra 108:244–256

Zhang M, Liu T, Hu R, Mu Z, Chen S, Chen G (2020) Understanding root humping in high-power laser welding of stainless steels: a combination approach. Int J Adv Manuf Technol 106:5353–5364

Lei Z, Wu S, Li P, Li B, Lu N, Hu X (2019) Numerical study of thermal fluid dynamics in laser welding of Al alloy with powder feeding. Appl Therm Eng 151:394–405

Huang L, Hua X, Wu D, Ye Y (2019) Role of welding speed on keyhole-induced porosity formation based on experimental and numerical study in fiber laser welding of Al alloy. Int J Adv Manuf Technol 103:913–925

Li X, Lu F, Cui H, Tang X, Wu Y (2014) Numerical modeling on the formation process of keyhole-induced porosity for laser welding steel with T-joint. Int J Adv Manuf Tech 72(1):241–254

Huang L, Hua X, Wu D, Li F (2017) Numerical study of keyhole instability and porosity formation mechanism in laser welding of aluminum alloy and steel. J Mater Process Technol 252:421–431

Funding

This research was financially funded by China Postdoctoral Science Foundation (No. 2020M671066) and Shanghai Super Postdoctoral (No. 2019080).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, P., Huang, L., Gan, L. et al. Effect of plate thickness on weld pool dynamics and keyhole-induced porosity formation in laser welding of Al alloy. Int J Adv Manuf Technol 111, 735–747 (2020). https://doi.org/10.1007/s00170-020-05818-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05818-5