Abstract

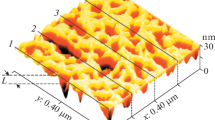

Five coextruded and one blown polyethylene (PE)-based packaging films were analyzed with the aim to determine the number and thickness of the film layers and tensile mechanical properties and to prove composition declared by a producer. They were chosen the most effective methods such as Fourier-transform infrared spectroscopy (attenuated total reflectance and transmission modes), differential scanning calorimetry (DSC), thermogravimetry, wide-angle X-ray diffraction (XRD), and confocal laser scanning microscopy. The latter turned out to be very effective method to show the film layers on its fracture surfaces due to very good contrast and different fracture patterns of each layer. Two to five layers were detected in the films, whereas silicone surface layer with the thickness not higher than 1 µm was very nicely detected in two coextruded films. The type of PE (low density, linear low density and high density) was determined by DSC, whereas miscible types of PE were differentiated only after performance of stepwise isothermal crystallization. This was performed in case of four films at 124, 114, 104, and 94 °C with 30-min dwell at each temperature. Random copolymer of polypropylene was identified by DSC in two films. Infrared spectroscopy revealed polymers present in low content (ethylene–vinyl acetate and silicon) and, in addition, additives such as calcite, which was detected also by XRD. The major polymer components were proved in four films. Mechanical properties varied in machine and transverse direction in case of all films. The methods used are also recommended for quality control of coextruded films.

Similar content being viewed by others

References

Wang D, Gao J (2006) Melting, nonisothermal crystallization behavior and morphology of polypropylene/random ethylene—propylene copolymer blends. J Appl Polym Sci 99:670–678. https://doi.org/10.1002/app.22507

Kyu T, Hu S, Stein R, Shanks R (1987) Characterization and properties of polyethylene blends II. Linear low-density with conventional low-density polyethylene. J Polym Sci B Polym Phys 25:89–103. https://doi.org/10.1002/9780470199008.ch3

Prasad A (1998) A quantitative analysis of low density polyethylene and linear low density polyethylene blends by differential scanning calorimetery and Fourier transform infrared spectroscopy methods. Polym Eng Sci 38:1716–1728. https://doi.org/10.1002/pen.10342

Wu X, Chen J, Zeng X (1991) The application of DSC in identification of LDPE/LLDPE blends mulching film. Die Angewandte Makromolekulare Chemie 189:183–193. https://doi.org/10.1002/apmc.1991.051890117

Lee H, Denn M (2000) Blends of linear and branchedpolyethylenes. Polym Eng Sci 40:1132–1142. https://doi.org/10.1002/pen.11241

Wignall G, Londono J, Lin J, Alamo R, Galante M, Mandelkern L (1995) Morphology of blends of linear and long-chain-branched polyethylenes in the solid state: a study by SANS, SAXS, and DSC. Macromolecules 28:3156–3167. https://doi.org/10.1021/ma00113a018

Mohammadi M, Yousefi A, Ehsani M (2012) Study of the thermal and mechanical properties of blown films of high- and low-density polyethylene blends. J Appl Polym Sci 125:755–767. https://doi.org/10.1002/app.36246

Norton D, Keller A (1984) On the morphology of blends of linear and branched polyethylene. J Mater Sci 19:447–456. https://doi.org/10.1007/bf00553568

Hu S, Kyu T, Stein R, Shanks R (1987) Characterization and properties of polyethyleneblends I. Linear low-density polyethylene with high-density polyethylene. J Polym Sci B Polym Phys 25:71–87. https://doi.org/10.1002/polb.1987.090250106

Hussein I, Mulcahy D (2004) Implications of melt compatibility/incompatibility on thermal and mechanical properties of metallocene and Ziegler–Natta linear low density polyethylene (LLDPE) blends with high density polyethylene (HDPE): influence of composition distribution and branch content of LLDPE. Polym Int 53:1327–1335. https://doi.org/10.1002/pi.1528

Wang B, Huang H (2012) Formation mechanism of crystal morphologies in LLDPE/HDPE blends investigated via water-assisted and conventional injection molding. Polym Eng Sci 52:117–124. https://doi.org/10.1002/pen.22053

Srivastava D (2005) Studies on mechanical and thermal properties of ternary blends of polyethylenes—I. J Appl Polym Sci 96:1691–1698. https://doi.org/10.1002/app.21127

Srivastava D (2006) Studies on mechanical and thermal properties of ternary blends of polyethylenes having fixed percentage of high-density polyethylene—II. Polym Plast Technol Eng 45:879–883. https://doi.org/10.1080/03602550600611784

Ehrenstein G (2004) Thermal analysis of plastics: theory and practice. Hanser, Munich

Silvestre C, Cimmino S, Raimo M, Duraccio D, Fernandez B, Lafuente P, Sanz VS (2006) Structure and morphology development in films of mLLDPE/LDPE blends during blowing. Macromol Mater Eng 291:1477–1485. https://doi.org/10.1002/mame.200600239

Olmos D, Rodríguez-Gutiérrez E, González-Benito J (2012) Polymer structure and morphology of low density polyethylene filled with silica nanoparticles. Polym Compos 33:2009–2021. https://doi.org/10.1002/pc.22343

Acknowledgements

Funding by Ministry of Education, Youth and Sports under the Project No. FCH-S-19-6100 is greatly appreciated.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Balkova, R., Kucera, F. & Jancar, J. Analysis of coextruded polyethylene-based packaging films: number of layers, composition, and mechanical properties. Polym. Bull. 78, 1981–1996 (2021). https://doi.org/10.1007/s00289-020-03196-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-020-03196-2