Abstract

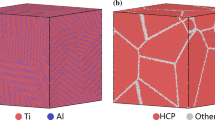

In the present work, the molecular dynamics (MD) simulation is employed to investigate the tensile and compressive deformation behavior of nano-polycrystalline Ti with the mean grain size of 6.8 nm. The deformation behaviors reveal that the nano-polycrystalline Ti has different deformation mechanisms under the tension or compression. When the nano-polycrystalline Ti is applied tensile loading, the dislocation density quantification shows that there is no significant new dislocation appearing before the tensile strain reaches the failure strain (ε = 0.12). Instead, a 25° difference in the grain boundary misorientation angle between two grains was observed, which indicates that the grain boundary rotation and sliding are appeared to dominate the tensile deformation process of nano-polycrystalline Ti. When the nano-polycrystalline Ti is applied compressive loading, the compressive stress increases linearly with the increase in compressive strain before the compressive strain arrives 0.075. Once the compressive strain exceeds 0.075, the nano-polycrystalline Ti enters the plastic deformation stage. In this case, the hcp-Ti atoms near the grain boundary were firstly transformed to the bcc-Ti atoms and then the hcp-Ti atoms within the grain transforms into the bcc-Ti atoms with the increase in compressive strain, which indicates that the plastic deformation of nano-polycrystalline Ti during the compression is dominated by the phase transformation from hcp-Ti to bcc-Ti. In addition, it is found that the deformation behaviors of nano-polycrystalline Ti are sensitive to strain rate and temperature. The present work could be beneficial for the design and fabrication of nano-polycrystalline Ti alloys with excellent mechanical properties.

Similar content being viewed by others

References

V.M. Tabie, C. Li, S.F. Wang, J.W. Li, X.J. Xu, Mechanical properties of near alpha titanium alloys for high-temperature applications—a review. Aircr. Eng. Aerosp. Tec. 92, 521–540 (2020)

P.F. Gao, M.W. Fu, M. Zhan, Z.N. Lei, Y.X. Li, Deformation behavior and microstructure evolution of titanium alloys with lamellar microstructure in hot working process: a review. J. Mater. Sci. Tec. 39, 56–73 (2020)

S.Y. Liu, Y.C. Shin, Additive manufacturing of Ti6Al4V alloy: a review. Mater. Des. 164, 107552 (2019)

M. Kaur, K. Singh, Review on titanium and titanium based alloys as biomaterials for orthopaedic applications. Mater. Sci. Eng. C 102, 844–862 (2019)

L.C. Zhang, L.Y. Chen, A review on biomedical titanium alloys: recent progress and prospect. Adv. Eng. Mater. 21, 1801215 (2019)

A.N. Omran, M.M. Ali, M.M. Kh, Biocompatibility, corrosion, and wear resistance of β titanium alloys for biomedical applications. Appl. Phys. A 126, 942 (2020)

K. Lu, Stabilizing nanostructures in metals using grain and twin boundary architectures. Nat. Rev. Mater. 1, 16019 (2016)

Z. Cheng, H.F. Zhou, Q.H. Lu, H.J. Gao, L. Lu, Extra strengthening and work hardening in gradient nanotwinned metals. Science 362, 559 (2018)

T. Chookajorn, H.A. Murdoch, C.A. Schuh, Design of stable nano-polycrystalline alloys. Science 24, 951–954 (2012)

Y.J. Wei, Y.Q. Li, L.C. Zhu, Y. Liu, X.Q. Lei, G. Wang, Y.X. Wu, Z.L. Mi, J.B. Liu, H.T. Wang, H.J. Gao, Evading the strength–ductility trade-off dilemma in steel through gradient hierarchical nanotwins. Nat. Commun. 5, 3580 (2014)

K. Hajizadeh, B. Eghbali, K. Topolski, K.J. Kurzydlowski, Untra-fine grained bulk cp-Ti processed by multi-pass ECAP at warm deformation region. Mater. Chem. Phys. 143, 1032–1038 (2014)

H.F. Wang, C.Y. Ban, N.N. Zhao, Y.Y. Kang, T.P. Qin, S.T. Liu, J.Z. Cui, Enhanced strength and ductility of nano-grained titanium processed by two-step severe plastic deformation. Mater. Lett. 266, 127485 (2020)

M.S. Hasan, R. Lee, W.W. Xu, Deformation nanomechanics and dislocation quantification at the atomic scale in nano-polycrystalline magnesium. J. Magnes. Alloy. 8, 1296–1303 (2020)

C. Huang, X.H. Peng, B. Yang, S.Y. Weng, Y.B. Zhao, T. Fu, Grain size dependence of tensile properties in nano-polycrystalline diamond. Comp. Mater. Sci. 157, 67–74 (2019)

W.H. Li, E.N. Hahn, X.H. Yao, T.C. Germann, B. Feng, X.Q. Zhang, On the grain size dependence of shock responses in nano-polycrystalline sic ceramics at high strain rates. Acta Mater. 200, 632–651 (2020)

X.Y. Zhou, X.S. Yang, J.H. Zhu, F. Xing, Atomistic simulation study of the grain-size effect on hydrogen embrittlement of nanograined Fe. Int. J. Hydrogen Energ. 45, 3294–3306 (2020)

P. Hirel, Atomsk: a tool for manipulating and converting atomic data files. Comput. Phys. Commun. 197, 212–219 (2015)

H. Talebi, M. Silani, S.P.A. Bordas, P. Kerfriden, T. Rabczuk, A computational library for multiscale modeling of material failure. Comput. Mech. 53, 1047–1071 (2014)

P.R. Budarapu, R. Gracie, S.W. Yang, X.Y. Zhuang, T. Rabczuk, Efficient coarse graing in multiscale modeling of fracture. Theor. Appl. Fract. Mec. 69, 126–143 (2014)

S. Plimpton, Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 117, 1–19 (1995)

Y.M. Kim, B.J. Lee, Modified embedded-atom method interatomic potentials for the Ti-C and Ti-N binary systems. Acta Mater. 56, 3481–3489 (2008)

A. Stukowski, Structure identification methods for atomistic simulations of crystalline materials. Modell. Simul. Mater. Sci. Eng. 20, 045021 (2012)

F. Zhang, J.Q. Zhou, Tension-compression asymmetry and twin boundaries spacings effects in polycrystalline Ni nanowires. J. Appl. Phys. 120, 044303 (2016)

X. Chen, W. Chen, Y. Ma, Y. Zhao, C.Y. Deng, X.H. Peng, T. Fu, Tension-Compression asymmetry of single-crystalline and nanocrystalline NiTi shape memory alloy: an atomic scale study. Mech. Mater. 145, 103402 (2020)

Acknowledgments

The authors acknowledge the financial support from the Key Project of Science and Technology Department of Henan Province (Grant No. 142102210508).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, H., Pan, A., Hei, R. et al. An atomistic simulation on the tensile and compressive deformation mechanisms of nano-polycrystalline Ti. Appl. Phys. A 127, 362 (2021). https://doi.org/10.1007/s00339-021-04522-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-021-04522-9