Abstract

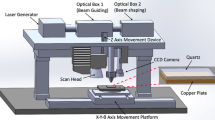

Pyrex glass etching using laser ablation is an important technology for the microfluid application to lab-on-a-chip devices but suffers from the formation of surface crack. In this article, the addition of nonionic surfactant to water for glass ablation using water-assisted CO2 laser processing (WACLAP) has been investigated to enhance ablation rate and to eliminate conventional surface defects of cracks in air. WACLAP for Pyrex glass ablation can reduce thermal-stress-induced crack with water cooling and hydrophilic nonionic surfactant to water can enhance ablation performance. Compared to pure water, the 15% weight percent Lauramidopropyl Betaine surfactant solutions for WACLAP can enhance ablation rate from 13.6 to 25 μm/pass of Pyrex glass ablation at a linear laser energy density of 2.11 J/cm, i.e., 24 W power, 114 mm/s scanning speed, and obtain through-wafer etching at 3.16 J/cm for 20 passes without cracks on the surface. Effect of surfactant concentration and linear energy density on WACLAP was also examined. The possible mechanism of surfactant-enhanced phenomenon was discussed by the Newton’s law of viscosity of surfactant solution.

Similar content being viewed by others

References

T. Cormany, P. Enoksson, G. Stemme, J. Micromech. Microeng. 8, 84 (1998)

S.W. Youn, C.G. Kang, Scr. Mater. 52, 117 (2005)

X. Li, T. Abe, M. Esashi, Sens. Actuators A 87, 139 (2001)

M.J. Madou, Fundamentals of Microfabrication, 2nd edn. (CRC Press, New York, 2002), p. 590

K. Zimmer, A. Braun, R. Böhme, Appl. Surf. Sci. 208–209, 199 (2003)

A. Ben-Yakar, A. Harkin, J. Ashmore, R.L. Byer, H.A. Stone, J. Phys. D 40, 1447 (2007)

Y. Hanada, K. Sugioka, H. Kawano, I.S. Ishikawa, A. Miyawaki, K. Midorikawa, Biomed. Microdevies 10, 403 (2008)

J. Zhao, J. Sullivan, T.D. Bennett, Appl. Surf. Sci. 225, 250 (2004)

G. Allcock, P.E. Dyer, G. Elliner, H.V. Snelling, J. Appl. Phys. 78, 7295 (1995)

A. Kruusing, Opt. Lasers Eng. 41, 329 (2004)

C.K. Chung, Y.C. Sung, G.R. Huang, E.J. Hsiao, W.H. Lin, S.L. Lin, Appl. Phys. A 94, 927 (2009)

A. Kruusing, Opt. Lasers Eng. 41, 307 (2004)

R.E. Mueller, J. Bird, W.W. Duley, J. Appl. Phys. 71, 551 (1992)

G.A. Shafeev, A.V. Simakhin, Appl. Phys. A 54, 311 (1992)

G.A. Shafeev, A.V. Simakhin, Laser Phys. 4, 631 (1994)

F. Mafuné, J. Kohno, Y. Takeda, T. Kondow, J. Phys. Chem. B 105, 5114 (2001)

F. Mafuné, J. Kohno, Y. Takeda, T. Kondow, J. Phys. Chem. B 104, 9111 (2000)

Deborah D. L. Chung, Materials for Electronic Packaging (1995), p. 218

C.K. Chung, M.Y. Wu, Opt. Express 15, 7269 (2007)

http://chemicalland21.com/specialtychem/perchem/LAURAMIDOPROPYL%20BETAINE.htm

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chung, C.K., Liao, M.W. & Lin, S.L. Effect of nonionic surfactant addition on Pyrex glass ablation using water-assisted CO2 laser processing. Appl. Phys. A 99, 285–290 (2010). https://doi.org/10.1007/s00339-009-5522-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00339-009-5522-6