Abstract

Natural fiber composites often exhibit significant acoustic behavior in low-frequency range. The focus of this study is to create soundproof panels using luffa and Kevlar fiber composites reinforced using nanoclay (MMT) filler. Mechanical testing was performed on the prepared samples. The addition of 4% MMT improved the mechanical characteristics. Mechanical parameters such as interlaminar shear, tensile, flexural, and impact strength were enhanced by 9.13%, 16.89%, 9.71% and 51.64%, respectively, as compared to the control sample. Tribological experiments were performed on the manufactured composite samples in dry sliding conditions as a function of control factors such as sliding speed, sliding distance, and effective load. The results reveal that using 6% MMT to Kevlar/LCF epoxy composites greatly increases the COF and specific wear rate. The sound absorption test results indicated that the incorporation of nano MMT with Kevlar/LCF composites increased the sound transmission loss. The reduced hydrophilicity effect has been reported with the addition of 4% (by weight) MMT in contact angle measurement studies. Moreover, the created biocomposites are low-cost and long-lasting materials suitable for use as soundproofing panels in automobiles and railway cabins.

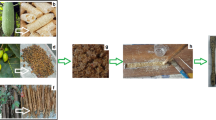

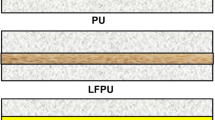

Graphical Abstract

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Maharana SM, Pradhan AK, Pandit MK (2020) Performance evaluation of mechanical properties of nanofiller reinforced jute-Kevlar hybrid composite. J Nat Fibers 19:984–998. https://doi.org/10.1080/15440478.2020.1777246

Sathishkumar GK, Gautham G, Gowri Shankar G, Rajkumar G, Karpagam R, Dhivya V, George Z, Gopinath B, Karthik P, Martin Charles M (2022) Influence of lignite fly ash on the structural and mechanical properties of banana fiber containing epoxy polymer matrix composite. Polym Bull 79:285–306. https://doi.org/10.1007/s00289-020-03524-6

Hossen MF, Hamdan S, Rahman MR, Rahman MM, Liew FK, Lai JC (2015) Effect of fiber treatment and nanoclay on the tensile properties of jute fiber reinforced polyethylene/clay nanocomposites. Fibers Polym 16:479–485. https://doi.org/10.1007/s12221-015-0479-x

García del Pino G, Kieling AC, Bezazi A, Boumediri H, Rolim de Souza JF, Díaz FV, Rivera JV, Dehaini J, Panzera TH (2020) Hybrid polyester composites reinforced with Curauá fibres and nanoclays. Fibers Polym 21:399–406. https://doi.org/10.1007/s12221-020-9506-7

Patnaik TK, Nayak SS (2018) Development of silicon carbide reinforced jute epoxy composites: physical, mechanical and thermo-mechanical characterizations. SILICON 10:137–145. https://doi.org/10.1007/s12633-015-9393-5

Papanicolaou GC, Psarra E, Anastasiou D (2015) Manufacturing and mechanical response optimization of epoxy resin/Luffa Cylindrica composite. J Appl Polym Sci 132:189–196. https://doi.org/10.1002/app.41992

Negawo TA, Polat Y, Buyuknalcaci FN, Kilic A, Saba N, Jawaid M (2019) Mechanical, morphological, structural and dynamic mechanical properties of alkali treated Ensete stem fibers reinforced unsaturated polyester composites. Compos Struct 207:589–597. https://doi.org/10.1016/j.compstruct.2018.09.043

Yan L, Chouw N, Huang L, Kasal B (2016) Effect of alkali treatment on microstructure and mechanical properties of coir fibres, coir fibre reinforced-polymer composites and reinforced-cementitious composites. Constr Build Mater 112:168–182. https://doi.org/10.1016/j.conbuildmat.2016.02.182

Mohanta N, Acharya SK (2018) Effect of alkali treatment on the flexural properties of a Luffa cylindrica-reinforced epoxy composite. Sci Eng Compos Mater 25:85–93. https://doi.org/10.1515/secm-2015-0148

Mourad AHI, Zaaroura N (2018) Impact of Nanofillers Incorporation on Laminated Nanocomposites Performance. J Mater Eng Perform 27:4453–4461. https://doi.org/10.1007/s11665-018-3523-3

Ashok KG, Vetrivel Sezhian M, Karthik K, Kousiharaaj G (2022) Energy absorption performance of Kevlar/snake grass fiber composites under ballistic impact test with nano Al 2 O 3 inclusion. Polym Compos 43:6082–6095. https://doi.org/10.1002/pc.26911

Ashok KG, Kalaichelvan K, Damodaran A (2020) Effect of Nano Fillers on Mechanical Properties of Luffa Fiber Epoxy Composites. J Nat Fibers 2020:1–18. https://doi.org/10.1080/15440478.2020.1779898

Wan Ramli WMA, Abdul Majid MS, Ridzuan MJM, Sultan MTH, Amin NAN, Gibson AG (2020) The effect of nanomodified epoxy on the tensile and flexural properties of Napier fiber reinforced composites. Polym Compos 41:824–837. https://doi.org/10.1002/pc.25413

Sheykh MJ, Tarmian A, Doosthoseini K, abdulkhani A, (2017) Wear resistance and friction coefficient of nano-SiO2 and ash-filled HDPE/lignocellulosic fiber composites. Polym Bull 74:4537–4547. https://doi.org/10.1007/s00289-017-1975-5

Ramakrishnan S, Krishnamurthy K, Rajasekar R, Rajeshkumar G (2019) An experimental study on the effect of nano-clay addition on mechanical and water absorption behaviour of jute fibre reinforced epoxy composites. J Ind Text 49:597–620. https://doi.org/10.1177/1528083718792915

Ashok KG, Kani K (2021) Experimental studies on interlaminar shear strength and dynamic mechanical analysis of luffa fiber epoxy composites with nano PbO addition. J Ind Text 51:3829–3854. https://doi.org/10.1177/15280837211052317

Daniel-Mkpume CC, Ugochukwu C, Okonkwo EG, Fayomi OSI, Obiorah SM (2019) Effect of Luffa cylindrica fiber and particulate on the mechanical properties of epoxy. Int J Adv Manuf Technol 102:3439–3444. https://doi.org/10.1007/s00170-019-03422-w

Ashok KG, Kalaichelvan K (2020) Mechanical, ballistic impact, and water absorption behavior of luffa/graphene reinforced epoxy composites. Polym Compos 41:4716–4726. https://doi.org/10.1002/pc.25745

Naveen J, Jawaid M, Zainudin ES, Sultan MTH, Yahaya R (2019) Improved interlaminar shear behaviour of a new hybrid Kevlar/Cocos nucifera sheath composites with graphene nanoplatelets modified epoxy matrix. Fibers Polym 20:1749–1753. https://doi.org/10.1007/s12221-019-3127-z

Jagadeesh P, Ningappa VSH, Puttegowda M, Girijappa YGT, Rangappa SM, Khan MR, Khan I, Siengchin S (2021) Pongamia pinnata shell powder filled sisal/kevlar hybrid composites: Physicomechanical and morphological characteristics. Polym Compos 42:4434–4447. https://doi.org/10.1002/pc.26160

Olcay H, Kocak ED (2021) Rice plant waste reinforced polyurethane composites for use as the acoustic absorption material. Appl Acoust 173:1077–1093. https://doi.org/10.1016/j.apacoust.2020.107733

Arumugam H, Krishnasamy B, Perumal G, Anto DA, Aleem MIA, Alagar M (2021) Bio-composites of rice husk and saw dust reinforced bio-benzoxazine/epoxy hybridized matrices: Thermal, mechanical, electrical resistance and acoustic absorption properties. Constr Build Mater 312:1253–1265. https://doi.org/10.1016/j.conbuildmat.2021.125381

Sambandamoorthy S, Narayanan V, Chinnapandi LBM, Aziz A (2021) Impact of fiber length and surface modification on the acoustic behaviour of jute fiber. Appl Acoust 173:1076–1087. https://doi.org/10.1016/j.apacoust.2020.107677

Prabhu L, Krishnaraj V, Gokulkumar S, Sathish S, Sanjay MR, Siengchin S (2022) Mechanical, chemical and sound absorption properties of glass/kenaf/waste tea leaf fiber-reinforced hybrid epoxy composites. J Ind Text 51:1674–1700. https://doi.org/10.1177/1528083720957392

Mina MF, Gafur MA, Ahmed AN, Dhar SA (2018) Effect of chemical modifications on surface morphological, structural, mechanical, and thermal properties of sponge-gourd natural fiber. Fibers Polym 19:31–40. https://doi.org/10.1007/s12221-018-7199-3

ASTM Committee D-30 on Composite Materials (2008) Standard test method for tensile properties of polymer matrix composite materials. ASTM international

Sherwani SFK, Sapuan SM, Leman Z, Zainudin ES, Khalina A (2021) Physical, mechanical and morphological properties of sugar palm fiber reinforced polylactic acid composites. Fibers Polym 22:3095–3105. https://doi.org/10.1007/s12221-021-0407-1

Method ST (2000) iTeh Standards iTeh Standards Document Preview. 08:3–4 https://doi.org/10.1520/D0638-22.1

Ashok KG, Sathish Kumar GK, Kalaichelvan K, Ajith D, Bibin C (2023) Calotropis gigantea stem fiber reinforced thermoset plastics: Interlaminar shear strength and related tribo-mechanical properties. Proc Inst Mech Eng Part L J Mater Des Appl 237:886–905. https://doi.org/10.1177/14644207221129292

Rajini N, Mayandi K, Manoj Prabhakar M, Siengchin S, Ayrilmis N, Bennet C, Ismail SO (2021) Tribological properties of cyperus pangorei fibre reinforced polyester composites (friction and wear behaviour of cyperus pangorei fibre/polyester composites). J Nat Fibers 18:261–273. https://doi.org/10.1080/15440478.2019.1621232

Bajpai PK, Singh I, Madaan J (2013) Tribological behavior of natural fiber reinforced PLA composites. Wear 297:829–840. https://doi.org/10.1016/j.wear.2012.10.019

Dwivedi UK, Singh S, Shukla SC, Hashmi SAR (2022) Investigation on tribo-characteristics of Calotropis gigantea fiber-reinforced-CNT modified polymer composites. Polym Bull 79:697–707. https://doi.org/10.1007/s00289-020-03532-6

Method ST Impedance and Absorption of Acoustical Materials Using a iTeh Standards iTeh Standards. 4–9 https://doi.org/10.1520/E1050-19.2

Lim ZY, Putra A, Nor MJM, Yaakob MY (2018) Sound absorption performance of natural kenaf fibres. Appl Acoust 130:107–114. https://doi.org/10.1016/j.apacoust.2017.09.012

Specimens P (2003) Standard Test Methods for iTeh Standards iTeh Standards Document Preview. i:1–6 https://doi.org/10.1520/D5946-17.2

Anbukarasi K, Kalaiselvam S (2015) Study of effect of fibre volume and dimension on mechanical, thermal, and water absorption behaviour of luffa reinforced epoxy composites. Mater Des 66:321–330. https://doi.org/10.1016/j.matdes.2014.10.078

Saba N, Paridah AK, Ibrahim NA (2016) Dynamic mechanical properties of oil palm nano filler/kenaf/epoxy hybrid nanocomposites. Constr Build Mater 124:133–138. https://doi.org/10.1016/j.conbuildmat.2016.07.059

Zaer-Miri S, Khosravi H (2019) Assessment of the wear behavior and interlaminar shear properties of modified nano-TiO2/jute fiber/epoxy multiscale composites. J Ind Text 51:1084–1099. https://doi.org/10.1177/1528083719893718

Dang CY, Shen XJ, Nie HJ, Yang S, Shen JX, Yang XH, Fu SY (2019) Enhanced interlaminar shear strength of ramie fiber/polypropylene composites by optimal combination of graphene oxide size and content. Compos Part B Eng 168:488–495. https://doi.org/10.1016/j.compositesb.2019.03.080

Hallad SA, Banapurmath NR, Hunashyal AM, Shettar AS, Ayachit NH, Mruthunjaya AK, Lohit RB, Uttur M (2017) Experimental investigation for graphene and carbon fibre in polymer-based matrix for structural applications. J Appl Res Technol 15:297–302. https://doi.org/10.1016/j.jart.2017.01.014

Dadkar N, Tomar BS, Satapathy BK (2009) Evaluation of flyash-filled and aramid fibre reinforced hybrid polymer matrix composites (PMC) for friction braking applications. Mater Des 30:4369–4376. https://doi.org/10.1016/j.matdes.2009.04.007

Reddy PV, Reddy RVS, Rajendra Prasad P, Krishnudu DM, Reddy RM, Raghavendra Rao H (2022) Evaluation of mechanical and wear performances of natural fiber reinforced epoxy composites. J Nat Fibers 19:2218–2231. https://doi.org/10.1080/15440478.2020.1807441

Ashok K, Ajith D, Bibin C, Sheeja R, Nishanth R (2022) Influence of nanofiller lignite fly ash on tribo-mechanical performance of sansevieria roxburghiana fiber reinforced epoxy composites. J Nat Fibers 19:6000–6014. https://doi.org/10.1080/15440478.2021.1902904

Molkara F, Najafi SK, Ghasemi I (2018) Foam morphology and sound transmission loss of foamed wood flour/low-density polyethylene (LDPE)/nanoclay composites. J Thermoplast Compos Mater 31:1470–1482. https://doi.org/10.1177/0892705717738298

Ahmadi S, Nassiri P, Ghasemi I, Esmaeilpoor MRM (2015) Sound transmission loss through nanoclay-reinforced polymers. Iran Polym J 24:641–649. https://doi.org/10.1007/s13726-015-0353-0

Mohammed M, Rahman R, Mohammed AM, Betar BO, Osman AF, Adam T, Dahham OS, Gopinath SCB (2022) Improving hydrophobicity and compatibility between kenaf fiber and polymer composite by surface treatment with inorganic nanoparticles. Arab J Chem 15:104233. https://doi.org/10.1016/j.arabjc.2022.104233

Acknowledgements

The authors wish to thank the Department of Science and Technology, Government of India for funding the Research Infrastructure under the Scheme entitled “Funds for the Improvement of S&T Infrastructure (DST-FIST)" Ref. No. SR/FST/College–110/2017 for Easwari Engineering College.

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

Ashok K G: Conceptualization, writing—original draft and Data curation. Praveen Kumar A: Supervision. Raju M: Investigation, Writing—review and editing. Kasirajan G: Formal analysis and Visualization.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that would appear to influence the work reported in this paper.

Ethical approval

This article does not contain any studies involving human or animal subjects.

Consent to participate

All authors were highly cooperative and involved equally in research activities and preparation of this article.

Consent for publication

All authors agreed to publish this research article.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ashok, K.G., Praveen Kumar, A., Raju, M. et al. Luffa and Kevlar fiber/nanoclay sustainable thermoset biocomposites: acoustic and tribo-mechanical study. Iran Polym J (2024). https://doi.org/10.1007/s13726-024-01306-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13726-024-01306-9