Abstract

Biodegradable polymers have emerged as fascinating materials due to their non-toxicity, environmentally benign nature and good mechanical strength. The toxic effects of non-biodegradable plastics paved way for the development of sustainable and biodegradable polymers. The engineering of biodegradable polymers employing various strategies like radical ring opening polymerization, enzymatic ring opening polymerization, anionic ring opening polymerization, photo-initiated radical polymerization, chemoenzymatic method, enzymatic polymerization, ring opening polymerization and coordinative ring opening polymerization have been discussed in this review. The application of biodegradable polymeric nanoparticles in the biomedical field and cosmetic industry is considered to be an emerging field of interest. However, this review mainly highlights the applications of selected biodegradable polymers like polylactic acid, poly(ε-caprolactone), polyethylene glycol, polyhydroxyalkanoates, poly(lactide-co-glycolide) and polytrimethyl carbonate in various fields like agriculture, biomedical, biosensing, food packaging, automobiles, wastewater treatment, textile and hygiene, cosmetics and electronic devices.

Similar content being viewed by others

Introduction

The rise in the global population leads to an increase in the usage of plastics which in turn increased environmental pollution [1, 2] synthetic plastics are usually made from non-renewable petroleum-based resources which are non-biodegradable [3]. The increase in the usage of synthetic non-biodegradable polymers in industries, households and agriculture, causes waste generation and serious issues in the environment [4]. It increased the demand for fossil resources which are depleting resources, and there is a major concern that these resources will get completely exhausted within several hundred years [5]. Industries, researchers and technologists were looking forward to the development of a cleaner and more efficient manufacturing process for biodegradable polymers that produces less waste and avoids the usage of harmful reagents and solvents [6–8]. There is an urgent need to develop renewable, eco-friendly biodegradable polymers to replace the existing synthetic polymers [9]. The current global goal is the development of an efficient and sustainable process for a greener and biopolymer-based future [10,11,12]. Biopolymers attract remarkable attention of scientists since they are found abundant [12]. The research and development of new biodegradable polymeric materials are gaining momentum [13].

Biodegradable polymers can be synthesized by various methods like ring opening polymerization (ROP) [14], chemoenzymatic methods [8], photo-initiated radical polymerization [15], enzymatic polymerization [16], cationic, anionic, enzymatic, coordinative and radical ring opening polymerization [17]. The definition of biodegradable polymers according to the American Society for Testing and Materials (ASTM) is "they are the polymers that degrade or decompose under chemical, physical and biological interactions with microorganisms from environment, such as bacteria, fungus and algae” [18]. They break down into natural components such as CO2, water and biomass without producing hazardous waste [19, 20] Biodegradable polymers can be classified based on their renewability and biodegradability level. The demand for biodegradable polymers is ever increasing because of their properties like degradability, eco-friendliness, sustainability and non-toxicity [21, 22].

Plastics are mainly used in the packaging field which are disposed of in landfills which results in environmental pollution and also a decrease in the availability of land space. The use of conventional plastic in agriculture increases the risk of non-degradation. The introduction of biodegradable polymers in place of these synthetic plastic materials enhances the rate of degradation since they are broken down by microorganisms present in the soil. The biomedical world is continuously changing, and the materials used in the field are also getting better by the use of these biodegradable polymers. Biodegradable polymers are ideally suited for biomedical, cosmetics and sanitary fields because of their non-toxic nature. In wastewater treatment, the use of conventional chemical methods for the removal of contaminants may sometimes release toxic by-products into water which can be overcome by the use of biodegradable polymers.

Usage of green/biodegradable polymers has increased over the past decade, as these are widely used in many fields like medical, agricultural, automobiles, packaging, electronics, health care, pharmacy and so on [23]. During this period, a large number of biodegradable polymers were developed, which found their applications in new biomedical techniques such as controlled drug delivery, regenerative medicine, biological nanotechnology, therapy and tissue engineering [24]. In this review, we mainly focused on the various methods of synthesis of biodegradable polymers and the application of these biodegradable polymers in different fields (Fig. 1).

In this present work, the complete information of biodegradable polymers beginning from their origin, various methods of synthesis, their properties, importance, degradation and applications in various fields is completely discussed. This reviews mainly highlight applications of biodegradable polymers in the field of agriculture, packaging, medical, cosmetics, automobiles, textiles and hygiene, biosensors, wastewater treatment and electronic devices. The polymers that are used in all these applications are non-toxic to environment and safe to use. The biodegradability of each polymers is achieved by various degradation mechanisms which give non-toxic substances.

Strategies in synthesis of biodegradable polymers

Diverse methods for the synthesis of sustainable biodegradable polymers are discussed below (Fig. 2). Some of the methods include radical ring opening polymerization, enzymatic ring opening polymerization, anionic ring opening polymerization, photo-initiated radical polymerization, chemoenzymatic method, enzymatic polymerization, ring opening polymerization and coordinative ring opening polymerization. Ring opening polymerization is considered one of the best methods to synthesize high molecular weight biodegradable polymers. Enzymatic and chemoenzymatic methods are also beneficial because of their regioselectivity and stereospecificity (Fig. 3). Each type of biodegradable polymer can be synthesized by choosing the appropriate method of synthesis.

White biodegradable film (WBF). A Black biodegradable film (BBF). B Control polyethylene films (CPF). C After 5 weeks in contact with soil [86]. Reprinted with the permission of Elsevier

Ring opening polymerization (ROP)

Polymerization of cyclic monomers into an acyclic monomeric unit is called ROP. Here a long polymer chain is formed by opening the ring system of cyclic monomers where the terminal end of a polymeric chain behaves as a reactive center. There are three propagating centers, namely radical, anionic and cationic. This method is considered one of the most versatile methods for the synthesis of biopolymers in huge quantities. Polylactic acid is a biodegradable polymer that is synthesized by using ROP as follows.

PLA (polylactic acid) is synthesized by the chain growth ROP of lactide. To carry out the ROP of lactide, various catalysts and initiators are used. Sn(oct)2 is a commonly used robust catalyst/initiator. ROP of lactide and glycolide results in the formation of PLGA. The catalyst used here is Sn(oct)2. The molecular weight of PLGA is high. PDS can be produced by the ROP of p-dioxanone which is a relatively weak and rapidly biodegradable polymer. But it generates degradation products that are less acidic than PLA and PGA [25].

Radical ring opening polymerization

The consecutive addition of free radicals as building blocks formed by various mechanisms which involve separate initiator molecules to produce polymers is called free radical ring opening polymerization (FROP). The initiating free radicals which are generated newly add the monomer units to the polymer chain which results in chain growth. FROP is considered as one of the most versatile forms of polymerization which allows facile reactions of polymeric free radical chain ends with other substrates or chemicals [26]. ε-Caprolactone-based materials are synthesized by using this method. For example, poly(HEMA-g-CLk) NPs are synthesized by using the free radical polymerization synthesis technique. Here, ε-caprolactone is combined with 2-hydroxyethyl methacrylate (HEMA) to produce poly(HEMAg-CLk) NPs [26].

Chemoenzymatic method of polymerization

Chemoenzymatic synthesis is well known for the production of active pharmaceutical ingredients (AAPIs). By using this approach, the scientists have fabricated some polymeric prodrugs which are optically active. These prodrugs are nonsteroidal anti-inflammatory substrates having high molecular weight [25]. This method combines conventional polymerization with an enzymatic approach which is highly efficient. Chemoenzymatic synthesis is coined as an attractive strategy for the synthesis of high molecular weight BPMS. For example, the PLA monomer can be synthesized by a chemoenzymatic approach [8].

Photo-initiated radical polymerization

Photo-initiated ring opening polymerization is an interesting technique because it provides rapid polymerization rates under physiological conditions with spatiotemporal control. It eliminates the use of a toxic cross-linker in the reaction medium. Most of the polymers that are commonly used in biomedical applications are commonly synthesized by using this greener route [15].

Enzymatic polymerization

In recent times, the enzymatic synthesis of biodegradable polymers is considered a novel and green methodology for the production of polymers. Enzymes are biocatalysts that are non-toxic and renewable with high catalytic activities. The use of enzymes for biodegradable polymer synthesis involves low activation energy compared to the conventional methods of synthesis [27]. The enzymatic synthesis of biodegradable polymers takes place even in milder conditions without the use of metal or toxic organic contaminants. This increases its application in various fields, especially in the biomedical field [28]. The enzyme lipase is used as a catalyst for the synthesis of novel biodegradable polymers like polyester by using methyl 12HS (12HS-Me). It is a thermoplastic elastomer that is biobased [29].

Anionic ring opening polymerization

Anionic ring opening polymerization is used as one of the elegant methods to synthesize telechelic polymers in various topologies such as hyper-branched, linear, star, core–shell polymers. Anionic ring opening polymerization is considered one of the most advantageous methods because of controllable polymerization kinetics and no side effects and provides a higher degree of monomer conversion [30].

PCL block–poly(butyrolactone) copolymers were synthesized utilizing anionic ring opening polymerization. PCL was synthesized by anionic ring opening polymerization of CL which is initiated with anhydrous KOH-activated 12-crown-4 cation complexing agent. This reaction is carried out in the presence of tetrahydrofuran solution and argon atmosphere at room temperature. Further, butyrolactone (BL) 16 crown-6 are added to the system which results in PCL-block-PBL copolymer [31].

Coordinative ring opening polymerization

In coordinative ROP, the metal atom will coordinate the molecule of the cyclic ester. Here, the metal atom plays the role of the electrophilic catalytic center. This coordination insertion mechanism results in carbon atom activation of the carbonyl group for cyclic esters or phosphorous atoms for the cyclic phosphates. The initiator like amino, alkoxy, alkyl, etc. is directly bonded or coordinated weakly with the metal. This dual monomer and initiator coordination form a reaction complex [33]. “Coordination–insertion” ROP is often called pseudo-anionic ring opening polymerization. This type of polymerization will yield well-defined polyesters through living polymerization [34].

Enzymatic ring opening polymerization

In this type of polymerization, the enzyme lipase is more commonly used. Some of the lipase enzymes that are used are pseudomonas cepacia lipase PS, porcine pancreatic lipase (PPL), Burkholderia cepacia lipase PS [35]. The enzymatic ring opening polymerization synthesis technique is very sensitive to reaction conditions such as water content, solvents and temperature [36]. For example, high molecular polylactic acid is synthesized through the enzymatic ring opening polymerization route using free enzyme and (CALB) candida Antarctica lipase enzyme [37].

Applications of biodegradable polymers

The applications of biodegradable polymers are vast and diverse. Each biodegradable polymer that is applied in different fields will have different synthetic routes. While designing a biodegradable polymer for specific applications, one should also look into its degradation mechanisms, as the degradation of biodegradable polymer is the most crucial property. Irrespective of any degradation mechanism, it should not produce any toxic by-products after decomposition.

Each biodegradable polymer has different properties which apply to various fields. A tabular representation of the synthesis and their applications have been displayed Table 1. PLA has properties like heat resistance, good stability and visual transparency which can be used for food packaging. PCL is a polyester that can be degraded by ester hydrolysis under physiological conditions, so it is used in injectable implants. PCL also stimulates collagen production; hence, it is used in periodontal regeneration. PHA has good moisture resistance and aroma barrier properties, so it is applicable in pesticide transfer in the field of agriculture. Superabsorbent polymers are biodegradable and have good water absorption properties and retain a large amount of liquid. It also has good antimicrobial properties and is non-toxic, so it is used in sanitary napkins, diapers and other personal hygiene products (Table 2).

Polysaccharides are one of the naturally available biodegradable polymer. It is a kind of monosaccharide or combination of more than one type of monosaccharides. These polysaccharides are most commonly found in living organisms such as animals and plants. The animal origin polysaccharides are chondroitin and chitin. The plant origin polysaccharides are mainly cellulose, hemicellulose, starch, alginate, etc. The slight differences in the microstructures of the polysaccharides gives a significant difference in the properties. For example, cellulose and starch which differ only in stereochemistry play a unique role in nature. These are abundant in functional groups such as carboxyl, hydroxyl, amide and other hydrophilic functional groups that can be used to modify the properties of polymers of polymers that suits the desired applications. These are known as amorphous polymers [38]. Aligiate is most common available polysaccharide in brown seaweed. It is composed of monomeric units of (1,4) linked-D-mannuronic acid and L-gulucronic acid residues which is used in thickening, stabilizing, gel producing, film forming. Polysaccharides are cross-linked with other synthetic biodegradable polymer to gain better desired altered properties such as improved mechanical strength, swelling capacity and intact in shape. These cross-linked polysaccharides such as alginate/polyacrylamide and chitosan/chondroitin sulfate are used in various biomedical applications such as tissue engineering, wound dressing and gene therapy [39].

Polysaccharide degradation is induced by ascorbic acid. A series of changes in the properties of polysaccharides like smoother apparent morphology and lower apparent viscosity will take place on the addition of ascorbic acid to polysaccharides. Based on molecular weight measurement, it was identified that molecular weight of polysaccharide product after the addition of ascorbic acid was lowered. This is because ascorbic acid generates hydroxyl radicals based on Fenton reaction. These hydroxyl radicals will attack polysaccharide molecules which causes a series of reaction such as depolymerization that results in lowering of molecular weight. This degradation of polysaccharides can be inhibited by radical scavengers, but prevented by catalase. Ascorbic acid reduces oxygen to hydrogen and reduces metal ions. The hydroxyl radical is formed by a Fenton reaction between reduced metal ion and hydrogen peroxide or these radicals are produced by oxidation of ascorbic acid by hydrogen peroxide which will produce 2,3-diketogulconic acid (DKG). The generated hydroxyl radicals are very reactive and react with hydrogen atoms of polysaccharide that causes the glycoside bond cleavage [40]. The redox enzymes role in biomass conversion is gaining more interest. These enzymes promote the conversion of recalcitrant polysaccharide. Lytic polysaccharide monooxygenases (LPMOS) are mono-copper enzymes [41]. In the presence of external electron donor. It catalyzes hydroxylation of one of the carbons (C1 or C4) in the scissile glycosidic bond, which leads to bond cleavage by elimination reaction. LPMOS will act on polysaccharide chains that reside in crystalline environment. This leads to the disruption of structure of polysaccharides [42].

Cellulose is a natural biodegradable polymer plays an important role as a raw material for the development of commercial plastics. Cellulose-based resins are used during the molding process in plastic industry. Cellulose films are used for the packaging of mangos instead of PE (polyethyelne). This decreases the diseases, extends the ripening period of fruits and increases color indexes of fruits [43]. Carboxymethyl cellulose (CMC) is a crucial derivative of cellulose. CMC is also used in packaging material as polymeric blends. The degradation of these blends depends on degradation of carbonyl groups and inactivation of side chain [44].

The degradation of cellulose can be carried out by the enzymes called “cellulases” which is responsible for the hydrolysis of beta-1,4-linkages present in the cellulose [45]. Cellulose is hydrolyzed by a variety of simultaneously acting enzymes which interacts each other to bring complete hydrolysis. At least three different type of enzyme activities are essential for the complete hydrolysis of this polymeric substrate into its monomeric unit. Exoglucanase activity (cellodextrinase or cellobiohydrolase), Endoglucanaoe activity and Glucosidase activity. By the cooperation of all these enzyme activities the disruption of cellulose structure will takes place. The mechanism of degradation will take place by the following ways. Endoglucanases produce random internal cuts within the amorphous region in the cellulose molecule which yields cell oligosaccharides of various length and new chain ends are generated. Exoglucanases act progressively on non-reducing/reducing ends producing either cellobiose, glucose or cello-olidosaccharides. These cellodextrins and cellobiose which are soluble are then hydrolyzed by glucosidases to glucose [46].

The degradation of cellulose can be achieved by hydrothermal method and sonication method. By hydrothermal method, cellulose degrades and produces reducing sugar. Sonication pretreatment changes the degradation phenomenon, which occurs faster, increasing the degradation rate. The pressurization of H2 C2 O4–NaCl solution with carbon dioxide has produced a solvent with high solvent power capable of swelling, penetrating and changing the cellulose chain interaction which results in production of reducing sugar. The combination of hydrothermal (at high temperature) sonication process has a greater risk of degradation than hydrothermal process alone [47, 48].

At the molecular level, plastics may be described as a backbone chain built from units (monomers) of mostly carbon. The functional group (or side chain) of the individual monomer is the main contribution to the difference in the chemical and mechanical properties of plastics. These vary from simple carbon chains, for examples polypropylene (PP) and polyvinyl chlorine (PVC), and complex side chains, for example poly(methyl methacrylate) (PMMA). In terms of biodegradation, the functional group is of critical importance, as some chemical groups and bonds are more easily degraded by biological agents. The basic driving force of biodegradation is the use of carbon bound in the polymer as a feedstock for microorganisms to grow under aerobic conditions, and this reaction can be simply written as

The rate of biodegradation is usually determined by measuring the amount of CO2 evolved or the amount of Cpolymer that has disappeared over time. The theoretical total amount of CO2 can be determined from the known input of Cpolymer. Biodegradability is based on a percentage of the theoretical CO2 produced over a given time frame. When oxygen is not available, methane gas (CH4) is also produced which can also be measured. Table 3 comprises the rate degradability of various biodegradable polymers. The timescale for biodegradable of place material is dependent on many factors, including the composition of starting material, environment and shape of the material (surface area) [49].

Application of biodegradable polymers in agriculture

In agriculture, biodegradable polymers are very important because of their degradability. Biodegradable Ecoflex films are used to cover the young plants which are sensitive to frost. As the plant grows, these biodegradable films will break down in the soil and it is degraded by microorganisms [65]. The biodegradable polymers can be developed by cost-effective techniques, and these polymers improve the phytostabilization of heavily contaminated soils by metals [66]. Chemical storage bags and fertilizer bags which are made up of polymers like polyethylene or polypropylene are replaced by biodegradable polymers [65]. Chemical pesticides are greatly affecting public health and the environment because of their toxicity. Nowadays botanical pesticides are in great demand. To deliver these pesticides, a suitable drug carrier is required, so the biodegradable polymer drug carrier like halloysite nanotubes (HNPs) are used [67]. Liquid marbles which are made up of PCL [poly(ε-caprolactone)] and PLA are used in fertilizer transfer. By using this method, urea can be successfully encapsulated inside these liquid marbles for safe fertilizer delivering systems [68]. The polymer-encapsulated formulation is superior to non-encapsulated formulation in extending activity and also in reducing evaporative and degradation loss [69].

The main problem in present-day agriculture is to increase land suitable for cultivation and enhance water productivity without causing any harm to the environment. The superabsorbent polymer hydrogels will influence the soil permeability, structure, texture, evaporation and infiltration rate of water through the soil. To increase the efficiency of herbicides and pesticides, some of the functionalized biodegradable polymers are used. The use of these polymers will reduce pollution and protect the environment [66]. These biodegradable hydrogels are widely used in modern agricultural and horticultural applications [70].

The usage of sprayable biodegradable polymer membrane (SBPM) increases the soil temperature, and in turn, it reduces the water evaporation which results in an improvement in seedling and crop yield. Table 3 The main purpose of SBPM is to increase crop germination, and the use of SBPM reduces seedbed water loss [71]. The biobased superabsorbent polymers (SAP) which are synthesized from modified starch (MS) are used for agricultural applications since it increases the antibacterial properties and biodegradability [72]. These SAPs will also increase the efficiency of water use of soil and also be used for the controlled release of fertilizers [73]. The modified starch-graft-polyacrylate superabsorbent polymer (MS-g-PA SAP) shows excellent reusability and biodegradation property. The (MS-g-PA SAP) will not impose inhibition of growth in mung beans (vigna radiata) and this provides some transient drought relief [72]. The SAPs improve the moisture contents of soil and help in water saving, so it is widely applied in the growth of many horticultural crops like gerbera [74]. There are many advantages of using SAP hydrogels in agriculture such as stabilization of fertilizers in the soil, reduction in the water consumption in irrigation, reduction in the death of plants and crops, and these hydrogels prevent draining out an active ingredient to the groundwater, thereby improving the plant growth [75].

Water hyacinth cellulose-graft-poly(ammonium acrylate-co-acrylic acid) polymer hydrogel is capable of absorption and retention of water in the soil. This also formulates the soil conditioning and slow liberation of fertilizers [76]. The biodegradable semi-interpenetrating polymer network (semi-IPN) hydrogels of cassava starch-g-polyacrylic acid/natural rubbers/polyvinyl alcohols blends (CSt-g-PAA/NR/PVA) are used in agriculture because of their good water absorption and excellent water retention capacity [70]. The polymer hydrogels (PHGs) are used in agriculture as slow release fertilizer (SRF) carriers and soil conditioners due to their water absorption and the retention property [77]. Polymer nanocomposites phosphate fertilizers are synthesized by grafting partially neutralized acrylic acid onto cellulose matrix in the presence of nano-HA (nanohydroxyapatite). This polymer increases phosphorus use efficiency and conditions of the soil due to improved moisture-holding capacity. The use of these polymeric nanocomposites is minimizing the cost of production and reduces environmental contamination [78].

The use of polyethylene (PE) fragments for mulching in agriculture increases soil pollution, since it is non-biodegradable and non-recoverable. So this can be overthrown by biodegradable polymers like poly(butylene adipate-co-terephthalate) (PBAT) and polybutylene terephthalate (PBT). The use of this polymers increases the mulching efficiency [79]. The preformed biodegradable plastic mulch is used in agriculture to improve the crop yield by suppressing the heat and altering the soil thermal environment [80]. The hydrolyzed proteins which are derived from waste products of the leather industry are used as biodegradable polymeric ingredients and are cross-linked with PEG (polyethylene glycol) and used for spray mulching [81].

The polyacrylic acid lignin hydrogel (LBPAA) is prepared by grafting lignin on the surface of the polyacrylic acid network. It is used for the sustainable release of pesticides, so it found its application in CPR (controlled pesticide release) [82]. Avermectin (Av) is extensively used to control weeds, plant diseases and insects. These are the derivatives of pentacyclic 16-membered lactones and a broad spectrum of antiparasitic agents. A controllable avermectin release system triggered by pH and temperature stimuli makes it an environmentally friendly hydrogel for controllable pesticide release [83] PHA (polyhydroxyalkanoates) is used as material for the construction of a controlled release system for agricultural pesticides. The mixture of PHA and pesticides can be designed in different forms like microparticles, granules, films and tablets. By using these strategies, some of the herbicides like metribuzin and tribenuron-methyl were successfully delivered and it showed a positive effect on the crop yield [84]. The biodegradable transplanting pots are designed by using the biobased composites with PLA, Ecoflex and wood fibers. These biodegradable plant pots are widely used in the nursery and greenhouse industry. The main advantage of these pots is that they can be planted along with the growing medium and seedling without causing any damage to the development of roots because these pots will easily break down and degrade fast after that is planted in the soil [85]. Poly(butylene adipate-co-terephthalate) is used for manufacturing agricultural mulching films and these biodegradable films are commonly used in strawberry plantations (Fig. 3) [86].

Biodegradable superabsorbent polymers and polymer hydrogels are playing a major role in agriculture due to their water absorption and retention properties. It also helps in the delivery of fertilizers to the plant. Apart from this, biodegradable pots, mulching films are also widely used. The use of biodegradable polymers in agriculture is environmentally safe. But, still, some advancement in polymer technology is needed in this field.

Application of biodegradable polymers in biomedical applications

Biodegradable polymers are widely used in various biomedical applications. These polymers are sterile and show a smart response toward various physiological stimuli [87]. Some of the biodegradable polymers are used in controlled release drug carriers and they have high water stability and improved pharmacokinetics [88]. The application of biodegradable polymers in surgeries and implantation medical devices reduces the chances of infection, and also, they have antimicrobial properties [89]. Some of the biodegradable polymers like poly(lactic acid) (PLA), poly(glycolic acid) (PGA) and their copolymers like poly(lactide-co-glycolide) (PLGA) are non-toxic to human tissues [90]. These are biodegradable polymers approved by the US Food and Drug Administration (FDA) [91]. Because of their non-toxicity, these polymers are widely used in medical applications like bone fixation devices, surgical sutures, artificial skin, wound dressing, cell scaffolding for tissue engineering and controlled drug delivery systems [90]. This is also used for disposable medical devices such as injection pipes, surgical gloves, pads and syringes. Hence, they have wide commercial applications [92]. Citrate-based biodegradable step index optical fibers were used for drug delivery, photodynamic therapy, optogenetics and tissue/scaffold imaging and monitoring [93].

The biodegradable polyhydroxyalkanoates are a promising biomaterial and extensively used in biomedical applications such as wound dressing, stents, orthopedic pins, nerve guides and bone marrow scaffolds [94]. It is also used in other medical applications like coronary angioplasty, nerve regeneration, bone tissue engineering and cardiac tissue engineering [95]. Biodegradable polymeric nanoparticles are greatly used in various biomedical applications. They show high potential for site-specific targeted drug delivery. It is mainly used for oral administration of peptides and proteins and it is also used in gene therapy. So, these biodegradable polymeric nanoparticles are usually synthesized from preformed polymers by using various technologies like emulsification–solvent evaporation, nanoprecipitation, dialysis and supercritical fluid technology, or these polymeric nanoparticles can be directly prepared by polymerization of monomers by using some of the polymerization techniques like mini-emulsion, microemulsion, surfactant-free emulsion and interfacial polymerization [96].

Application of biodegradable polymers in tissue engineering

Biodegradable electrospun nanofibers have the same size as biomolecules and mimic biological properties. Since electrospinning is a simple and inexpensive technique, these electrospun nanofibers are playing a very important role in biomedical applications like cardiac tissue engineering, skin tissue engineering, bone tissue engineering and nerve tissue engineering [97]. The biodegradable thermoresponsive polymers can be used for 3D printing of hydrogel scaffolds in tissue engineering [98]. These polymers can act as sacrificial materials for bioprinting. By using the freeform reversible embedding of suspended hydrogels (FRESH) technique, the printing of low viscosity and soft hydrogels like collagen can be obtained. Therefore, thermoresponsive biodegradable polymers are used for 3D printing of hydrogels such as collagen and gelatin and notably widening the range of printable materials for tissue regeneration [99].

Poly(tri-methylene carbonate) (PTMC) is used in the fabrication of non-commercial devices of soft tissue engineering [92]. The biodegradable polyurethane (cPU) is produced by cross-linking with hexamethylene diisocyanate (HDI), polyethylene glycol (PGA) and prepolymer PLEG and is used as a scaffolding material for hypopharyngeal tissue engineering. This has excellent hydrophilicity and relatively quick degradation. It can support the growth of human hypopharyngeal fibroblasts [72].

Application of biodegradable polymers in drug delivery

Biodegradable polymers have vast applications in the areas of drug design, development and therapy [101]. To obtain steady drug release, the two prominent groups of polymeric materials, i.e., degradable polymeric and porous polymers, are used. These polymers are used to encapsulate the drug compounds [102]. The biodegradable hyper-branched polyglycerols consisting of oligo caprolactone segments in the backbone (hPGOCs) are used as intradermal drug delivery. This polymer penetrates the skin and transports the hydrophobic guest molecules through the stratum corneum into deeper skin layers [103]. These hPGOCs may degrade into lighter fragments in the presence of the enzymes' skin lysate [104]. Because of this property, there will be a facilitated release of drugs and less accumulation inside the tissues without causing any serious effect on the viable dermal layers [103]. The biodegradable silk fibroin (SF)/alginate blend films are used in the controlled release delivery system for water-soluble drugs. It is used in the controlled release of an antimicrobial model drug called tetracycline hydrochloride [105].

The biodegradable PLA thin-film composites which are developed by using polylactic acid and microspheres of hydrothermally converted coralline hydroxyapatite (cHAp) are used in drug delivery systems for regeneration [106]. In this system, PLA provides flexibility and biodegradability to the drug delivery system [107]. On the other hand, coralline hydroxyapatite supplies a sufficient amount of phosphate and calcium ions for bone regeneration [106].

Electrospun nanofibers have a high surface area–volume ratio and these fibers possess interconnected pores which enhance dissolution rate and therapeutics index because this property is more likely used in drug delivery [97]. Biodegradable thermoresponsive polymers like collagen, gelatin, cellulose, poly(N-vinyl caprolactam) is used for drug delivery system [98]. Silk fibroin–poly(sebacic acid) diacetoxy terminated (SF-PSADT) polymeric composite coatings are used in drug delivery. This polymer prevents drug denaturation and also enhances drug stability. Here, the SF matrix can be degraded by enzymes and get excretes without any side effects from the body [108].

Plasma co-polymerized nanocoatings like biodegradable PCL-co-PEG coating are used for tunable drug delivery applications which reduces nephrotoxicity and myelosuppression [109]. The biodegradable polymeric solid implants (PSIs) are used for ultra-long-acting (ULA) drug delivery of antiretroviral drugs for HIV PrEP/ART (HIV preexposure profile access/antiretroviral therapy) and delivering the other drugs [110]. The biodegradable phosphazene–tannic acid nanospheres are antioxidants and have good drug-holding capacity with a drug release rate linked to pH. They act as nanocarriers to transport drugs in the treatment of diseases like stomach, uterus, esophageal and colon cancer [111].

Application of biodegradable polymers in anticancer drug delivery

Cancer or tumor is a growth of abnormal mass of tissue that has a distinct tumor microenvironment and complex structure [112]. Anticancer drugs are usually toxic or lethal and it also shows serious side effects. The risk of these side effects can be reduced by delivering the drugs to the tumor site without leaking into other sites. This can be done by developing a suitable drug delivery system that can ensure the encapsulation of suitable drugs before reaching the targeted tumor site without any leakage, but can be able to discharge the drug after entering the tumor tissues [113]. Biodegradable polymer conjugates are used as anticancer agents in cancer therapy, these anticancer polymer conjugates are effective in delivering the drugs and genes [114].

The biodegradable polyphosphazenes are used as a carrier in anticancer drug delivery of platinum-based anticancer agents like cisplatin. Poly(organo) phosphazenes are also used in various biomedical applications like polyelectrolytes which are used as vaccine immunoadjuvants and polyplexes for gene delivery [115]. The biodegradable PEG–poly(pentadecalactone-co-N-methyl-diethyleneamine sebacate-co-2,2’-thiodiethylene sebacate) (PEG-PMT) micelles are used as eminent vectors for controlled release of antitumor drugs at their tumor intracellular site. The PEG-PMT nanoparticles show non-toxicity toward the normal organs like kidneys and liver [112]. The hydrophobic anticancer drugs such as paclitaxel (PTX) and doxorubicin (DOX) are successfully delivered to the targeted site by using biodegradable polymeric micelle. The use of these micelles has numerous advantages such as enhancement of water solubility of anticancer drugs, passive targeting tumor tissue via the enhanced permeability and retention (EPR), prolonged drug circulation time, improved drug bioavailability and excellent biocompatibility [2].

The biodegradable polymeric nanoparticles are also used in the treatment of colorectal cancer [116]. The polytyrosine nanoparticles are multifunctional biodegradable nanovehicles that have high encapsulation of doxorubicin (DOX) and it exhibits superstability, prolonged blood circulation time and stimulated drug release inside the cancer cells. It shows high specificity toward HCT-116 colorectal cancer cells and notably improves tumor accumulation [117]. The biodegradable poly(1,4-phenyleneacetone dimethylene thioketal) (PPADT) nanoparticles are used as intracellular drug delivery of anticancer drug agents [118]. PLA or PAMAM (polyamidoamin)-based polymers are used as topical delivery of drugs and also as carrier systems for the treatment of different types of skin tumors or skin cancers [119].

The major side effects observed in conventional cancer therapeutics could be reduced with a targeted polymeric system. Drug delivery systems based on biodegradable polymers have a significantly high potential to deliver the payload to the targeted site and can improve drug availability at the targeted site (Fig. 4) [120].

Schematic representation of biodegradable polymers as facile tools for targeted anticancer drug delivery: a carriers for systemic drug delivery: micelles, nanoparticles, polymer lipid hybrid nanoparticles, polymersome, dendrimers, polyplexes, polymer–drug conjugates loaded with chemotherapeutic agents. b Carriers for local drug delivery: in situ gels, wafers, meshes, millirods. c Polymeric products used for cancer treatment in clinic. d Clinical trials on biodegradable polymer-based drug delivery [99]. Reprinted with the permission of Taylor and Francis

Application of biodegradable polymers as contraceptive Drugs

Hormonal contraceptives are used to prevent or delay pregnancy. There are many contraceptive methods, some of the most common ones are combined oral contraceptives (COC) or progestogen-only pill (POP) which contains combined progestogen and estrogen, and only progestogen hormone. But they are not much effective and also require daily oral intake of pills [121]. There are other contraceptive methods such as the use of male and female condoms, subdermal implants, vaginal rings, intrauterine devices (IUDs) [122]. But the use of these conventional contraceptive implants and injectables has shown less effectiveness. The use of IUDs is not economically efficient and also it should be inserted and removed through surgical procedures every few months. Certain IUDs can be used greater than one-year providing contraceptive therapy, but they are extremely costly, also lead to discomfort to patients and irregularities in menstrual bleeding [123].

PCL [poly(ε-caprolactone)] is a biodegradable polymer which is FDA-approved and it is extensively used as an implantable biomaterial and injectable implants for controlled release drug delivery system. PCL microsphere is fabricated with two loading concentrations of levonorgestrel (LNG) for long-term contraceptive drug delivery. LNG is an FDA-approved progestin hormone that prevents ovulation by eliciting changes in the uterine lining. PCL–LNG system has many advantages compared to many other commercially available products. This ensures prolonged contraceptive therapy combined with steady degradation for therapy and also overcomes the need for secondary surgery [121]. PLGA (polylactic-co-glycolic acid) microsphere fabricated with etonogestrel (ENG) which is also a progestin hormone used as a controlled contraceptive drug delivery system and releases the drug ENG [124].

The biodegradable passive implants which are made up of polymers or block copolymers can be degraded and eliminated or absorbed by the body. Polymers such as PCL, PLA PLGA are used in these implants. The mechanism of drug delivery in these implants is a combination of diffusion dependent drug release with matrix degradation. The matrix degradation is a major driving force. The use of these biodegradable polymer implants over non-degradable implants is more advantageous. They do not need any procedure for extraction after their intended course of use [125].

Application of biodegradable polymers in medical packaging

A blend of polypropylene/poly(lactic acid) is used in medical packaging because of its water barrier property, contamination reduction, prevention of bacterial growth and antimicrobial properties. It is extensively used in medical fields and hospitals [126]. The development of biodegradable polymeric material in pharmaceutical packaging is a complex task. In this case biodegradable polymers should have certain characteristics and properties as follows: biodegradable polymeric material should not allow penetration into production; it should not change the formulation of medicine and should not react within or change medicinal ingredients; it should be consistent and able to withstand external influencing factors like moisture, heat, oxygen, light, mechanical and biological contamination, etc. [127]. The PLA/SIS blends (polylactic acid/styrene–isoprene–styrene) are also used in medical packaging applications. The presence of SIS enhances the oxidation strength, so it has a wide range of applications in the field of medical packaging [128].

Application of biodegradable polymers as Orthopedics

Nowadays biodegradable polymers are used in orthopedics applications. The bioceramics like Hydroxyapatite (HA) as excellent biocompatibility, bioactivity and osteoconductivity properties. The hybrid polymer products that are based on HA–poly(PEG-co-propylene fumarate-co-ascorbate) hybrid macromers are used in bone graft materials because of their excellent mechanical properties and osteointegration ability and promote albumin adsorption and osteoconduction [129].

The biodegradable implants which contain magnesium-based materials are used for temporary orthopedic and cardiovascular stent applications. The use of magnesium-based biodegradable implants avoids second surgical procedures and reduces the stress-shielding effect. So, it is more advantageous than compared to other metallic implants such as 316L steel, titanium alloys and Co–Cr alloys. Nowadays AZ31Mg alloy sheets that are coated with PCL nanofibers are used in designing biodegradable Mg-based implants and it has shown excellent corrosion resistance, wettability, bioactivity and degradation properties [130].

Most of the materials that are commonly used for bone fracture fixation are 316L stainless steel, cobalt–chromium-based alloys, pure titanium and its alloys, but all these are non-biodegradable. One of the important characteristics of an implant is its ability to degrade after the healing of bone. Since the implant is metallic, it is a foreign body to the tissue due to which local inflammation may take place, and in some cases, a second surgery may be required for the removal of that implant. To avoid such risks, biodegradable metallic implants came into use. One of the most commonly used degradable metallic materials is magnesium and its alloys. But again, there is an issue of corrosion and also it degrades rapidly with the release of hydrogen gas on degradation. To overcome this issue, several strategies like alloying, various surface treatments were tried to enhance the corrosion resistance of magnesium. To alter its original mechanical properties some of the rare earth metals like Zr, Ce is added into the Mg substrate, but they are toxic to the human cells and also the cytocompatibility of these elements is not known. To overcome all these drawbacks, the biodegradable polymeric membrane fabricated by dichloromethane and PCL onto Mg alloys is developed. By coating this controllable polymeric membrane on Mg alloy, the corrosion and degradation rate is reduced and also it provides good cytocompatibility of eGFP and SaOS-2 osteoblasts. The cell toxicity is also not observed. Now, these biodegradable polymeric membrane implants are extensively used in clinical use for orthopedic applications [131].

Some of the important parameters of ideal biodegradable implants are lower rates of biodegradability, to provide sufficient mechanical support until the healing process gets completed. Another parameter is biocompatibility which can be controlled by using bioinert elements, nutrients, etc. [132]. The organ which undergoes the most transplants/grafts every year is bone. Bone fracture is a common problem everywhere due to the increased rate of accidents/diseases. It is also estimated that every year over 3 million bone surgeries are performed worldwide. For this reason, the quality and efficiency of bone fracture treatments are more important for patients as well as for doctors [133].

The biodegradable cortical screws with porous interconnections were recently developed. The porous biodegradable screws have interconnected pores similar to that of native bone tissue (~ 300 μm) and have similar mechanical strength so that the stress-shielding effect has been prevented. These biodegradable porous screws showed enhanced mineralization over 4 weeks and the pores act as nucleation sites for the deposition of salt which was confirmed by the invitro degradation test [134]. There are a lot of biomaterials that have been developed by researchers for various orthopedic applications like stents, scaffolds, hard tissue replacements and spinal degeneration disease [135].

Application of biodegradable polymers in periodontal regeneration

Periodontal disease is one of the inflammatory diseases in the tooth which leads to the destruction of periodontal tissues and is also associated with severe pain. The biodegradable polymers like Helixician (HX) immobilized biodegradable chitosan (CS)/poly(vinyl alcohol) (PVA)/hydroxyapatite (HA)-based electrospun films and fibers are used in this periodontal treatment. These systems were tailored to achieve prolonged drug release. These biodegradable scaffolds are used for periodontal tissues regeneration, because of anti-inflammatory and antimicrobial properties these polymers are greatly used [136]. Nanofibrous scaffolds prepared from PCL or PCL/CA (polylactic acid/cellulose acetate) are used for periodontal tissue regeneration and also in bone regeneration with antibacterial activity [137].

A drug delivery system consisting of ionic liquid (IL) 1-butyl-3-methylimidazolium hexafluorophosphate ([BMIM][PF6] incorporated and chitosan modified polymeric nanoparticles by using the base materials like poly(DL lactide-co-glycolide) (PLGA) and polyvinyl caprolactam–polyvinyl acetate–polyethylene glycol graft polymer is used for the prevention and early treatment of periodontal disease. These polymeric nanoparticles have high tissue affinity and antimicrobial activity [138]121. Periodontitis is mainly caused due to bacterial infection. Because of this, antibacterial agents are commonly added to GTR/GBR scaffolds. Silver nanoparticles can also be used because it belongs to broad spectrum antibacterial activity. Electrospun nanofibrous scaffolds are used for GTR/GBR applications. The nanofibers are synthesized either by the combination of polylactic acid and cellulose acetate (PLA/CA) or poly(caprolactone) (PCL) polymers. In addition to this, silver nanoparticles (AgNPs) and hydroxyapatite nanoparticles (HANPs) which are green synthesized are incorporated into the scaffolds to improve their antibacterial and bone regeneration activity. These GTR/GBR scaffolds (Fig. 5) are biodegradable, antibacterial, Osteoconductive and provide optimal mechanical strength, so it helps in periodontal tissue and bone regeneration [137].

Development of a new series of electrospun nanoparticles-in-nanofibrous scaffolds for GTR/GBR applications with enhanced antibacterial and bone regeneration activity [137]. Reprinted with the permission of Elsevier

Application of biodegradable polymers in food packaging

Biodegradable polymers are biocompatible, non-toxic and highly selective [139]. In the packaging industry, they are replacing conventional petroleum-based polymers [140]. In the plastic industry packaging field is one of the largest sectors. Nowadays these biodegradable polymers are in great demand for packaging [141].

A commercial biodegradable polymer named Mater-Bi is based on biodegradable polyesters has numerous applications in the packaging industry because of its interesting thermal stability, processability, mechanical property and biodegradability. It is used as one of the polymers in the manufacturing of nets for fruits and vegetables [112].

Polyvinyl alcohol (PVA) is blended with some biodegradable polymers like sodium alginate, gelatin, carboxymethyl cellulose and K-carrageenan, but particularly PVA is blended with K-carrageenan to form a strong binary blend film which exhibits high resistance and water barrier property. So, it is used as a packing material in the food industry [144].

To improve the water vapor barrier property, biodegradable polymers like PCL are more favorable because of their flexibility. The polar groups which are present on the side chains of biodegradable polymers tend to decrease the water vapor barrier property. Biodegradable PCL/C18 blends are used in packaging materials due to their high oxygen and water vapor barrier property even at high humidity. The biodegradable polymers which are having the polar groups –OH at their molecular side chains show less water vapor barrier property. To improve the water vapor barrier property, biodegradable polymers like PCL are mixed with glycerol tris stearate (C18) which in turn increases the hydrophobicity. This is an extensively used biopolymer over polyethylene due to its better biostability and mechanical strength [140].

The conventional thermoplastic materials used in food packaging can be replaced by biodegradable cellulose esters. Cellulose esters such as cellulose triacetate and cellulose diacetate can be prepared by the addition of additives. Montmorillonite is a biodegradable nanoclay biocomposite and it is hydrated alumina silicate layered clay. The specialty of this is to limit the penetration of gases during food packaging. Biodegradable films like whey protein isolate films are strengthened by the addition of nanoparticles like TiO2 and SiO2 and these films are effectively used as a packaging material that favors food quality and safety [145].

The biodegradable polymer films like poly(3-hydroxybutyrate-co-3-ydroxyl valerate) which is developed from the Ceiba pentandra. These biocomposite films are specially designed for fruits packaging. This extends the shelf life of perishable fruits and also shows antimicrobial activity [141]. The bionanocomposite films are prepared by blending cellulose nanocrystals with silver alginate from cellulose nanocrystal alginate (CNC/Alg). These are used in food packaging due to their UV and water barrier properties [146].

Biodegradable TiO2 NPs embedded cellulose acetate (CA) films which have photo-catalytic activity, high transparency and antimicrobial property are packing materials in the food packaging industry [147]. The polypyrrole silver-coated layered double hydroxide (LDH/Ppy-Ag) embedded into a biodegradable polymer matrix, i.e., LDH/Ppy-Ag/PCL nanocomposites are used widely in the packaging industry. These biodegradable polymer nanocomposites possess excellent gas barrier and mechanical properties; in addition to this, they also show good antibacterial activity [148].

Biodegradable polyglycolic acid is used as a packaging material to enclose perishable foods or goods with limited shelf life. This packing film contains two layers with a reactive chemical layer that is interposed between two layers. If one layer degrades, the synthetic layer is exposed to air and it causes the change of color in the remnant layer which indicates the expiry of the shelf life of the package [149]. PLA is used as packaging material and it is considered a “Green” food packaging polymer as it possesses good microbial activity. It is used in the retail market for packaging vegetables, fruits and salads [150]. Natural biodegradable polymer-based silane cross-linked blended films are also used in the food packing industry because of their antioxidant activity, biodegradability, water vapor permeability, lower water vapor transmission rate has shown better shelf life. Hence, these biodegradable films have good potential for food and packaging [151].

Active packaging is essential to extend the shelf life of the goods and to keep the product fresh. It should also maintain the quality of the product and should ensure the safety of the environment [143]. The direct disposal of plastic bags brought many serious concerns, so this led to the use of biodegradable polymers in the food packing industry and also in other packaging materials. This resulted in a decrease in the ecological impacts due to synthetic packaging materials [151].

The starch-based biodegradable polymer is used as thermoplastic. They are prepared by plasticization through destructuration with water or plasticizers and by heating. So thermoplastic starch blended with other biodegradable polymers or additives shows good mechanical strength and resistance to water. So, this is widely used in the food packaging field. Protein-based biodegradable polymers are also widely used in food packaging and other non-food packaging applications. The protein polymers like whey protein, milk protein, zein, wheat gluten, corn, soy protein, etc. are used in food packaging. These protein-based biodegradable polymers can be consumed along with the food. These edible films in food packaging with barrier and mechanical properties are very much useful in food packaging [152].

Packaging is mainly dealt with polymers. But synthetic polymers are extensively used in packaging because of their low cost of production. But there are many disadvantages of using synthetic polymers. The use of biodegradable polymers in place of synthetic polymer had become a greater and greener alternative. However, the cost of production is high compared to that of conventional polymers. But there are many advantages of using biodegradable polymers. It is user-friendly as well as eco-friendly. In this review, we discussed the majority of biodegradable polymers that are applied in the packaging field. Most of the biopolymers that are obtained from nature are used as food packaging materials.

Application of biodegradable polymers in making paper boards

Paper boards are one of the extensively used polymers which are used in industries. Since paper boards are highly water-soluble, they are coated with some biodegradable polymers like polyurethane, paraffin wax, polyamides, polyesters and polyvinyl copolymers. This, in turn, increases the physical and mechanical strength of the paper board, since they are hydrophobic; the surface of the paper board is prevented from wetting, and the water barrier property is enhanced. Paraffin waxes are not preferentially used as coating copolymer because of their instability and less durability at high temperatures. So other copolymers like PVB (polyvinyl butyral) which is water-insoluble are used for coating on paper boards because of which it exhibits excellent commercial applications [153].

Application of biodegradable polymers in automobiles

In recent times, biodegradable polymers are extensively used in automobile industries because of their good mechanical properties, high specific strength and eco-friendly nature. It is now replacing conventional fiber like glass, aramid and carbon. Nowadays industrial and agricultural waste materials are used for making biodegradable polymers. For example, the coconut shell powder-reinforced composite is used in the interiors of spacecraft, ships, aircraft, motor cars and automobiles instead of conventional plastic materials [154].

The biodegradable polymers can be used for both exterior and interior components of automobiles, but because of present materials properties constraints, these biobased materials are only used in the manufacturing of interior components of automobiles [155]. The biodegradable bark cloth-reinforced epoxy biocomposites are used in making the interior automotive panels because of their mechanical property and high tensile strength. It is used in the manufacturing of interior panels in cars like dashboards (Fig. 6) [156]. Henry Ford has used biopolymers in the manufacturing of his own Ford cars [157]. The epoxy matrix with the addition of jute is used indoor panels of E-class vehicles of Mercedes Benz. The ecoplastic developed which is made from sugarcane is developed by TOYOTA and it is used as the interior lining of cars [154]. The application of biodegradable polymers in automobiles is considered to be interesting and challenging. Most of the high-branded automotive companies have switched to biodegradable polymers to manufacture various parts of the vehicle.

Biocomposite processing: a bark cloth fabrics, b fabricated composite mold [156]. Reprinted with the permission of Elsevier

Application of biodegradabe polymers in wastewater treatment

The natural biodegradable polymeric absorbents can be used to remove toxic dyes [158]. Dye contamination is found to be one of the serious issues which are occurring in water bodies which also affects human health. The amount of freshwater availability decreases as the amount of wastewater production [129]. To solve this problem, biodegradable polymeric materials were designed to clean up the dye-contaminated water. These polymeric absorbents have high dye removal efficiency with vast sensitivity. The biodegradable wheat flour absorbent which is a carbohydrate absorbent is used for the removal of cationic Rhodamine B (RB) dye from water. This polymer shows high sensitivity and selectivity toward this particular dye. RB dye is a cationic organic dye compound and it is applied for various industrial purposes like dying in textiles, paints, leathers, paper and printing. There are many metals for organic dye removal like coagulation–flocculation, degradation, adsorption, oxidation, etc. Since these techniques are effective and show low selectivity, the bioadsorbents are widely used [160]. Several pollutants are causing pollution in water and other harmful health issues to humans and other living organisms. But among them, the presence of heavy metals in water is a major concern. This heavy metal contamination leads to death of living beings [161].

As the result of rapid industrialization, there are many toxic heavy metals, released into water. This leads to damaging the aquatic ecosystem as well as human health [162]. Many methods like precipitation, reverse osmosis and electrolysis were developed for the removal of heavy metals from industrial wastewater. But these techniques are so expensive and also inefficient in the removal of toxic heavy metal ions. Sometimes, the application of these methods produces toxic waste. This can be overcome by using natural biodegradable polymers. Even superabsorbent polymers are also used to remove these ions, but due to their high cost this is not much encouraged. The chemically modified graft product, polyacrylonitrile-g-Arabic gum were used which is very effective in removing Pb2+, Cd2+, Hg2+, etc. from the wastewater. So, this method is cheap and easily accessible [133].

The removal of heavy metals from wastewater is a major concern [164]. They are carcinogenic and is mainly discharged from industries [165]. Heavy metals cannot be destroyed like other organic pollutants. Once these heavy metals are released into the ecosystem they can be easily absorbed and accumulated in the tissues of an organism which leads to several serious health issues [164]. One of the widely used methods for the removal of heavy metals from wastewater is adsorption techniques [166]. Cell EDTA (cellulose-EDTA) or cell CM (carboxymethyl) are the two modified cellulose that is used as bioadsorbent for the removal of heavy metal ions like Pb2+ and Cd2+. The cellulose fiber is obtained from pineapple leaves or modified as bioadsorbent for heavy metals removal from wastewater [167]. Most of the biopolymers are applied in offshore oil and gas pipelines since it is biodegradable and also prevents the gas hydrates from the gas pipelines [168].

Cross-linked porous starch is prepared by cross-linking of corn starch with the epichlorohydrin followed by treatment of hydrolyzation with α-amylase. This novel biopolymer-based sorbent is very much useful in removing methylene blue dye from water [169]. Magnetic carboxy methyl starch (CMS)/poly(vinyl alcohol) hydrogel (mCMS/PVA) is also used in the effective removal of methylene blue dye contamination from the water [170].

Magnetic nanoparticles (MNPs)/starch-g-poly(vinylsulfate) nanocomposite is used in the adsorption of various cationic dyes like methylene blue and malachite green which are present in the wastewater [171]. The cross-linked cationic starch is used for the removal of golden yellow dye from the water samples [172]. Toxic metals and other harmful organic compounds are also removed from water by using this cross-linked starch [169]. Cellulose-based nanomaterials are also used in the removal of various hazardous chemicals and other contaminants from the water, because of their non-toxicity, biodegradability and availability [173]. Kappa-carrageenan/poly(glycidyl methacrylate) (CG/PG) hydrogel is an environmental-friendly adsorbent which contains many functional groups. These are used in the removal of cationic methylene blue dye during wastewater treatment [174]. Cross-linked chitosan/sepiolite composites are also used to remove the organic and inorganic pollutants from water. They are very selective in the removal of dyes like reactive orange 16, acid red-2 and methylene blue when epichlorohydrin is added as an additive [175]. Calcium alginate-based hydrogel beads are a low-cost biomaterial used to remove the mutagen and mitotic poison, methyl Violet from wastewater [176]. Endocrine-disrupting chemicals (EDCs) present in the wastewater can be removed by using biodegradable polymers. Pharmaceuticals, personal care products, industrial compounds, pesticides, dyes and heavy metals which are present in wastewater are considered as EDCs. These chemicals have a severe impact on humans and animals [177].

Applications of biodegradable polymers in textiles and hygiene products

In recent times, the usage of personal protective equipment like face masks, gloves, gowns, aprons, hoods, eye shields and shoe covers has increased across the globe due to the COVID-19 pandemic [178]. Majorly the usage of face masks has increased to a great extent. Since most of the face masks are made up of petroleum-based non-biodegradable polymers, the amount of waste generated is high which leads to severe environmental pollution [179]. Generally, there are three different types of masks consisting of different layers, namely N95 mask (four layers), surgical mask (three layers) and cloth mask (one layer) [180]. These masks can be replaced by biodegradable polymers, but complete replacement of biodegradable polymers in face masks production is not possible. So any one of the layers in the mask can be replaced by biodegradable like PLA, PHA, poly(lactic-co-glycolic acid), cellulose acetate, polycaprolactone, etc. [181]. In particular, the layer which is in contact with skin is replaced by using biodegradable polymers. In addition to air filtration, these masks are antimicrobial, antifungal, UV protective and skin-friendly [182]. The ear loops of both N95 and surgical masks are made up of biodegradable polymers called poly(isoprene) units (latex-free rubber) [183].

Biodegradable polymers like PLA and cellulose are used in the manufacturing of face masks. These polymers are lightweight, low cost, safely disposable and comfortable to use. In addition to this, it provides adequate filtering performance and readily degrades after discarding [184]. Melt-blown PLA (MBPLA) electret membranes are used as interesting material for the production of face masks due to their excellent air filter capacity. These PLA melt-blown nonwoven fabrics can form electrets by corona charging technology [185]. The biodegradable cellulose acetate polymer nanofibers provide high-efficiency filtration for aerosol nanoparticles and also provide antibacterial properties, so it majorly used in the production of masks [186]. The biodegradable mask filters manufactured by using CsW (chitosan nanowhiskers) and PBS (polybutylene succinate) are highly efficient sustainable and fully biodegradable within a month in the soil [187]. The gluten-based biodegradable face masks are also being manufactured and it has good viral filtration capacity. Its antiviral properties can be enhanced by using natural products like turmeric, basil, neem oil, moringa seeds, etc. The nanofiber membrane in this mask can be produced by the electrospinning method and gluten sheets are produced by the hot-press method (Fig. 7)[188].

Production of gluten-based biodegradable polymers [189]. Reprinted with the permission of Elsevier

In this review, we mainly focus on the applications of biodegradable polymers in tissue engineering, drug delivery, anticancer drugs, contraceptive drugs, orthopedics and medical packaging. Biodegradable polymeric electrospun nanofibers are also used particularly in tissue engineering and drug delivery. The use of biodegradable polymers in the biomedical field is extremely safe for the human body as well as for the environment.

The use of personal hygiene disposable products is increased 50% more due to COVID-19 outbreak [190]. The presence of non-biodegradable polymers in personal hygiene products like diapers and sanitary napkins leads to the emission of methane after disposal into landfills which in turn increases global warming issues [191]. Superabsorbent polymers (SAP) are hydrogels that are cross-linked 3D hydrophilic polymers, these can absorb, swell and retain a large quantity of water or any biological fluids. Because of these properties, it is widely used in most commercial products such as sanitary napkins, disposable diapers and also used in some other areas [192]. The SAPs absorb and retain the fluids under mild mechanical pressure and this swollen gel retains the fluids in a solid, rubbery state and prevents the leaking of fluid onto the baby's skin and clothing [193]. The physiological fluids are retained within a gel structure and are not even released under pressure of baby weight. As the result, these SAPs are greatly used in the personal hygiene products and healthcare industries [194].

The disposable baby diapers are made up of multiple layers consisting of different materials. The top layer consists of polypropylene sheets which are hydrophilic nonwoven and allow the urine to pass through it. The middle layer is made up of superabsorbent polymer which helps in holding the urine. The bottom layer is made up of hydrophobic nonwoven films which consist of polypropylene fibers. Since polypropylene is toxic and non-degradable, it can be replaced by biodegradable viscous nonwoven which is made up of cellulose. The advantages of using this cellulose provide physiological safety, skin tolerance, better moisture absorbance, easily degradable and being eco-friendly [193]. Chitosan, citric acid and urea (CHCAUR) is biodegradable polymer which has excellent water absorption property. It has maximum saline water-absorbing capacity and it is also used as an alternative for SAPs in diapers due to its superior water absorption characteristics [195].

The use of synthetic SAPs like polyacrylate-based sap in sanitary napkins is toxic and carcinogenic. They are non-biodegradable and lead to environmental pollution, so to overcome these drawbacks some of the greener alternative SAPs are used in sanitary napkins. For example, the natural polysaccharides-based SAPs which are made from chia seeds (salvia histanica), chia flour and mimosa pudica hydrogel (MPH) are used as the absorbent core of sanitary napkins. These are biodegradable, biocompatible, renewable and non-toxic. The chia seeds have the highest swelling capacity, but MPH has the highest absorbing capacity compared to chia seeds and chia flour. Because of its high absorbing capacity, low re-wet value, good antibacterial property, biodegradability. This MPH is used as SAP in sanitary napkins [196].

Synthetic sanitary napkins have poor fluid retention capacity and because the use of these synthetic materials, blocks moisture and temperature that further leads to yeast and bacterial infection in vagina which causes toxic shock syndrome. The use of plasticizers in sanitary pads leads to multiple organ failures. In order to overcome these problems, the biodegradable polymer-based sanitary napkins came into existence. Sodium alginate and carboxy methyl cellulose (CMC)-based hydrogels are used as an absorbent core for sanitary napkins and these napkins are non-infectious, biodegradable and non-toxic [197].

Since the use of non-biodegradable polymers in sanitary napkins increases the risk of the health of tissues, it can be replaced by biodegradable polymers which are obtained from natural and sustainable raw materials like bamboo fiber, banana fibers, jute fiber and coconut fiber. In order to increase the absorbance of sanitary napkins, cellulose-based hydrogels were used. For example, sodium carboxymethylcellulose (NaCMC) and hydroxyethyl cellulose (HEC) cross-linked with divinyl sulfone (DVS) are used as a hydrogel [198]. It has better fluid retention property and antimicrobial property is improved by treating the absorbent core with 70% halogen extract. The cellulose-based hydrogels are biodegradable and environment-friendly, and possess excellent biocompatibility. The use of natural fibers in sanitary napkins will reduce the cost of production and also prevents waste generation [199, 200]. The superabsorbent polymers can be obtained from recycled carboxymethyl cellulose material by using it as a precursor. These biobased SAPs are very much used in diaper applications [201].

The application of biodegradable polymer in sanitary needs like sanitary napkins and diapers is extremely beneficial. Majorly SAPs are used in sanitary napkins and diapers. Since the biodegradable polymers possess antibacterial and antifungal properties, it will be an added advantage. The use of biodegradable SAPs in sanitary needs is considered to be safer. The use of biodegradable polymers in sanitary needs had also controlled many health-related issues and also environment-related issues.

Application of biodegradable polymers in electronic devices

In the present era, the generation of E-waste is ever increasing. To overcome this, biodegradable polymers are used in the manufacturing of various electronic devices [202]. The biomaterial-based organic electronics or “green” electronics are having good potential and create a positive impact in the future [203]. The utilization of biodegradable and organic electronic materials can contribute to minimizing the environmental impact in the electronic industry [204]. Silk is an enzymatically degradable biomaterial which is widely used [205].

Poly(1,4-cyclohexylenedimethylene terephthalate-co 1,4 cyclohexylene dimethylene 2,6-naphthalene dicarboxylate) copolyester (PCITN) is a biobased polymer used as smart films for making flexible optical devices and electronic devices. It has high thermal, mechanical, optical and water barrier property compared to other conventional polymers, so it is used as a smart film in various industrial applications [206]. Cellulose is used as a substrate material in different electronic applications like in the manufacturing of field-effect transistors (FET), organic light-emitting diodes (OLEDs) and also solar cells (Fig. 8) [207]. The ultra-thin cellulose film which is chemically and thermally stable is used as a biodegradable substrate for the development of charge transport, transient and biodegradable electronics [208].

Application of biopolymers in the flexible display: a structure and flexibility of biodegradable devices on chitin transparent paper. b Schematic representation of the fabrication of luminescent CNC-PGM-RG composites with white light generation [207]. Reprinted with the permission of Elsevier

A common strategy, to develop biodegradable dielectrics is by incorporating high-dielectric-constant (K) fillers into a matrix of the degradable polymer. Some of the general high (K) metal oxides are SiO2 (K = 3.9), HfO2 (K = 25) and Al2O3(K = 9). Dielectronic substrates are insulators that are used to fabricate capacitors [189]. Semiconducting polymers possess good biocompatibility which is one of the essential requirements for the manufacturing of implantable medical devices or sensory devices that can directly contact living tissues [208]. Semiconducting polymers are used in the development of organic FET devices for prosthetic skins and biosensors [190]. The biodegradable polymer electrolytes in particularly polycaprolactone (PCL)-based electrolytes have electrochemical stability, high ionic conductivity, high thermal stability, ease of molding into desired shapes and sizes. So, they are used in different electronic devices like ion batteries, solar cells, supercapacitors, electrochemical display devices and fuel cells [191].

Cellulose nanocrystals (CNC) are used in the modification of internal photonic crystal structure of cellulose-based liquid crystals (LC). Because of its low-cost sustainability, non-toxicity, easy availability of raw ingredients simple manufacturing methods and low energy consumption. This innovative type of liquid crystals materials as the potential for commercial large-scale use [212].

Since biodegradable polymers conduct electricity, they had found their application even in the manufacturing of electronic devices. Various strategies are used for the applications of biodegradable polymers in electronic devices. The biopolymers like cellulose Silk and biodegradable polymer like PCL is majorly used in electronic devices. Till now, we have only limited use of biodegradable polymers in electronic devices. Still, research is needed for the efficient use of biodegradable polymers in various electronic devices. The work done in biosensors with the use of biodegradable polymers is more beneficial, especially in the biomedical field.

Application of biodegradable polymers in biosensors

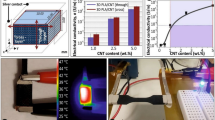

Nowadays eco-friendly biodegradable polymeric materials which are having good mechanical and thermal properties were developed and used in biosensors [192]. Among the biodegradable polymers, the bioblends of poly(ethylene oxide) (PEO), polylactic acid and CNT were used. The PLA and PEO are easily degradable and biocompatible. Bioblends and conductive nanocomposites are used in biomedical biosensors [193]. The biodegradable PLA-based microneedles (MN) are used in glucose sensing for diabetes patients. The PLA-based MNs are coated with gold nanoparticles to enhance their conductivity. So, these MN-based glucose sensors can easily penetrate the skin without causing any pain and also avoid invasions that are caused by some of the commercial glucometer blood samplings from fingers. So, these biodegradable MN-based glucose sensors are used in the continuous monitoring of glucose in diabetic-based patients in a minimally invasive way [215]. Polyacrylamide–poly(ethylene glycol) hydrogen are polyacrylamide-15-crown-h Hydrogen with pendent phenylboronic acid groups are used in manufacturing of photonic crystals in glucose in glucose sensors. In this, boronic acid and PEG functional groups are prepositioned in the photonic crystals hydrogen such that glucose cells assemble these functional groups into a supramolecular complex. This complex results in an increase in the hydrogel cross-linking, which for physiologically relevant glucose concentration blue shift the photonic crystals diffractions. These materials response too glucose at physiological ionic strengths and pH values, and they are selective in their mode of response for glucose over fructose, mannose and galactose [216].

Flexible biosensors need various methodologies to tune materials for different biomedical applications; poly(3,4-ethylene dioxythiophene):poly(styrene sulfonate) (PEDOT:PSS) is fabricated on biodegradable and flexible silk fibroin matrix by photolithographic technique (Fig. 9). So, these biosensors are mechanically flexible, electroactive, optically transparent, cytocompatible and biodegradable. By this technique, inexpensive biosensors can be developed with better degradability [217].

Formation of the complex microstructure of PEDOT:PSS via photolithography a Large area micropatterns of PEDOT:PSS formed on flexible and conformable silk fibroin sheets, b optical micrographs. c SEM images of PEDOT:PSS micropatterns on glass [217]. Reprinted with the permission of Elsevier