Abstract

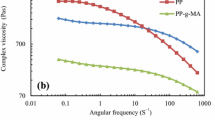

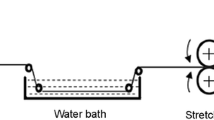

Due to the importance of rheology and morphology of microfibrillar reinforced composites (MFCs), a study has been conducted on MFCs based on high-density polyethylene (HDPE) and polyamide-6 (PA-6) using scanning electron microscope and dynamic rheometer. In the absence of an interfacial modifier and at 10 wt% concentration of the dispersed phase (PA-6), two principal factors, elongational deformation and coalescence, were found to be controlled by viscosity and elasticity ratios of the pure constituents accounting for the observed morphology of MFCs. The developed microfibrillar morphology remarkably influenced the viscoelastic properties of MFCs. It was observed that when the viscosity ratio approached unity and the elasticity ratio was minimal, the extent of coalescence in composite was significant. The rheological assessment showed enhanced storage modulus and complex viscosity upon microfibrils formation. This was more pronounced for samples with thinner microfibrils due to more strongly entangled network, compared to the composites with thicker microfibrils. The length-to-diameter ratio of the microfibrils could not be estimated due to their highly asymmetric length scale.

Similar content being viewed by others

References

Simon GP (2019) Polymer blends and alloys. CRC Press, Boca Raton

Utracki LA, Wilkie CA (2014) Polymer blends handbook. Springer, Dordrecht

Macosko C (2000) Morphology development and control in immiscible polymer blends. Macromol Symp 149:171–184

Fakirov S (2013) Nano- and microfibrillar single-polymer composites: a review. Macromol Mater Eng 298:9–32

Cheng L, Wan J (2018) Crystallization and morphological and crystal structures of PP in an in situ microfibrillar composite of modified PA66 with pp. Compos Sci Technol 155:205–212

Shields R, Bhattacharyya D, Fakirov S (2008) Fibrillar polymer–polymer composites: morphology, properties and applications. J Mater Sci 43:6758–6770

Dencheva N, Denchev Z, Stribeck N, Motovilin M, Zeinolebadi A, Funari SS, Botta S (2013) nanostructure transitions and their relation to mechanical properties in polyethylene/polyamide 6 microfibrillar composites as revealed by SAXS/straining studies. Macromol Mater Eng 298:1100–1116

Denchev Z, Dencheva N, Funari SS, Motovilin M, Schubert T, Stribeck N (2010) Nanostructure and mechanical properties studied during dynamical straining of microfibrillar reinforced HDPE/PA blends. J Polym Sci Part B 48:237–250

Feng J, Zhang RY, Wu JJ, Yang W, Yang MB, Feng JM (2014) Largely enhanced molecular orientation and mechanical property of injection-molded high-density polyethylene parts via the synergistic effect of polyamide 6 in situ microfibrillar and intense shear flow. Colloid Polym Sci 292:3033–3044

Liu T, Wang Q, Xie Y, Lee S, Wu Q (2014) Effects of use of coupling agents on the properties of microfibrillar composite based on high-density polyethylene and polyamide-6. Polym Bull 71:685–703

Liu H, Yao F, Xu Y, Wu Q (2010) A novel wood flour-filled composite based on microfibrillar high-density polyethylene (HDPE)/Nylon-6 blends. Bioresour Technol 101:3295–3297

Rizvi A, Park CB, Favis BD (2015) Tuning viscoelastic and crystallization properties of polypropylene containing in-situ generated high aspect ratio polyethylene terephthalate fibrils. Polymer 68:83–91

Huang Y, He Y, Ding W, Yang K (2017) Improved viscoelastic, thermal, and mechanical properties of in situ microfibrillar polypropylene/polyamide 6,6 composites via direct extrusion using a triple-screw extruder. RSC Adv 7:5030–5038

Wei L, Dong J, Qi Y, Sun J (2016) In situ polyolefin elastomer/poly (trimethylene terephthalate) microfibrillar composites fabricated via multistage stretching extrusion. Fiber Polym 17:1916–1924

Chomat D, Soulestin J, Lacrampe MF, Sclavons M (2015) In situ fibrillation of polypropylene/polyamide 6 blends: effect of organoclay addition. J Appl Polym Sci 132:41680–41692

Safaei A, Masoomi M, Razavi SMR (2017) In-situ microfibrillar PP–PA6 composites: rheological, morphological and mechanical properties. B Mater Sci 40:971–982

Xu HS, Li ZM, Yang S, Pan JL (2005) Rheological behavior comparison between PET/HDPE and PC/HDPE microfibrillar blends. Polym Eng Sci 45:1231–1238

Dencheva N, Oliveira MJ, Carneiro OS, Pouzada AS, Denchev Z (2010) Preparation, structural development, and mechanical properties of microfibrillar composite materials based on polyethylene/polyamide 6 oriented blends. J Appl Polym Sci 115:2918–2932

Yi X, Xu L, Wang YL, Zhong GJ (2010) Morphology and properties of isotactic polypropylene/poly(ethylene terephthalate) in situ microfibrillar reinforced blends: influence of viscosity ratio. Eur Polym J 46:719–730

Huang WY, Shen JW, Chen XM, Chen HY (2003) Factors influencing the fiberization and mechanical properties of polypropylene/polyamide 66 in situ composites. Polym Int 52:1131–1135

Shen J, Wang M, Li J, Guo S (2011) In situ fibrillation of polyamide 6 in isotactic polypropylene occurring in the laminating-multiplying die. Polym Adv Technol 22:237–245

Jiang CH, Zhong GJ, Li ZM (2007) Recyclability of in situ microfibrillar poly(ethylene terephthalate)/high-density polyethylene blends. Macromol Mater Eng 292:362–372

Jayanarayanan K, Jose T, Thomas S, Joseph K (2009) Effect of draw ratio on the microstructure, thermal, tensile and dynamic rheological properties of insitu microfibrillar composites. Eur Polym J 45:1738–1747

Fakirov S, Kamo H, Evstatiev M, Friedrich K (2004) Microfibrillar reinforced composites from PET/LDPE blends: morphology and mechanical properties. J Macromol Sci Part B 43:775–789

Li ZM, Yang W, Huang R, Fang XP (2004) Essential work of fracture parameters of in-situ microfibrillar poly(ethylene terephthalate)/polyethylene blend: influences of blend composition. Macromol Mater Eng 289:426–433

Li ZM, Yang MB, Feng JM, Yang W (2002) Morphology of in situ poly(ethylene terephthalate)/polyethylene microfiber reinforced composite formed via slit-die extrusion and hot-stretching. Mater Res Bull 37:2185–2197

Bigdeli A, Nazockdast H, Rashidi A, Yazdanshenas ME (2012) Role of nanoclay in determining microfibrillar morphology development in PP/PBT blend nanocomposite fibers. J Polym Res 19:9990–9999

Li ZM, Yang MB, Xie BH, Feng JM, Huang R (2003) In-situ microfiber reinforced composite based on PET and PE via slit die extrusion and hot stretching: Influences of hot stretching ratio on morphology and tensile properties at a fixed composition. Polym Eng Sci 43:615–628

Gonzalez-Nunez R, De Kee D, Favis BD (1996) The influence of coalescence on the morphology of the minor phase in melt-drawn polyamide-6/HDPE blends. Polymer 37:4689–4693

Tsebrenko MV, Danilova GP, Malkin AY (1989) Fracture of ultrafine fibers in the flow of mixtures of non-Newtonian polymer melts. J Non-Newtonian Fluid Mech 31:1–26

Cigana P, Favis BD, Jerome R (1996) Diblock copolymers as emulsifying agents in polymer blends: influence of molecular weight, architecture, and chemical composition. J Polym Sci Part B 34:1691–1700

Ghodgaonkar PG, Sundararaj U (1996) Prediction of dispersed phase drop diameter in polymer blends: the effect of elasticity. Polym Eng Sci 36:1656–1665

Asadinezhad A, Yavari A, Jafari SH, Khonakdar HA, Bohme F (2005) Description of the dynamic moduli of poly (trimethylene terephthalate)/polyamide-12 blends in molten state. Polym Eng Sci 45:1401–1407

Xu HS, Li ZM, Pan JL, Yang MB, Huang R (2004) Morphology and rheological behaviors of polycarbonate/high density polyethylene in situ microfibrillar blends. Macromol Mater Eng 289:1087–1095

Baird DG, Collias DI (2014) Polymer processing: principles and design. Wiley Interscience, New York

Morrison FA (2001) Understanding rheology. Oxford University Press, New York

Wu S (1987) Formation of dispersed phase in incompatible polymer blends: interfacial and rheological effects. Polym Eng Sci 27:335–343

Huneault M, Shi Z, Utracki L (1995) Development of polymer blend morphology during compounding in a twin-screw extruder. part IV: a new computational model with coalescence. Polym Eng Sci 35:115–127

Fakirov S, Bhattacharyya D, Lin R, Fuchs C, Friedrich K (2007) Contribution of coalescence to microfibril formation in polymer blends during cold drawing. J Macromol Sci Part B 46:183–194

Perilla J, Jana SC (2004) A time-scale approach for analysis of coalescence in polymer processing flows. Polym Eng Sci 44:2254–2265

Kakroodi AR, Kazemi Y, Ding W, Ameli A, Park CB (2015) Poly(lactic acid)-based in situ microfibrillar composites with enhanced crystallization kinetics, mechanical properties, rheological behavior, and foaming Ability. Biomacromol 16:3925–3935

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Falaki, P., Masoomi, M. & Asadinezhad, A. Rheology–morphology interrelationship in high-density polyethylene/polyamide-6 microfibrillar composites. Polym. Bull. 78, 6675–6688 (2021). https://doi.org/10.1007/s00289-020-03446-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-020-03446-3