Abstract

A Nd:YAG laser operating at a wavelength of 266 or 355 nm is used to deposit a thin layer of copper on the (0 0 0 1)α-Al2O3 surface. The formation process is precisely controlled by identification of time distribution of two characteristics: energy and flux density of particles incident on the substrate. For this purpose, the Cu-plasma expansion is described by means of an analytical hydrodynamic model whose self-similar solutions are fitted to the experimental plasma images and time-of-flight spectra. The obtained nanocomposite is examined by the aberration-corrected high-resolution transmission electron microscopy (Cs-HRTEM) method. The results reveal that copper crystals assume one main orientation relative to the substrate (1 1 1)[2 −1 −1]Cu\(\Vert\) (0 0 0 1)[−1 −1 2 0]α–Al2O3 and the formed interface has a specific microstructure. To reconstruct the phase boundary region, molecular dynamic (MD) and static (MS) simulations are carried out. The results show that strong bonding between copper and sapphire induces structural changes in the (1 1 1) Cu layer nearest the substrate and leads to formation of the system of partially dissociated dislocations in the next layer. In consequence, the Cu/α–Al2O3 interface becomes the semicoherent system. The lattice matching regions of the individual Cu layers are significantly lowered, which results in strong deformations along the closed packed planes. The reconstructed interface is used for Cs-HRTEM image simulation. A good accordance with the experimental results indicates that the MD model correctly maps the microstructure at the phase boundary of the synthesized nanocomposite.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

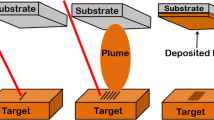

Metal/ ceramic interfaces play a key role in performance of many devices and structural elements, representative examples include: electronic packaging devices, composites, thermal barrier coatings and photovoltaic cells. Pulsed laser deposition (PLD) method enables us to control formation of this type of heterostructures. Appropriate selection of parameters as well as measurement of the energy distribution and the flux density of particles reaching the substrate allows us to avoid interface amorphization and to obtain very thin metallic layers. Deposition in a pulse mode makes it also possible to study what microstructure is preferred by a given metal/ceramic system [1].

Hetero-epitaxial copper/sapphire junctions are of particular interest because of technological applications. Their microstructure was not fully identified. The first studies of Cu/α–Al2O3 interfaces indicated that they are incoherent [2, 3]. Formation of this type of structure was justified by too large lattice-parameter mismatch. Subsequently, Oh et al. [4] showed that an appropriate treatment of the α-Al2O3 surface enables to obtain the systems with different disorientations and some of them are semicoherent. The present paper contains characterization of the microstructure identified in the series of Cu/(0 0 0 1)α–Al2O3 interfaces obtained by PLD method with varied deposition parameters.

2 Experiment

Copper target irradiation was performed with the use of an Nd:YAG laser (Quantel 981E) operating at a wavelength of 266 or 355 nm with a pulse energy of 50 mJ and 10 ns pulse duration. Repetition rate amounted to 10 Hz. A copper target of purity 99.999 % (Kurt J. Lesker) was used. It was rotated to avoid crater formation. The focal spot on the target was 2.5 mm2 and the incident angle of the laser beam was 45°. As a result, the laser fluence approximately amounted to 2 J/cm2 (intensity I = 200 MW/cm2). The deposition was made in a PLD chamber evacuated to a background pressure of 5 × 10−6 Pa. The (0 0 0 1) α-Al2O3 substrate (CrysTec GmbH) was positioned at a distance of 4 cm from the target and kept at a temperature of 1,100 K. The number of pulses changed from 12,000 to 72,000 (2 h). The deposition rate measured at room temperature was about 0.1 nm per pulse. Several steps were undertaken to avoid contamination resulting from possible copper oxidization [1]. In addition to the usual cleaning in acetone, isopropanol and deionized water as well as using a RF plasma discharge, prior to deposition the Cu target was ablated for several minutes, while the substrate was kept shielded. Later scanning transmission electron microscopy-energy dispersive X-ray (STEM–EDX) examination excluded the presence of a copper oxide layer in the obtained Cu/α–Al2O3 heterostructures.

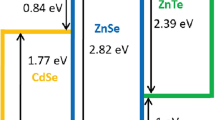

A simple analytical hydrodynamic model similar to that of Anisimov et al. [5] was used to describe the Cu-plasma expansion. The self-similar solutions of the model were fitted to the experimental plasma images and time-of-flight spectra. The model allowed us to determine the flux density of particles reaching the substrate and their energy as functions of time. The calculated particle flux density and particle energy in the case of 355 nm wavelength is shown in Fig. 1.

The synthesized Cu/α–Al2O3 nanocomposites were examined with the use of the aberration-corrected high-resolution transmission electron microscope (FEI TITAN 80-300) operating at 300 kV with spherical aberration coefficient fixed to slight negative value C s ≅ −10 μm. Thin transparent focus ion beam (FIB) lamellas from the interface regions for electron TEM observation were obtained by means of Helios Nanolab dual beam machine. The final thinning of the cross-section was performed directly on FIB applying Ga ions and acceleration voltage of 2 kV with beam current 28 pA. HRTEM investigations show that the copper layer grows in a form of islands—the Volmer–Weber growth type [6]. The Cu crystals exhibit one main orientation relative to the sapphire substrate: (1 1 1)[2 −1 −1]Cu\(\Vert\)(0 0 0 1)[−1 −1 2 0]α–Al2O3 regardless of depositions parameters. The same disorientation was obtained by Oh et al. [4] with the application of a sapphire terminated by an aluminum layer. To retrieve the interface microstructure registered in Cs-HRTEM images, MD and MS simulations are carried out.

3 Interface reconstruction

MD/MS calculations are performed for the hexagonal cell with the edge a = 128.466 Å. In the assumed system, the copper layer is negligibly compressed to match the (0 0 0 1) α–Al2O3 surface (E = −0.05 %). The considered interface contains points of lattice matching (O points [7]) which correspond to Cu atoms of the second layer above hollow sites threefold coordinated by the oxygen atoms of the terminating oxide layer. The O nodes determine a periodic cell of the semicoherent structure (a rhombus with the edge a = 74.17 Å). Additionally, in the assumed system there can be localized five O points at which the lattice matching is achieved with accuracy to 0.1 Å. The bonding between copper and sapphire is approximated by the Long and Chen model [8]. The interactions between Cu atoms are described by the Voter potential [9, 10] which is specified with the use of symmetry-based conditions [11, 12]. The equilibrium state of the heterostructure is established by means of the canonical ensemble with the assumption of the periodic conditions along the interface plane. The obtained result is confirmed by minimization of the system energy with the application of the Conjugate-gradient method (maximal force on atom is < 2 × 10−4 eV/Å). The calculations are performed with the use of LAMMPS Molecular Dynamics Simulator [13].

Hexagonal symmetry (P6mm) of the individual layers of the initial system results in a set of particular force systems in lattice matching points of the first Cu layer (the resultant and moment perpendicular to the interface). In consequence, each three Cu atoms arranged around the coherency sites undergo rotation (α = 33.5°) and displacement towards the sapphire surface. Finally, the first Cu layer forms the lattice matching regions with the altered symmetry. They are incorporated in the sapphire structure. Besides these regions, the higher situated zones constituting A layers of the face centered cubic (fcc) structure are present (see Fig. 2a). In the second Cu layer, development of lattice matching regions leads to formation of a system of dislocations which are partially dissociated. The structural changes in the first copper layer as well as interactions with O and Al atoms induce lowering the areas surrounding the O nodes (Fig. 2b). As a result, successive Cu layers undergo bending, which is accompanied by significant deformations along the closed packed planes (−1 1 1), (1 −1 1) and (1 1 −1) (see Figs. 2b, 3).

For the relaxed heterostructure HRTEM image simulation is performed with the use of a multislice algorithm and QSTEM software. The best matching between the experimental and simulated image is obtained for the following parameters: foil thickness t = 9.8 nm, beam tilt = 4 mrad in x and y direction, C s = −10 μm, focal spread = 4 nm, convergence of incident beam = 1.2 mrad, defocus = 3 nm, and energy dispersion of the electron beam = 1.2 eV. The simulated image exhibits a good agreement with the experimental one (see Fig. 4). Thus, the obtained reconstruction captures key features of the Cu/(0 0 0 1)α–Al2O3 interface formed by PLD method. The comparison of the atomistic model with Cs-HRTEM image is presented in Fig. 5.

4 Summary

The Cu/α–Al2O3 nanocomposite was formed with the use of PLD method. The HRTEM studies revealed that, the copper grains exhibit one main orientation relative to the sapphire substrate: (1 1 1)[2 −1 −1]Cu\(\Vert\)(0 0 0 1)[−1 −1 2 0] α-Al2O3. To obtain an accurate characterization of the phase boundary, MD/MS simulations were carried out. They show that the copper layer forms strong bonding with the (0 0 0 1) sapphire substrate, which results in the semicoherent interface. In lattice matching regions, Cu atoms displace towards the α-Al2O3 surface. As a result, the first Cu layer undergoes structural changes and farther ones bend. Due to fitting, the system of partially dissociated dislocations forms in the second Cu layer. The obtained reconstruction captures key features of the synthesized Cu/(0 0 0 1)α–Al2O3 interface. The confirmation is a good agreement between HRTEM image simulation performed for the presented model and the experimental results.

References

H.H. Liu, N. Pryds, J. Schou, X. Huang, Appl. Phys. A 101, 677 (2010)

G. Dehm, C. Scheu, G. Möbus, R. Brydson, M. Rühle, Ultramicroscopy 67, 207 (1997)

Sasaki T, Matsunaga K, Ohta H, Hosono H, Yamamoto T, Ikuhara Y, Sci. Technol. Adv. Mater. 4, 575 (2003)

S. Oh, C. Scheu, T. Wagner, M. Rühle, Appl. Phys. Lett. 91, 141912 (2007)

S.I. Anisimov, D. Bäuerle, B.S. Lukyanchuk, Phys. Rev. B 48, 12076 (1993)

Ed. by R. Eason, Pulsed Laser Deposition of Thin Films: Applications-led Growth of Functional Materials (Wiley, Hoboken, 2007)

W. Bollmann, Crystal Defects and Crystalline Interfaces (Springer, New York, 1970)

Y. Long, N.X. Chen, J. Phys. Condens. Matter. 21, 315003 (2009)

A.F. Voter, Los Alamos Unclassified Technical Report No. LA-UR 93-3901 (1993)

Y. Mishin, M.J. Mehl, D.A. Papaconstantopoulos, A.F. Voter, J.D. Kress, Phys. Rev. B 63, 224106 (2001)

K. Nalepka, Comp. Mater. Sci. 56, 100 (2012)

K. Nalepka, Bull. Pol. Ac. Tech. 61, 441 (2013)

Plimpton S, Fast parallel algorithms for short-range molecular dynamics. J. Comp. Phys. 117, 1 (1995)

Acknowledgments

This work was supported, within the framework of the Project N N501 156638, by the National Science Centre (NCN) in Poland. The TEM investigations were performed with the use of the infrastructure funded by European Regional Development Fund within the Innovative Economy Operational Programme 2007–2013 ‘Analytical high resolution transmission electron microscope for nanoscience, nanotechnology and spintronics’, No. POIG.02.01-00-14-032/08.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Nalepka, K., Hoffman, J., Kret, S. et al. Laser-deposited Cu/α–Al2O3 nanocomposite: experiment and modeling. Appl. Phys. A 117, 169–173 (2014). https://doi.org/10.1007/s00339-014-8317-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00339-014-8317-3