Abstract

Co–B/Chi, which is made up of highly distributed Co–B particles, was synthesized by impregnation and chemical reduction methods. Scanning electron microscopy, energy-dispersive spectroscopy, X-ray diffraction, Brunauer–Emmett–Teller adsorption and Fourier transform infrared spectroscopy analyses were used to describe the morphology and microstructure of Co–B/Chi. The synthesized catalyst showed high catalytic activity in the hydrolysis reaction of NaBH4. The unsupported Co–B samples were compared with the chitin-supported Co–B catalyst, and the result showed that higher catalytic activity and good cycling stability for NaBH4 hydrolysis were obtained with the chitin-supported catalyst. The reaction conditions were investigated to achieve high hydrogen production. The maximum rate of hydrogen production was obtained at 40 °C and 20 mg catalyst amount. At ideal conditions, the hydrolysis reaction’s activation energy was determined to be 51.65 kJ mol−1. It is indicate that Co–B/Chi is a viable low-cost catalyst for the hydrolysis of NaBH4 for hydrogen production.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Global energy demand has significantly increased as a result of the continual rise in both living standards and population around the world. The use of fossil fuels causes various damages to human health and the ecosystem. The short summary of these problems is the limited fossil resources and the fact that they are not evenly distributed around the world, as well as the changing pricing policy. In addition, rapid consumption of fossil fuels is a large contribution to greenhouse gas emissions [1, 2].

Therefore, there is a need for a coherent energy saving strategy that examines not only the aspects of energy supply but also the demand [3]. Among the energy products, thanks to its high energy density and environmentally being nature of the H2 source for fuel cells has attracted great interest in recent years and also it is by-products non-toxic [4].

In this context, the production of hydrogen from sodium borohydride (NaBH4) has piqued the interest of researchers due to its high storage capacity (10.8 wt%) and potentially safe operation [5, 6]. Pure H2, which is accepted as a green fuel, proceeds with an exothermic and spontaneous reaction under moderate conditions, and recyclable and water-soluble sodium metaborate is formed as a by-product. The NaBH4 hydrolysis reaction is also known to be thermodynamically stable and has slow kinetics. A well-designed catalyst is required for such reactions in order to produce high amounts of hydrogen production (HG) in a controlled manner and to accelerate the reaction [7]. The hydrolysis of NaBH4 is given as:

Various catalysts have been studied in the literature; different noble-metal catalysts and their supported catalysts (Pt, Pd, Au, Rh, etc.) have shown excellent properties in the production of hydrogen via decomposing chemical hydride [8]. But these noble-metal catalysts are not cost-effective. The Co–B and Ni–B-based catalysts have attracted the interest of many researchers because of their high activity, reusability and relatively low cost. However, when compared to noble-metal catalysts, they demonstrated low activity. As a result, improving the hydrogen production rate of these catalysts is critical. In the reaction medium, the electronic interaction of Co, B and other atoms increases the electron density and the active sites effected reaction possibility [9]. However, due to their high surface energies, accumulation tendency of metal nanoparticles, leading to a reduction in catalytic activity. The synthesis of metal catalysts with a support material is used to prevent this reduction. Much of the research studies on H2 production in NaBH4 hydrolysis have emphasized the importance of heterogeneous catalysts prepared by loading metal nanoparticles on to support materials such as Ce2O3, Al2O3, SiO2 and TiO2 to increase catalytic activity while improving durability and reusability [7, 10].

There are many examples in the literature of supports such as bases, acids, organic polymers, silica and inexpensive tailing samples such as Pinus brutia [11] and ground apricot kernel shells [12]. Chitosan has been used as a catalyst for hydrogen production from NaBH4 in different studies. Chitosan/urea/Co(NO3)2·6H2O was synthesized via a hydrothermal process [13]; Co–Ce–B nanoparticles supported on chitosan-derived carbon (Co–Ce–B/Chi–C) were synthesized by chemical reduction and carbonization [14]. However, to our knowledge, residual chitin has not yet been used as a catalyst support for the hydrolysis reaction of NaBH4. In this study, for an alternative to the above-mentioned catalyst supports, which have not yet been tested, a new and never before studied supporter, namely the macromolecule “chitin,” was tested. It is obtained from an insect species “Zabrus tenebrioides Goeze 1777,” which is known as a plant pest among ground beetles. Chitin C8H13O5N is known as the second most abundant biopolymer in the world (among natural macromolecules). This macromolecule is a long-chain polymer of N-acetyl-d-glucosamine (GlcNAc), (1–4)-linked 2-acetamido-2-deoxy-β-d-glucan, a derivative of glucose (Fig. 1) [15, 16]. Currently, chitin is mainly extracted from crustacean waste by physical, chemical and biological methods [17]. It was initially characterized and isolated from fungi, but nowadays it can be obtained from many natural sources such as the exoskeleton of crayfish, shrimp and crabs. Besides, the exoskeletons of insects, which are a dominant group in nature with a large number of individuals, are composed of chitin. Especially in groups such as ground beetles, which have lost their flight function, the exoskeleton has become thicker and more protective, so that it can be used as an alternative source of chitin in these groups [18, 19].

Chemical structure of chitin [20]

In scope of this study, insect chitin was used as a biosupporter to develop a low-cost and innovative catalyst with high activity in hydrogen production by hydrolysis/dehydrogenation and to increase catalytic activity by impregnation with low-cost transition metals. In this study, “Zabrus tenebrioides Goeze 1777” chitin was used as a support to prepare a Co-based metallic catalyst. The prepared catalysts were characterized in detail using advanced spectroscopic techniques. The catalysts prepared with untreated chitin (Co–B/Chi) and acid-activated (Co–B/Chi_AA) were tested for their catalytic activity in the hydrolysis reaction under appropriate conditions. Various parameters such as the amount of catalyst, NaOH concentration, initial amount of NaBH4 and temperature were investigated. The kinetic analysis of the hydrolysis reaction in the presence of the biocatalyst was examined and compared with previously reported similar literature data. Reusability was also investigated in detail.

Materials and methods

Materials

Zabrus tenebrioides is one of the main pests of wheat crops worldwide and is really difficult to control. This species is widespread both in our country and in the Palaearctic region. The species are usually dark black–brown in color, large, bloated and strongly built and can be easily distinguished from other Carabidae genera when viewed from the front due to the peculiar structure of their pronotum [21].

The specimens were collected in Eskişehir, a province in the central Anatolian region of Turkey [22]. The chitin was gathered from the elytra, mandible and antennae (body parts which have the most chitin polymer) of Z. tenebrioides, air dried and powdered.

Cobalt (II) chloride hexahydrate (> 97%), sodium hydroxide pellets (> 98%) and sodium borohydride powder (> 98%) were purchased from Acros Organics and Sigma-Aldrich, respectively. All chemicals used in this study were of analytical grade without further processing.

Catalyst synthesis

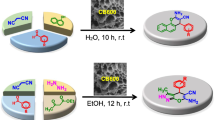

A appropriate amount of cobalt (II) chloride hexahydrate (CoCl2·6H2O) was dissolved in an ethyl alcohol–water mixture, and then chitin was added to allow chitin impregnation of the metals at a temperature of 70 °C for 1 h (Fig. 2). At 50 °C, the ethyl alcohol–water mixture was removed and distilled water was added to the metal-impregnated chitin, which was then placed in an ice bath. The NaBH4 solution was added dropwise to reduce the metal impregnated on the biosupport material at a molar ratio of 5:1 of the total metal molecules and mixed for 1 h to complete the reduction. The black precipitate particles were filtered and washed several times with distilled water and ethyl alcohol after chemical reduction. The synthesized catalyst was dried in a vacuum oven at 40 °C for one night.

Different conditions were investigated to compare the effects of the synthesis process on the catalytic activity of the Co–B catalyst on chitin support for the NaBH4 hydrolysis reaction. For the synthesis of the acid-activated catalysts, 500 mg of chitin was dissolved in 50 mL of acetic acid solution (1 wt%) and mixed at 400 rpm at room temperature. The pH of the hydrogel was adjusted to 4 by stepwise addition of NaOH solution. This hydrogel was dissolved in CoCl2·6H2O, and the resulting solution was stirred at 400 rpm for one hour. Then, 50 mL of NaBH4 solution was added dropwise in a molar ratio of 5:1 to of the total metal mole to reduce the metal impregnated on the biosupport material and mixed for 4 h to complete the reduction. After filtration, the resulting solid was dried in a vacuum oven at 60 °C for 24 h and then ground into a fine powder.

Catalyst characterization

Various methods were used to characterize the morphological structure, crystallinity and surface composition of the chitin and catalysts. The isotherms of N2 sorption were measured at 77 K using a Tristar 3020 (Micromeritics, Norcross, GA, USA) at 196 °C. Before measuring, all samples were degassed at 90 °C for 1 h and then at 300 °C for 24 h under vacuum. The BET method was used to calculate the specific surface areas of the samples. The powder diffractometer XRD D8 advance (Bruker AXS, Karlsruhe, Germany) was used to record XRD patterns. The samples were scanned at a scan rate of 2°min−1 in a range of 2 = 10°–70°. The morphology and surface composition of the catalysts and chitin were examined using a FE-SEM (Hitachi Regulus 8230) with EDS. Cobalt-based catalysts were dissolved using a microwave-assisted acid digestion method (Milestone, Sorisole, BG, Italy) and analyzed by inductively coupled plasma mass spectroscopy (ICP-MS) (Thermo Scientific iCAP RQ, Waltham, MA, USA). FT-IR analyzes were carried out using a Nicolet IS10 FT-IR from Thermoscientific, which was equipped with a universal ATR sampling accessory. For 64 scans, ATR-FT-IR spectra were recorded in the spectral range 4000–650 cm−1 with a resolution of 4 cm−1.

Catalytic activity test

By monitoring the rates of hydrogen produced during the hydrolysis of NaBH4, the catalytic activity of chitin-supported catalysts was examined. NaBH4, NaOH and catalyst were added in the proper amounts to a jacketed reactor. The temperature of the reactor was kept constant with a water circuit. A magnetic stirrer was used at a speed of 400 rpm to mix the contents of the reactor. The water displacement method was used to measure the volume of hydrogen generated during the experiment (Fig. 3). The hydrogen volume as a function of time and the amount of catalyst used were used to calculate the hydrogen generation rate (HGR, mL min−1 g catalyst−1).

To determine the optimal reaction conditions for the hydrolysis reaction by NaBH4 using cobalt boride catalysts on the chitin support of Zabrus tenebrioides, the effects of the catalyst amount (10–50 mg), initial NaBH4 concentration (1–2.5 wt%), initial NaOH concentration (1–2.5 wt%) and temperature (20–50 °C) were investigated using a range of values.

Results and discussion

Catalyst characterization

Table 1 shows the results in terms of surface area, pore volume and pore size of the synthesized Co-based catalysts. The values of 18.2 and 18.7 nm obtained for the pore size are almost the same for both samples. These values indicate that the synthesized catalyst has a mesoporous sample structure [23]. In Table 1, the BET surface area of the samples was reported as 23.85 and 24.69 m2/g for Co–B/Chi and Co–B/Chi_AA, respectively. The surface area of Co–B/Chi is smaller than that of the activated sample. The result is related to the interaction of cobalt with the substrate surface, since the process of metal loading blocks the pores of chitin and the acid activation treatment affects the surface interaction with the metal and the chitin sample. However, the average pore size of Co/Chitin was maintained by the treatment. These results also show that the cobalt is well dispersed in both supports. The cumulative pore volume of Co–B/Chi and Co–B/Chi_AA was found to be 0.117 cm3/g and 0.109 cm3/g, respectively.

The chemical composition of the catalysts and the presence of cobalt and boron in the catalysts were determined by ICP-MS analysis. The catalyst samples were pretreated in the microwave and then dissolved in nitric acid before being subjected to ICP analysis. Cobalt contents of 20.24% and 18.64% by weight were determined for the Co–B/Chi and Co–B/Chi_AA catalysts, respectively, and no Co and B content in the basic structure of chitin (Table 2). The weight percentage of boron is lower than that required for the stoichiometric value. For the catalysts Co–B/Chi and Co–B/Chi_AA, boron contents of 7.6 and 8.4 wt%, respectively, were determined. The Co/NaBH4 ratio, the rate of mixing, the presence or absence of oxygen and other factors all play a role in the complex process of reduction of cobalt precursors by NaBH4. When the precursors react rapidly, only Co2B is produced; when they react more slowly, various by-products are produced [24]. The activation effect has a positive influence on catalyst production.

Figure 4 shows the SEM images, and Table 3 contains the SEM–EDS analysis of Co–B/Chi and Co–B/Chi_AA. As can be seen from the SEM images, Co–B/Chi shows a relatively smooth surface with some agglomerates. However, the acid-activated catalyst showed a very homogeneous and smooth surface. To better understand the distribution and amount of cobalt and other ingredients in the tested catalysts, the results are summarized in Table 3. From the EDS results of Chitin C, O and N were found to be predominant. Co appeared after impregnation and reduction, confirming the successful introduction of Co into the chitin hydrogel. The quantitative amount of Co was 22.99% and 29.00% for the catalysts Co–B/Chitin and Co–B/Chitin_AA, respectively. The C, O and N contents were dependent on the treatment of the catalyst and the synthesis method. The acid treatment also affected the metal content, and the sodium ions were associated with the chemical reduction process. The Co particles are uniformly placed on the chitin of Zabrus tenebrionides Goeze 1777 (Coleoptera: Carabidae) that gives the particles the ability to additionally breakout off hydrogen thanks to the functional –COOH bonds in their chemical structure.

The XRD patterns of the prepared catalysts and the support are shown in Fig. 5. It can be seen that the characteristic peaks can be seen 18°, 40 and 50 at 2θ degrees which represent the main chitin structure. According to JCPDS (Joint Committee on Powder Diffraction Standards), peaks at 38.2°, 45.6° and 62.5° at 2θ degrees were observed in synthesized Co–B/Chi, which are features of a typical amorphous structure and are consistent with the results found for other amorphous Co–B alloys [25].

Figure 6 shows the FT-IR spectra of chitin, Co–B/Chi and Co–B/Chi_AA. The absorption bands around 1660 cm−1, 1550 cm−1 and 973 cm−1 characteristic of chitin are generally described as amide I, II and III bands, respectively. The band at nearly 1400 cm−1 was assigned to the symmetric deformation mode –CH3. These characteristic bands are similar for both samples, but the amide I band is slightly different depending on the crystalline structure due to hydrogen bonding and catalytic changes. Similar results were found in related studies [26]. The vibrations observed in Co–B/Chi and Co–B/Chi_AA at about 2300–2500 cm−1 represent Co peaks. The peak of –OH tension observed at 3300 cm−1 in chitin was preserved but decreased in the synthesized catalysts. Various absorption peaks for Co were obtained in the range of 2900 cm−1–2300 cm–1. Other peaks in the support and catalyst were preserved with some shifts. However, the new peak in the catalyst structure at 660 cm−1 shows the B–O vibration [27].

Comparison the catalytic activity of Co–B/Chi and Co–B/Co–B/Chi_AA catalysts

To compare the effect of the catalyst on the hydrolysis reaction of NaBH4, the volumes of hydrogen generation in the hydrolysis of NaBH4 with Co–B/Chi and Co–B/Chi_AA catalysts are shown in Fig. 7. The hydrolysis reaction was studied at optimal reaction conditions, which were determined for each catalyst in the previous section. NaBH4 hydrolysis was performed with metal-free chitin samples, but no hydrogen generation was observed. The duration of NaBH4 hydrolysis was about 7 and 13 min for the Co–B/Chi and Co–B/Chi_AA catalysts, respectively, and the volume of hydrogen generated was 1220 mL for Co–B/Chi and 1110 mL for Co–B/Chi_AA for the catalysts at the same reaction conditions (20 mg catalyst; 2.5 wt% NaOH; 2.5 wt% NaBH4; 40 °C; 400 rpm). For the Co–B/Chi and Co–B/Chi_AA catalysts, the hydrogen generation rate was found to be 2124 mLgcat−1 min−1 and 4207 mLgcat−1 min−1, respectively. The CoCl2·6H2O precursor allows perfect decomposition, and acid activation accelerates nucleation and growth of Co, while simple impregnation and reduction lead to well dispersed, rather agglomerated cobalt oxides.

The HGR of this study and reported studies are compared (Table 4). As shown in Table 4, Co–B/Chi_AA showed higher catalytic activity (5546 ml min−1 gcat−1), than other chitosan-based catalysts. The synthesized Co–B/Chi composites with Z. tenebrioides chitin supports showed comparable activity to these studies.

Effect of reaction conditions

To investigate the effects of catalyst amount and Co2+ precursor on the performance of H2 production from NaBH4 hydrolysis, different amounts of the prepared catalysts were added to 20 mL NaBH4 solution at 50 °C and a mixing speed of 400 rpm. As shown in Fig. 8a, the H2 volume reached equilibrium (1220 mL) within 32.5; 10.5; 10 and 7 min when 10; 20; 30 and 40 mg of catalyst were used, respectively. 10 mg of catalyst showed relatively poor catalytic performance, so that the volume of H2 produced was only captured within 32.5 min and 1220 mL of H2 was obtained. As shown in Fig. 8a, the Co2+ concentration of the precursor had a positive effect on the catalytic performance, which can be explained by the fact that with increasing Co2+ concentration, the Co particles are beneficial for the catalytic properties [28]. As a general phenomenon, the rate of hydrogen formation increased due to the increase of active cites in the reaction medium.

To investigate the impact of NaBH4 concentration in the hydrolysis reaction, the initial amounts of catalyst and temperature were kept constant at 20 mg and 40 °C, respectively, whereas the initial concentrations of NaBH4 were changed between 1 and 2.5 wt%. The procedure for performing the work was the same as described in the previous part. The effect of NaBH4 concentration on hydrogen generation with Co–B/Chi_AA catalyst at 40 °C is shown in Fig. 8b. As the NaBH4 concentration increases, the amounts of hydrogen produced by NaBH4 hydrolysis also increase linearly. The maximum hydrogen generation rate from NaBH4 hydrolysis with 1 wt%, 1.5 wt%, 2 wt% and 2.5 wt%, NaBH4 was found to be 4928 mL min−1 gcat−1, 5000 mL min−1 gcat−1, 5250 mL min−1 gcat−1 and 5546 mL min−1 gcat−1, respectively. It can be said that sodium borohydride and water molecules are first adsorbed on the catalyst surface and then weaken the hydrogen bonds within the reactant molecules as a result of the interactions between the reactant molecules and the active metal sites, creating convenient conditions for the release of H2 [29]. As can be seen, the rate of hydrogen generation increases with increasing concentration of NaBH4. However, there is a significant increase in the rate of hydrogen generation can be seen when the amount of NaBH4 is increased from 1 to 1.5 wt%, compared to a further increase. This potential reason is brought on by the limited impact of NaBO2, a result of NaBH4 hydrolysis processes. High NaBH4 and NaBO2 concentrations also make the solution more viscous, which slows down the mass transfer of NaBH4 to the catalyst surface [30].

NaOH is always added to the NaBH4 solution at the stabilizer to raise the pH and keep the NaBH4 solution stable at room temperature. However, the rate of hydrogen generation is significantly influenced by the NaOH concentration (Fig. 8c). The volume of hydrogen generated was 940 mL, 1050 mL, 1150 mL,1220 mL and 1100 mL for 1 wt%, 1.5 wt%, 2.0 wt%, 2.5 wt% and 3 wt%, respectively. When the NaOH concentration was increased from 1 to 2.0 wt%, the calculated hydrogen generation rate increased with hydrogen volume and time from 2447 to 4928 mL min−1 gcat−1. The increase in the amount of hydrogen continued from 2.0 wt% to 2.5 wt%. However, the hydrogen generation rate decreased from 5546 to 5116 mL min−1 gcat−1 when the NaOH content was increased to 3 wt%. These results are comparable to those of several catalysts from the study [31, 32]. This fact suggests that OH− plays a dual role in the hydrolysis of NaBH4. A certain amount of NaOH can keep the reaction solution alkaline and make NaBH4 more stable. The stability of hydrogen generation is also affected by the basicity of the medium, as the volume of hydrogen increases linearly as a function of time.

Hydrolysis kinetics

In order to determine the activation energy of the NaBH4 hydrolysis reaction catalyzed by Co–B/Chi_AA, the rate of hydrogen production was investigated at different temperatures. The volume and rate of hydrogen releases as a function of reaction time and temperature are shown in Fig. 8d (20 mg catalyst; 2.5 wt% NaBH4; 2.5 wt% NaOH; 400 rpm). As expected, the HGR increased with temperature. The volume of hydrogen generated was 1000 mL within 29.10 min at 20 °C, 1100 mL within 15.50 min at 30 °C and 1220 mL within 11 min at 40 °C. The hydrogen production rates were calculated as 1714 mL min−1 gcat−1, 3548 mL min−1 gcat−1 and 5546 mL min−1 gcat−1 at 20 °C, 30 °C and 40 °C, respectively. The volume of hydrogen produced versus time showed a linear relationship, proving that the hydrolysis of NaBH4 by the Co–B/Chi_AA catalyst is a first-order reaction with respect to temperature. The first-order kinetics is related to the diffusion of BH4− on the catalyst surface. The hydride/catalyst molar ratio is low, which means that the catalyst surface is not completely covered with BH4− reactants and some unsaturated active sites on the surface are available for the reaction [33]. By fitting the values of the rate constant k obtained for various temperatures, the Arrhenius law, where Ea is the activation energy (kJ/mol), A is the preexponential factor and R is the ideal gas constant, can be used to study reaction kinetics (Eq. 2).

The slope of the linear component of the zero- and first-order kinetic analysis was used to determine the reaction rate constant k at various temperatures. Figure 9 displays the Arrhenius plot of lnk versus 1/T for the catalyst. Ea for NaBH4 hydrolysis catalyzed by the Co–B/Chi_AA catalyst was calculated to be 51.65 kJ/mol based on the slope of the straight line. This value is lower than most previously reported values (Table 5). The relatively low activation energy indicates that Co–B/Chi_AA has a favorable catalytic performance and that the synergistic interactions between Co and B may have also influenced the results. Based on the kinetic analysis of NaBH4 hydrolysis at different temperatures, the calculated Ea value is closer to most other Co-based catalysts, including CoB/Clay (56.32 kJ mol−1), CoB/TiO2 (51.0 kJ mol−1), Co3O4/Chitosan/urea (47.97 kJ mol−1), etc. (Table 5). This indicates that the synthesized biocatalyst is effective for the NaBH4 hydrolysis reaction according to the hydrolysis mechanism.

Reusability of catalysts

The reusability of catalysts is a crucial evaluating criterion for their prospective use. Figure 10 shows the reusability of the Co–B/Chi AA catalyst for the hydrolysis of NaBH4 up to the fifth run (40 °C and 20 mg catalyst amount, 2.5 wt% NaBH4; 2.5 wt% NaOH; 400 rpm). As shown in Fig. 10, the same amount of H2 was obtained in each cycle tested, indicating that the yield of H2 was not affected by the repeated use of the catalysts. Excellent reusability is essential for a catalyst in practice. The fact that hydrogen generation remained constant and did not decrease noticeably suggests that the catalyst is highly reusable. According to these data, the Co–B/Chi_AA catalysts are sufficiently durable. Mapping analysis of the CoB/Chi and CoB/Chi_AA showed an even distribution of C, N and O. The particles together with C, N and O showing with certainty that only cobalt particles were impregnated on chitin without other impurities. This is a clear indication that the biocatalyst remained unchanged after the hydrolysis reaction and the catalyst activity did not decrease significantly. As shown in Fig. 10, the yield of H2 generation after five repeated applications of the prepared catalyst was 82.5%. However, the relative catalytic activity of the prepared catalyst gradually decreased as the number of applications increased. The decreasing activity was probably due to the accumulation of NaBO2 on the surface of the catalyst and the oxidation of the metal nanoparticles [37].

Conclusion

Co–B particles impregnated on Zabrus tenebrionides Goeze 1777 (Coleoptera: Carabidae) for the synthesis of an innovative catalyst. The catalytic activities of the two different catalysts (Co–B/Chi and Co–B/Chi_AA) were tested during sodium borohydride hydrolysis reaction under the same conditions. They showed excellent catalytic activity (HGR) for the hydrolysis of NaBH4 as 2124 mL min−1 gcat−1 with Co–B/Chi and 5546 mL min−1 gcat−1 with Co–B/Chi_AA at 40 °C. The acid activation of chitin improved the stability of the catalyst and HGR of the reaction. The increase in metal concentrations means that more active sites are available to catalyze the reaction, so the amount of catalyst used affects the rate of hydrogen generation. A series of tests were carried out at temperatures from 20 to 40 °C to determine the activation energy (Ea) for the hydrolysis of NaBH4 over the Co–B/Chi_AA catalyst. It was found that the reaction rate accelerates with increasing reaction temperature. This is due to the fact that a high reaction temperature promotes molecular collisions and the miscibility of the reactants and the catalyst, which speeds up the reaction rate. The calculated value of Ea is 51.65 kJ/mol, which is lower than most other Co-based catalysts. The synthesized Co–B/Chi_AA catalysts exhibit a uniform structure and good stability for reuse. Moreover, the Co–B/Chi_AA catalysts showed excellent catalytic activity for the hydrolysis of NaBH4 even after five runs. Chitin-supported cobalt particles are a green catalyst with useful applications due to the advantages of chitin as well as the high activity and strong reusability. Co–B/Chi catalysts are promising for on-demand hydrogen synthesis for fuel cells due to their ease of preparation and high performance.

Data availability

All data included in this study are available upon request by contact with the corresponding author.

References

Zhu T, Liu J, Wang Q et al (2023) Enhanced hydrogen production by microwave liquid-phase discharge plasma reforming of methanol solution without catalyst. J Energy Inst 108:101246. https://doi.org/10.1016/j.joei.2023.101246

Ozturk M, Dincer I (2021) A comprehensive review on power-to-gas with hydrogen options for cleaner applications. Int J Hydrog Energy 46:31511–31522. https://doi.org/10.1016/j.ijhydene.2021.07.066

Zeppini P, van den Bergh JCJM (2020) Global competition dynamics of fossil fuels and renewable energy under climate policies and peak oil: a behavioural model. Energy Policy 136:110907. https://doi.org/10.1016/j.enpol.2019.110907

Kord S, Fathirad F, Afzali D, Fayazi M (2022) Boron-Cobalt-Nickel-Yttrium nanocatalysts for hydrogen production from the hydrolysis of alkaline sodium borohydride solution. Inorg Chem Commun 136:109130. https://doi.org/10.1016/j.inoche.2021.109130

Retnamma R, Novais AQ, Rangel CM (2011) Kinetics of hydrolysis of sodium borohydride for hydrogen production in fuel cell applications: a review. Int J Hydrog Energy 36:9772–9790. https://doi.org/10.1016/j.ijhydene.2011.04.223

Şahin Ö, Karakaş DE, Kaya M, Saka C (2017) The effects of plasma treatment on electrochemical activity of Co–B–P catalyst for hydrogen production by hydrolysis of NaBH4. J Energy Inst 90:466–475. https://doi.org/10.1016/j.joei.2016.03.003

Colak TO, Tuc Altaf C, Minkina VG et al (2022) Efficient hydrogen generation with Co3O4@TiO2-g-C3N4 composite catalyst via catalytic NaBH4 hydrolysis. Catal Lett 152:2779–2788. https://doi.org/10.1007/s10562-021-03848-6

Liu M, Zhou L, Luo X et al (2020) Recent advances in noble metal catalysts for hydrogen production from ammonia borane. Catalysts 10:788. https://doi.org/10.3390/catal10070788

Simagina VI, Ozerova AM, Komova OV, Netskina OV (2021) Recent advances in applications of Co-B catalysts in NaBH4-based portable hydrogen generators. Catalysts 11:268. https://doi.org/10.3390/catal11020268

Lu Y-C, Chen M-S, Chen Y-W (2012) Hydrogen generation by sodium borohydride hydrolysis on nanosized CoB catalysts supported on TiO2, Al2O3 and CeO2. Int J Hydrog Energy 37:4254–4258. https://doi.org/10.1016/j.ijhydene.2011.11.105

Uzunoğlu D, Özer A (2020) Hydrogen gas production during the synthesis of the iron nanoparticles by using Pinus brutia, an accumulator plant. Int J Hydrog Energy 45:26472–26489. https://doi.org/10.1016/j.ijhydene.2020.03.217

Fangaj E, Ceyhan AA (2020) Apricot kernel shell waste treated with phosphoric acid used as a green, metal-free catalyst for hydrogen generation from hydrolysis of sodium borohydride. Int J Hydrog Energy 45:17104–17117. https://doi.org/10.1016/j.ijhydene.2020.04.133

Tomboc GRM, Tamboli AH, Kim H (2017) Synthesis of Co3O4 macrocubes catalyst using novel chitosan/urea template for hydrogen generation from sodium borohydride. Energy 121:238–245. https://doi.org/10.1016/j.energy.2017.01.027

Zou Y, Yin Y, Gao Y et al (2018) Chitosan-mediated Co–Ce–B nanoparticles for catalyzing the hydrolysis of sodium borohydride. Int J Hydrog Energy 43:4912–4921. https://doi.org/10.1016/j.ijhydene.2018.01.125

Park BK, Kim M-M (2010) Applications of chitin and its derivatives in biological medicine. Int J Mol Sci 11:5152–5164. https://doi.org/10.3390/ijms11125152

Wang Y, Zhang A, Mo X et al (2020) The effect of ultrasonication on enzymatic hydrolysis of chitin to N-acetyl glucosamine via sequential and simultaneous strategies. Process Biochem 99:265–269

Wang Y, Yang Y, Wang R et al (2022) Effectively inhibiting the degradation of chitin during extraction from crustacean waste via a novel deep eutectic solvent aqueous solution. Process Biochem 121:142–151. https://doi.org/10.1016/j.procbio.2022.06.029

Cauchie H-M (2002) Chitin production by arthropods in the hydrosphere. Hydrobiol 470:63–95. https://doi.org/10.1023/A:1015615819301

Mohan K, Ganesan AR, Muralisankar T et al (2020) Recent insights into the extraction, characterization, and bioactivities of chitin and chitosan from insects. Trends Food Sci Technol 105:17–42. https://doi.org/10.1016/j.tifs.2020.08.016

Kurtuluş G, Vardar F (2020) Kitosanın Özellikleri, Uygulama Alanlari, Bitki Sistemlerine Etkileri. Int J Adv Eng Pure Sci 32:258–269. https://doi.org/10.7240/jeps.635430

Lodos N (1983) Türkiye faunasına ait ekin kambur böcekleri, Zabrus Clairv. (Coleoptera: Carabidae) cinsinin yeniden gözden geçirilmesi. Türk Bitki Koruma Dergisi 7:51–63

Fidan ÊC, Sirin U (2016) The changes related with altitudinal gradient and seasonal variation in the species composition of Carabidae (Coleoptera) in Türkmen Mountain (Eskisehir, Turkey). Ekoloji Dergisi 25:98

Liebau F (2003) Ordered microporous and mesoporous materials with inorganic hosts: definitions of terms, formula notation, and systematic classification. Microporous Mesoporous Mater 58:15–72. https://doi.org/10.1016/S1387-1811(02)00546-2

Krishnan P, Advani SG, Prasad AK (2008) Cobalt oxides as Co2B catalyst precursors for the hydrolysis of sodium borohydride solutions to generate hydrogen for PEM fuel cells. Int J Hydrog Energy 33:7095–7102. https://doi.org/10.1016/j.ijhydene.2008.09.026

Guo J, Hou Y, Li B, Liu Y (2018) Novel Ni–Co–B hollow nanospheres promote hydrogen generation from the hydrolysis of sodium borohydride. Int J Hydrog Energy 43:15245–15254. https://doi.org/10.1016/j.ijhydene.2018.06.117

Jang M-K, Kong B-G, Jeong Y-I et al (2004) Physicochemical characterization of α-chitin, β-chitin, and γ-chitin separated from natural resources. J Polym Sci Part A Polym Chem 42:3423–3432. https://doi.org/10.1002/pola.20176

Manna J, Roy B, Vashistha M, Sharma P (2014) Effect of Co+2/BH4− ratio in the synthesis of Co–B catalysts on sodium borohydride hydrolysis. Int J Hydrog Energy 39:406–413. https://doi.org/10.1016/j.ijhydene.2013.10.018

Lin K-YA, Chang H-A (2016) Efficient hydrogen production from NaBH4 hydrolysis catalyzed by a magnetic cobalt/carbon composite derived from a zeolitic imidazolate framework. Chem Eng J 296:243–251. https://doi.org/10.1016/j.cej.2016.03.115

Duman S, Kaya B, Caf F et al (2021) Innovative hydrogen release from sodium borohydride hydrolysis using biocatalyst-like Fe2O3 nanoparticles impregnated on Bacillus simplex bacteria. Int J Hydrog Energy 46:15410–15430. https://doi.org/10.1016/j.ijhydene.2021.02.028

Yolcular S, Karaoglu S (2020) Hydrogen generation from sodium borohydride with cobalt boride catalysts. Alkü Bilim Derg 2:84–96

Liu C-H, Chen B-H, Hsueh C-L et al (2009) Hydrogen generation from hydrolysis of sodium borohydride using Ni–Ru nanocomposite as catalysts. Int J Hydrog Energy 34:2153–2163. https://doi.org/10.1016/j.ijhydene.2008.12.059

Zhu J, Li R, Niu W et al (2013) Fast hydrogen generation from NaBH4 hydrolysis catalyzed by carbon aerogels supported cobalt nanoparticles. Int J Hydrog Energy 38:10864–10870. https://doi.org/10.1016/j.ijhydene.2013.01.150

Patel N, Fernandes R, Miotello A (2009) Hydrogen generation by hydrolysis of NaBH4 with efficient Co–P–B catalyst: a kinetic study. J Power Sources 188:411–420. https://doi.org/10.1016/j.jpowsour.2008.11.121

Liao J, Huang H (2020) Magnetic sensitive hericium erinaceus residue chitin/Cu hydrogel nanocomposites for H2 generation by catalyzing NaBH4 hydrolysis. Carbohyd Polym 229:115426

Erol S, Özdemir M (2017) Development of Co-B/Magnesite catalyst for hydrogen generation by hydrolysis of sodium borohydride. J Turk Chem Soc Sect B Chem Eng 1:69–76

Tian H, Guo Q, Xu D (2010) Hydrogen generation from catalytic hydrolysis of alkaline sodium borohydride solution using attapulgite clay-supported Co-B catalyst. J Power Sources 195:2136–2142. https://doi.org/10.1016/j.jpowsour.2009.10.006

Ding J, Li Q, Su Y et al (2018) Preparation and catalytic activity of wheat straw cellulose based hydrogel-nanometal composites for hydrogen generation from NaBH4 hydrolysis. Int J Hydrog Energy 43:9978–9987. https://doi.org/10.1016/j.ijhydene.2018.04.077

Funding

Open access funding provided by the Scientific and Technological Research Council of Türkiye (TÜBİTAK).

Author information

Authors and Affiliations

Contributions

S.H. was involved in conceptualization, methodology, investigation and writing—original draft. E.C.F. helped with investigation, resources and writing—original draft. E.Z.H. took part in investigation, data curation and writing—review and editing. D.Ü.Ş. was responsible for resources, supervision and writing—review and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Ethical approval

Not applicable for human and/or animal studies.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Hoşgün, S., Fidan, E.C., Hoşgün, E.Z. et al. Hydrogen generation from sodium borohydride hydrolysis using a heterogeneous biocatalyst prepared with Zabrus tenebrionides Goeze 1777 (Coleoptera: Carabidae) chitin. Polym. Bull. 81, 10841–10857 (2024). https://doi.org/10.1007/s00289-024-05230-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-024-05230-z