Abstract

In this study, magnetic material was synthesized using iron salts, then silicon-specific material was used to gain porosity, straight-chain polyacrylamide (PAM) was modified to give the surface functional properties, and the final product synthesized Fe3O4/SiO2/PAM nanocomposite material. Heavy metal (Pb and Cd) removal studies were carried out with the synthesized composite material, considering the central composite design and response surface methodology (CCD-RSM) optimization model. The effects of various parameters, for example, the initial concentration, pH, adsorbent dose, temperature and contact time, were investigated as a part of this study. To optimize these parameters, the CCD-RSM model was applied to design the experiments. Analysis of variance (ANOVA) was applied to evaluate statistical parameters and investigate interactions of variables. In the designed experimental set, the amount of adsorbent (30 mg), pH 7.0 value, temperature (40 °C), initial concentration of Pb (80 mg/L) and Cd (20 mg/L) and 90 min contact time were determined as the optimum conditions. The high coefficient of determination of both metals showed good agreement between experimental results and predicted values (R2 0.99; 0.95). TEM, SEM, XRD, FTIR, BET and Zeta potential analyses were performed to characterize the structure and morphology of the adsorbent. In Pb2+ and Cd2+ heavy metal removal studies, maximum adsorption capacities were determined as 66.54 and 13.22 mg/g, respectively. Additionally, adsorption isotherms, adsorption kinetics and thermodynamic modeling studies were conducted. Features such as large surface area and high adsorption capacity of the synthesized nanoparticles were observed. In this study, Fe3O4/SiO2/PAM demonstrated its potential as an effective adsorbent for the removal of heavy metal ions present in simulated wastewater samples. In particular, we can say that the material has a strong selectivity, as well as a high affinity for Pb(II) ions.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Wastewater generated as a result of industrial, agricultural and human activities causes contamination of water resources and environmental pollution. The presence of toxic and hazardous heavy metals can cause serious negative impacts on the environment and human health. For decades, the excessive release of heavy metals into both surface and ground water resources has raised serious concerns among researchers around the world [1]. Unlike organic pollutants, heavy metals are not biodegradable and tend to accumulate in living organisms. Also, many heavy metal ions are known to be toxic or carcinogenic [2]. Therefore, water pollution with different heavy metals such as lead (Pb) and cadmium (Cd) has become a serious issue that needs to be addressed due to their high toxic risks for the environment and human health [3, 4]. It is known that long-term exposure to heavy metals can cause diseases such as cancer, systemic sclerosis or diabetes. Heavy metals such as lead and cadmium, which can significantly pollute the environment, are among the most toxic elements according to the ATSDR (Agency for toxic substances and disease registry) [5]. Accordingly, removing or reducing toxic ions from industrial wastewater is becoming increasingly important. Common techniques used to remove metal ions from wastewater include precipitation, ion exchange, adsorption, filtration and electrolytic processes. Among these methods, adsorption is widely used due to its low economic cost and easy recovery [6, 7]. In adsorption, the presence of chemical functional groups on the adsorbent surface is an important factor affecting the adsorption process [8]. Especially in adsorption applications, modification processes with organic functional groups can be widely used to increase the surface stability of magnetic nanoparticles and reduce the phenomenon of agglomeration [9]. The most basic thing to consider here is that materials and methods that are environmentally friendly, have low economic value and have high performance should be preferred [10, 11].

Nanostructured adsorbents are thought to provide much higher efficiency and faster adsorption in environmental treatment compared to traditional adsorbent materials [12, 13]. The usability of magnetic nanoparticles in the adsorption process is possible by increasing the adsorption capacity, surface activation and improving chemical stability. Here, modification, easy removal and reusability are among the most important issues that should be emphasized.

Superparamagnetic materials to be prepared using metal ions have (1) superparamagnetic properties, (2) high dispersibility, (3) stability, (4) large surface area, (5) ease of synthesis, (6) ultrafine particle size and (7) surface modification. They are effective adsorbents for the treatment of wastewater containing heavy metal ions [14, 15]. However, its direct application may limit its use in some cases due to various facts such as (1) reduction of surface area due to inevitable agglomeration, (2) uncertainty due to environmental settings, (3) toxicity, (4) leaching and (5) oxidation [16, 17]. To overcome this situation, coating its surface with non-magnetic shell (encapsulation of magnetic particles with organic or inorganic materials) is an attractive way to overcome the above-mentioned problems. This may also lead to a decrease in the toxicity of the magnetic material, its biocompatibility and an increase in its performance [18, 19].

In studies on the subject, it is seen that polymer-based materials can be highly preferred due to their adsorption properties and use for modification purposes [20]. After the Fe3O4 composite material is given magnetic properties, it can be easily removed from the aqueous environment. Fe3O4 has the potential to overcome many limitations in applications and provide more effective advantages. Non-toxic silica is a very excellent surface coating material for magnetic nanoparticles, forming an external protective layer to protect magnetic nanoparticles. Additionally, high-yield composite materials can be synthesized by coating polymer on Fe3O4/SiO2. Polyacrylamide [PAM, (C3H5NO)n] has a linear chain structure and is highly water absorbent and has the ability to form a soft gel when hydrated. Due to this feature, it has been transformed into a superior nanocomposite by adding it to previously synthesized magnetic silicate nanomaterial. It is thought that obtaining a porous material with high solid/liquid interface activity by synthesizing Fe3O4/SiO2/PAM is very high as a result of various variations. In the similar studies, since the interaction of SiO2 and Fe3O4 gives the material a core–shell feature, it increases the adsorption feature of the composite material [21]. Additionally, considering that Fe3O4 nanoparticles may cause instability in acidic solution and their applications may be limited, there are studies showing that silica layer and PAM materials can provide more protection and effectiveness to the magnetic particle.

In the presented study, Fe3O4/SiO2/PAM magnetic nanoadsorbent material was synthesized, characterized and used as an adsorbent material in the removal of Pb2+ and Cd2+ ions from water samples. Modifying the Fe3O4/SiO2 material surface by synthesizing straight-chain polyacrylamide is a unique situation in the literature. The functional groups provided by the straight-chain polymer provide active sites specific to the surface area of the synthesized material. In the presented study, it was aimed to develop a selective material with adsorbent and functional groups that can be easily removed by the effect of magnetic field in aqueous environment. Therefore, this situation constituted the purpose and originality of our study.

The adsorption capacity of the material was examined using the CCD-RSM experimental design optimization model on Pb2+ and Cd2+ adsorption, considering parameters such as pH, initial metal concentration, adsorbent dosage, temperature and contact time. Adsorption isotherm models and kinetic and thermodynamic studies were conducted to determine the adsorption behavior of Fe3O4/SiO2/PAM nanoadsorbent material.

Materials and methods

Reagents

The reagents used in the experiments were obtained commercially. Iron (III) nitrate nonahydrate (Fe(NO3)3·9H2O), iron(II) sulfate heptahydrate (FeSO4·7H2O), ammonia solution (NH4OH 25%), tetraethyl orthosilicate (TEOS), polyvinyl pyrrolidone (PVP), toluene (C6H5CH3), magnesium sulfate (MgSO4), acrylamide (C3H5NO) and benzoyl peroxide (C14H10O4) were supplied by Sigma-Aldrich. Pb(II) and Cd(II) standard solutions were purchased from Merck. Purchased analytical grade chemicals (99%) were used as received without any further processing. Ultrapure water (18.2 mω cm) was used to prepare the working solution in all experiments.

Polyacrylamide (PAM) synthesis

Toluene, which was used as a solvent in the experiment, was dried with anhydrous MgSO4 to remove any traces of water it might contain. The system was placed in a water bath, and when the temperature was fixed at 80 °C, acrylamide (14.21 g) was added to the solvent and the mixture was mixed for 10 min. Then, (0.40 g) benzoyl peroxide (BPO) was dissolved in 20 ml toluene and added to the reaction medium. Polymerization started with the addition of initiator (BPO). During the reaction, nitrogen gas was passed through the system and the polymerization was terminated by mixing for approximately 3 h. Polyacrylamide, which is insoluble in toluene, was washed 3–4 times with hot toluene to remove excess initiator. The washed polymer was dried in an oven at 60–65 °C for approximately 3–4 days to remove its solvent. The scheme of the synthesized polymer is given in Fig. 1.

Fe3O4 synthesis

Fe3O4 nanoparticles have been traditionally synthesized by coprecipitation method. First of all, the amounts of chemicals that will react are calculated. The experimental process was started by using a 16.16 g Fe(NO3)3 and 5.56 g FeSO4 salts in 100 mL of distilled water. This process was carried out with the help of a sonicator to ensure maximum interaction in terms of homogeneity and degradability. After obtaining a homogeneous mixture, 25% NH3 solution was added until it turned black, slowly dropping it to pH 10, and stirred for two hours at room temperature. Afterward, the prepared magnetic nanoparticles were separated from the solution with a magnet, washed with ethanol and deionized water and then dried under vacuum at 60 °C. Thus, Fe3O4 nanoparticles were obtained.

Fe3O4/SiO2 synthesis

The synthesis of Fe3O4/SiO2 was carried out using a method described by [20]. Accordingly, 1.0 g of Fe3O4 nanoparticles were added to 50 mL of distilled water and dispersed, and then 2 mL of tetraethylorthosilicate (TEOS) was added to this mixture. Then, 25 mL NaOH (0.1 M) was added dropwise while stirring at room temperature and stirred at 40 °C for one hour. Finally, Fe3O4/SiO2 nanoparticles were washed several times with pure water and dried under vacuum at 60 °C.

Fe3O4/SiO2/PAM synthesis

0.2 g of the polyacrylamide (PAM) sample with a straight-chain structure, which was briefly explained above and synthesized in this context, was taken and dissolved in 100 ml of water for approximately 30 min. Then, 0.2 g of Fe3O4/SiO2 nanoparticles was added to this mixture and mixed. Afterward, 0.3 g of polyvinylpyrrolidone (PVP) was added and mixed for 5 h and washed several times with pure water. The obtained samples were dried under vacuum at 60 °C and stored away from light. The schematic situation of the prepared polymeric material is given in Fig. 2.

Characterization process

A comprehensive characterization study of the synthesized Fe3O4/SiO2/PAM material was carried out using various analytical techniques. To examine the material morphologically, elementally and structurally, JEOL JEM 1220 device was used for TEM analysis and Rigaku Smart-Lab X-Ray Diffractometer device was used for XRD analysis of phase changes in the samples. For SEM analyses, JEOL brand JSM-7600F model, Thermo Scientific, Nicolet Is10, was used for FTIR spectra (in the range of 400–4000 cm−1), Zeta potential and mobility measurement device (MALVERN Nano ZS90) was used to determine the isoelectric point of the adsorbent, and MICROMERITICS GEMINI VII 2390t (BET) Device was used for surface area measurements. In all adsorption experiments, it was used the ZHWY-200D Incubator device with adjustable temperature and shaking speeds. The Agilent 240FS AA atomic absorption spectrophotometer was used for heavy metal analysis.

Adsorption experiments

The removal of Pb2+ and Cd2+ ions was carried out to evaluate the adsorption efficiency of the synthesized adsorbent. Adsorption experiments designed by CCD-RSM are an effective method for modeling and optimizing various parameters affecting the adsorption of metals. These parameters include initial concentration, pH value, amount of adsorbent, temperature and contact time. Trace amounts of 0.1 M NaOH and 0.1 M HCl were used to adjust the suspension pH. All adsorption experiments were carried out with the help of an Incubator device with a constant stirring speed of 130 rpm. Concentrations of metal ions were determined using atomic absorption spectrophotometry. The adsorption capacity (amount of metal ions adsorbed per unit mass) was calculated according to Eq. 1.

Here, qe is the adsorption capacity of the synthesized adsorbent (mg/g), Co and Ce are the initial concentration and equilibrium concentration of ions (mg/L), respectively, V is the solution volume (L), and m is the amount of adsorbent (g).

Experimental design and central composite design (CCD)

The experimental design was considered to optimize the critical parameters affecting the response function by simultaneously changing them and to improve the experimental result by performing a limited number of trials [22, 23]. The CCD-RSM method was applied to the experimental design to improve the removal performance as a response function and optimize the influencing parameters. Adsorbent amount (A), temperature (B), contact time (C), pH (D) and initial concentration (E) constitute the main parameters of the experimental design. Dependent variables were designed by coding lead (Pb: R1) and cadmium (Cd: R2). The total number of experiments to be performed on the CCD was obtained using the following formula:

Here, k is the number of independent parameters and L is the number of central points. Forty-four trials were designed using this equation. Two of the trial numbers were considered central points to reduce experimental errors. A quadratic polynomial regression equation was used to relate the response variable to the independent variables.

In this equation, Y represents the response function, while β0 is a constant coefficient. “k” represents the total number of variables, and Xi and Xj denote the independent variables (C0, pH, mg, T and t). βi is the ith coefficient of linearity, βii represents the quadratic coefficient, βij is linear with the linear interaction coefficient, and ε is a random error. Analysis of variance (ANOVA) was used to evaluate the regression mathematical model for statistical significance. CCD-RSM was examined using DesignExpert software version 12 for statistical and graphical analysis of experimental data.

The adsorption experimental design and levels of independent parameters are given in Table 1. As seen in Table 1, five coded levels were studied using the CCD method: − α, − 1, 0, + 1 and + α, to which the parameter levels are related. For each parameter, + α indicates the highest level, 0 indicates the middle level, and −α indicates the lowest level.

Results and discussion

Characterization of Fe3O4/SiO2/PAM nanoadsorbent material

Various analytical techniques, for example, TEM, SEM, XRD, FTIR, Zeta potential and BET analyses, were used to characterize the structure and morphology of the Fe3O4/SiO2/PAM nanoadsorbent material. The relevant results are presented below.

In Fig. 3, the TEM images of the all material samples are given. As can be seen from the figure, bare Fe3O4 shows nanorods structure and lower aggregation with regular orders. Also, TEM images of Fe3O4/SiO2 samples typically show dark, roughly rods-shaped Fe3O4 nanoparticles embedded in a lighter, more diffuse SiO2 matrix. The contrast between the Fe3O4 and SiO2 phases in TEM images is due to the difference in their electron density. Fe3O4 is more electron-dense than SiO2, so it scatters electrons more strongly and appears darker in the image. When PAM-supported Fe3O4/SiO2 (Fe3O4/SiO2/PAM) materials were evaluated, Fe3O4 and SiO2 morphology did not change and PAM has created a nebular image. The reason for this is beam sensitivity and low electron density. Beam damage manifests as blurred edges, holes or even complete disintegration of the polymer regions in the image. Lower electron density results in weaker scattering, leading to a faint and less defined appearance compared to the other phases.

Changes in the surface morphology of adsorbents can provide certain information about the adhesion characteristics and mechanism. SEM and EDS results of adsorbents in the presented study are given in Fig. 4.

It can be seen from Fig. 4a, b and c that Fe3O4/SiO2/PAM presents a regular spherical shape, and the magnetic particles do not have any breaking phenomenon. From comparing B and C, the decrease in mesopores shows that it is due to the adsorbed mass of adsorbates in the mesopores, which is consistent with the TEM results. EDS is widely used to determine the elemental composition, content, chemical value and chemical bonding properties of materials.

The size of nanoparticles was measured from the SEM micrograph using ImageJ software. It can be seen that the particle size of Fe3O4, Fe3O4/SiO2 and Fe3O4/SiO2/PAM is 22.27 ± 8.25, 26.52 ± 4.11 and 19.18 ± 3.11 nm, respectively. The increased size of Fe3O4 nanoparticles is explained by the SiO2 coating. However, a decrease in particle sizes was observed later. This decrease was observed as a result of Fe3O4/SiO2/PAM reaching a porous and porous structure as a result of being coated with PAM.

Figure 5a shows the XRD pattern of the samples. As seen from the figure, four peaks of two theta degrees at 30.04, 35.44, 57.14 and 62.74 have been attributed to the pure Fe3O4 with 220, 311, 511 and 440 planes, respectively. The X-ray analysis revealed that the nanoparticles made by the sol–gel method possessed a specific arrangement of atoms known as the “spinel magnetite” cubic crystal structure [24]. For magnetite Fe3O4 particles have a fairly high suitability between the peaks that appear in the sample with the literature Joint Committee on Powder Diffraction Standards (JCPDS) 19–0629. These same peaks were also observed in another sample containing Fe3O4 nanoparticles coated with silica (Fe3O4/SiO2). This suggests that even with an outer layer, the core of the nanoparticles still retains the characteristic Fe3O4 structure. However, there was another angle to consider: 2θ = 21.07°. This peak didn't fit the typical Fe3O4 fingerprint. This additional peak could be attributed to the presence of amorphous SiO2. As known, Fe3O4 nanoparticles were coated with SiO2. While the core remained Fe3O4, the presence of this peak suggests that the coating wasn't entirely crystalline (ordered), but potentially had some non-crystalline (amorphous) regions as well [25]. In order to see the peaks more clearly in the XRD analysis for PAM, spectra between 20° and 25°are shown in Fig. 5b. The X-ray diffraction pattern of polyacrylamide (PAM) appears as a blurry "bump" instead of sharp peaks (Fig. 5b). This “bump” tells us that the polymer doesn't have a well-defined, ordered structure like a crystal, but rather a more disorganized, random arrangement of molecules that is amorphous structure.

Crystallite sizes were calculated using Scherrer equation given below:

where d is the crystal size, K is a constant (0.89), k is the wavelength of X-ray, β is the full width of half maximum (FWHM) and θ is the diffraction angle. The most intense peak was referenced to calculate the average crystallite size of the samples. The average crystallite size of the samples was calculated as 0.234, 0.255 and 0.256 nm, respectively. This indicates that the crystallite size of the Fe3O4 did not change indicating SiO2 forms a shell around the existing Fe3O4 crystals. This shell acts as a barrier, preventing the Fe3O4 crystals from growing or shrinking significantly. Similarly, since the polyacrylamide is added after the Fe3O4/SiO2 crystals have already formed, it won't affect the Fe3O4/SiO2 size.

Figure 6 presents the FTIR spectra of the all samples. In Fig. 6, the observed peaks at 632 cm−1 N–H bending, 1114 cm−1 C–N stretching, 1442 cm−1 C = O stretching (amide I), 1672 cm−1 N–H bending, (amide II), 2944 cm−1 C–H stretching, 3184 cm−1 C = O stretching (amide III) and 3409 cm−1 O–H stretching are shown, respectively [26].

Also, the FTIR peak of the pure Fe3O4 shows five characteristic peaks at 576 cm−1 Fe–O, stretching, 887 cm−1 Fe–O–Fe bending, 1384 cm−1 multiple modes (including Fe–O stretching and O–Fe–O bending), 1631 cm−1 O–H bending and 3386 cm−1 O–H stretching (adsorbed water), respectively [27].

In the FTIR of Fe3O4/SiO2, the peak at 557 cm−1 displays the Fe–O–Si stretching. This mode arises from the vibrations between the iron (Fe) and oxygen (O) atoms that are bonded to silicon (Si) atoms. In addition, another peak is at 1062 cm−1 Si–O stretching. It originates from the vibrations between the silicon (Si) and oxygen (O) atoms within the SiO2 component of the material. For FTIR spectra of Fe3O4/SiO2/PAM, the monitoring four peaks at 566, 800, 1062 and 1643 cm−1 can be attributed to the above stretching and bending vibration with some shifting [28]. The shift observed in the peak position in the FTIR spectra can be connected to the change in bond length. When Fe3O4 interacts with SiO2, the Fe–O bond length involved in the vibration responsible for the peak can change. This change in bond length affects the vibrational frequency, resulting in a shift in the peak position. In this case, the Fe–O bond length may be slightly longer in Fe3O4/SiO2 compared to pure Fe3O4, leading to a lower vibrational frequency (lower wavenumber) and the observed shift to 557 cm−1.

A negative zeta potential value indicates that the surface of a particle or colloid in a suspension has a net negative charge. This net charge arises from the distribution of ions around the particle's surface. Generally, a stronger negative value signifies a stronger repulsion between particles, preventing them from aggregating and potentially leading to stability in the suspension [29]. Zeta potential data of the characterized and synthesized materials are given in Fig. 7.

From Fig. 7, the zeta potential of the Fe3O4/SiO2 and Fe3O4/SiO2/PAM was − 30.1 and − 9.19 mV, respectively. The net surface charge of the synthesized particles is negative. This result also allowed more efficient adsorption of positively charged metal ions. In addition, when the Fe3O4/SiO2 surface was supported with PAM, the net surface negative charge value changed significantly toward positive axis indicating that the polymeric material PAM was effectively dispersed on the Fe3O4/SiO2 surface.

The BET surface area is a measure of the total surface area of a material, including both external and internal surface area. The Langmuir surface area is a measure of the external surface area of a material, which is the surface area that is accessible to gas molecules. As you can see in Table 2, the BET surface area of all three materials is greater than the Langmuir surface area. This is because the BET surface area includes the surface area of both the external and internal pores of the materials, while the Langmuir surface area only includes the surface area of the external pores. The material with the highest BET surface area and Langmuir surface area is Fe3O4, followed by Fe3O4/SiO2/PAM, and then Fe3O4/SiO2, respectively. This suggests that Fe3O4 has the most pores and external surface area than that of the others. In addition, the PAM resulted in an increase in the surface area of the material compared to Fe3O4/SiO2. This result was due to the efficient interaction of the polymer material with Fe3O4/SiO2, which resulted in an even greater increase in the adorable branching on the particle surface.

The pore and pore distributions of the materials are examined, and the results are given in Fig. 8. According to the International Union of Pure and Applied Chemistry (IUPAC) classification, if the diameters of the particles are less than 2 nm, between 2 and 50 nm and greater than 50 nm, they are classified as microporous, mesoporous and macroporous groups, respectively [30]. In general, it is seen that the pore diameters in all samples are in the range of 19.00–26.52 nm. This means that the adsorption process occurs mainly in physical form, and it is thought that the material modified with iron oxide and silicate and containing certain functional groups on the surface can have a high adsorption capacity even if the surface area is reduced. Moreover, N2 adsorption–desorption is approximately equal for all materials examined. It is reported that the IUPAC classification belongs to type IV, whose N2 adsorption–desorption isotherm corresponds to the mesoporous nature of adsorbents [31].

Statistical analysis of adsorption studies

The effect of the parameters on Pb2+ and Cd2+ ions of the Fe3O4/SiO2/PAM nanoadsorbent material was optimized, and its adsorption properties were examined. The second order describing the interrelationships between the experimental parameters and the response function was obtained as Eqs. 5 and 6 for Pb (II) and Cd (II):

Here Yqe is the adsorption capacity of the adsorbent material for Pb(II) and Cd(II). Adsorbent amount (A), temperature (B), contact time (C), pH (D) and initial concentration (E) are coded independent variables. The quadratic model was chosen to describe the effects of variables on heavy metal adsorption capacities. In Table 3, forty-four trial runs designed in CCD were completed and adsorption capacities for Pb2+ and Cd2+ were determined (Table 3). To evaluate the model obtained from CCD-RSM, analysis of variance (ANOVA) test of both heavy metals was performed (Tables 3 and 4).

Analysis of variance (ANOVA) was used to clarify the significance of the parameters and the adequacy of the model obtained from CCD-RSM. In studies conducted for both metals, the significance of the parameters and the adequacy of the quadratic regression model were confirmed by a small p value (< 0.0001). The significance of the model coefficients was evaluated by considering F and p values [32]. The fact that the F values of the model are high, 95.03 (Pb) and 23.45 (Cd), shows that the model is significant (Table 5). Model category explains a large portion of the total variance and is statistically significant. The p values of the model are less than 0.05, indicating that the independent variables of the model have a significant effect on the response variable. In particular, the selected variables A, D, E, AE, A2, E2 for Pb adsorption capacity and A, B, D, E, AD, AE, BC, DE, A2 for Cd and some interactions are significant model terms. The fact that some values are greater than 0.1000 indicates that the model terms are not significant. The high coefficients of determination of Pb (R2 0.99) and Cd (R2 0.95) indicate good correlation fit between the actual and predicted values of the response. Therefore, we can say that the model fits the experimental data, considering the significant effects of the independent variables or parameters on the response.

The standard deviation of the model is determined as 2.42 (Pb) and 0.75 (Cd) and is shown in Table 6. The estimated R2 of 0.9460 for Pb is in reasonable agreement with the adjusted R2 of 0.9776, and the estimated R2 of 0.8100 for Cd is in reasonable agreement with the adjusted R2 of 0.9126. The difference between them being less than 0.2 indicates the closeness of the model's predicted values to the response values. Accuracy rates of 30.847 (Pb) and 20.106 (Cd) for both metals, respectively, indicate high signal-to-noise ratio. The fact that these ratios are higher than 4 indicates the statistical suitability of the model.

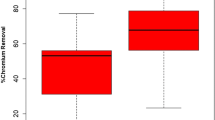

Figure 9a, b visually shows the normal percentage probability plot of the experimental capacity residuals. These graphs indicate how well the data obtained in the experiments fit the normal distribution. The fact that the points are approximately on the line shows that the data are closer to normal distribution [33]. This confirms that the data have a normal distribution. We can evaluate the agreement between predicted values and actual values according to Fig. 9c, d. The distribution of points close to the line indicates a difference between the actual values of adsorption capacities and the predicted values.

A distance indicates harmony, while a distance indicates deviation. In conclusion, both graphs were useful for visual analysis and provided important information for interpreting the experimental results.

Effects of selected parameters on adsorption

The effects of Fe3O4/SiO2/PAM nanoadsorbent material on Pb2+ and Cd2+ adsorption capacities were analyzed with 3D surface graphics. Simultaneous optimization of the parameters and the effects of the designed variables on the response function are shown in Fig. 10.

Initial pH effect

The pH effect of Fe3O4/SiO2/PAM nanoadsorbent material on Pb2+ and Cd2+ adsorption is shown in Fig. 10a and d. Solution pH is an important parameter that affects the qe values of adsorbents by determining the presence and effectiveness of active sites on the nanoadsorbent [34]. A pH range of 4–8 was designed by CCD-RSM to determine the optimum conditions for both heavy metals. By increasing the pH values from 4 to 8, the adsorption capacity for Pb2+ increased from 21 to 37 mg/g, and for Cd2+ from 3.5 to 7.6 mg/g. Briefly, it was observed that Pb2+ and Cd2+ adsorption capacities showed an increasing and then decreasing trend with the increase of pH from 4 to 8. The maximum qe value was obtained at pH 7, and the adsorption capacity reached saturation above pH 7. At high pH values, a decrease in qe values was observed as a result of the formation of various metal complex ions or Pb2+ and Cd2+ precipitates. Another factor that determines pH range effectiveness is the adsorbent surface charge. Considering zeta potential measurements, it reveals that there is interaction between the negatively charged adsorbent surface and positively charged heavy metal ions at neutral pH. Therefore, the optimum value of pH 7 for both metals reflects a situation confirming this interaction.

Also, the low removal at low pH values can be explained by the presence of protons in the environment. It is expected that the surface of the polymer-coated material will be positive at low pH, adsorbent–adsorbate interactions will be low due to the same charge, and as pH increases, the surface charge will shift from positive to negative, which will have a positive effect. It affects the adsorption of positively charged metal ions. In addition, the excess of OH ions in the high pH environment can be attributed to precipitation of excretions in the form of metal hydroxide as well as adsorption. In all experiments, it was observed that Pb adsorption performance was higher than Cd at the same parameters. This is related to the fact that the atomic radius and covalent radius of Pb are higher than the values of Cd. Similar studies report that the lower hydration radius and higher electronegativity of Pb result in higher adsorption performance compared to other metals [34]. These results are parallel to the data we obtained.

Effect of adsorbent amount

Another parameter that affects adsorption capacity and is of critical importance is the amount of adsorbent. The effect of the amount of adsorbent was studied in the range of 20–60 mg as indicated in Fig. 10b and e. To determine the optimum conditions, by increasing the amount of adsorbent between 20 and 60 mg, the adsorption capacity for Pb2+ decreased from 66 to 24 mg/g and for Cd2+ from 12 to 5 mg/g. A decrease was observed. The adsorption capacity reached the maximum value at 30 mg for both metals. That is, with the decrease in the amount of adsorbent, there is an increase in Pb2+ and Cd2+ qe values. Additionally, increasing the amount of adsorbent resulted in saturation of the existing binding sites on the Fe3O4/SiO2/PAM surface. Another important situation encountered in the use of high amounts of adsorbents is the decrease in surface area as a result of aggregation of adsorbents [35]. Therefore, increasing the amount of adsorbent will not affect the qe values.

Initial concentration effect

The effect of initial concentration on adsorption capacity was examined in the Pb2+ 30–90 mg/L and Cd2+ 5–25 mg/L concentration ranges, as shown in Fig. 10c and f. It was observed that the adsorption capacity increased from 18 to 51 mg/g with increasing concentration for Pb2+ and from 3 to 9 mg/g for Cd2+. The adsorption capacities for both metals showed an increasing and then decreasing trend with increasing concentration. It was observed that the adsorption capacity reached the maximum value at the concentration of 80 and 20 mg/L for Pb2+ and Cd2+, respectively, and they were considered optimum conditions. This can be explained by the fact that the number of adsorbent active sites increases as the concentration increases [36]. Additionally, the decrease in adsorption capacity at high concentrations may be associated with saturation of binding sites.

Contact time effect

As seen in Fig. 10c and e, contact time is one of the parameters that affects the adsorption capacity. To determine the optimum conditions, contact time was studied in the range of 20–100 min. The adsorption capacity for Pb2+ and Cd2+ was found to be 30.2 mg/g and 6.6 mg/g, respectively, as a result of 20 min contact time. It was observed that as the contact time increased, the adsorption capacity increased and reached the maximum qe value at 90 min. The adsorption capacities of both metals decreased in 100 min due to the desorption process. With the increase of contact time, saturation and desorption process occurred on the adsorbent surface [37]. As a result, the adsorption process reached equilibrium.

Temperature effect

Temperature can influence the process by increasing or decreasing the adsorption capacity, so it has a significant impact on qe values. The temperature effect on the adsorption capacity of the nanoadsorbent material is shown in Fig. 10b and f. The temperature effect was investigated in the range of 15–45 °C, and the optimum value for both metals was determined as 40 °C. The adsorption capacity was observed to decrease above 40 °C, and this is due to the delay of chemisorption [38]. At the same time, the kinetic energy of metal ions increases with increasing temperature. In this case, we can understand that the bond between metal ions and the active sites of the Fe3O4/SiO2/PAM adsorbent material is blocked or broken. Therefore, the electrostatic interaction between the adsorbent and adsorbate is disrupted.

Optimization of parameters

CCD-RSM optimization process was applied to increase the adsorption capacity of the Fe3O4/SiO2/PAM nanoadsorbent material and optimize the five parameters affecting adsorption. Optimum conditions were obtained by adjusting the desired target maximum for adsorption capacity and other independent parameters within certain ranges. In the experimental set designed for both metals, the amount of adsorbent (30 mg), pH value of 7, temperature (40 °C), initial concentration of Pb (80 mg/L) and Cd (20 mg/L) and contact time of 90 (min) were determined as optimum conditions. The maximum adsorption capacity was calculated with the proposed models and found to be 66.54 and 13.22 mg/g for Pb2+ and Cd2+, respectively. The values obtained from the optimization results (Pb Desirability = 1 and Cd Desirability = 0.94) show that the predicted values are compatible with the experimental data.

Comparison of Fe3O4/SiO2/PAM adsorption capacity with other adsorbents

To evaluate the adsorption capacity performance of Fe3O4/SiO2/PAM nanoadsorbent material on Pb2+ and Cd2+ ions, a comparison with other adsorbents was made. The differences in qe values of various adsorbents shown in Table 7 are due to the properties of the adsorbents such as functional groups and surface area. Compared to other adsorbents, the adsorption capacity of Fe3O4/SiO2/PAM material is quite high. SiO2 in its structure increases the physical properties of the material and provides resistance to acids and bases. In particular, –OH and –NH2 functional groups provide specific active sites to the adsorbent material. This indicates that the affinity between the adsorbent and metal ions is higher. Therefore, considering the qmax values, we can say that the Fe3O4/SiO2/PAM adsorbent material has a greater affinity for Pb2+ ions.

Adsorption mechanism

Figure 11 shows the FTIR spectra of the Fe3O4/SiO2/PAM sample after/before adsorption. As can be seen from Fig. 11, there are new peaks in the spectrum at around 1640 cm−1 and 3400 cm−1. These peaks are indicative of the presence of water molecules, which suggests that the adsorbent has absorbed water during the adsorption process. In addition, the intensities of some of the peaks have changed after adsorption. For example, the peak at around 1030 cm−1 has decreased in intensity. This decrease in intensity could be due to the interaction of the adsorbate molecules with the functional groups on the surface of the adsorbent. As the final, some of the peaks have shifted in position after adsorption. The peak at around 1540 cm−1 has shifted to a slightly higher wavenumber. This shift could be due to changes in the hydrogen bonding interactions between the adsorbent and the adsorbate molecules.

The adsorption mechanism for the adsorption of Pb2+ and Cd2+ metal ions on Fe3O4/SiO2/PAM is designed in Fig. 12. It is reported that heavy metal ions can be adsorbed through electrostatic interaction, ion exchange and coordination [46]. In the presented study, metal ions are thought to form coordinated bonds with electron-rich functional groups such as carbonyl and amino groups. The strong interaction between these functional groups and heavy metal ions shows that the synthesized nanoadsorbent material has high adsorption capacity. These results are consistent with FTIR results.

Adsorption isotherms

The widely used Langmuir and Freundlich models were used to evaluate the isotherm data on Pb2+ and Cd2+ adsorption and find the best model. These isotherms provide information for examining the equilibrium between the adsorbent and metal ions, as well as determining the adsorption capacity and equilibrium parameters. The Langmuir adsorption isotherm model states that adsorbed molecules are removed by monolayer adsorption on homogeneous surfaces without interaction. The linear formula of the Langmuir isotherm is as follows:

where Ce (mg/L) is the equilibrium concentration, qe (mg/g) is the amount of adsorbate adsorbed, qmax is the maximum adsorption capacity and KL (L/mg) is the Langmuir constant. The Freundlich isotherm is a model that describes the physical adsorption of substances onto the heterogeneous surface of an adsorbent. Compared to the Langmuir isotherm model, the Freundlich model has a broader scope that is not limited to single-layer adsorption and is represented by the following equation:

where qe (mg/g) is the adsorbed amount of adsorbate at equilibrium, Ce (mg/L) is the adsorbate concentration at equilibrium, KF (L/mg) is the adsorption capacity and n is the constant representing the intensity of the adsorption process.

Both adsorption isotherm models described above were used to study the adsorption behavior of the nanoadsorbent material and the competitive effect between both metals and the surface properties of the nanoadsorbents. The results obtained from these models are given in Table 8.

When Table 8 is examined, it is seen that the Langmuir model is higher than the Freundlich model. This shows that homogeneous monolayer adsorption of Pb and Cd adsorption occurs on nanoadsorbents. Additionally, the calculated RL values are between 0 and 1, indicating that the adsorption is positive [34]. According to the Langmuir model, the qmax values obtained for Pb2+ and Cd2+ were 66.54 and 13.22 mg/g, respectively. A higher KL value indicates a higher affinity between the adsorbent and metal ions. In this study, the KL value of Cd(II) was found to be higher than the other metal.

Adsorption kinetics

Pb2+ and Cd2+ adsorption kinetics were tested with two different kinetic models: pseudo-first-order and pseudo-second-order. These models describe the rate at which an adsorbate binds to an adsorbent surface and how this process changes with time. It is also widely used to evaluate adsorbent performance and predict adsorption capacity [5]. Adsorption kinetic experiments were carried out at different concentrations and temperatures, taking into account the 30 mg adsorbent amount and pH 7 optimum values for both metals. Experiments were mixed at 130 rpm for a total of 90 min, taking samples every 15 min. The adsorption kinetic models are shown below as pseudo-first-order Eq. (9) and pseudo-second-order Eq. (10).

where k1 (min−1) are pseudo-first-order and k2 (g mg−1 min−1) are pseudo-second-order rate constants, qe and qt are the amount of metal ions adsorbed on the nanoparticles at equilibrium and at any time t (mg g−1), respectively. By plotting log (qe − qt) versus t plot and t/qt versus t plot, k1, k2 and qe values were obtained.

In order to investigate the mechanism of adsorption, the pseudo-first-order kinetics model and the pseudo-second-order kinetics model were used to test dynamical experimental data.

The correlation coefficients and the other parameters calculated from both models are given in Table 9. From these mechanisms, it was observed that the first-order kinetic model did not adequately fit the experimental values (R2 < 0.91).

As seen in Table 9, the equilibrium sorption capacity calculated for the second-order model and the values of qe,calc and qe,exp for the polymer-coated magnetic material are very close to each other. Additionally, while the linear regression analysis values of the first-order velocity equation were below R2 (0.94), the linear regression analysis of the second-order velocity equation gave a high R2 value (0.99). This shows that Pb and Cd adsorption onto Fe3O4/SiO2/PAM follows the pseudo-second-order model [47, 48].

Thermodynamic modeling

Thermodynamic modeling is a modeling process to mathematically explain the behavior of systems using the basic principles of thermodynamics. It is used to evaluate the efficiency and performance of the adsorption process. These studies help determine how effectively the adsorbent can retain the adsorbate and under what conditions the adsorption process is most efficient [49]. Therefore, thermodynamic studies of the adsorption process contribute to a more efficient and sustainable use of adsorption. The enthalpy change (ΔH), Gibbs free energy change (ΔG) and entropy change (ΔS) of adsorption were calculated using the following equations:

Here, KD is the equilibrium distribution constant, T(K) is the absolute temperature of the solution, and R (8.314 J mol−1 K−1) is the universal gas constant. By drawing 1/T graphs against lnKD, ΔH° and ΔS° values were calculated from the slope and intercept, respectively.

As seen in Table 10, ΔH° is positive for Pb2+ adsorption and Cd2+ adsorption. This shows that both metal adsorptions are endothermic [50]. A positive ΔS° value indicates that the randomness of the adsorption process decreases during possible interactions between metal ions and Fe3O4/SiO2/PAM. Moreover, the negative ΔG° value confirms the spontaneous feasibility of the adsorption process at the specific temperatures studied [51]. The increase in negative ΔG° values for Pb2+ with increasing temperature shows that the adsorption of these ions on Fe3O4/SiO2/PAM gives more positive results at higher temperatures, while in the Cd2+ adsorption process, negative values occur spontaneously after 313 K. It is seen that this situation becomes endothermic up to a certain temperature and exothermic after a certain temperature. When the Gibbs free energy changes were examined at different temperatures in the range of 298–313 K, it was observed that as the temperature increased in Pb2+ adsorption, ΔG° values decreased and the spontaneous realization potential increased (from − 7.454 to − 12.725). Moreover, in Cd2+ adsorption, these values tended to move from positivity to negativity with increasing temperature (from 1.729 to − 3.018). Additionally, negative free energy values indicate that the adsorption process of the nanoadsorbent material on Pb2+ and Cd2+ metals may have a physical character [37, 52].

Conclusions

In this study, the preparation, characterization and adsorption performances of Fe3O4/SiO2/PAM magnetic nanoadsorbent material in the removal of hazardous heavy metals such as Pb2+ and Cd2+ on simulated wastewater were investigated. As a result of the characterization studies carried out after the synthesis of the nanoadsorbent, it was seen that straight-chain polyacrylamide provides specific active sites on the material surface and significantly increases the adsorption capacity. When CCD-RSM optimization model is used, the amount of adsorbent (30 mg), pH value of 7, temperature (40 °C), initial concentration of Pb (80 mg/L), Cd (20 mg/L) and contact time of 90 min as optimum conditions were determined. From the kinetic results, it was seen that the reaction rate followed the pseudo-second-order reaction and that the isotherm studies provided a better fit according to the Langmuir > Freundlich order. The maximum adsorption capacities were determined as 66.54 and 13.22 mg/g for Pb2+ and Cd2+, respectively. It has been observed that Cd2+ adsorption is more effective, especially in low concentration ranges. Considering the adsorption capacities of both metals, it has been observed that the Fe3O4/SiO2/PAM nanoadsorbent material exhibits high affinity and selective adsorption properties toward Pb2+ ions. These properties will make it possible to use the nanocomposite material for potential applications.

Data availability

The experimental findings, results or content presented in the article have not been used in any other study or publication. Should any raw data files be needed in another format they are available from the corresponding author upon reasonable request. Source data are provided with this paper.

References

Han X, Wu H, Li Q, Cai W, Hu S (2024) Assessment of heavy metal accumulation and potential risks in surface sediment of estuary area: a case study of Dagu river. Marine Environ Res 196:106416

Isaac R, Siddiqui S, Aldosari OF, Uddin MK (2023) Magnetic biochar derived from Juglans regia for the adsorption of Cu2+ and Ni2+: characterization, modelling, optimization, and cost analysis. J Saudi Chem Soc 27:101749

Guan L, Chen Z, Liu Y, Wang R, Yan K, Xu Z, Liu H (2024) Engineering sulfur-rich MoS2 adsorbent with abundant unsaturated coordination sulfur sites for gaseous mercury capture from high-concentration SO2 smelting flue gas. Chem Eng J 483:149122

Li M, Lv S, Yang R, Chu X, Wang X, Wang Z, Yang J (2023) Development of lycopene-based whole-cell biosensors for the visual detection of trace explosives and heavy metals. Anal Chimica Act 1283:341934

Phouthavong V, Hagio T, Park JH, Nijpanich S, Duangkhai K, Rujiravanit R, Thaveemas P, Chounlamany V, Kong L, Li L, Ichino R (2024) Removal of heavy metals by BEA zeolite/Fe3O4 composite prepared via dry-gel conversion method using agrowaste-derived raw material. Solid State Sci 149:107473

Hashemi SA, Mousavi SM, Ramakrishna S (2019) Effective removal of mercury, arsenic and lead from aqueous media using Polyaniline-Fe3O4-silver diethyldithiocarbamate nanostructures. J Clean Prod 239:118023

Medeiros VL, Araujo LG, Ratero DR, Paula AS, Molina EF, Jaeger C, Marumo JT, Nery JG (2020) Synthesis and physicochemical characterization of a novel adsorbent based on yttrium silicate: a potential material for removal of lead and cadmium from aqueous media. J Environ Chem Eng 8:103922

Lee DW, Yoo BR (2016) Advanced silica/polymer composites: materials and applications. J Ind Eng Chem 38:1–12

Nasiri A, Golestani N, Rajabi S, Hashemi M (2024) Facile and green synthesis of recyclable, environmentally friendly, chemically stable, and cost-effective magnetic nanohybrid adsorbent for tetracycline adsorption. Heliyon. https://doi.org/10.1016/j.heliyon.2024.e24179

Gharaghani MA, Dehdarirad A, Mahdizadeh H, Hashemi H, Nasiri A, Samaei MR, Mohammadpour A (2024) Photocatalytic degradation of acid red 18 by synthesized AgCoFe2O4@ Ch/AC: recyclable, environmentally friendly, chemically stable, and cost-effective magnetic nano hybrid catalyst. Int J Biol Macromol 269:131897

He H, Ye S, Zhang W, Li S, Nie Z, Xu X, Hu G (2024) Synthesis of magnetic mesoporous silica adsorbents by thiol-ene click chemistry with optimised lewis base properties through molecular imprinting for the rapid and effective capture of Pb (II). Chem Eng J 489:151294

Gharaghani MA, Samaei M, Mahdizadeh H, Nasiri A, Keshtkar M, Mohammadpour A, Khaneghah AM (2024) An effective magnetic nanobiocomposite: preparation, characterization and its application for adsorption removal of P-nitroaniline from aquatic environments. Environ Res 246:118128

Mahmoudian MH, Azari A, Jahantigh A, Sarkhosh M, Yousefi M, Razavinasab SA, Ghasemian M (2023) Statistical modeling and optimization of dexamethasone adsorption from aqueous solution by Fe3O4@ NH2-MIL88B nanorods: isotherm, kinetics, and thermodynamic. Environ Res 236:116773

Kermani M, Dowlati M, Gholami M, Sobhi HR, Azari A, Esrafili A, Ghaffari HR (2021) A global systematic review, meta-analysis and health risk assessment on the quantity of Malathion. Diazinon Chlorpyrifos VeG Chemosphere 270:129382

Reddy DHK, Wei W, Shuo L, Song MH, Yun YS (2017) Fabrication of stable and regenerable amine functionalized magnetic nanoparticles as a potential material for Pt (IV) recovery from acidic solutions. ACS Appl Mater Interf 9:18650–18659

Gawande MB, Monga Y, Zboril R, Sharma RK (2015) Silica-decorated magnetic nanocomposites for catalytic applications. Coord Chem Rev 288:118–143

Gharibzadeh F, Kalantary RR, Esrafili A, Ravanipour M, Azari A (2019) Desorption kinetics and isotherms of phenanthrene from contaminated soil. J Environ Health Sci Eng 17:171–181

Gui CX, Li QJ, Lv LL, Qu J, Wang QQ, Hao SM, Yu ZZ (2015) Core–shell structured MgO@ mesoporous silica spheres for enhanced adsorption of methylene blue and lead ions. RSC Adv 5:20440–20445

Harinath Y, Reddy DHK, Sharma LS, Seshaiah K (2017) Development of hyperbranched polymer encapsulated magnetic adsorbent (Fe3O4@ SiO2–NH2-PAA) and its application for decontamination of heavy metal ions. J Environ Chem Eng 5:4994–5001

Zamani F, Izadi E (2014) Polyvinyl amine coated Fe3O4@SiO2 magnetic microspheres for Knoevenagel condensation. Chin J Catal 35:21–27

Faaizatunnisa N, Ediati R, Fansuri H, Juwono H, Suprapto S, Hidayat ARP, Zulfa LL (2023) Facile green synthesis of core–shell magnetic MOF composites (Fe3O4@ SiO2@ HKUST-1) for enhanced adsorption capacity of methylene blue. Nano-Struct Nano-Objects 34:100968

Aldahash SA, Siddiqui S, Uddin MK (2023) Eco-friendly synthesis of copper nanoparticles from fiber of Trapa natans L. shells and their impregnation onto polyamide-12 for environmental applications. J Nat Fibers 20(2):2224976

Shi X, Karachi A, Hosseini M, Yazd MS, Kamyab H, Ebrahimi M, Parsaee Z (2020) Ultrasound wave assisted removal of Ceftriaxone sodium in aqueous media with novel nano composite g-C3N4/MWCNT/Bi2WO6 based on CCD–RSM model. Ultrason Sonochem 68:104460

Shagholani H, Ghoreishi SM, Mousazadeh M (2015) Improvement of interaction between PVA and chitosan via magnetite nanoparticles for drug delivery application. Int J Biol Macromol 78:130–136

Xu J, Ju C, Sheng J, Wang F, Zhang Q, Sun G, Sun M (2013) Synthesis and characterization of magnetic nanoparticles and its application in lipase immobilization. Bull Korean Chem Soc 34:2408–2412

Dumitrescu AM, Lisa G, Iordan AR, Tudorache F, Petrila I, Borhan AI, Munteanu C (2015) Ni ferrite highly organized as humidity sensors. Mater Chem Phys 156:170–179

Smiri M, Guey F, Chemingui H, Dekhil AB, Elarbaoui S, Hafiane A (2020) Remove of humic acid from water using magnetite nanoparticles. European Journal of Advanced Chemistry Research

Ahangaran F, Hassanzadeh A, Nouri S (2013) Surface modification of Fe3O4@SiO2 microsphere by silane coupling agent. Int Nano Lett 3:1–5

Liu F, Niu F, Peng N, Su Y, Yang Y (2015) Synthesis, characterization, and application of Fe3O4@SiO2–NH2 nanoparticles. RSC Adv 5:18128–18136

İlteriş YS, Osman H, Uğurlu M, Ali İmranV, Chaudhary AJ (2023) Synthesıs of activated carbon supported catalysis systems and research for electrocatalytic performance on wastewater treatment. Iranian Journal of Chemistry and Chemical Engineering

Najafi A (2017) A novel synthesis method of hierarchical mesoporous MgO nanoflakes employing carbon nanoparticles as the hard templates for photocatalytic degradation. Ceram Int 43(7):5813–5818

Hashemi SY, Azari A, Raeesi M, Yaghmaeian K (2023) Application of response surface methodology (RSM) in optimisation of fluoride removal by magnetic chitosan/graphene oxide composite: kinetics and isotherm study. Int J Environ Anal Chem 103(17):5368–5386

Manzar MS, Khan G, dos Santos Lins PV, Zubair M, Khan SU, Selvasembian R, Kayed TS (2021) RSM-CCD optimization approach for the adsorptive removal of Eriochrome Black T from aqueous system using steel slag-based adsorbent: characterization, isotherm, kinetic modeling and thermodynamic analysis. J Mol Liq 339:116714

Kothavale VP, Sharma A, Dhavale RP, Chavan VD, Shingte SR, Selyshchev O, Patil PB (2023) Carboxyl and thiol-functionalized magnetic nanoadsorbents for efficient and simultaneous removal of Pb (II), Cd (II), and Ni (II) heavy metal ions from aqueous solutions: Studies of adsorption, kinetics, and isotherms. J Phys Chem Solids 172:111089

Choi H, Han HH, Parale VG, Kim T, Park W, Kim Y, Kim J, Choi Y, Bae YS, Park HH (2024) Rigid amine-incorporated silica aerogel for highly efficient CO2 capture and heavy metal removal. Chem Eng J 483:149357. https://doi.org/10.1016/j.cej.2024.149357

Ece MS (2021) Synthesis and characterization of activated carbon supported magnetic nanoparticles (Fe3O4/AC@SiO2@Sulfanilamide) and its application in removal of toluene and benzene. Colloids Surf, A 617:126231

Ebrahimpour E, Kazemi A (2023) Mercury (II) and lead (II) ions removal using a novel thiol-rich hydrogel adsorbent; PHPAm/Fe3O4@SiO2-SH polymer nanocomposite. Environ Sci Pollut Res 30:13605–13623

Sebastian A, Nangia A, Prasad MNV (2018) A green synthetic route to phenolics fabricated magnetite nanoparticles from coconut husk extract: implications to treat metal contaminated water and heavy metal stress in Oryza sativa L. J Clean Prod 174:355–366

Tan Y, Chen M, Hao Y (2012) High efficient removal of Pb (II) by amino-functionalized Fe3O4 magnetic nano-particles. Chem Eng J 191:104–111

Badruddoza AZM, Shawon ZBZ, Tay WJD, Hidajat K, Uddin MS (2013) Fe3O4/cyclodextrin polymer nanocomposites for selective heavy metals removal from industrial wastewater. Carbohyd Polym 91:322–332

Ding Y, Zhu W, Xu Y, Qian X (2015) A small molecular fluorescent sensor functionalized silica microsphere for detection and removal of mercury, cadmium, and lead ions in aqueous solutions. Sens Actuators, B Chem 220:762–771

Shafiee M, Foroutan R, Fouladi K, Ahmadlouydarab M, Ramavandi B, Sahebi S (2019) Application of oak powder/Fe3O4 magnetic composite in toxic metals removal from aqueous solutions. Adv Powder Technol 30:544–554

Lan S, Leng Z, Guo N, Wu X, Gan S (2014) Sesbania gum-based magnetic carbonaceous nanocomposites: facile fabrication and adsorption behavior. Colloids Surf, A 446:163–171

Ohno M, Hayashi H, Suzuki K, Kose T, Asada T, Kawata K (2011) Preparation and evaluation of magnetic carbonaceous materials for pesticide and metal removal. J Colloid Interf Sci 359:407–412

Guo X, Du B, Wei Q, Yang J, Hu L, Yan L, Xu W (2014) Synthesis of amino functionalized magnetic graphenes composite material and its application to remove Cr (VI), Pb (II), Hg (II), Cd (II) and Ni (II) from contaminated water. J Hazard Mater 278:211–220

Wang Z, Li TT, Peng HK, Ren HT, Lou CW, Lin JH (2021) Low-cost hydrogel adsorbent enhanced by trihydroxy melamine and β-cyclodextrin for the removal of Pb (II) and Ni (II) in water. J Hazard Mater 411:125029

Nasiri A, Rajabi S, Amiri A, Fattahizade M, Hasani O, Lalehzari A, Hashemi M (2022) Adsorption of tetracycline using CuCoFe2O4@ Chitosan as a new and green magnetic nanohybrid adsorbent from aqueous solutions: isotherm, kinetic and thermodynamic study. Arab J Chem 15:104014

Maleky S, Asadipour A, Nasiri A, Luque R, Faraji M (2022) Tetracycline adsorption from aqueous media by magnetically separable Fe3O4@ Methylcellulose/APTMS: isotherm, kinetic and thermodynamic studies. J Polym Environ 30(8):3351–3367

Sarangi NV, Rajkumar R (2024) Biosorption potential of Stoechospermum marginatum for removal of heavy metals from aqueous solution: equilibrium, kinetic and thermodynamic study. Chem Eng Res Des 203:207–218

Sahmoune MN (2019) Evaluation of thermodynamic parameters for adsorption of heavy metals by green adsorbents. Environ Chem Lett 17(2):697–704

Pasalari H, Ghaffari HR, Mahvi AH, Pourshabanian M, Azari A (2017) Activated carbon derived from date stone as natural adsorbent for phenol removal from aqueous solution. Desalin Water Treat 72:406–417

Azari A, Malakoutian M, Yaghmaeain K, Jaafarzadeh N, Shariatifar N, Mohammadi G, Kamani H (2022) Magnetic NH2-MIL-101 (Al)/Chitosan nanocomposite as a novel adsorbent for the removal of azithromycin: modeling and process optimization. Sci Rep 12(1):18990

Acknowledgements

This study was financially supported as a project by the Scientific Research Projects Coordination Unit (BAP) (23/158/01/1), Muğla Sıtkı Koçman University.

Funding

Open access funding provided by the Scientific and Technological Research Council of Türkiye (TÜBİTAK).

Author information

Authors and Affiliations

Contributions

Scientific data and experiments of the article are provided by HO and MA. Material preparation, data collection and analysis were performed by AİV. Partial writing and linguistic evaluation of the article was performed by AJC. In short, all authors contributed to the concept and design of the study. The first draft of the article was written by MU and served as the responsible author. All authors commented on the final versions of the article, and the accepted version was submitted to your journal for publication.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal conflicts or adversities that would appear to have influenced the work reported in this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Osman, H., Uğurlu, M., Vaizoğullar, A.İ. et al. Statistical modeling and optimization of heavy metals (Pb and Cd) adsorption from aqueous solution by synthesis of Fe3O4/SiO2/PAM: isotherm, kinetics, and thermodynamic. Polym. Bull. (2024). https://doi.org/10.1007/s00289-024-05404-9

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00289-024-05404-9