Abstract

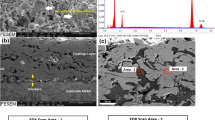

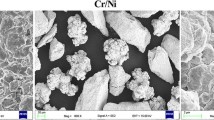

In this study, surface modification of high-carbon steel was carried out using 2 kW fiber laser and thermal, microstructural and tribological characterizations were performed. The process parameters selected for laser surface treatment were laser power (600-1500 W) and scan speed (3000-4500 mm/min). Infrared pyrometer was used to record the surface temperature during the process. The metallographic analysis was carried out using an optical microscope to find the depth and width of the laser-treated zone. Scanning electron microscopy and energy-dispersive spectroscopy were performed to reveal the microstructure and compositional changes taking place in the laser-treated zone. It was observed that the dendritic growth took place from the top surface toward the center of the laser-treated zone. The amount of dendritic growth can be related to the maximum surface temperature generated during the process. XRD analysis indicated the formation of some intermetallic compounds and phase shifts taking place in the laser-treated zone. Residual stress analysis was performed to analyze the amount of stress accumulation in the laser-treated zone. When the temperature cycle was analyzed, it was found that the melting of the steel resulted in the formation of a surface under compressive stress while the non-melt hardened zone developed a surface under tensile stress. The maximum Vickers microhardness value achieved was about 958.8 HV0.5 for 1500 W power and 3000 mm/min scan speed. Scratch test was performed on the laser-treated track, and it was found that the hardened zone showed better tribological properties with respect to the parent material. Finally, it was observed that the surface roughness value increased with higher heat input probably due to high rate of oxide formation as well as due to the presence of martensite in the laser-treated zone.

Similar content being viewed by others

References

A. Agarwal and N.B. Dahotre, Laser Surface Engineering of Steel for Hard Refractory Ceramic Composite Coating, Int. J. Refract. Met. Hard Mater., 1999, 17(4), p 283–293

M. Bojinović, N. Mole, and B. Štok, A Computer Simulation Study of the Effects of Temperature Change Rate on Austenite Kinetics in Laser Hardening, Surf. Coatings Technol., 2015, 273(1), p 60–76

Y.D. Chung, H. Fujii, R. Ueji, and N. Tsuji, Friction Stir Welding of High Carbon Steel with Excellent Toughness and Ductility, Scr. Mater., 2010, 63(2), p 223–226. https://doi.org/10.1016/j.scriptamat.2010.03.060

M. Kulka and A. Pertek, Microstructure and Properties of Borided 41Cr4 Steel after Laser Surface Modification with Re-Melting, Appl. Surf. Sci., 2003, 214(1–4), p 278–288

M. Kulka and A. Pertek, Microstructure and Properties of Borocarburized 15CrNi6 Steel after Laser Surface Modification, Appl. Surf. Sci., 2004, 236(1), p 98–105

C.T. Kwok, F.T. Cheng, and H.C. Man, Laser Surface Modification of UNS S31603 Stainless Steel. Part I: Microstructures and Corrosion Characteristics, Mater. Sci. Eng., A, 2000, 290(1–2), p 55–73

C.T. Kwok, F.T. Cheng, and H.C. Man, Laser Surface Modification of UNS S31603 Stainless Steel: Part II: Cavitation Erosion Characteristics, Mater. Sci. Eng., A, 2000, 290(1–2), p 74–88

I. Manna, J. Dutta Majumdar, B. Ramesh Chandra, S. Nayak, and N.B. Dahotre, Laser Surface Cladding of Fe-B-C, Fe-B-Si and Fe-BC-Si-Al-C on Plain Carbon Steel, Surf. Coatings Technol., 2006, 201(1–2), p 434–440

M.S. Raza, M. Hussain, V. Kumar, and A.K. Das, In Situ Production of Hard Metal Matrix Composite Coating on Engineered Surfaces Using Laser Cladding Technique, J. Mater. Eng. Perform., 2017, 26(1), p 76–83

A.K. Nath, A. Gupta, and F. Benny, Theoretical and Experimental Study on Laser Surface Hardening by Repetitive Laser Pulses, Surf. Coatings Technol., 2012, 206(8–9), p 2602–2615. https://doi.org/10.1016/j.surfcoat.2011.11.019

A. Pertek and M. Kulka, Characterization of Single Tracks after Laser Surface Modification of Borided 41Cr4 Steel, Appl. Surf. Sci., 2002, 205(1–4), p 137–142

P. Peyre, X. Scherpereel, L. Berthe, C. Carboni, R. Fabbro, G. Béranger, and C. Lemaitre, Surface Modifications Induced in 316L Steel by Laser Peening and Shot-Peening: Influence on Pitting Corrosion Resistance Mater, Sci. Eng. A, 2000, 280(2), p 294–302

R. Komanduri and Z.B. Hou, Thermal Analysis of the Laser Surface Transformation Hardening Process, Int. J. Heat Mass Transf., 2001, 44(15), p 2845–2862

R. Komanduri and Z.B. Hou, Thermal Analysis of Laser Surface Transformation Hardening - Optimization of Process Parameters, Int. J. Mach. Tools Manuf, 2004, 44(9), p 991–1008

T. Mioković, V. Schulze, O. Vöhringer, and D. Löhe, Influence of Cyclic Temperature Changes on the Microstructure of AISI, 4140 after Laser Surface Hardening, Acta Mater., 2007, 55(2), p 589–599

S. Sarkar, M. Gopinath, S.S. Chakraborty, B. Syed, and A.K. Nath, Analysis of Temperature and Surface Hardening of Low Carbon Thin Steel Sheets Using Yb-Fiber Laser, Surf. Coatings Technol., 2016, 302, p 344–358. https://doi.org/10.1016/j.surfcoat.2016.06.045

L. Orazi, A. Fortunato, G. Cuccolini, and G. Tani, An Efficient Model for Laser Surface Hardening of Hypo-Eutectoid Steels, Appl. Surf. Sci., 2010, 256(6), p 1913–1919

J.S. Selvan, K. Subramanian, and A.K. Nath, Effect of Laser Surface Hardening on En18 (AISI, 5135) Steel, J. Mater. Process. Technol., 1999, 91(1), p 29–36

Y.K. Madhukar, S. Mullick, D.K. Shukla, S. Kumar, and A.K. Nath, Effect of Laser Operating Mode in Paint Removal with a Fiber Laser, Appl. Surf. Sci., 2013, 264, p 892–901. https://doi.org/10.1016/j.apsusc.2012.10.193

G. Muvvala, D. Patra Karmakar, and A.K. Nath, Online Monitoring of Thermo-Cycles and Its Correlation with Microstructure in Laser Cladding of Nickel Based Super Alloy, Opt. Lasers Eng., 2017, 88, p 139–152. https://doi.org/10.1016/j.optlaseng.2016.08.005

C. Technology, A Study on Residual Stresses in Laser Surface, 1989, 38, p 311–324

B.S. Yilbas, M. Sami, and S.Z. Shuja, Laser-Induced Thermal Stresses on Steel Surface, Opt. Lasers Eng., 1998, 30(1–5), p 25–37

N. Huber and J. Heerens, On the Effect of a General Residual Stress State on Indentation and Hardness Testing, Acta Mater., 2008, 56(20), p 6205–6213. https://doi.org/10.1016/j.actamat.2008.08.029

K. Tosha, Influence of Residual Stresses on the Hardness Number in the Affected Layer Produced by Shot Peening, Second Asia–Pacific Forum Precis. Surf. Finish. Deburring Technol., 2002, p 48–54.

S. Roy, J. Zhao, P. Shrotriya, and S. Sundararajan, Effect of Laser Treatment Parameters on Surface Modification and Tribological Behavior of AISI, 8620 Steel, Tribol. Int., 2017, 112(February), p 94–102

A. Speidel, A. Hugh, A. Lutey, J. Mitchell-smith, G.A. Rance, E. Liverani, A. Ascari, A. Fortunato, and A. Clare, Surface & Coatings Technology Surface Modi Fi Cation of Mild Steel Using a Combination of Laser and Electrochemical Processes, Surf. Coat. Technol., 2016, 307, p 849–860. https://doi.org/10.1016/j.surfcoat.2016.09.077

D.A. Lesyk, S. Martinez, V.V. Dzhemelinskyy, A. Lamikiz, B.N. Mordyuk, and G.I. Prokopenko, Surface Microrelief and Hardness of Laser Hardened and Ultrasonically Peened AISI, D2 Tool Steel, Surf. Coatings Technol., 2015, 278, p 108–120

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Raza, M.S., Datta, S., Vivekanand, K. et al. Surface Modification of High-Carbon Steel Using Fiber Laser and Its Thermal, Microstructural and Tribological Analysis. J. of Materi Eng and Perform 28, 1873–1883 (2019). https://doi.org/10.1007/s11665-019-03943-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-019-03943-1