Abstract

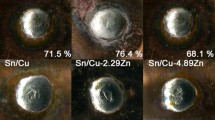

The effects of Zn (5 and 10 wt%) additions into Sn37Pb solder and isothermal solid state aging on the interfacial reactions between Sn37Pb–xZn solders and Cu substrates were investigated in this study. It was found that the addition of Zn changed the types and morphologies of interfacial IMC layers during reflowing and thereafter under aging condition. During reflowing, the planar-type Cu5Zn8 compound was the interfacial IMC for Sn37Pb–xZn (5 and 10 wt%) solder, while the scallop-type Cu6Sn5 was the interfacial IMC for Sn37Pb solder. After aging, the final interfacial structure for Sn37Pb–5Zn solder was solder/Cu5Zn8/Cu6(Sn,Zn)5/Cu, while solder/Cu6Sn5/Cu3Sn/Cu for Sn37Pb solder and solder/Cu5Zn8/Cu for Sn37Pb–10Zn solder, respectively. The Kirkendall voids disappeared with Zn addition into Sn37Pb solder. For the Sn37Pb–5Zn/Cu solder joint, the thickness of Cu6(Sn,Zn)5 layer increased, while the thickness of Cu5Zn8 layer decreased with aging time extended to 360 h due to the decomposition of the Cu5Zn8 IMC layer by diffusing Cu and Zn atoms into nether IMC layer, combining Sn atoms diffused from solder matrix to form Cu6(Sn,Zn)5 IMCs. Furthermore, the growth of Cu6Sn5 and Cu3Sn layers for Sn37Pb/Cu solder joint and the total IMC layer at the interface of Sn37Pb–xZn (x = 0, 5, and 10 wt%) solder with Cu substrate followed the diffusion control mechanism. Compared to the Sn37Pb–5Zn/Cu solder joint, higher Zn concentration depressed the growth of Cu5Zn8 layer for Sn37Pb–10Zn solder. In the end, refining effect on IMC grains was found by the addition of Zn into Sn37Pb solder and the 10 wt% Zn-doping significantly refined the interfacial IMC grains.

Similar content being viewed by others

References

L. Zhang, S.B. Xue, G. Zeng, L.L. Gao, H. Ye, Interface reaction between SnAgCu/SnAgCuCe solders and Cu substrate subjected to thermal cycling and isothermal aging. J. Alloys Compd. 510, 382–387 (2012)

C.Y. Lin, C.C. Jao, C. Lee, Y.W. Yen, The effect of non-reactive alloying elements on the growth kinetics of the intermetallic compound between liquid Sn-based eutectic solders and Ni substrates. J. Alloys Compd. 440, 333–340 (2007)

Y.C. Liang, H.W. Lin, H.P. Chen, C. Chen, K.N. Tu, Y.S. Lai, Anisotropic grain growth and crack propagation in eutectic microstructure under cyclic temperature annealing in flip-chip SnPb composite solder joints. Scrip. Mater. 69, 25–28 (2013)

K.J. Puttlitz, G.T. Galyon, Impact of the ROHS directive on high-performance electronic systems. J. Mater. Sci. Mater. Electron. 18, 331–346 (2007)

M.J. Dong, Z.M. Gao, Y.C. Liu, X. Wang, L.M. Yu, Effect of indium addition on the microstructural formation and soldered interfaces of Sn–2.5Bi–1Zn–0.3Ag lead-free solder. Int. J. Min. Metall. Mater. 19, 1029–1034 (2012)

M.H. Manhdavifard, M.F.M. Sabri, S.M. Said, D.A. Shnawah, I.A. Badruddin, S. Rozali, Effects of Fe and Bi minor alloying on mechanical, thermal, and microstructural properties of Sn–0.7Cu solder alloy. J. Electron. Mater. 45, 3671–3682 (2016)

H.R. Kotadia, O. Mokhtari, M.P. Clode, M.A. Green, S.H. Mannan, Intermetallic compound growth suppression at high temperature in SAC solders with Zn addition on Cu and Ni–P substrates. J. Alloys Compd. 511, 176–188 (2012)

R.M. Shalaby, Effect of rapid solidification on mechanical properties of a lead free Sn–3.5Ag solder. J. Alloys Compd. 505, 113–117 (2010)

Y.K. Jee, Y.H. Ko, J. Yu, Effect of rapid solidification on mechanical properties of a lead free Sn–3.5Ag solder. J. Mater. Res. 22, 1879–1887 (2007)

Y.K. Jee, J. Yu, Y.H. Ko, Effects of Zn addition on the drop reliability of Sn–3.5Ag–xZn/Ni(P) solder joints. J. Mater. Res. 22, 2776–2784 (2007)

M.G. Cho, H.Y. Kim, S. Seo, H.M. Lee, Enhancement of heterogeneous nucleation of Sn phases in Sn-rich solders by adding minor alloying elements with hexagonal closed packed structures. Appl. Phys. Lett. 95, 39–45 (2009)

S.K. Kang, D.Y. Shih, D. Leonard, D.W. Henderson, Controlling Ag3Sn plate formation in near-ternary-eutectic Sn–Ag–Cu solder by minor Zn alloying. JOM 56, 34–38 (2004)

D.H. Kim, M.G. Cho, S.K. Seo, H.M. Lee, Effects of Co addition on bulk properties of Sn–3.5Ag solder and interfacial reactions with Ni–P UBM. J. Electron. Mater. 38, 39–45 (2009)

H.R. Kotadia, O. Mokhtari, M. Bottrill, M.P. Clode, Reactions of Sn–3.5Ag-based solders containing Zn and Al additions on Cu and Ni(P) substrates. J. Electron. Mater. 39, 2720–2731 (2010)

X.W. Hu, Y.L. Li, Z.X. Min, Interfacial reaction and IMC growth between Bi-containing Sn0.7Cu solders and Cu substrate during soldering and aging. J. Alloys Compd. 582, 341–347 (2014)

A.A. El-Daly, A.M. El-Taher, Evolution of thermal property and creep resistance of Ni and Zn-doped Sn–2.0Ag–0.5Cu lead-free solders. Mater. Des. 51, 789–796 (2013)

Q.B. Tao, L. Benabou, L. Vivet, V.N. Li, F.B. Ouezdou, Effect of Ni and Sb additions and testing conditions on the mechanical properties and microstructures of lead-free solder joints. Mater. Sci. Eng. A 669, 403–416 (2016)

K. Zeng, R. Stierman, T.C. Chiu, D. Ewards, K. Ano, Kirkendall void formation in eutectic SnPb solder joints on bare Cu and its effect on joint reliability. J. Appl. Phys. 97, 024508 (2005)

J.Y. Kim, J. Yu, S.H. Kim, Effects of sulfide-forming element additions on the Kirkendall void formation and drop impact reliability of Cu/Sn–3.5Ag solder joints. Acta Mater. 57, 5001–5012 (2009)

X. Yu, X.W. Hu, Y.L. Li, R.H. Zhang, Effect of alloying Cu substrate on microstructure and coarsening behavior of Cu6Sn5 grains of soldered joints. J. Mater. Sci. Mater. Electron. 26, 2782–2794 (2015)

L. Zhang, L.L. Gao, Interfacial compounds growth of SnAgCu (nano La2O3)/Cu solder joints based on experiments and FEM. J. Alloys Compd. 635, 55–60 (2015)

M. Yang, M. Li, J. Kim, Texture evolution and its effects on growth of intermetallic compounds formed at eutectic Sn37Pb/Cu interface during solid-state aging. Intermetallics 31, 177–185 (2012)

K.N. Tu, Solder joint technology: material, properties, and reliability (Springer, New York, 2007)

W.Q. Peng, E. Monlevade, M.E. Marques, Effect of thermal aging on the interfacial structure of SnAgCu solder joints on Cu. Microelectron. Reliab. 47, 2161–2168 (2007)

C. Yu, Y. Yang, H. Lu, J.M. Chen, Effects of current stressing on formation and evolution of Kirkendall voids at Sn–3.5Ag/Cu interface. J. Electron. Mater. 39, 1309–1314 (2010)

C.Y. Liu, J.T. Chen, Y.C. Chuang, L. Ke, S.J. Wang, Electromigration-induced Kirkendall voids at the Cu/Cu3Sn interface in flip-chip Cu/Sn/Cu joints. J. Appl. Phys. Lett. 90, 337–662 (2007)

F.Y. Ouyang, C.L. Kao, In situ observation of thermomigration of Sn atoms to the hot end of 96.5Sn–3Ag–0.5Cu flip chip solder joints. J. Appl. Phys. 110, 123525 (2011)

J.Y. Kim, J. Yu, S.H. Kim, Effects of sulfide-forming element additions on the Kirkendall void formation and drop impact reliability of Cu/Sn–3.5Ag solder joints. Acta Mater. 57, 5001–5012 (2009)

W.H. Muller, K. Weinberg, On the effect of Kirkendall voids on solder joint reliability. T. Bohme. Proc. Appl. Math. Mech. 7, 4030035–4030036 (2007)

J.Y. Kim, J. Yu, S.H. Kim, Effects of sulfide-forming element additions on the Kirkendall void formation and drop impact reliability of Cu/Sn–3.5Ag solder joints. Acta Mater. 57, 5001–5012 (2009)

F.J. Wang, Z.S. Yu, K. Qi, Intermetallic compound formation at Sn–3.0Ag–0.5Cu–1.0Zn lead-free solder alloy/Cu interface during as-soldered and as-aged conditions. J. Alloys Compd. 438, 110–115 (2007)

L.J. Liu, W. Zhou, W.K. Mu, P. Wu, Interfacial reactions of Sn–3.5Ag–xZn solders and Cu substrate during liquid-state aging. J. Electron. Mater. 40, 306–314 (2011)

R. Mayappan, Z.A. Ahmad, Effect of Bi addition on the activation energy for the growth of Cu5Zn8 intermetallic in the Sn–Zn lead-free solder. Intermetallics 18, 730–735 (2010)

R. Hultgren, P.D. Desai, D.T. Hawkins, M. Gleiser, K.K. Kelley, Wiley 66, 55–98 (1972)

S.C. Yang, C.R. Kao, Selected values of thermodynamic properties of the elements. Int. Microsyst. Packag. Assem. Circuits Technol. 65, 102–105 (2007)

D.L. Ma, P. Wu, Improved microstructure and mechanical properties for Sn58Bi0.7Zn solder joint by addition of graphene nanosheets. J. Alloys Compd. 671, 127–136 (2016)

Y.C. Liu, J.B. Wan, Z.M. Gao, Intermediate decomposition of metastable Cu5Zn8 phase in the soldered Sn–Ag–Zn/Cu interface. J. Alloys Compd. 465, 205–209 (2008)

J.Y. Wang, C.F. Lin, C.M. Chen, Retarding the Cu5Zn8 phase fracture at the Sn-9wt.% Zn/Cu interface. Scripta. Mater. 64, 633–636 (2011)

D.G. Kim, S.B. Jung, Interfacial reactions and growth kinetics for intermetallic compound layer between In–48Sn solder and bare Cu substrate. J. Alloys Compd. 386, 151–156 (2005)

J. Shen, M. Zhao, P. He, Growth behaviors of intermetallic compounds at Sn–3Ag–0.5Cu/Cu interface during isothermal and non-isothermal aging. J. Alloys Compd. 574, 451–458 (2013)

M.J. Rizvi, Y.C. Chan, C. Bailey, H. Lu, M.N. Islam, Effect of adding 1wt% Bi into the Sn–2.8Ag–0.5Cu solder alloy on the intermetallic formations with Cu-substrate during soldering and isothermal aging. J. Alloys Compd. 407, 208–214 (2006)

N. Zhao, J.H. Wang, H.T. Ma, L. Wang, Interfacial reactions in Sn–xZn–Cu/Cu couples during soldering. Key Eng. Mater. 373, 543–546 (2008)

X.W. Hu, Z.R. Ke, Growth behavior of interfacial Cu–Sn intermetallic compounds of Sn/Cu reaction couples during dip soldering and aging. J. Mater. Electron. 25, 936–945 (2014)

F.J. Wang, F. Gao, X. Ma, Y.Y. Qian, Depressing effect of 0.2wt.%Zn addition into Sn–3.0Ag–0.5Cu solder alloy on the intermetallic growth with Cu substrate during isothermal aging. J. Electron. Mater. 35, 1818–1824 (2006)

Acknowledgements

This work was supported by the Nature Science Foundation of China (Nos. 51465039, 51665038, and 51765040), Nature Science Foundation of Jiangxi Province (20151BAB206041 and 20161BAB206122).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

We declare that we have no financial and personal relationships with other people or organizations that can inappropriately influence our work, there is no professional or other personal interest of any nature or kind in any product, service, and/or company that could be construed as influencing the position presented in, or the review of, the manuscript entitled, “Influence of Zn additions on the interfacial reaction and microstructure of Sn37Pb/Cu solder joints”.

Rights and permissions

About this article

Cite this article

Qiu, Y., Hu, X., Li, Y. et al. Influence of Zn additions on the interfacial reaction and microstructure of Sn37Pb/Cu solder joints. Appl. Phys. A 123, 635 (2017). https://doi.org/10.1007/s00339-017-1244-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-017-1244-3