Abstract

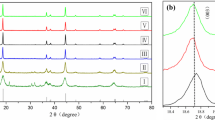

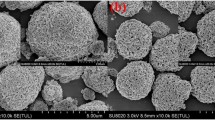

Material synthesis plays an important role in determining the performance and cost of final devices. In this paper, rheological phase method has been applied to conveniently synthesize carbon-coated LiNi0.6Co0.2Mn0.2O2 (LNCM622/C) as the cathode material of high-performance lithium-ion batteries (LIBs), avoiding the use of co-precipitation route with complicated procedures and environmental issues. Importantly, the addition of citric acid enabled a relative low temperature of crystallization initiation of the reaction of forming LNCM622/C, which is crucial for the material synthesis. As a result, highly ordered LNCM622/C materials have been obtained with a final calcinating temperature of 900 °C, which is comparable to that being used in co-precipitation route. It is worth mentioning that the synthesis reaction was processed in air without the extra-oxygen gas supply. By varying lithium contents (Li/TM = 0.95, 1.00, 1.05, 1.10, 1.15, and 1.20 by molar, TM = Ni, Co, and Mn), the structure and morphology of resulted LNCM622/C materials were changed, leading to different electrochemical performances of corresponded LIBs. It was found that the Li/TM = 1.15 sample had the best initial discharged capacity at 0.1 °C rate (177.1 mAh g− 1), whereas the Li/TM = 1.05 sample showed the best cycling and rate performance (100.6 mAh g− 1 at 1 °C) among synthesized samples. Overall, these results suggest that rheological phase method can be considered as an effective route for synthesizing carbon-coated LiNi0.6Co0.2Mn0.2O2 cathode materials for high-performance LIBs.

Similar content being viewed by others

References

P. Gibot, M. Casas-Cabanas, L. Laffont, S. Levasseur, P. Carlach, S. Hamelet, J.M. Tarascon, C. Masquelier, Nat. Mater. 7, 741–747 (2008)

J.M. Tarascon, M. Armand, Nature 6861, 359–414 (2001)

Z. Yang, J. Zhang, M.C. Kintner-Meyer, X. Lu, D. Choi, J.P. Lemmon, J. Liu, Chem. Rev. 111, 3577–3613 (2011)

W.Y. Liu, W.H. Hua, Z. Zheng, B.H. Zhong, Z.Y. Zhang, Ionics. 22, 1781–1790 (2016)

Z. Zheng, X.D. Guo, S.L. Chou, W.B. Hua, H.K. Liu, S.X. Dou, X.S. Yang, Electrochim. Acta 191, 401–410 (2016)

L.W. Liang, K. Du, W. Lu, Z.D. Peng, Y.B. Cao, G.R. Hu, Electrochim. Acta 146, 207–217 (2014)

C.C. Pan, Y.R. Zhu, Y.C. Yang, H.S. Hou, M.J. Jing, W.X. Song, X.M. Yang, X.B. Ji, Trans. Nonferrous Met. Soc. China 26, 1396–1420 (2016)

L.W. Liang, K. Du, Z.D. Peng, Y.B. Cao, G.R. Hu, Chin. Chem. Lett. 25, 883–886 (2014)

L.W. Liang, K. Du, Z.D. Peng, Y.B. Cao, G.R. Hu, Electrochim. Acta 130, 82–89 (2014)

L.W. Liang, K. Du, Z.D. Peng, Y.B. Cao, G.R. Hu, J. Alloys Compd. 613, 296–305 (2014)

N.Y. Kim, T.E. Yim, J.H. Song, J.S. Yu, Z.H. Lee, J. Power Sources 307, 641–648 (2016)

H. Tang, J. Xu, Mater. Sci. Eng. B 178, 1503–1508 (2013)

H. Tang, M.Y. Xi, X.M. Huang, C.Q. Feng, Y. Zhang, K.L. Zhang, J. Mater. Sci. Lett. 21, 999–1001 (2002)

H. Tang, C.Q. Feng, Q. Fan, T.M. Lei, J.T. Sun, L.J. Yuan, K.L. Zhang, Chem. Lett. 2002, 822–822 (2002)

J. Yan, P. Wang, H. Fang, L.X. Wang, L. Li, H.L. Gao, L.Z. Wang, L.S. Zhang, Y.H. Song, Z.Y. Tang, Mater. Res. Bull. 106, 250–256 (2018)

X.M. Sun, S.Y. Yin, C.Q. Feng, J. Solid State Electrochem. 21, 1625–1630 (2017)

Y.J. Zhong, Z.G. Wu, J.T. Li, W. Xiang, X.D. Guo, B.H. Zhong, X.L. Wang, Ionics. 6058, 1–11 (2017)

X.Y. Huang, Q.H. Hu, J.Q. Liu, H.W. Liu, Ionics. 23, 2269–2273 (2017)

H.W. Liu, P.Y. Ji, X.Y. Han, Mater. Chem. Phys. 183, 152–157 (2016)

X.B. Zheng, X.H. Li, Z.J. Huang, B. Zhang, Z.X. Wang, H.J. Guo, Z.H. Yang, J. Alloys Compd. 644, 607–614 (2015)

L. Wang, B.R. Wu, D.B. Mu, X.J. Liu, Y.Y. Peng, H.L. Xu, L. Gai, F. Wu, J. Alloys Compd. 674, 360–367 (2016)

B. Piskin, M. Kadri-Aydino, Int. J. Hydrog. Energy 41, 9852–9859 (2016)

K.L. Cheng, D.B. Mu, B.R. Wu, L. Wang, Y. Jiang, R. Wang, Int. J. Miner. Metall. Mater. 24, 342–351 (2017)

C.C. Pan, Y.R. Zhu, Y.C. Yang, H.S. Hou, M.J. Jing, W.X. Song, X.M. Yang, X.B. Ji, Trans. Nonferrous Met. Soc. China. 26, 1396–1402 (2016)

D. Li, F. Lian, X.M. Hou, K.C. Chou, Int. J. Miner. Metall. Mater. 19, 856–862 (2012)

P. Yue, Z.X. Wang, Q. Zhang, G.C. Yan, H.J. Guo, X.H. Li, Ionics. 19, 1329–1334 (2013)

Z.Q. Chen, J. Wang, J.X. Huang, T. Fu, G.Y. Sun, S.B. Lai, R. Zhou, K. Li, J.B. Zhao, J. Power Sources. 363, 168–176 (2017)

Acknowledgements

This work was supported by the special financial grant from the Jiangxi Provincial Education Department Technology Landing Program (KJLD14008).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Xie, T., Sun, F., Zhou, X. et al. Rheological phase method synthesis of carbon-coated LiNi0.6Co0.2Mn0.2O2 as the cathode material of high-performance lithium-ion batteries. Appl. Phys. A 124, 720 (2018). https://doi.org/10.1007/s00339-018-2022-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-018-2022-6