Abstract

Polylactic acid (PLAs) and polycaprolactones (PCLs) are emerging to be polyesters of choice because they are biodegradable and biocompatible. The industrial viable method currently used for their production is catalytic ring-opening polymerization (ROP) of their respective cyclic ester monomers. The catalyst is at the core of ROP chemical transformation and as such research is dedicated towards the innovation of more efficient and selective catalysts. Catalyst structural features greatly influence catalyst performance in ROP, and this review discusses the effects of ligand and catalyst structure and system dynamics, on catalytic activity and polymer properties. The effects of associated catalyst components such as initiating groups, ligand chirality, and stereochemical in relation to catalyst activity and polymer properties were also reviewed. The effects of metal nuclearity and catalyst flexibility on catalytic activity were also reviewed. The effect of solvent and temperature was briefly considered.

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Catalytic ring-opening polymerization (ROP) reactions have had incredible influence on the synthesis of polyesters with distinctive, molecular weights, microstructures, molecular weight distributions and end group functionalities. These ROP reactions have mostly been effectively mediated by complexes synthesised using alkali group metals [1,2,3], copper [4, 5], iron [6, 7], indium [8], magnesium [9, 10], tin [11, 12], zinc [13, 14], aluminium [15, 16], silver [17, 18], cobalt, [19], titanium [20, 21] lanthanides (ytterbium, yttrium, samarium) [22, 23] amongst others. Of these, magnesium complexes have shown the greatest activity compared to the other systems [10, 24,25,26], but their industrial adoption has been hampered by low stability at industrial relevant conditions. ROP reactions involving metal complexes are normally multicomponent systems, consisting of the catalyst or initiator, monomer, and in some cases co-initiator. Tin(II) complexes are currently the mostly used systems in industry because of their high activity, viability, and they are easy to handle. However, they come with disadvantages of toxicity, and high polymerization temperatures which promote inter- and intra-molecular transesterification reactions compromising polymerization control. To circumvent the above disadvantages, there is an increased interest in the design of ROP catalysts that are active, less toxic, and selective. This has led to the synthesis and testing of a whole assortment of catalytic systems. Amongst the designed catalysts, ligand-supported metal complexes have display a lot of promise [27,28,29,30]. The ligand structures have a significant impact on the product composition, selectivity and productivity in polymerization reactions [31,32,33,34]. Current studies of ROP are focused on the use of N- and/or O-ligands stabilised metal-based catalysts [13, 35,36,37,38]. Ligands with soft donor atoms such as P and S have however, been seldom explored, regardless of their positive effect in ROP reaction processes [14, 39]. Previous studies have shown the benefits of including such soft donor atoms in improving catalyst performance and polymer properties [40,41,42]. Of late, there is a growing interest in the use of N-heterocyclic carbenes (NHCs) supported metal complexes in ROP since their inception by Tolmans group [43]. The NHCs compete with phosphines and other ligands in catalysis due to robust σ-donating and easily modified π-accepting capabilities [44].

Environmental alarms coupled with a drive towards polymeric material devoid of potentially toxic and carcinogenic metals compounds have propelled research in macromolecular engineering processes towards bio-organo-catalytic transformations. Enzymes have emerged as suitable candidates towards green and safer alternative for ROP transformations [45, 46]. Enzymes generally display reaction stereo-control, substrate specificity and, they originate from renewable materials that are readily recycled. Enzyme assisted ROP and condensation using lipase was pioneered by Kobayashi [47] and Knani [48] groups. Lipase B from Candida antarctica (CALB) has demonstrated to be the most suitable ROP enzyme, and its thermal stability and recovery have been improved by immobilization on a solid support [46]. The most widely used solid supports include silica [49], polymer resins [50], nanoparticles [51], and carbon nanostructures materials [52]. A notable advantage is their capability to polymerize larger lactone rings beyond seven units with subsequent rate increase with ring size.

Organo-catalytic living ROP is another metal free method pioneered by Nederberg et al. [53] using 4-dimethylaminopyridine (DMAP) and 4-pyrrolidinopyridine (PPY) in the presence alcohol co-initiators. Remarkable merit of DMAP is its competence and ability to shut undesirable intra and/or intermolecular transesterifications reactions. DMAP was formerly anticipated to follow the nucleophilic AMM but computational studies pointed to a co-initiator activation mechanism which can be concerted or stepwise [54].

Many polymer properties depend on molecular weights and the molecular weight distributions. The molecular weights are usually expressed as weight average molecular weights (Mw) and number-average molecular weights (Mn). The ratio Mw/Mn (also referred to as dispersity index, Ð) defines the molecular weight distribution and it approaches a unit for a controlled polymerization process [55]. There are few manipulations that can be used to increase the molecular weights and reduce the polymer dispersity values. One such manipulation is the reduction in the concentration of the initiating species which reduces the number of growing chains per centre, ultimately enabling the chains to grow to full length. Another manipulation is to reduce transesterification reactions of which should reduce chain shuffling and subsequently the chain lengths [56].

The focus of this review is to give an understanding of ring opening polymerization process by correlating catalyst structure with activity and polymer structures. The selected examples were chosen to explain the principles under consideration, which will serve as a starting point. The influence of ligand structure on activity and polymer properties is highlighted with emphasis on steric and electronic properties, and chirality. The influence of general catalyst structural features such as initiation groups, nuclearity and rigidity also, an analysis of reaction variables is considered.

Overview of ring opening polymerization of lactides and ε-caprolactone

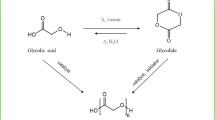

Polyesters can be synthesised with varying molar masses, architectures and stereochemistries, through ring opening polymerization (ROP) of cyclic ester monomers, the common ones being ε-caprolactone (ε-CL) and lactides (LAs) (Fig. 1). The ring opening reaction is usually initiated by a catalyst but in certain instances, alcohols can be added as co-initiator often furnishing polymers with an alkoxyl end groups.

Thermodynamics and kinetics of ROP reactions

Macromolecules generally results from polymerization of small monomeric units associated with a reduction in entropy of the thermodynamic system. The polymerization process is promoted at low temperatures, while, the reverse process is only favoured at a higher temperature. The entropy change (ΔSp) is typically negative and renders the TΔSp term positive in the Gibb’s free energy relationship Eq. (1) [57].

where \({\Delta H}_{p}\) = enthalpy of polymerization, T = temperature and \({\Delta G}_{p}\) = Gibb’s free energy.

At comparatively elevated temperatures, TΔS is acceptably positive such that the overall chemical process becomes endergonic. The system temperature when, ΔG = 0 is referred to as the ceiling temperature, Tc and defined by Eq. (2) [55, 58].

“Tc is the temperature at or above which the monomer concentration is in equilibrium with its polymer becomes fundamentally equivalent to the original monomer concentration” [55, 58]. The fundamental thermodynamic principles of this concept were explained by Dainton and Irvin [57], who argued that this phenomenon is largely influenced by the initial monomer concentration. This lead to the derivation of Dainton’s Eq. (3) [59].

Ring size and strain are interrelated to the thermodynamic enthalpic and entropic terms. Relieving ring strain propels the polymerization process and is coupled to entropy reduction, owing to loss in translational degrees of motion [55, 58]. Disregarding the monomer-solvent interaction effects the enthalpy of polymerization can give an idea about the ring strain. The polymerization process becomes thermodynamically feasible only when the enthalpic contribution into ∆G dominates; hence, larger ring strain corresponds to lower equilibrium monomer concentration ([M]eq) [59].

Polymerization reaction rates are defined by the change in monomer concentration that is converted to a polymer. The change in monomer [M] and polymer [P] concentration per given time is expressed by rate Eqs. 4 and 5.

Then, polymerization rate for an nth order reaction can be expressed as shown in Eq. (6)

where k = kp[I]x; kp = chain propagation rate, I = initiator; and x = order of reaction. The integrated rate law is expressed by Eq. (7).

Hence, the semi-logarithmic plots of ln([M]0/[M]t) vs time are linear and the rate constants can be extrapolated from the slope. Depending on the reaction time scale and monomer functionalities, different instrumental techniques can be utilized to monitor the polymerization reaction. These include nuclear magnetic resonance (NMR) [60], infrared (IR) [61], Raman [62], and ultraviolet–visible (UV/Vis) [63] spectroscopy techniques. Amongst these, NMR has proven to be the more powerful tool in polymerization reaction monitoring [64,65,66] and polymer characterisation [60, 67,68,69,70,71].

Ring opening polymerization mechanisms of cyclic esters

The most extensively researched ROP catalysts/initiators are organometallic complexes and their mechanism of operation has been a subject under review. There are four mechanisms that have been put forward and are discussed in the following section. These including cationic and ionic mechanisms, activated monomer (AM), and coordination-insertion (CI) mechanisms.

Cationic ROP mechanism

The cationic ROP mechanism (Scheme 1) of cyclic eaters encompasses the generation of positively charged intermediate species which react with the monomer. The cyclic ring will open via an SN2-mechanism. The cationic polymerization transformation is poorly regulated, and polymers with low molecular weight are produced [56]. The initial step involves monomer activation by alkylation or protonation of the carbonyl oxygen generating a carbocation intermediate. Nucleophilic attack by an incoming monomer lead to ring opening through scission of the C–O bond resulting in a positively charged species. The propagation step occurs by successive addition of monomers until the polymerization is terminated by protonation [72].

Anionic ROP mechanism

In anionic ROP of cyclic ester monomers, a negatively charged nucleophilic attack the carbon near the acyl–oxygen. The raptured monomers will act as nucleophiles and the replication of the same process occurs. The bonding in the activated transition state shuttle between ionic and covalent. This depends on the chain-end propagating species and the solvent Scheme 2 [56].

ROP coordination-insertion and activated monomer mechanisms

The coordination-insertion mechanism (Scheme 3) [73] has been extensively studied and is the mostly accepted ROP mechanism. The mode of action has been supported by theoretical studies using density functional theory (DFT) computations [74,75,76]. The first step has been proposed to be complexation of the monomer via the carbonyl oxygen of the cyclic monomer. This enhances the monomer keto carbon electrophilicity rendering scission of the oxygen–acyl link. The coordination-insertion method is a controlled process which allows control of polymer molecular weight, molecular weight distributions (Ð) and hinders epimerization reactions [77]. Furthermore, it allows synthesis of stereo-regular polymers with well-defined end group functionalities.

ROP coordination-insertion mechanism [78]

In activated monomer mechanism (Scheme 4) [79, 80] an external nucleophile is added, whilst in CIM, the nucleophile is integrally attached to the active metal centre as an auxiliary ligand. In AMM the monomer is first coordinated to the metal centre for activation. An external nucleophile is then added, e.g. an alcohol (ROH), which then attack the electrophilic carbonyl carbon and initiate the polymerization resulting in the heterocycle ring rapture of the oxygen–acyl bond [81].

ROP activated monomer mechanism [78]

Borohydride initiated ROP also follow the CIM mechanism like the alkoxide, alkyls, amides counter parts, with some differences (Scheme 5) [82]. In this instance, the first step involves monomer coordination to the metal complex which is proceeded by a hydride migration to the monomer keto carbon and coordination of the borane ligand to the exocyclic carbonyl oxygen of the monomer [82, 83]. A second step involves relocation of the hydride from the O–C(H)(R)–O···BH3 moeity to the monomer carbonyl carbon resulting in acyl–oxygen bond scissoring furnishing a R–CH2–O–BH2 end group ultimately giving a catalyst-alkoxylborane derivative. Finally, quenching by hydrolysis releases the α,ω-dihydroxy telechelic polyesters [82].

CIM for borohydride initiated ROP [82]

ROP catalysts structural features

A complete structural characterization of ligands and complexes used in ROP can shed more light in unravelling reaction mechanisms and can provide important information about catalyst design and efficiency. A typical ROP metal-based catalyst comprises of the metal centre ligated with the main and auxiliary ligands. When only one metal centre is present, the catalysts are normally termed “single-site catalysts” and denoted with a structural formula (Ln-M-X), where L is the ligand and n the equivalents coordinated to the active metal centre (M) and X is the auxiliary initiating moiety. In literature, the words catalyst or initiator are interchangeably used. In principle, most compounds used perform both functions where one fragment (initiating group) of the molecule initiates the reaction whilst the other part act as the catalyst. The following subsection will discuss the correlation between the initiating groups/ligands types and activity.

Types of initiating ligands

Ring opening polymerization is characterised by three stages namely initiation, propagation and termination. The initiation phase is paramount to the process; hence, catalyst design must factor in the prerequisite condition for this process. Several initiating groups have been investigated which include, carboxylates [84, 85], alkoxides [86, 87], borohydrides [88, 89], carbenes [90, 91] and amides [24, 92]. These groups can be integrated into the ligands system or they can be attached as separate auxiliary ligands. In other scenarios, they are added as external nucleophiles during the polymerization reaction where they are referred to as chain transfer agents. Alkoxides are the most effective initiators compared to the others; hence, many studies have been devoted in probing such systems.

Carboxylate type initiating ligands

The carboxylate-based tin(II)bis-(2-ethylhexanoate) (Sn(Oct)2) laid the foundation for metal complex-based catalytic ROP since its conception. The tin(II) catalysts appear to be the most active and are predominantly utilized in industrial production of aliphatic polyesters. The complexes display a variety of structures in which, the carboxylate ligands assume a range of bonding modes (Fig. 2), which include monodentate (a), chelating (b), bidentate (c), symmetric and asymmetric (d) and mono-bidentate bridging (e). The stereo-electronic environment hugely influences the bonding modes of the carboxylate ligands. The various bonding modes generally results in varying initiation efficiencies. The chelate bridging modes are generally more binding which eventually results in slow initiation and polymerization rates. On the other hand, monodentate, symmetric and asymmetric modes are weakly binding hence more active [27].

Research by our group [27, 85] investigated the use formamidine zinc and copper complexes with acetate and benzoate auxiliary ligands in ROP (Fig. 3). Complex 1 exhibited a short induction period compared to complex 2 in ROP of ε-CL and ʟ-LA. The same trend was observed in complexes 3 and 4. The metal centres in complex 3 are arguably slightly crowded because of low repulsion of the methyl groups, which cause the ligands to approach more towards the metal compared to the bulk isopropyl groups. Presumably, the steric factors are comparable in both cases and the activities depend on the difference in the coordination modes of the acetate groups. Complex 2 with acetate groups was less active than complex 4 with benzoate groups. These findings resonance with the principle that benzoates are generally loosely bound to the metal centre, hence making them more reactive that the acetates. Selected examples of carboxylate initiators use in ROP are listed in Table 1.

Alkoxy, alkyls and amides initiating ligands

Alkoxy, alkyls and amides are the most studied initiating groups and have proved to be the best relatively. Amongst these, the alkoxy is the most active and better at giving controlled polymerization processes [86, 87]. Alkyl complexes are seldom used due to their instability and difficulty in isolation. In most cases, they are used as intermediates to generate alkoxy species in-situ [104]. The difference in initiation efficiency and activity of alkoxy, alkyls and amides lies in the variation between the polarities of the metal–oxygen, metal–carbon and metal-nitrogen bonds, which are broken during the initiation step. Selected examples of alkoxy, alkyls and amides, borohydrides and carbenes initiating systems are given in Table 2.The effect of integrating the oxygen atom in the ligand framework together with alkoxyl was investigated by Fliedel et al. [14], using phosphino phenolates alkoxides in ROP of ε-CL (Fig. 4). Under similar conditions, complex 5 was active whilst 6 did not show any activity eliminating the possibility of initiation through metal–Oligand (Zn–Oligand) bond. The implication was that in this instance, the oxygen bound strongly to be involved in the initiation process. However, the addition of benzyl alcohol to generate the benzyl alkoxide species in-situ resulted in increased activity for complex 6. Other catalytic systems have been reported which are capable of initiation via the M–Oligand bond, for example the zinc guanidine complexes (7 and 8) reported by Schafer et al. [105], (Fig. 4). Complexes 7 and 8 showed similar activities despite the different auxiliary halides ligands. The guanidine ligand fragment was part of the polymers isolated confirming its involvement in the initiation step.

In principle, alkoxides are more active than the amide analogues a trend exhibited by many catalytic systems [106,107,108]. However, a contrasting trend was observed by Thevenon et al. [109], using zinc complexes (9 and 10) supported by Schiff base ligands (Fig. 5). Extremely high activities were realised using the amide complex 10 compared to complex 9. The crystal structures analysis of complexes 9 and 10, showed that the M–O and M–N bond distances are almost similar except that in complex 9 the alkoxide bridge two metal centres. Therefore, the difference in activity was attributed to the structural geometry, where the ligand framework in complex 10 was found to be folded exposing the metal centres in contrast to complex 9 where the bridging alkoxide maintains a planar ligand conformation. Bearing this in mind, it appears that the initiator bond strength is not the only factor that determine initiation efficiency but also structural effects.

The nature of the alkoxide also influences the activity as well as polymer properties. The use of aromatic- and phenoxy-initiating groups in ROP is seldom explored due to their low nucleophilicity compared to alkoxyl counterparts. Hao et al. [110], studied the effect of three different initiating groups in complexes 11–13 (Fig. 6) having 2-aminobenzyl, 9-hydroxyfluorenyl, and trans-4-aminocyclohexyl moieties, respectively. Complex 11 with 2-aminobenzyl alkoxide was the most active compared to complexes 12 and 13. Looking at the average Al–O bond lengths, they range between 1.701 and 1.702 Å and are almost similar, which seem to suggest that the activity is comparable. Therefore, the difference in activity can be attributed to structural dynamics. The fluorenyl derivative complex 12 gave low molecular weights (Mn) polymers with a value of 7068 g mol−1 compared to 20,095 g mol−1 and 11,045 g mol−1 for complexes 11 and 13, respectively. This reduction can be associated with greater steric hindrance of the fluorenyl group which can inhibit monomer approach towards the metal centre.

In an effort to understand the correlation between initiator structural effects with activity Chile et al. [111], studied an indium system with alkoxy and aromatic initiating groups (Fig. 7). As expected, the polymerization for the alkoxy derivative complex 14 was higher than that of the aromatic derivatives complexes 15a–e. For complexes 15, the para substituted aromatic series rates decreased as the electron withdrawing potency increased. Noteworthy, the complex with a para substituted nitro phenoxy group was virtually inactivity. This trend is attributed to reduced nucleophilicity associated with low electron density induced by the electron withdrawing groups. The study was extended by investigating the effect of adding diols compounds i–iv to complex 14. Activity was only observed for 1,5-naphthalenediol (ii), whilst the rest completely prevented polymerization. The crystal structure of isolated complex after adding compound 17 showed that the diol chelates one of the indium metal centre, which hinder monomer coordination as both metals are involved in polymerization.

Organophosphates have been intensively used as an organocatalyst in ROP, producing polymers with higher molecular weights and narrow distribution. Combining the organophosphates with metal introduces M–O bond which is responsible for initiation. However, it has been shown that metal-organophosphates are not active on their own but in the presence of external initiators [112]. More recently, Chen et al., [113], reported a dual activation mechanism using alkaline and alkaline earth metal organophosphate complexes 16a–b (Fig. 8). The catalyst presents Lewis acidic and Lewis basic bifunctionalities where the monomer is activated on the former whilst the later activate the alcohol co-initiator as shown in 16a. The authors observed that the activity depended on the electropositivity of the Lewis acidic centre.

Borohydrides initiating ligands

Borohydrides have caught prominence as ROP initiators for lactones and lactides since their inception in 2003 by Guillaume et al., [114]. Literature mostly contains rare-earth (RE) metal borohydride complexes because of their stability and easy of syntheses [115, 116]. The BH4 ligand performs dual roles; it acted both as an initiator as well as a reducing agent producing α,ω-dihydroxy telechelic polyesters unlike alkoxide, amide and/or alkyl initiated ROP products which α-amide/ester-ω-hydroxyl polyesters. Experimental mechanistic investigation of a mixed complex RE(BH4)2(C3H5)(THF)x (RE = La, Nd, Sm, Y, Sc) by Fadlallah et al. [117], showed a borohydride preferred initiation.

Seifert et al. [118], investigated enantiopure mono(borohydride) rare-earth complexes 17a in ROP of rac-lactides. They observed that the lutetium catalyst was more active than the scandium under experimentally similar conditions achieving quantitative monomer conversion in less than 60 min. The reaction timescale is comparable to other initiators mainly alkoxides. The scandium complex gave PLAs polymers with minor syndiotactic enrichment, whilst lutetium hardly induces any in contrast to expectation of the stereo regulatory effect expect for chiral ligands. More recently, Radkova et al. [119], reported on Lanthanide bis(borohydride) complexes 17b initiated ROP of ɛ-CL and rac-LA in toluene at 25 °C. Higher catalytic activity was observed for ɛ-CL with complete monomer conversion within 30 min compared to 3 h for rac-LA. The PLAs are characterised by atactic structures (Pr = 0.54–0.58) and slightly narrow dispersity (Ð, between 1.1 and 1.5).

N-heterocyclic carbene initiating ligands

The chemistry of N-heterocyclic carbenes (NHC) is well established and they have proven to rival many ligands in catalytic transformation. Carbenes molecular architecture and electronics can be easily manipulated by changing the ring heteroatom, substituents on the imidazole and nitrogen(s) and degree of saturation. Essentially in ROP catalysis, carbenes can act as metal supporting ligands and as initiators because of their nucleophilic nature and metal free carbene organocatalysis have been reported [91, 120].

The effect of aliphatic N-alkyl chain lengths on the polymer yield of ionic Ag–NHC complexes 18a–e were investigated by Balcan et al., [121] in bulk ROP of L-LA (Fig. 9). Complexes with longer carbon chain proved to be the most active and an increase in temperature above 130 °C resulted in decrease in polymer yield and growth. This was alluded to thermally initiated monomer decomposition and trans esterification reactions. The presence of silver resulted in antimicrobial polymers which were also depended on the chain length.

Functionalised NHCs with N-side arms possessing heteroatoms capable of forming chelates increase the stability of the complexes. One such class is the bimetallic bis(phenolate) N‑Heterocyclic Li/K-lanthanide complexes designed by Zhang et al. [122], complexes 19a–e. The NHC alkali-lanthanide complexes were active as initiators for the ROP of L-LA, and it was observed that the carbene was responsible for the initiation. The catalytic activity of K-Ln series depended on Ln ionic radius and they also showed greater activity than complex Li-Ln complex.

Possible M-HNC dissociation can also be curbed by using expanding the carbine ring which results in increased sigma- bonding. Ring-expanded Zn–NHCs complexes 19f–g were used investigated in ROP of rac-LA by Colins et al. [123]. They observed that the polymerization activity and polymer yields were influenced by the solvent though more pronounced in THF possibly due to monomer-solvent competing for the metal centre. However, there was a slight difference between polymerization data between free carbine and Zn-NHC complexes which was alluded to possible dissociation of the Zn–NHC complexes.

Ligand chirality, symmetry and stereo chemical polymerization

Monomers with chiral centres polymerize to give polymers with variable microstructures referred to as the polymer tacticity. Lactides (LAs) comprise of two stereogenic carbons which results in three isomeric forms i.e. ʟ-(R,R)-, d-(S,S)-, and meso-(S,R)-lactide (Fig. 10) [169]. The d/ʟ system tags the entire molecule, whilst R/S classification labels the absolute configuration of each chiral point and the probable polylactide microstructures illustrated in Fig. 10.

Polymerization of rac-LA results in heterotactic or atactic polymers whereby RRSS or SSRR configurations define the chain units. If the chain contains a large R and S block segments in sequence, then, the polymer is referred to as stereo-block, which is a testimony that propagation of one stereoisomer is kinetically preferred. There are two scenarios which results in the formation of stereo-block polymers [170]. The first is when the second monomer is included in the growing chain after the consumption of the first one, and the second is when there is a monomer mismatch, which is then propagated. The extent of stereoregularity in lactide polymerization is denoted as the probability of racemic (Pr) or meso (Pm) enrichment [169].

Use of ROP techniques and careful ligand designs can be used to control the order of monomer insertion. Polymer microstructure and stereochemistry can be dictated by the operational propagation mechanism. There are two mechanisms which have been projected namely chain-end control mechanism (CECM) [11, 171] and enantiomorphic site control mechanism (ESCM) [172]. In the CECM, the stereogenic point controls the polymer stereochemistry of the last inserted repeating fragment in the growing macromolecule whilst in ESCM the monomer arrangement is communicated from the chiral ligand framework. Therefore, careful design of ligands motifs can serve as a tool to prepare polymers with varying properties.

Salen-type ligands have been extensively used in ring opening polymerization [173,174,175]. A small variation in their backbone usually results in a significant change in their catalytic activity as well as polymer characteristics. Luo et al. [33] have illustrated this by varying the symmetry and substituents on the ligand framework (Fig. 11). They investigated the polymerization of rac-LA using aluminium complexes 20a–c. Catalysis using unsymmetrical complexes 20a–c resulted in isoselective polymerization furnishing isotactic polymers (Pm = 77) compared to a value of 66 for symmetrical t-butyl substituted complex 20b. However, it was comparable to that of symmetrical phenyl substituted complex 20c (Pm = 78). This phenomenon was alluded to the bulky phenyl groups, which induce greater repulsion, hence creating greater space around the metal centre, which affect monomer selectivity hence compromising isotacticity. Research has shown that ligand chirality can also result in increased isotactic enrichment [170]. Using chiral (R,R)-1,2-diammonium cyclohexane salen-complexes Feijin et al. [173], and Gao et al. [174], achieved enriched isotactic polylactide with Pm of values 0.88 and 0.91 for complexes 21 and 22, respectively. The slight difference was attributed to symmetry and different substituents of the ligands. However, one has to bear in mind that polymer end groups and the choice of solvent can result in complexity of the polymerization mechanism controlling the stereochemistry [176,177,178].

Aluminium complexes have remarkably, exhibited supreme stereo-control in rac-lactide polymerization [179,180,181]. A comparative study by Normand et al. [182], using aluminium and indium complexes 23 and 24 (Fig. 12). The aluminium complex 23 resulted in isotactic enrichment while, indium complex 24 furnished atactic polymers. This manifestation was alluded to the different operational mechanisms where aluminium complexes reacted via a CIM, whilst indium complexes proceeded through AMM. Selected examples of chiral complexes used in ROP are shown in Fig. 13 complexes 25–36 [137, 174, 183,184,185,186,187].

Effect of the nature of hetero-donor atoms on ROP catalytic activity

The apparent rates constant depends on the ligand architecture, i.e. nature and denticity of the hetero-donor atoms, stereo-electronic environment and linking atoms between the hetero-donor atoms. The hybridization and substituent groups determine the nature of the heteroatoms. A combination of soft hetero-donor ligating atoms (e.g. P and S) and hard (e.g. N and O) atoms result in an interesting class termed hemilabile ligands [188]. During the catalytic cycle, the weakly ligating soft donor atom disconnects from the metal canter creating a vacant site for reagents to enter the catalytic transformation cycle [189]. This mechanism backs oxidative addition reactions and enables ligands to stabilise small oxidation states [189, 190]. This behaviour is also vital in stabilising diverse catalytic species that are involved in the catalytic cycle [191, 192].

A study by Tschan et al. [193], demonstrated the effect of changing the donor-atoms on catalytic performance using complexes 37–40 (Fig. 14). They observe a drastic change in activity when the tetradentate system was changed from N3O in complex 37 to N2PO in complex 38. The turnover frequency increased from 43 to 418 h−1 for complex 37 and 38, respectively. The same trend was also noticed for complexes 39 (N2P2) and 40 (NP3) as evidenced by the change in activity from 218 to 770 h−1. This behaviour is a clear testimony of the advantage inherited from hemiliability of the ligand system, which makes the metal centre to be more accessible in the presence of phosphorus donor atoms.

Another effective way to fine tune the catalytic activity is to change the nucleophilicity of the hetero-donor atoms. Fortun et al. [194], studied the effect of Namine compared to Npyridyl in ROP of lactides using complexes 41 and 42 (Fig. 15). Complex 41 with pyridyl methoxyl bridge was less active compared to complex 42. This behaviour was explained by the coordination tenacity of pyridyl methoxyl as compared to amino ethoxide group, which makes the complex to easily dissociate into active monomeric species.

Hybridization of nitrogen hetero-donor atoms also affects the basicity, which in turn affect the redox potential of the metal centre. The redox potential of the metal centre interferes with monomer catalyst interaction, which in turn influences activity. Ebrahim et al. [13], explored the effect of nitrogen hybridization on the polymerization of lactides using complexes 43–45 (Fig. 16). All the complexes could polymerize rac-LA within 10 min. Complex 43 was less active than complex 44 although they were all more active than the mononuclear specie complex 45. The binuclear species exhibit the same structure the differences in activity is mainly due to nitrogen hybridization. The differences can be accounted for by the differences in basicity of the nitrogen atoms where the imine nitrogen reduces the electron density of the metal hence increasing monomer coordination compared to the amine nitrogen. N-alkylation resulted to the lowest rate as complex 45 was the least active, the electron donating nature of the methyl substituent render the metal centre to be less nucleophilic hence reducing the probability of monomer binding. All complexes displayed higher molecular weights between (27.1–157.8 kDa) and a controllable living polymerization process shown by narrow dispersity (Ð) (1.02–1.19). The binuclear complexes 43 and 44 showed good heterotacticity displaying Pr values of up to 80, which improved slightly at low temperature. In contrast, the mononuclear complex 45 furnish mainly atactic polylactide polymers.

Typically, phosphorous is modified by changing the substituent groups attached to the hetero-donor atom, whilst sulphur and oxygen are usually etherified. The effect of substituents on phosphorus hetero-donor atom on ROP was put forward by D’Auria et al. [195], using diphosphino pincer aluminium complexes 46a and c (Fig. 17). Complexes 46a and 46c bearing phenyl phosphine showed increased activity in ROP of ε-CL and ʟ-LA compared to isopropyl phosphine analogue (46b). This trend was inferred to greater positive inductive effect of isopropyl compared to phenyl group, which renders the metal to be more nucleophilic thereby retarding monomer activation.

In a related study, Chang et al. [28] study the effect of N,S- and N,O-Schiff base aluminium complexes 47a and 47b (Fig. 17) in ROP of ε-CL and LAs The thio-based complexes showed greater activity compared to the oxygen-based. Using density functional theory (DFT) calculations the authors showed that complex 47a with thio hetero-donor has a lower activation energy barrier (17.6 kcal/mol) compared complex 47b (19.0 kcal/mol) which possess an oxygen hetero-donor atom. Selected examples of different chelating ligands used in ROP are given in Table 3.

Effect of catalytic system rigidity and flexibility on ROP

The ring opening reaction proceed via the most accessible transition state. The resting state of the catalyst in not necessarily the active state but rather there is reorganisation after monomer coordination to generate the reactive transition state. Therefore, the structural features of the complex must allow free rotation to permit monomer access to the metal centre; hence, flexibility is an important aspect of the catalyst design. In further understanding the effect of catalyst rigidity, Chen et al., [219] studied the ROP of LAs using alkali earth metals supported by mono-4,6-di-tert-butyl-phenol and 2,2-ethylidene-bis(4,6-di-tert-butyl-phenol) (EDBP) ligands (Fig. 18). Complexes 48 and 50 showed greater activity compared to the chelate complex 50 of EDBP and the difference can be accounted for by steric and electronic considerations [220]. The authors explained the variation using DFT calculations. They established that the freedom to rotate of the Cph–O–M angle from linear to about 120° in complex 51 and 52 reduces the electrophilicity of the metal centre causing greater lability of M–O bond hence increasing activity. On the contrary, the chelating effect causes the metal complex to maintain its electrophilicity resulting in low catalytic activity due to reduced monomer in cooperation.

Li et al. [215], studied the flexibility and the rigidity of potassium calix[4]arene complexes 53–56 in ROP of rac-LA (Fig. 19). The crown ether was introduced either as separate ligand or integrated as part of the calix moiety. Complex 53 without the crown was the most active because the metal centre is exposed to monomer coordination. However, introduction of the crown ether head resulted in reduced rates, which further decreased upon fixing it on the calix framework. Complex 55 was less active than complex 56, and this difference was attributed to hydrogen bonding. Hydrogen bonding interactions reduces the phenoxide nucleophilicity hence reducing monomer and co-initiator activation.

Huang et al. [221], investigated the effects of benzocyclane frame link length, flexibility and ring dimension of salan type ligands on ROP catalytic activity of complexes 57. They observed that the more flexible complex 57a, 57c and 57f with 2,2-dimethylpropylene link and the five membered cyclic ring was more active compared to the other counterparts. Migrating from the 2,2-dimethyl propylene diamine-bridge complex to ethylene resulted in decrease in the polymerization rate. This behaviour can be rationalised by the change in conformation from merimodal to facial which reduces the crowding around the metal centre for coordination of monomer with respect to the increasing polymer chain. The more rigid benzene and cyclohexane diamine bridges further compromised reactivity (Fig. 20).

Ligand steric and electronic effects in ROP

The prime role of ligands is to stabilise the oxidation states and adjust the ionic character of the metal centre. The presence of either, electron donating groups (EDG) or electron withdrawing groups (EWG), can further influence the metal redox potential, thereby affecting the catalyst activity and efficiency. Generally, in ring opening, polymerization increased steric hindrance around the metal centre builds up repulsion in transition states raising the activation barrier thereby reducing reaction rates [222]. Contradictory results have been presented in literature in terms of the effect of EDG and EWG in ROP and the general precedence has been electron withdrawing groups generally increase the electrophilicity of the metal centre and encourage monomer biding there by increasing reaction rates [223]. Various connection trends between ligand substituents effects and catalytic performance have been reported [223, 224]. Hence, it is prudent to conclude that each ligand is unique, and it is difficult to assign the same trend across the whole spectrum of ligands. For one to be able to assign the apparent effect of the substituents of the rate of polymerization, a clear understanding of the kinetics and mechanism supported by DFT computations is required. To try and understand the whole picture, we will try and consider the substituents variation of both the ligand and the alkoxide. As highlighted above, metal alkoxide prefer a “coordination-insertion” mechanism, where the metal (Lewis acid) coordinate to the monomer and activates it, promoting nucleophilic attack by the alkoxide (nucleophile) Fig. 21 [78]. Hence, the “coordination” and “insertion” step are vital in controlling the kinetics of the reaction.

If the ligand dominant electronic effects on metal Lewis acidity are presumed on monomer coordination, an increase metal positive charge encourages monomer coordination and rapid activation thereby enhancing activity [225]. However, on the contrary, electronic influences that induce a more positive charge on the metal strengthen the M–O bond hence reducing its migration, slowing the reaction (Fig. 22) [225, 226]. And conversely factors that reduce the positive charge weaken the M–O bond hence resulting in increased rates.

Now if the electronic contribution from the ligand is kept constant whilst varying the substituent of the alkoxide, this presents a complicated scenario; the EWG will result in increased metal electrophilicity, and weakening of the M–O bond, and must result in increased rates in contrast to ligand effects. However, the nucleophilicity of the alkoxide is also reduced, and at the same time the electrophilicity of the metal increase, hence, the overall trend is determined by the predominant factor [226]. There is a need to fully understand how “coordination” and “insertion” steps are influenced by the change in charge density of the metal centre by separating the kinetic parameters from each step. Most of the reported apparent kinetic constants (kaap) are a combination of coordination (Keq) and insertion (k2) constants, limiting a concise explanation of kinetic and thermodynamic terms [227].

Many examples appear in literature which try to correlate ROP rates and electronic effects. A comparative study by Chen et al. [228], using aluminium complexes presented the effects of ketimate ligand steric and electronic on catalytic activity in ROP of ε-CL and ʟ-LA (Fig. 23). Kinetic studies using alkyl-substituted complexes 58a and 58b showed that steric bulk substituents resulted in increased activity in polymerization of ε-CL, but an opposite trend was observed when the monomer was changed to ʟ-LA. This trend is attributed to the repulsion between the monomer methyl groups with the substituents. The claim by the authors that it is due to greater ring size of ʟ-LA compared to ε-CL, is rather invalid considering that ε-CL size is, greater than that of ʟ-LA.

The same monomer dependence on the reactivity trend was also observed using the pentafluoro complex 59 and trisubstituted complexes 60a–60c. Reactivity order was 59 > 60b > 60a > 60c in ʟ-LA polymerization which was reversed in ε-CL polymerization. This trend could be rationalised by the greater Lewis acidity induced by pentafluoro substituents compare to trichloro and tribromo groups. They also investigate the effect of ortho- and para-substitution on activity using complexes 61a–61e [228]. The substituents influenced the apparent rates in the following order p-NO2 > p-F > p-Cl ⁓ o-F > H > OMe for ε-CL and p-F > p-NO2 > o-F > p-Cl > H > OMe for ʟ-LA. Usually, electron withdrawing effects reduced metal nucleophilicity, and encourage monomer coordination.

In a related study by Wang et al. [229], the activity and induction time of β-quinolyl-enamino aluminium complexes was investigated and related to the substituted groups (Fig. 24). Generally, the reaction rates decreased with reduction in electron donating ability of the substituent groups. As observed by Chen et al. [228], the most substituted pentafluoro derivative complex 62a showed the greatest activity. Of interest were the induction periods, for instance comparing complexes 62a and 62b, the induction time for complex 62a is greater than that of complex 62b although the former has a greater reaction rate post the induction period. This anomaly would suggest that these complexes are acting both as initiators as well catalysts with complex 62b being a good initiator but a poor catalyst.

To understand the effect of ortho and para substituents, Chen et al. [230], studied the ROP on lactides using diphenolate ligated Al complexes 63 (Fig. 25). They observed that the ortho substitution resulted in higher catalytic activities than the para counterparts. In addition, the size of the substituent also influenced the catalytic activity. This behaviour was attributed to the metal- ortho-substituent interactions which would possibly increase activity and they are absent in the para analogues.

Catalyst metal nuclearity effects on ROP

Complexes comprising of homo- or hetero-multimetallic centres in close proximity can exhibit interesting properties compared to individual monometallic complexes. Multimetallic complexes generally have shown higher possibility of using adjacent metal centres to increase catalytic activity and selectivity; the metal centre is in close proximity within the range 3.5–6 Å [147, 231,232,233]. It is believed that bimetallic complexes have the potential to result in stabilisation of unusual ligand coordination modes, and multiple electron redox processes. This cooperative behaviour was reported by Chen et al. [231], using phenolate aluminium complexes (Fig. 26). The bimetallic species 64 were observed to be active than the mononuclear species 65. This superior behaviour was observed in other catalytic systems [24, 234].

However, a contrasting trend was observed by Ding et al. [175], in ROP of rac-LA using salen-ligated complexes 66 and 67 (Fig. 27). The heterobimetallic system 67 assembled by adding a lanthanide ion to the nickel complex 66 showed no synergistic effects but rather a decline in activity was observed. However, there was an improvement in molecular weights and polymerization controllability. The authors speculate that because the nitrate groups crowd the lanthanide metal in such way that it prevents monomer access to the metal hence excluding it from catalysis. The distortion in geometry because of the second ion also aided in increased Lewis acidity of the nickel centre, thereby reducing its affinity for the monomer hence slower rates. This finding might lead to the conclusion that bond angle distortion, and steric interference factors need to be fine tune to have maximum activity of the catalytic system. In general, nuclearity can influence the polymerization process, although it might be a challenge to have definitive trends due to other catalytic system variables. A comprehensive consideration of dineuclearity can be found in a review article by Kremer and Mehrkhodavandi [235].

However, when considering multimetallic systems, there are some factors that we have to cautiously consider. One has to bear in mind that in most catalytic systems, only solid-state crystal structures data are presented, viz solutions structures. Thus, during catalysis in solution, catalysts adopt slightly different structures making it tricky to correlate solid state structures and catalytic activity. It has been postulated that for most multimetallic complexes, during catalysis, they dissociate to the actual catalytic species, hence if possible, their characterisation, can shed more light in understanding catalyst polymerization activity relationship. Selected examples of multimetallic catalytic systems used in ROP are given in Table 4.

Solvent and temperature effects on ROP

For complete understanding of ROP reactions, one considers variables such as solvent and temperature. Industrially, ROP of ε-CL and LAs is done in bulk or melt conditions, and activity is generally higher at higher temperatures. In academia, the use of solvents has been investigated and a correlation was established between reaction medium and activity as well as polymer properties [237, 244]. It has been shown that the activity is greater in high boiling temperature solvents and oxygen containing solvents compete with monomer binding resulting in slow rates. A contrasting temperature depended activity was observed by Zhang and co-workers [3] using sodium and potassium complexes (68) for ROP of rac-LA (Fig. 28). The complexes showed an interesting trend where higher catalytic activities were observed at a lower temperature. The authors speculate that the vibrations of the crown block the access of the monomer and co-initiator to the metal centre. As a result, the vibrations are arrested at lower temperature resulting in increased activity. PLA polymers with a Pm (0.86) were obtained which they claim to be superior over those reported for alkali-metal complexes systems.

Conclusion

Structural features of some ROP catalyst focusing on ligand effects on catalytic activity and polymer properties were discussed. The initiation groups, which are also central for the success of the polymerization process, were also reviewed. It can be concluded from the discussion in the review that the ROP reaction is a complicated process such that it is difficult to solely pinpoint system dynamics on one variable. Each catalyst is distinctive and several factors such as ligand steric, chirality and electronic effects as well as metal identity regulate the polymerisation processes. In addition, experimental variables such as temperature and solvent also affect the polymerization reaction. Notwithstanding the progress made in search of active ROP catalyst/initiators, there is still a need to develop novel initiators/catalysts, which can control the polymerization process. Catalysts structural design and mechanistic studies have played an important role in development of ROP catalyst/initiators. Complexes and ligand structures have been discussed and correlated with the catalyst activity, selectivity and polymer properties. The structure of the ligands and catalyst is discussed in context of how structural variations affect ROP.

References

Alhashmialameer D, Ikpo N, Collins J, Dawe LN, Hattenhauer K, Kerton FM (2015) Ring-opening polymerization of rac-lactide mediated by tetrametallic lithium and sodium diamino-bis(phenolate) complexes. Dalton Trans 44(46):20216–20231

Dai Z, Sun Y, Xiong J, Pan X, Tang N, Wu J (2016) Simple sodium and potassium phenolates as catalysts for highly isoselective polymerization of rac-lactide. Catal Sci Technol 6(2):515–520

Zhang J, Xiong J, Sun Y, Tang N, Wu J (2014) Highly iso-selective and active catalysts of sodium and potassium monophenoxides capped by a crown ether for the ring-opening polymerization of rac-lactide. Macromolecules 47(22):7789–7796

Ahn SH, Chun MK, Kim E, Jeong JH, Nayab S, Lee H (2017) Copper(II) complexes containing N, N′-bidentate N-substituted N-(pyridin-2-ylmethyl)amine: synthesis, structure and application towards polymerisation of rac-lactide. Polyhedron 127:51–58

Appavoo D, Omondi B, Guzei IA, van Wyk JL, Zinyemba O, Darkwa J (2014) Bis(3,5-dimethylpyrazole) copper(II) and zinc(II) complexes as efficient initiators for the ring opening polymerization of ε-caprolactone and d, l-lactide. Polyhedron 69:55–60

Biernesser AB, Li B, Byers JA (2013) Redox-controlled polymerization of lactide catalyzed by bis(imino)pyridine iron bis(alkoxide) complexes. J Am Chem Soc 135(44):16553–16560

Manna CM, Kaplan HZ, Li B, Byers JA (2014) High molecular weight poly(lactic acid) produced by an efficient iron catalyst bearing a bis(amidinato)-N-heterocyclic carbene ligand. Polyhedron 84:160–167

Osten KM, Mehrkhodavandi P (2017) Indium catalysts for ring opening polymerization: exploring the importance of catalyst aggregation. Acc Chem Res 50(11):2861–2869

Wang Y, Zhao W, Liu D, Li S, Liu X, Cui D, Chen X (2012) Magnesium and zinc complexes supported by N, O-bidentate pyridyl functionalized alkoxy ligands: synthesis and immortal ROP of ε-CL and L-LA. Organometallics 31(11):4182–4190

Xie H, Mou Z, Liu B, Li P, Rong W, Li S, Cui D (2014) Phosphinimino-amino magnesium complexes: synthesis and catalysis of heteroselective ROP of rac-lactide. Organometallics 33(3):722–730

Dove AP, Gibson VC, Marshall EL, Rzepa HS, White AJP, Williams DJ (2006) Synthetic, structural, mechanistic, and computational studies on single-Site β-diketiminate tin(II) initiators for the polymerization of rac-lactide. J Am Chem Soc 128(30):9834–9843

Kowalski A, Duda A, Penczek S (2000) Mechanism of cyclic ester polymerization initiated with tin(II) octoate. 2. Macromolecules fitted with tin(II) alkoxide species observed directly in MALDI−TOF spectra. Macromolecules 33(3):689–695

Ebrahimi T, Mamleeva E, Yu I, Hatzikiriakos SG, Mehrkhodavandi P (2016) The role of nitrogen donors in zinc catalysts for lactide ring-opening polymerization. Inorg Chem 55(18):9445–9453

Fliedel C, Rosa V, Alves FM, Martins AM, Aviles T, Dagorne S (2015) P, O-Phosphinophenolate zinc(II) species: synthesis, structure and use in the ring-opening polymerization (ROP) of lactide, ε-caprolactone and trimethylene carbonate. Dalton Trans 44(27):12376–12387

Gong S, Du P, Ma H (2018) Binuclear aluminum complexes supported by linked bis(β-diketiminate) ligands for ring-opening polymerization of cyclic esters. Chin J Polym Sci 36(2):190–201

Hermanová S, Moya Cabrera MM, Vyroubalová Z, Vojtová L (2011) Novel triazole-based aluminum complex for ring-opening polymerization of lactones. Polym Bull 67(9):1751–1760

Njogu EM, Omondi B, Nyamori VO (2017) Silver(I)-pyridinyl Schiff base complexes: synthesis, structural characterization and reactivity in ring-opening polymerisation of ε-caprolactone. Inorg Chim Acta 457:160–170

Samantaray MK, Katiyar V, Roy D, Pang K, Nanavati H, Stephen R, Sunoj RB, Ghosh P (2006) A cationic (N-heterocyclic carbene)silver complex as catalyst for bulk ring-opening polymerization of L-lactides. Eur J Inorg Chem 2006(15):2975–2984

Rajashekhar B, Chakraborty D (2014) Co(II) and Mn(II) catalyzed bulk ring-opening polymerization of cyclic esters. Polym Bull 71(9):2185–2203

Webster RL (2014) Random copolymerisations catalysed by simple titanium α-amino acid complexes. RSC Adv 4(10):5254–5260

Gilmour DJ, Webster RL, Perry MR, Schafer LL (2015) Titanium pyridonates for the homo- and copolymerization of rac-lactide and ε-caprolactone. Dalton Trans 44(27):12411–12419

Hu X, Lu C, Wu B, Ding H, Zhao B, Yao Y, Shen Q (2013) Synthesis and structural diversity of lanthanide amidate complexes and their catalytic activities for the ring-opening polymerization of rac-lactide. J Organomet Chem 732:92–101

Medina DA, Contreras JM, López-Carrasquero FJ, Cardozo EJ, Contreras RR (2018) Use of samarium(III)–amino acid complexes as initiators of ring-opening polymerization of cyclic esters. Polym Bull 75(3):1253–1263

Range S, Piesik DFJ, Harder S (2008) Binuclear magnesium, calcium and zinc complexes based on bis(salicylaldimine) ligands with rigid bridges. Eur J Inorg Chem 2008(22):3442–3451

Wang H, Guo J, Yang Y, Ma H (2016) Diastereoselective synthesis of chiral aminophenolate magnesium complexes and their application in the stereoselective polymerization of rac-lactide and rac-[small beta]-butyrolactone. Dalton Trans 45(27):10942–10953

Wang H, Yang Y, Ma H (2014) Stereoselectivity switch between zinc and magnesium initiators in the polymerization of rac-lactide: different coordination chemistry, different stereocontrol mechanisms. Macromolecules 47(22):7750–7764

Akpan ED, Ojwach SO, Omondi B, Nyamori VO (2016) Zn(II) and Cu(II) formamidine complexes: structural, kinetics and polymer tacticity studies in the ring-opening polymerization of ?-caprolactone and lactides. New J Chem 40(4):3499–3510

Chang M-C, Lu W-Y, Chang H-Y, Lai Y-C, Chiang MY, Chen H-Y, Chen H-Y (2015) Comparative study of aluminum complexes bearing N, O- and N, S-Schiff base in ring-opening polymerization of ε-caprolactone and l-lactide. Inorg Chem 54(23):11292–11298

Du H, Velders AH, Dijkstra PJ, Zhong Z, Chen X, Feijen J (2009) Polymerization of lactide using achiral bis(pyrrolidene) Schiff base aluminum complexes. Macromolecules 42(4):1058–1066

Gupta S, Arora R, Sinha N, Alam MI, Haider MA (2016) Mechanistic insights into the ring-opening of biomass derived lactones. RSC Adv 6(16):12932–12942

Castro-Osma JA, Alonso-Moreno C, Márquez-Segovia I, Otero A, Lara-Sánchez A, Fernández-Baeza J, Rodríguez AM, Sánchez-Barba LF, García-Martínez JC (2013) Synthesis, structural characterization and catalytic evaluation of the ring-opening polymerization of discrete five-coordinate alkyl aluminium complexes. Dalton Trans 42(25):9325–9337

Li D, Peng Y, Geng C, Liu K, Kong D (2013) Well-controlled ring-opening polymerization of cyclic esters initiated by dialkylaluminum β-diketiminates. Dalton Trans 42(31):11295–11303

Luo W, Shi T, Liu S, Zuo W, Li Z (2017) Well-designed unsymmetrical salphen-al complexes: synthesis, characterization, and ring-opening polymerization catalysis. Organometallics 36(9):1736–1742

Wu M-C, Hu T-C, Lo Y-C, Lee T-Y, Lin C-H, Lu W-Y, Lin C-C, Datta A, Huang J-H (2015) New types of bi- and tri-dentate pyrrole-piperazine ligands and related zinc compounds: synthesis, characterization, reaction study, and ring-opening polymerization of ε-caprolactone. J Organomet Chem 791:141–147

Han Y, Feng Q, Zhang Y, Zhang Y, Yao W (2017) Ring-opening polymerization of rac-lactide by mononuclear zinc complexes that contain chiral tetra-azane ligands. Polyhedron 121:206–210

Kong W-L, Chai Z-Y, Wang Z-X (2014) Synthesis of N, N, O-chelate zinc and aluminum complexes and their catalysis in the ring-opening polymerization of ε-caprolactone and rac-lactide. Dalton Trans 43(38):14470–14480

Kong W-L, Wang Z-X (2014) Dinuclear magnesium, zinc and aluminum complexes supported by bis(iminopyrrolide) ligands: synthesis, structures, and catalysis toward the ring-opening polymerization of ε-caprolactone and rac-lactide. Dalton Trans 43(24):9126–9135

Otero A, Fernández-Baeza J, Sánchez-Barba LF, Tejeda J, Honrado M, Garcés A, Lara-Sánchez A, Rodríguez AM (2012) Chiral N, N, O-scorpionate zinc alkyls as effective and stereoselective initiators for the living ROP of lactides. Organometallics 31(11):4191–4202

Sun H-M, Li H-R, Yao C-S, Yao Y-M, Sheng H-T, Shen Q (2005) Lanthanide thiolate complexes: novel initiators for ring-opening polymerization of ε-caprolactone. Chin J Chem 23(11):1541–1544

Meppelder G-JM, Fan H-T, Spaniol TP, Okuda J (2009) Synthesis, structure, and olefin polymerization activity of titanium complexes bearing asymmetric tetradentate [OSNO]-type bis(phenolato) ligands. Inorg Chem 48(15):7378–7388

Jia A-Q, Jin G-X (2009) Syntheses, reactions, and ethylene polymerization of titanium complexes with [N, O, S] ligands. Organometallics 28(6):1872–1877

Jia A-Q, Wang J-Q, Hu P, Jin G-X (2011) Synthesis, reactions, and ethylene polymerization of titanium complexes with [N, N, S] ligands. Dalton Trans 40(30):7730–7736

Jensen TR, Breyfogle LE, Hillmyer MA, Tolman WB (2004) Stereoelective polymerization of d, l-lactide using N-heterocyclic carbene based compounds. Chem Commun 21:2504–2505

Jain I, Malik P (2021) N-heterocyclic carbene complexes in ring opening polymerization. Eur Polym J 150:110412

O’Hagan D, Parker AH (1998) Enzyme mediated polyester synthesis with the lipase from Candida rugosaPreparation of an enantiomerically enriched polymer from an A-B monomer. Polym Bull 41(5):519–524

Poojari Y, Beemat JS, Clarson SJ (2013) Enzymatic synthesis of poly(ε-caprolactone): thermal properties, recovery, and reuse of lipase B from Candida antarctica immobilized on macroporous acrylic resin particles. Polym Bull 70(5):1543–1552

Hiroshi U, Shiro K (1993) Enzymatic ring-opening polymerization of pactones catalyzed by lipase. Chem Lett 22(7):1149–1150

Knani D, Gutman AL, Kohn DH (1993) Enzymatic polyesterification in organic media. Enzyme-catalyzed synthesis of linear polyesters. I. Condensation polymerization of linear hydroxyesters. II. Ring-opening polymerization of ϵ-caprolactone. J Polym Sci Part A Polym Chem 31(5):1221–1232

Zdarta J, Klapiszewski L, Jedrzak A, Nowicki M, Moszynski D, Jesionowski T (2017) Lipase B from Candida antarctica immobilized on a silica-lignin matrix as a stable and reusable biocatalytic system. Catalysts 7(1):14

Peirce S, Tacias-Pascacio V, Russo M, Marzocchella A, Virgen-Ortíz J, Fernandez-Lafuente R (2016) Stabilization of Candida antarctica Lipase B (CALB) Immobilized on Octyl Agarose by Treatment with Polyethyleneimine (PEI). Molecules 21(6):751

Raita M, Arnthong J, Champreda V, Laosiripojana N (2015) Modification of magnetic nanoparticle lipase designs for biodiesel production from palm oil. Fuel Process Technol 134(Supplement C):189–197

Botta L, Bizzarri BM, Crucianelli M, Saladino R (2017) Advances in biotechnological synthetic applications of carbon nanostructured systems. J Mater Chem B 5(32):6490–6510

Nederberg F, Connor EF, Möller M, Glauser T, Hedrick JL (2001) New paradigms for organic catalysts: the first organocatalytic living polymerization. Angew Chem Int Ed 40(14):2712–2715

Bonduelle C, Martin-Vaca B, Cossio FP, Bourissou D (2008) Monomer versus alcohol activation in the 4-dimethylaminopyridine-catalyzed ring-opening polymerization of lactide and lactic O-carboxylic anhydride. Chemistry (Weinheim an der Bergstrasse, Germany) 14(17):5304–5312

Hillmyer MA (1999) Polymer chemistry: an introduction, 3rd edn, By Malcolam P. Stevens Oxford University Press, New York

Mandal BM (2013) Fundamentals of polymerization, World Scientific, New Jersey, London

Dainton F, Ivin K (1948) Reversibility of the propagation reaction in polymerization processes and its manifestation in the phenomenon of a ‘ceiling temperature.’ Nature 162:705–707

Duda A, Kowalski A (2009) Thermodynamics and kinetics of ring-opening polymerization. In: Handbook of ring-opening polymerization. Wiley-VCH Verlag GmbH & Co. KGaA, pp 1–51

Penczek S (2002) Terminology of kinetics, thermodynamics, and mechanisms of polymerization. J Polym Sci Part A Polym Chem 40(11):1665–1676

Savant DM, Reddy DV, McCord EF, Rinaldi PL (2007) 2D NMR Studies of Poly(ethylene-co-vinyl acetate-co-carbon monoxide). Macromolecules 40(12):4199–4210

Ollagnier J-N, Tassaing T, Harrisson S, Destarac M (2016) Application of online infrared spectroscopy to study the kinetics of precipitation polymerization of acrylic acid in supercritical carbon dioxide. React Chem Eng 1(4):372–378

Parnell S, Min K, Cakmak M (2003) Kinetic studies of polyurethane polymerization with Raman spectroscopy. Polymer 44(18):5137–5144

Kaastrup K, Aguirre-Soto A, Wang C, Bowman CN, Stansbury JW, Sikes HD (2016) UV-Vis/FT-NIR in situ monitoring of visible-light induced polymerization of PEGDA hydrogels initiated by eosin/triethanolamine/O2. Polym Chem 7(3):592–602

Duewel M, Vogel N, Weiss CK, Landfester K, Spiess H-W, Münnemann K (2012) Online monitoring of styrene polymerization in miniemulsion by hyperpolarized 129Xenon NMR spectroscopy. Macromolecules 45(4):1839–1846

McLeary JB, Calitz FM, McKenzie JM, Tonge MP, Sanderson RD, Klumperman B (2004) Beyond inhibition: a 1H NMR investigation of the early kinetics of RAFT-mediated polymerization with the same initiating and leaving groups. Macromolecules 37(7):2383–2394

Vargas MA, Cudaj M, Hailu K, Sachsenheimer K, Guthausen G (2010) Online low-field 1H NMR spectroscopy: monitoring of emulsion polymerization of butyl acrylate. Macromolecules 43(13):5561–5568

Holycross DR, Chai M (2013) Comprehensive NMR studies of the structures and properties of PEI polymers. Macromolecules 46(17):6891–6897

Izunobi JU, Higginbotham CL (2011) Polymer molecular weight analysis by 1H NMR spectroscopy. J Chem Educ 88(8):1098–1104

Shit SC, Maiti S (1986) Application of NMR spectroscopy in molecular weight determination of polymers. Eur Polym J 22(12):1001–1008

Thakur KAM, Kean RT, Hall ES, Kolstad JJ, Lindgren TA, Doscotch MA, Siepmann JI, Munson EJ (1997) High-resolution 13C and 1H solution NMR study of poly(lactide). Macromolecules 30(8):2422–2428

Thakur KAM, Kean RT, Hall ES, Kolstad JJ, Munson EJ (1998) 1H NMR spectroscopy in the analysis and characterization of poly(lactide). Int J Polym Anal Charact 4(5):379–391

Dubois P, Coulembier O, Raquez J-M (2009) Handbook of ring-opening polymerization. John Wiley & Sons

Kowalski A, Duda A, Penczek S (2000) Kinetics and mechanism of cyclic esters polymerization initiated with tin(II) octoate. 3. Polymerization of L/L-dilactide. Macromolecules 33(20):7359–7370

Ling J, Shen J, Hogen-Esch TE (2009) A density functional theory study of the mechanisms of scandium-alkoxide initiated coordination–insertion ring-opening polymerization of cyclic esters. Polymer 50(15):3575–3581

Miranda MO, DePorre Y, Vazquez-Lima H, Johnson MA, Marell DJ, Cramer CJ, Tolman WB (2013) Understanding the mechanism of polymerization of ε-caprolactone catalyzed by aluminum salen complexes. Inorg Chem 52(23):13692–13701

Rosal ID, Poteau R, Maron L (2011) DFT study of the ring opening polymerization of ε-caprolactone by grafted lanthanide complexes: effect of the initiator ligand. Dalton Trans 40(42):11228–11240

Rao W, Cai C, Tang J, Wei Y, Gao C, Yu L, Ding J (2021) Coordination insertion mechanism of ring-opening polymerization of lactide catalyzed by stannous octoate Chin. J Chem 39(7):1965–1974

Ajellal N, Carpentier J-F, Guillaume C, Guillaume SM, Helou M, Poirier V, Sarazin Y, Trifonov A (2010) Metal-catalyzed immortal ring-opening polymerization of lactones, lactides and cyclic carbonates. Dalton Trans 39(36):8363–8376

Kricheldorf HR, Kreiser-Saunders I, Boettcher C (1995) Polylactones: 31. Sn(II)octoate-initiated polymerization of L-lactide: a mechanistic study. Polymer 36(6):1253–1259

Kricheldorf HR, Kreiser-Saunders I, Stricker A (2000) Polylactones 48: SnOct2-initiated polymerizations of lactide: a mechanistic study. Macromolecules 33(3):702–709

Liu J, Ling J, Li X, Shen Z (2009) Monomer insertion mechanism of ring-opening polymerization of ɛ-caprolactone with yttrium alkoxide intermediate: a DFT study. J Mol Catal A Chem 300(1–2):59–64

Barros N, Mountford P, Guillaume SM, Maron L (2008) A DFT study of the mechanism of polymerization of epsilon-caprolactone initiated by organolanthanide borohydride complexes. Chemistry 14(18):5507–5518

Dyer HE, Huijser S, Susperregui N, Bonnet F, Schwarz AD, Duchateau R, Maron L, Mountford P (2010) Ring-opening polymerization of rac-lactide by bis(phenolate)amine-supported samarium borohydride complexes: an experimental and DFT study. Organometallics 29(16):3602–3621

Munzeiwa WA, Nyamori VO, Omondi B (2018) Zn(II) and Cu(II) unsymmetrical formamidine complexes as effective initiators for ring-opening polymerization of cyclic esters. Appl Organomet Chem 32(4):e4247

Akpan ED, Ojwach SO, Omondi B, Nyamori VO (2016) Structural and kinetic studies of the ring-opening polymerization of cyclic esters using N, N′ diarylformamidines Zn(II) complexes. Polyhedron 110:63–72

Kan C, Ge J, Ma H (2016) Aluminum methyl, alkoxide and α-alkoxy ester complexes supported by 6,6’-dimethylbiphenyl-bridged salen ligands: synthesis, characterization and catalysis for rac-lactide polymerization. Dalton Trans 45(15):6682–6695

Wang C-H, Li C-Y, Huang B-H, Lin C-C, Ko B-T (2013) Synthesis and structural determination of zinc complexes based on an anilido-aldimine ligand containing an O-donor pendant arm: zinc alkoxide derivative as an efficient initiator for ring-opening polymerization of cyclic esters. Dalton Trans 42(30):10875–10884

Guillaume SM, Brignou P, Susperregui N, Maron L, Kuzdrowska M, Roesky PW (2011) Bis(phosphinimino)methanide borohydride complexes of the rare-earth elements as initiators for the polymerization of methyl methacrylate: combined experimental and computational investigations. Polym Chem 2(8):1728–1736

Nifant'ev I, Ivchenko P (2019) Coordination ring-opening polymerization of cyclic esters: a critical overview of DFT modeling and visualization of the reaction mechanisms. Molecules 24(22)

Schnee G, Bolley A, Hild F, Specklin D, Dagorne S (2017) Group 13 metal (Al, Ga, In) alkyls supported by N-heterocyclic carbenes for use in lactide ring-opening polymerization catalysis. Catal Today 289:204–210

Wang Y, Li N, Zhang L, Guo J, Liu Q (2014) Ring-opening polymerization by N-heterocyclic carbenes as catalysts: characteristics and kinetics. Kinet Catal 55(4):416–421

Rezayee NM, Gerling KA, Rheingold AL, Fritsch JM (2013) Synthesis and structures of tridentate ketoiminate zinc complexes bearing trifluoromethyl substituents that act as L-lactide ring opening polymerization initiators. Dalton Trans 42(15):5573–5586

Zikode M, Ojwach SO, Akerman MP (2016) Bis(pyrazolylmethyl)pyridine Zn(II) and Cu(II) complexes: molecular structures and kinetic studies of ring-opening polymerization of ε-caprolactone. J Mol Catal A Chem 413:24–31

Obuah C, Lochee Y, Zinyemba O, Jordaan JHL, Otto DP, Darkwa J (2015) (Ferrocenylpyrazolyl)zinc(II) acetate complexes as initiators and catalysts for the ring opening polymerization of ϵ-caprolacton. J Mol Catal A Chem 406:185–193

Zhu D, Li Y, Chen J, Song X (2020) L2Zn and LZnX complexes bearing half-salphen ligands and their catalysis of ring-opening polymerization of ε -caprolactone. J Organomet Chem 920:121317

Mandal M, Monkowius U, Chakraborty D (2016) Cadmium acetate as a ring opening polymerization catalyst for the polymerization of rac-lactide, ε-caprolactone and as a precatalyst for the polymerization of ethylene. J Polym Res 23(10):220

Zikode M, Ojwach SO, Akerman MP (2016) Structurally rigid bis(pyrazolyl)pyridine Zn(II) and Cu(II) complexes: structures and kinetic studies in ring-opening polymerization of ε-caprolactone. Appl Organomet Chem 31:e3556

Posada AF, Macías MA, Movilla S, Miscione GP, Pérez LD, Hurtado JJ (2018) Polymers of ε-caprolactone using new copper(II) and zinc(II) complexes as initiators: synthesis, characterization and X-Ray crystal structures. Polymers (Basel) 10(11):1239

Obuah C, Lochee Y, Jordaan JHL, Otto DP, Nyokong T, Darkwa J (2015) (Ferrocenylpyrazolyl)zinc(II) benzoates as catalysts for the ring opening polymerization of ε-caprolactone. Polyhedron 90:154–164

Akintayo DC, Munzeiwa WA, Jonnalagadda SB, Omondi B (2022) Zn(II) pyridinyl amine complexes, synthesis and crystal structure studies: a comparative study of the effect of nuclearity and benzoate type on the ring-opening polymerization of cyclic esters. Polyhedron 213:115589

Akintayo DC, Munzeiwa WA, Jonnalagadda SB, Omondi B (2022) Influence of nuclearity and coordination geometry on the catalytic activity of Zn(II) carboxylate complexes in ring-opening polymerization of ε-caprolactone and lactides. Inorg Chim Acta 532:120715

Akintayo DC, Munzeiwa WA, Jonnalagadda SB, Omondi B (2022) N3/4-pyridinyl Schiff base copper(II) benzoate complexes: synthesis, crystal structures and ring-opening polymerization studies. Transit Met Chem 47:113–126

Appavoo D, van Wyk JL, Spencer LC, Guzei IA, Darkwa J (2022) Pyrazolyl-based zinc(II) carboxylate complexes: synthesis, characterization and catalytic behaviour in ring opening polymerization of ε-caprolactone and D, L-lactide. Results Chem 4:100261

Li J, Deng Y, Jie S, Li B-G (2015) Zinc complexes supported by (benzimidazolyl)pyridine alcohol ligands as highly efficient initiators for ring-opening polymerization of ε-caprolactone. J Organomet Chem 797:76–82

Schäfer PM, Fuchs M, Ohligschläger A, Rittinghaus R, McKeown P, Akin E, Schmidt M, Hoffmann A, Liauw MA, Jones MD, Herres-Pawlis S (2017) Highly active N, O zinc guanidine catalysts for the ring-opening polymerization of lactide. Chemsuschem 10(18):3547–3556

Chisholm MH, Huffman JC, Phomphrai K (2001) Monomeric metal alkoxides and trialkyl siloxides: (BDI)Mg(OtBu)(THF ) and (BDI)Zn(OSiPh3)(THF ). Comments on single site catalysts for ring-opening polymerization of lactides. Dalton Trans 3:222–224

Dubois P, Jérǒme R, Teyssié P (1991) Aluminium alkoxides: a family of versatile initiators for the ring-opening polymerization of lactones and lactides. Makromol Chem Macromol Symp 42–43(1):103–116

Jian C, Zhang J, Dai Z, Gao Y, Tang N, Wu J (2013) Synthesis and characterization of magnesium alkoxides incorporated into bulky aluminium tetraphenolate helices and application in the ring-opening polymerization of lactides. Eur J Inorg Chem 2013(20):3533–3541

Thevenon A, Romain C, Bennington MS, White AJP, Davidson HJ, Brooker S, Williams CK (2016) Dizinc lactide polymerization catalysts: hyperactivity by control of ligand conformation and metallic cooperativity. Angew Chem Int Ed 55(30):8680–8685

Hao P, Yang Z, Li W, Ma X, Roesky HW, Yang Y, Li J (2015) Aluminum complexes containing the C-O–Al–O–C framework as efficient Initiators for ring-opening polymerization of ε-caprolactone. Organometallics 34(1):105–108

Chile LE, Ebrahimi T, Wong A, Aluthge DC, Hatzikiriakos SG, Mehrkhodavandi P (2017) Impact of aryloxy initiators on the living and immortal polymerization of lactide. Dalton Trans 46(20):6723–6733

Ren Y, Kularatne RN, Miller JT, Polderman ST, Vo TD, Biewer MC, Stefan MC (2018) Neodymium-based catalysts bearing phosphate ligands for ring-opening polymerization of ɛ-caprolactone. J Polym Sci Part A Polym Chem 56(12):1289–1296

Chen S, Wang H, Li Z, Wei F, Zhu H, Xu S, Xu J, Liu J, Gebru H, Guo K (2018) Metallic organophosphate catalyzed bulk ring-opening polymerization. Polym Chem 9(6):732–742

Guillaume SM, Schappacher M, Soum A (2003) Polymerization of ε-caprolactone initiated by Nd(BH4)3(THF)3: synthesis of hydroxytelechelic poly (ε-caprolactone). Macromolecules 36(1):54–60

Schmid M, Guillaume SM, Roesky PW (2014) β-diketiminate rare earth borohydride complexes: synthesis, structure, and catalytic activity in the ring-opening polymerization of ε-caprolactone and trimethylene carbonate. Organometallics 33(19):5392–5401

Visseaux M, Bonnet F (2011) Borohydride complexes of rare earths, and their applications in various organic transformations. Coord Chem Rev 255(3):374–420

Fadlallah S, Jothieswaran J, Del Rosal I, Maron L, Bonnet F, Visseaux M (2020) Rationalizing the reactivity of mixed allyl rare-earth borohydride complexes with DFT Studies. Catalysts 10(8):820

Seifert TP, Brunner TS, Fischer TS, Barner-Kowollik C, Roesky PW (2018) Chiral mono(borohydride) complexes of scandium and lutetium and their catalytic activity in ring-opening polymerization of D/L-lactide. Organometallics 37(23):4481–4487

Rad’kova N, Rad’kov V, Cherkasov A, Kovylina T, Trifonov A (2019) Lanthanide bis(borohydride) complexes coordinated by tetradentate phenoxide ligand: synthesis, structure, and catalytic activity in ring-opening polymerization of rac-lactide and ε-caprolactone. Inorg Chim Acta 489:132–139

Li H, Ai B-R, Hong M (2018) Stereoselective ring-opening polymerization of rac-lactide by bulky chiral and achiral N-heterocyclic carbenes. Chin J Polym Sci 36(2):231–236

Balcan S, Balcan M, Çetinkaya B (2013) Poly(l-lactide) initiated by silver N-heterocyclic carbene complexes: synthesis, characterization and properties. Polym Bull 70(12):3475–3485

Zhang M, Ni X, Shen Z (2014) Synthesis of bimetallic bis(phenolate) N-heterocyclic carbene lanthanide complexes and their applications in the ring-opening polymerization of l-lactide. Organometallics 33(23):6861–6867

Collins LR, Moffat LA, Mahon MF, Jones MD, Whittlesey MK (2016) Lactide polymerisation by ring-expanded NHC complexes of zinc. Polyhedron 103:121–125

Petrus R, Sobota P (2013) Zinc complexes supported by methyl salicylato ligands: synthesis, structure, and application in ring-opening polymerization of L-lactide. Dalton Trans 42(38):13838–13844

Minyaev ME, Nifant’ev IE, Shlyakhtin AV, Ivchenko PV, Lyssenko KA (2018) Phenoxide and alkoxide complexes of Mg, Al and Zn, and their use for the ring-opening polymerization of ϵ-caprolactone with initiators of different natures. Acta Crystallogr Sect C Struct Chem 74(5):548–557

Vuorinen S, Lahcini M, Hatanpää T, Sundberg M, Leskelä M, Repo T (2013) Bismuth(III) alkoxide catalysts for ring-opening polymerization of lactides and ϵ-caprolactone. Macromol Chem Phys 214(6):707–715

Vuppalapati GP, Rathore RS, Pathak M, Kulathu Iyer S (2016) Hepta-coordinated heteroleptic derivatives of zirconium(IV): synthesis, structural characterization and ring opening polymerization of ε-caprolactone. Polyhedron 107:163–171

Pilone A, De Maio N, Press K, Venditto V, Pappalardo D, Mazzeo M, Pellecchia C, Kol M, Lamberti M (2015) Ring-opening homo- and co-polymerization of lactides and [varepsilon]-caprolactone by salalen aluminum complexes. Dalton Trans 44(5):2157–2165

Bandelli D, Weber C, Schubert US (2019) Strontium isopropoxide: a highly active catalyst for the ring-opening polymerization of lactide and various lactones. Macromol Rapid Commun 40(20):1900306

Ghosh S, Schäfer PM, Dittrich D, Scheiper C, Steiniger P, Fink G, Ksiazkiewicz AN, Tjaberings A, Wölper C, Gröschel AH, Pich A, Herres-Pawlis S, Schulz S (2019) Heterolepic β-ketoiminate zinc phenoxide complexes as efficient catalysts for the ring opening polymerization of lactide. ChemistryOpen 8(7):951–960

González DM, Cisterna J, Brito I, Roisnel T, Hamon J-R, Manzur C (2019) Binuclear Schiff-base zinc(II) complexes: synthesis, crystal structures and reactivity toward ring opening polymerization of rac-lactide. Polyhedron 162:91–99

Morozov AG, Martemyanova TV, Dodonov VA, Kazarina OV, Fedushkin IL (2019) Four- and five-coordinate titanium(IV) complexes supported by the DPP-BIAN ligand in ROP of L-lactide. Eur J Inorg Chem 2009(39–40):4198–4204

Yu C-J, Li C-Y, Tsai C-Y, Ko B-T (2019) Titanium, zirconium and hafnium complexes bearing amino-benzotriazole phenolate ligands as efficient catalysts for ring-opening polymerization of lactides. Inorg Chem Commun 109:107561

Lai F-J, Huang T-W, Chang Y-L, Chang H-Y, Lu W-Y, Ding S, Chen H-Y, Chiu C-C, Wu K-H (2020) Titanium complexes bearing 2,6-Bis(o-hydroxyalkyl)pyridine ligands in the ring-opening polymerization of L-Lactide and ε-caprolactone. Polymer 204:122860

Al-Khafaji YF, Elsegood MRJ, Frese JWA, Redshaw C (2017) Ring opening polymerization of lactides and lactones by multimetallic alkyl zinc complexes derived from the acids Ph2C(X)CO2H (X = OH, NH2). RSC Adv 7(8):4510–4517