Abstract

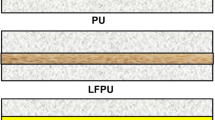

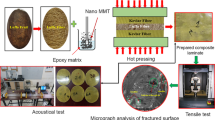

The presented study outlines the development and characterisation of a sandwich composite comprising coarse wool and polylactic acid (PLA). The PLA granules were placed in between two coarse wool fabrics and the sandwich model composite was prepared through hot pressing. The morphological, thermal, physico-mechanical and aging properties of the composite were systematically analysed. Additionally, as a part of product development, an acoustic panel was fabricated with the developed composites. The composite exhibited high stiffness, displaying a modulus of 964 MPa. The XRD analysis indicated that the wool-PLA composite is amorphous in nature. In the water diffusion test, the wool-PLA composite demonstrated permeability to water, resulting in 31% gain upon saturation. The accelerated UV aging did not mark significant changes in the tensile strength of the composite. However, the thermal aging led to a drastic reduction in tensile strength. During the soil burial test for 120 days, the composite lost 20% of its weight. The acoustic panel developed from the wool-PLA composite exhibited an impressive noise reduction coefficient of 0.97 and excellent thermal resistance (0.055 m2 W/K). The newly developed wool-PLA composite could find potential applications in biodegradable secondary ceilings, partition boards, thermal and acoustic panels.

Graphical abstract

Similar content being viewed by others

References

Gholampour A, Ozbakkaloglu T (2020) A review of natural fiber composites: properties, modification and processing techniques, characterization, applications. J Mater Sci 55:829–892

Açık G (2020) Synthesis, properties and enzymatic biodegradation behavior of fluorinated poly (epsilon-caprolactone) s. Express Polym Lett 14:272–280

Shahdan D, Rosli NA, Chen RS et al (2023) Strategies for strengthening toughened poly(lactic acid) blend via natural reinforcement with enhanced biodegradability: a review. Int J Biol Macromol 251:126214

Auras RA, Lim LT, Selke SE et al (2011) Poly (lactic acid): synthesis, structures, properties, processing, and applications. John Wiley & Sons, New York

Yashas Gowda TG, Sanjay MR, Subrahmanya Bhat K et al (2018) Polymer matrix-natural fiber composites: an overview. Cogent Eng 5:1446667

Tripathi N, Misra M, Mohanty AK (2021) Durable polylactic acid (PLA)-based sustainable engineered blends and biocomposites: recent developments, challenges, and opportunities. ACS Eng Au 1:7–38

Samant L, Fernandes FA, Jose S et al (2022) Natural composites in aircraft structures. Materials structures and manufacturing for aircraft. Springer, Cham

Pawlak F, Aldas M, Parres F, López-Martínez J et al (2020) Silane-functionalized sheep wool fibers from dairy industry waste for the development of plasticized pla composites with maleinized linseed oil for injection-molded parts. Polymers 12:2523

Tawiah B, Yu B, Ullah S et al (2019) Flame retardant poly (lactic acid) biocomposites reinforced by recycled wool fibers–thermal and mechanical properties. Express Polym Lett 13:697–712

Jose S, Thomas S, Jibin KP et al (2022) Surface modification of wool fabric using sodium lignosulfonate and subsequent improvement in the interfacial adhesion of natural rubber latex in the wool/rubber composites. Ind Crops Prod 177:114489

Jose S, Shanumon PS, Paul A et al (2022) Physico-mechanical, thermal, morphological, and aging characteristics of green hybrid composites prepared from wool-sisal and wool-palf with natural rubber. Polymers 14:4882

Tessier D (2018) Testing thermal properties of textiles. Advanced characterization and testing of textiles. Woodhead Publishing, Elsevier

Jose S, Shanmugam N, Das S et al (2019) Coating of lightweight wool fabric with nano clay for fire retardancy. J Text Inst 110:764–770

Jose S, Nachimuthu S, Das S et al (2018) Moth proofing of wool fabric using nano kaolinite. J Text Inst 109:225–231

Rani S, Kadam V, Rose NM et al (2020) Wheat starch, gum arabic and chitosan biopolymer treatment of wool fabric for improved shrink resistance finishing. Int J Biol Macromol 163:1044–1052

Kadam V, Rani S, Jose S et al (2021) Biomaterial based shrink resist treatment of wool fabric: a sustainable technology. Stain Mater Technol 29:00298

Yang SL, Wu ZH, Yang W et al (2008) Thermal and mechanical properties of chemical crosslinked polylactide (PLA). Polym Test 27:957–963

Edith D, Six JL (2006) Surface characteristics of PLA and PLGA films. Appl Surf Sci 253:2758–2764

ChenHayJenkins ZJM (2012) FTIR spectroscopic analysis of poly (ethylene terephthalate) on crystallization. Eur Polym J 48:1586–1610

Picciochi R, Wang Y, Alves NM et al (2007) Glass transition of semi-crystalline PLLA with different morphologies as studied by dynamic mechanical analysis. Colloid Polym Sci 285:575–580

Badia JD, Strömberg E, Karlsson S et al (2012) Material valorisation of amorphous polylactide. Influence of thermo-mechanical degradation on the morphology, segmental dynamics, thermal and mechanical performance. Polym Degrad Stab 97:670–678

Cristea M, Ionita D, Iftime MM (2020) Dynamic mechanical analysis investigations of PLA-based renewable materials: how are they useful? Materials 13:5302

Mofokeng JP, Luyt AS, Tábi T et al (2012) Comparison of injection moulded, natural fibre-reinforced composites with PP and PLA as matrices. J Thermoplast Compos Mater 8:927–948

Tábi T, Sajó IE, Szabó F et al (2010) Crystalline structure of annealed polylactic acid and its relation to processing. Express Polym Lett 1:4

Teixeira ED, De Campos A, Marconcini JM et al (2014) Starch/fiber/poly (lactic acid) foam and compressed foam composites. RSC Adv 4:6616–6623

Kobayashi Y, Ueda T, Ishigam A et al (2021) Changes in crystal structure and accelerated hydrolytic degradation of polylactic acid in high humidity. Polymers 13:24

Horrocks AR, Davies PJ (2020) Char formation in flame-retarded wool fibres. Part 1. Effect of intumescent on thermogravimetric behaviour. Fire Mater 24:151–157

Zou H, Yi C, Wang L et al (2009) Thermal degradation of poly (lactic acid) measured by thermogravimetry coupled to Fourier transform infrared spectroscopy. J Therm Anal Calorim 97:929–935

Sankaran A, Kamboj A, Samant L et al (2021) Synthetic and natural UV protective agents for textile finishing. Innov Emerg Technol Text Dye Finish. https://doi.org/10.1002/9781119710288.ch11

Ejaz M, Azad MM, Shah AU et al (2020) Mechanical and biodegradable properties of jute/flax reinforced PLA composites. Fibers Polym 21:2635–2641

Bednarek M, Borska K, Kubisa P (2020) Crosslinking of polylactide by high energy irradiation and photo-curing. Molecules 25:4919

Saadi Z, Rasmont A, Cesar G et al (2012) Fungal degradation of poly (l-lactide) in soil and in compost. J Polym Environ 20:273–282

Lv S, Zhang Y, Gu J, Tan H (2018) Physicochemical evolutions of starch/poly (lactic acid) composite biodegraded in real soil. J Environ Manage 228:223–231

Rodrigues CA, Tofanello A, Nantes IL et al (2015) Biological oxidative mechanisms for degradation of poly (lactic acid) blended with thermoplastic starch. ACS Sustain Chem Eng 3:2756–2766

Pelegrini K, Donazzolo I, Brambilla V et al (2016) Degradation of PLA and PLA in composites with triacetin and buriti fiber after 600 days in a simulated marine environment. J Appl Polym Sci 15:133

Muniyasamy S, Patnaik A (2021) Biodegradable behavior of waste wool and their recycled polyester preforms in aqueous and soil conditions. J Renew Mater 9:1661–1671

Broda J (2019) Biodegradation of sheep wool geotextiles designed for erosion control. Environmental chemistry and recent pollution control approaches. IntechOpen, London, UK

Nieddu E, Mazzucco L, Gentile P et al (2009) Preparation and biodegradation of clay composites of PLA. React Funct Polym 69:371–379

Berardi U, Iannace G (2015) Acoustic characterization of natural fibers for sound absorption applications. Built Environ 94:840–852

Göransson P (2006) Acoustic and vibrational damping in porous solids. Philos Trans Math Phys Eng 364:89–108

Acknowledgements

The authors would like to express their gratitude to their respective institute for providing facilities to conduct the present research.

Funding

There are no funders to this research.

Author information

Authors and Affiliations

Contributions

SJ contributed to the conceptualisation, composite preparation and testing, PSS was involved in the first draft preparation and composite preparation, VK contributed to the analysis of acoustic and thermal properties and manuscript editing and correction, MT assisted in the testing of samples and ST was involved in the technical guidance and manuscript correction.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing financial interests and conflict of interest.

Ethical approval

We confirm that all the research meets ethical guidelines and adheres to the legal requirements of the study country. The research does not involve any human or animal welfare related issues.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jose, S., Shanumon, P.S., Kadam, V. et al. Preparation, characterisation and application of biodegradable coarse wool-poly(lactic acid) sandwich composite. Polym. Bull. (2024). https://doi.org/10.1007/s00289-024-05186-0

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00289-024-05186-0