Abstract

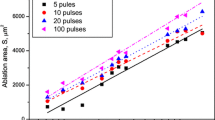

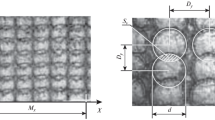

In this paper, double-pulse laser processing is experimentally studied with the aim to explore the influence of ultrashort pulses with very short time intervals on ablation efficiency and quality. For this, sequences of 50 double pulses of varied energy and inter-pulse delay, as adjusted between 400 fs and 18 ns by splitting the laser beam into two optical paths of different length, were irradiated to technical-grade stainless steel. The depth and the volume of the craters produced were measured in order to evaluate the efficiency of the ablation process; the crater quality was analyzed by SEM micrographs. The results obtained were compared with craters produced with sequences of 50 single pulses and energies equal to the double pulse. It is demonstrated that double-pulse processing cannot exceed the ablation efficiency of single pulses of optimal fluence, but the ablation crater surface formed smoother if inter-pulse delay was in the range between 10 ns and 18 ns. In addition, the influence of pulse duration and energy distribution between the individual pulses of the double pulse on ablation was studied. For very short inter-pulse delay, no significant effect of energy variation within the double pulse on removal rate was found, indicating that the double pulse acts as a big single pulse of equal energy. Further, the higher removal efficiency was achieved when double-pulse processing using femtosecond pulses instead of picosecond pulses.

Similar content being viewed by others

References

J. Schille, L. Schneider, U. Loeschner, Process optimization in high-average-power ultrashort pulse laser microfabrication: how laser process parameters influence efficiency, throughput and quality. Appl. Phys. A 120(3), 847–855 (2015)

U. Loeschner, J. Schille, A. Streek, T. Knebel, L. Hartwig, R. Hillmann, C. Endisch, High-rate laser microprocessing using a polygon scanner system. J. Laser Appl. 27, S29303 (2015)

A. Ancona, F. Roeser, K. Rademaker, J. Limpert, S. Nolte, A. Tuennermann, Opt. Exp. 16(12), 8958 (2008)

J. Schille, R. Ebert, U. Loeschner, P. Regenfuss, T. Suess, H. Exner, Micro structuring with highly repetitive ultra short laser pulses, in Proceedings of LPM2008-the 9th International Symposium on Laser Precision Microfabrication (2008), pp. 08–57

S. Panchatsharam, B. Tan, K. Venkatakrishnan, Femtosecond laser-induced shockwave formation on ablated silicon surface. J. Appl. Phys. 105(9), 093103 (2009)

J. Schille, Investigation of Micromachining Using a High Repetition Rate Femtosecond Fibre Laser, Ph.D. Thesis, The University of Manchester, UK (2013)

F. Bauer, A. Michalowski, T. Kiedrowski, S. Nolte, Heat accumulation in ultra-short pulsed scanning laser ablation of metals. Opt. Exp. 23, 1035–1043 (2015)

A. Nebel, T. Herrmann, B. Henrich, R. Knappe, Generation of tailored picosecond-pulse-trains for micro-machining. Proc. SPIE 6108, 610812-1 (2006)

B. Klimt, Micromachining with industrial picosecond lasers. Laser Tech. J. 4(1), 40–43 (2007)

R. Knappe, H. Haloui, A. Seifert, A. Weis, A. Nebel, Scaling ablation rates for picosecond lasers using burst micromachining. Proc. SPIE 7585, 75850H-1 (2010)

C. Hartmann, T. Fehr, M. Brajdic, A. Gillner, Investigation on laser micro ablation of steel using short and ultrashort IR multipulses. J. Laser Micro/Nanoeng. 2(1), 44–48 (2007)

R. Knappe, H. Haloui, A. Seifert, A. Weis, A. Nebel, Scaling ablation rates for picosecond lasers using burst micromachining, in Proceedings of SPIE, vol. 7585 (2010)

W. Hu, Y.C. Shin, G. King, Modeling of multi-burst mode pico-second laser ablation for improved material removal rate. Appl. Phys. A 98(2), 407–415 (2010)

P. Deladurantaye, A. Cournoyer, M. Drolet, L. Desbiens, D. Lemieux, M. Briand, Y. Taillon, Material micro-machining using bursts of high repetition rate picosecond pulses from a fiber laser source. Proceedings of SPIE 7914 (2011)

S. Amoruso, R. Bruzzese, X. Wang, J. Xia, Ultrafast laser ablation of metals with a pair of collinear pulses. Appl. Phys. Lett. 93, 191504 (2008)

T. Donnelly, J.G. Lunney, S. Amoruso, R. Bruzzese, X. Wang, X. Ni, Double pulse ultrafast laser ablation of nickel in vacuum. J. Appl. Phys. 106(1), 013304 (2009)

X. Zhao, Y.C. Shin, Laser–plasma interaction and plasma enhancement by ultrashort double-pulse ablation. Appl. Phys. B 120, 81–87 (2015)

A.A. Andreev, J. Limpouch, A.B. Iskakov, H. Nakano, Enhancement of x-ray line emission from plasmas produced by short high-intensity laser double pulses. Phys. Rev. E 65, 026403 (2002)

J. Semerok, C. Dutouquet, Ultrashort double pulse laser ablation of metals. Thin Solid Films 453–453, 501–505 (2004)

V. Piñon, D. Anglos, Optical emission studies of plasma induced by single and double femtosecond laser pulses. Spectrochim. Acta Part B 64, 950–960 (2009)

J. Mildner, C. Sarpe, N. Götte, M. Wollenhaupt, T. Baumert, Emission signal enhancement of laser ablation of metals (aluminum and titanium) by time delayed femtosecond double pulses from femtoseconds to nanoseconds. Appl. Surf. Sci. 302, 291–298 (2014)

X. Zhao, Y.C. Shin, Ablation enhancement of silicon by ultrashort double-pulse laser ablation. Appl. Phys. Lett. 105, 111907 (2014)

L. Jiang, H.L. Tsai, Modeling of ultrashort laser pulse-train processing of metal thin films. Int. J. Heat Mass Transf. 50, 3461–3470 (2007)

H.S. Sim, S. Park, T.H. Kim, Y.K. Choi, J.S. Lee, S.H. Lee, Femtosecond laser pulse train effect on optical characteristics and nonequilibrium heat transfer in thin metal films. Mater. Trans. 51(6), 1156–1162 (2010)

D.E. Roberts, A. du Plessis, L.R. Botha, Femtosecond laser ablation of silver foil with single and double pulses. Appl. Surf. Sci. 256, 1784–1792 (2010)

Y. Ren, J.K. Chen, Y. Zhang, Heat transfer in metal films irradiated by combined nanosecond laser pulse and femtosecond pulse train. Front Heat Mass Transf 3, 023001 (2012)

R. Le Harzic, D. Breitling, S. Sommer, C. Föhl, K. König, F. Dausinger, E. Audouard, Processing of metals by double pulses with short laser pulses. Appl. Phys. A 81(6), 1121–1125 (2005)

M.E. Povarnitsyn, T.E. Itina, M. Sentis, P.R. Levashov, K.V. Khishchenko, Simulation of ultrashort double-pulse laser ablation. Appl. Surf. Sci. 257, 5168–5171 (2011)

S. Noel, J. Hermann, Reducing nanoparticles in metal ablation plumes produced by two delayed short laser pulses. Appl. Phys. Lett. 94, 053120 (2009)

Y. Ren, C.W. Cheng, J.K. Chen, Y. Zhang, D.Y. Tzou, Thermal ablation of metal films by femtosecond laser bursts. Int. J. Therm. Sci. 70, 32–40 (2013)

C.M. Liebig, P. Srisungsitthisunti, A.M. Weiner, X. Xu, Enhanced machining of steel using femtosecond pulse pairs. Appl. Phys. A 101(3), 487–490 (2010)

J. Roth, A. Krauß, J. Lotze, H.R. Trebin, Simulation of laser ablation in aluminum: the effectivity of double pulses. Appl. Phys. A 117(4), 2207–2216 (2014)

J. Schille, L. Schneider, U. Loeschner, Process optimization in high-average-power ultrashort pulse laser microfabrication: how laser process parameters influence efficiency, throughput and quality. Appl. Phys. A 120(3), 847–855 (2015)

B. Neuenschwander, Th. Kramer, B. Lauer, B. Jaeggi, Burst mode with ps- and fs-pulses: influence on the removal rate, surface quality, and heat accumulation. Proc. SPIE 9350, 93500U-1 (2015)

M.E. Povarnitsyn, T.E. Itina, K.V. Khishchenko, P.R. Levashov, Suppression of ablation in femtosecond double-pulse experiments. Phys. Rev. Lett. 103(19), 195002 (2009)

J. Koenig, S. Nolte, A. Tuennermann, Plasma evolution during metal ablation with ultrashort laser pulses. Opt. Exp. 13, 10597–10607 (2005)

J.M. Liu, Simple technique for measurements of pulsed Gaussian-beam spot sizes. Opt. Lett. 7(5), 196–198 (1982)

G. Raciukaitis, M. Brikas, P. Gecys, B. Voisiat, M. Gedvilas, Use of high repetition rate and high power lasers in microfabrication: how to keep the efficiency high? J. Laser Micro Nanoeng. 4(3), 186 (2009)

P. Lickschat, J. Schille, M. Mueller, S. Weissmantel, G. Reisse, Comparative study on microstructuring of steel using pico- and femtosecond laser pulses. of SPIE, P14 (2012)

Acknowledgments

The presented results have been conducted in course of the projects “Innoprofile Transfer—Rapid Micro/Hochrate—Laserbearbeitung” (03IPT506X) and GROminaS (03FH037PX4) funded by the Federal Ministry of Education and Research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Schille, J., Schneider, L., Kraft, S. et al. Experimental study on double-pulse laser ablation of steel upon multiple parallel-polarized ultrashort-pulse irradiations. Appl. Phys. A 122, 644 (2016). https://doi.org/10.1007/s00339-016-0169-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-016-0169-6