Abstract

Photodegradation of PLA/PE, PLA/PE/TiO2 nanospheres and PLA/PE/TiO2 nanotubes was obtained under simulated sunlight. The nanocomposites were analyzed by infrared spectroscopy, scanning electron microscopy and tensile-deformation measurements. TiO2 nanospheres and TiO2 nanotubes were found to present different effects on the crystallinity of PLA and a straight correlation between structural organization and photostability was observed. According to the results, TiO2 promotes the degradation of PLA and PE, affecting the organizational level of the polymers. By adding TiO2 nanoparticles to the PLA/PE films, vibration modes characteristic of degradation products were promptly observed and the lifetime of the polymer decreased when compared to the PLA/PE without TiO2 nanoparticles. Mechanical measurements showed an improvement of the mechanical properties when adding the TiO2 nanoparticles.

Similar content being viewed by others

References

Grigoriadou I, Paraskevopoulos KM, Chrissafis K, Pavlidou E, Stamkopoulos T-G, Bikiaris D (2011) Effect of different nanoparticles on HDPE UV stability. Polym Degrad Stab 96:151–163

Kim J, Kim JH, Shin TK, Choi HJ, John MS (2001) Miscibility and rheological characteristics of biodegradable aliphatic polyester and linear low density polyethylene blends. Eur Polym J37:2131–2139

Rajakumar K, Sarasvathy V, Chelvan AT, Chitra R, Vijayakumar CT (2011) Effect of iron carboxylates on the photodegradability of polypropylene. II. Artificial weathering studies. J Appl Polym Sci 123(5):2968–2976

Omar MF, Akil HM, Ahmad ZA (2012) Effect of molecular structures on dynamic compression properties of polyethylene. Mater Sci Eng A 538:125–134

Chum PS, Swogger KW (2008) Olefin polymer technologies—history and recent progress at The Dow Chemical Company. Prog Polym Sci 33:797–819

Zan L, Fa W, Wang S (2006) Novel photodegradable low-density polyethylene-TiO2 nanocomposite film. Environ Sci Technol 40:1681–1685

Rezgui F, G’Sell C, Dahoun A, Hiver JM, Sadoun T (2011) Plastic deformation of low-density polyethylene reinforced with biodegradable polylactide, part 1: microstructural analysis and tensile behavior at constant true strain-rate. Polym Eng Sci 51(1):117–125

Rodriguez-Gonzalez FJ, Ramsay BA, Favis BD (2003) High performance LDPE/thermoplastic starch blends: a sustainable alternative to pure polyethylene. Polymer 44:1517–1526

Siracusa V, Rocculi P, Romani S, Rosa MD (2008) Biodegradable polymers for food packaging: a review. Trends Food Sci Technol 19:634–643

Armentano I, Dottori M, Fortunati E, Mattioli S, Kenny JM (2010) Biodegradable polymer matrix nanocomposites for tissue engineering: a review. Polym Degrad Stab 95:2126–2146

Balakrishnan H, Hassan A, Wahit MU, Yussuf AA, Razak SBA (2010) Novel toughened polylactic acid nanocomposite: mechanical, thermal and morphological properties. Mater Des 31:3289–3298

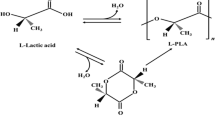

Garlotta D (2002) A literature review of poly (lactic acid). J Polym Environ 9(2):63–83

Gupta P, Kumar V (2007) New emerging trends in synthetic biodegradable polymers—polylactide: a critique. Eur Polym J 43(10):4053–4074

Baiardo M, Frisoni G, Scandola M, Rimelen M, Lips D, Ruffieux K, Wintermantel E (2003) Thermal and mechanical properties of plasticized poly(l-lactic acid). J Appl Polym Sci 90:1731–1738

Kulinski Z, Piorkowska E (2005) Crystallization, structure and properties of plasticized poly(l-lactide). Polymer 46:10290–10300

Auras R, Harte B, Selke S (2004) An overview of polylactides as packaging materials. Macromol Biosci 4:835–864

Martino P, Jiménez A, Ruseckaite RA, Avérous L (2011) Structure and properties of clay nano-biocomposites based on poly (lactic acid) plasticized with polyadipates. Polym Adv Technol 22:2206–2213

Yu L, Dean K, Li L (2006) Polymer blends and composites from renewable resources. Prog Polym Sci 31:576–602

Huneault MA, Li H (2007) Morphology and properties of compatibilized polylactide/thermoplastic starch blends. Polymer 48:270–280

Hasook A, Tanoue S, Iemoto Y (2006) Characterization and mechanical properties of poly (lactic acid)/poly(ε-caprolactone)/organoclay nanocomposites prepared by melt compounding. Polym Eng Sci 46(8):1001–1007

Hamad K, Kaseem M, Deri F (2011) Rheological and mechanical characterization of poly (lactic acid)/polypropylene polymer blends. J Polym Res 18:1799–1806

Hamad K, Kaseem M, Deri F (2010) Rheological and mechanical properties of poly(lactic acid)/polystyrene polymer blends. Polym Bull 65:509–519

Choudhary P, Mohanty S, Nayak SK, Unnikrishnan L (2011) Poly (l-lactide)/polypropylene blends: evaluation of mechanical, thermal, and morphological characteristics. J Appl Polym Sci 121:3223–3237

Kaminsky W (2008) Trends in polyolefin chemistry. Macromol Chem Phys 209(5):459–466

Muelhaupt R (2003) Catalytic polymerization and post polymerization catalysis fifty years after the discovery of Ziegler’s catalysts. Macromol Chem Phys 204(2):289–327

Zhao X, Li Z, Chen Y, Shi L, Zhu Y (2007) Solid-phase photocatalytic degradation of polyethylene plastic under UV and solar light irradiation. J Mol Catal A Chem 268:101–106

Ikada E (1997) Photo- and biodegradable polyesters. Photodegradation behaviors of aliphatic polyesters. J Photopolym Sci Technol 10(2):265–270

Hoffmann MR, Martins ST, Choi W, Bahnemann DW (1995) Environmental applications of semiconductor photocatalysis. Chem Rev 95(1):69–96

Nakayama N, Hayashi T (2007) Preparation and characterization of poly (l-lactic acid)/TiO2 nanoparticle nanocomposite films with high transparency and efficient photodegradability. Polym Degrad Stab 92:1255–1264

Richard C, Boule P (1991) Oxidizing species involved in photocatalytic transformations on zinc oxide. J Photochem Photobiol A Chem 60(2):235–243

Mucha M, Bialas S, Kaczmarek H (2014) Effect of nanosilver on photodegradation of Poly(lactic acid). J Appl Polym Sci 131:40144

Zhao X, Li Z, Chen Y, Shi L, Zhu Y (2007) Solid-phase photocatalytic degradation of polyethylene plastic under UV and solar light irradiation. J Mol Catal A Chem 268:101–106

Ikada E (1993) Role of the molecular structure in the photodecomposition of polymers. J Photopolym Sci Technol 6(1):115–122

Torres A, Li SM, Roussos S, Vert M (1996) Screening of microorganisms for biodegradation of Poly(lactic acid) and lactic acid-containing polymers. Appl Environ Microbiol 62:2393–2397

Copinet A, Bertrand C, Govidin S, Coma V, Couturier Y (2004) Effects of ultraviolet light (315 nm) temperature and relative humidity on the degradation of polylactic acid plastic films. Chemosphere 55:763–773

Buzarovska A, Grozdanov A (2012) Biodegradable poly(l-lactic acid)/TiO2 nanocomposites: thermal properties and degradation. J Appl Polym Sci 123(4):2187–2193

Ha CS, Cho W (2002) Miscibility, properties, and biodegradability of microbial polyester containing blends. Prog Polym Sci 27(4):759–809

Qian J, Zhu L, Zhang J, Whitehouse R (2007) Comparison of different nucleating agents on crystallization of poly (3-hydroxybutyrate-co-hydroxyvalerates). J Polym Sci B Polym Phys 45:1564–1577

Singh A (1999) Irradiation of polyethylene: some aspects of crosslinking and oxidative degradation. Radiat Phys Chem 56(4):375–380

Furukawa T, Sato H, Murakami R, Zhang J, Noda I, Ochiai S, Ozaki Y (2007) Comparison of miscibility and structure of poly(3-hydroxybutyrate-co-3-hydroxyhexanoate)/poly(l-lactic acid) blends with those of poly(3-hydroxybutyrate)/poly(l-lactic acid) blends studied by wide angle X-ray diffraction, differential scanning calorimetry, and FTIR microspectroscopy. Polymer 48(6):1749–1755

Snyder RG (1980) Spectroscopic methods. In: Marton L, Marton C (eds) Methods of experimental physics, vol 16: Part A. Academic, New York, pp 188–200

Snyder RG (1961) Vibrational spectra of crystalline n-paraffins: II. Intermolecular effects. J Mol Spectrosc 7:116–144

Snyder RG (1967) Vibrational study of the chain conformation of the liquid n-paraffins and molten polyethylene. J Chem Phys 47(4):1316–1360

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

da Silva, K.I.M., Fernandes, J.A., Kohlrausch, E.C. et al. Structural stability of photodegradable poly(l-lactic acid)/PE/TiO2 nanocomposites through TiO2 nanospheres and TiO2 nanotubes incorporation. Polym. Bull. 71, 1205–1217 (2014). https://doi.org/10.1007/s00289-014-1119-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-014-1119-0