Abstract

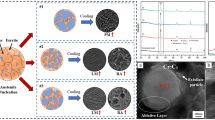

Unwanted removal of carbon from surface may occur during laser surface processing of steels despite the short interaction time and thermal cycle. However, no attention is paid in literature to investigate this phenomenon systematically. This paper presents two different scenarios during laser surface processing of steels: complete absence of decarburization for an alloy steel but decarburization with depth up to 70 µm for a plain carbon steel, showing that alloying elements tend to retard decarburization process by reducing the mobility of carbon in austenite. Further analysis reveals that the laser-induced decarburization is dependent primarily on peak temperature and austenitization kinetics.

Similar content being viewed by others

References

D. Herring, Atmosphere Heat Treatment: Atmospheres, Quenching, Testing, vol. 2, 1st edn. (BNP Media, Troy, 2015)

R.I. Carroll, J.H. Beynon, Wear 260, 523 (2006)

A.K. Nath, S. Sarkar, Advances in Laser Materials Processing, 2nd edn. (Elsevier, New York, 2018), pp 257–298

C.T. Kwok, K.H. Lo, F.T. Cheng, H.C. Man, Surf. Coatings Technol. 166, 221 (2003)

J.H. Abboud, K.Y. Benyounis, A.G. Olabi, M.S.J. Hashmi, J. Mater. Process. Technol. 182, 427 (2007)

M.F. Yan, Y.X. Wang, X.T. Chen, L.X. Guo, C.S. Zhang, Y. You, B. Bai, L. Chen, Z. Long, R.W. Li, Mater. Des. 58, 154 (2014)

Y.X. Wang, M.F. Yan, B. Li, L.X. Guo, C.S. Zhang, Y.X. Zhang, B. Bai, L. Chen, Z. Long, R.W. Li, Opt. Laser Technol. 67, 57 (2015)

X. Zhao, B. Song, Y. Zhang, X. Zhu, Q. Wei, Y. Shi, Mater. Sci. Eng. A 647, 58 (2015)

ASTM, Subcomittee, E04.14, 10 (2014)

P.L. Larsson, A.E. Giannakopoulos, E. Söderlund, D.J. Rowcliffe, R. Vestergaard, Int. J. Solids Struct. 33, 221 (1996)

L. Qian, M. Li, Z. Zhou, H. Yang, X. Shi, Surf. Coatings Technol. 195, 264 (2005)

T. Mioković, V. Schulze, O. Vöhringer, D. Löhe, Acta Mater. 55, 589 (2007)

S.N. Aqida, D. Brabazon, S. Naher, Appl. Phys. A 110, 673 (2013)

N. Maharjan, W. Zhou, Y. Zhou, N. Wu, High-Power Laser Mater. Process. Appl. Diagnostics, Syst. VII. (International Society for Optics and Photonics, San Francisco, 2018)

A. Nagode, K. Jerina, I. Jerman, D. Vella, M. Bizjak, B. Kosec, B. Karpe, B. Zorc, J. Sol-Gel. Sci. Technol. 86, 568 (2018)

J.I. Goldstein, D.E. Newbury, J.R. Michael, N.W.M. Ritchie, J.H.J. Scott, D.C. Joy, Scanning Electron Microscopy and X-Ray Microanalysis. (Springer, New York, 2017)

Z.-Q. Liu, G. Miyamoto, Z.-G. Yang, T. Furuhara, Acta Mater. 61, 3120 (2013)

F. Boué-Bigne, Spectrochim. Acta Part B At. Spectrosc. 63, 1122 (2008)

P.T. Pinard, A. Schwedt, A. Ramazani, U. Prahl, S. Richter, Microsc. Microanal. 19, 996 (2013)

G.F. Vander Voort, Adv. Mater. Process. 137, 6 (2015)

G. Krauss, Steels: Processing, Structure, and Performance. (ASM International, Material Park, Ohio, 2015)

E. Gharibshahiyan, A.H. Raouf, N. Parvin, M. Rahimian, Mater. Des. 32, 2042 (2011)

Z.X. Qiao, Y.C. Liu, L.M. Yu, Z.M. Gao, Appl. Phys. A 95, 917 (2009)

H.D. Alvarenga, T. Van De Putte, N. Van Steenberge, J. Sietsma, H. Terryn, Metall. Mater. Trans. A 46, 123 (2015)

H. Pantsar, J. Mater. Process. Technol. 189, 435 (2007)

R.D. Cioffi, R. Wright, A comparison study on depth of decarburization and the role of stable carbide forming elements in 1075 plain carbon steel and 440 A stainless steel (New York, n.d.). https://www.forging.org/uploaded/content/members/public/PDF/Role%20of%20Stable%20Carbide%20Formers%20on%20Decarburization%20Depth.pdf

O.K. Rowan, R.D. Sisson, J. Phase Equilibria Diffus. 30, 235 (2009)

J. Gegner, A.A. Vasilyev, P.J. Wilbrandt, M. Kaffenberger, Proc. 7th Int. Conf. Math. Model. Comput. Simul. Mater. Technol. 20, 22 (2012)

J.O. Andersson, T. Helander, L. Höglund, P. Shi, B. Sundman, Calphad 26, 273 (2002)

F.J. Harvey, Metall. Mater. Trans. A 9, 1507 (1978)

S.W. Mayott, Analysis of the effects of reduced oxygen atmospheres on the decarburization depths of 300M alloy steel (New York, 2010). https://www.forging.org/uploaded/content/media/Modern_Look_at_Decarburization_Rensselaer_Phase1_2010.pdf

J. Andersson, J. Ågren, J. Appl. Phys. 72, 1350 (1992)

N. Maharjan, W. Zhou, Y. Zhou, Y. Guan, Appl. Phys. A 124, 519 (2018)

W. Pakieła, T. Tanski, M. Pawlyta, K. Pakieła, Z. Brytan, M. Sroka, Appl. Phys. A 124, 263 (2018)

D.I. Pantelis, E. Bouyiouri, N. Kouloumbi, P. Vassiliou, A. Koutsomichalis, Surf. Coatings Technol. 161, 125 (2002)

C.P. Ma, Y.C. Guan, W. Zhou, Opt. Lasers Eng. 93, 171 (2017)

G. Telasang, J.D. Majumdar, G. Padmanabham, I. Manna, Surf. Coatings Technol. 261, 69 (2015)

S. Guarino, M. Barletta, A. Afilal, J. Manuf. Process. 28, 266 (2017)

Acknowledgements

Support from A*STAR SINGA Scholarship, Nanyang Technological University and Advanced Remanufacturing and Technology Center (ARTC), Singapore under the Collaborative Research Project RCA-15/287 is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Maharjan, N., Zhou, W., Zhou, Y. et al. Decarburization during laser surface processing of steel. Appl. Phys. A 124, 682 (2018). https://doi.org/10.1007/s00339-018-2104-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-018-2104-5