Abstract

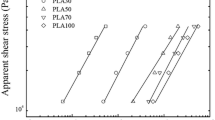

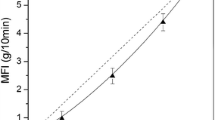

Properties modification by blending polymers has been an area of immense interest. In this work, rheological and mechanical properties of poly(lactic acid)/polystyrene (PLA/PS) blends were investigated. PLA/PS blends in different ratios were prepared using a laboratory scale single screw extruder to obtain (3 mm) granules. Rheological properties were studied using a capillary rheometer and the Bagley’s correction was performed. True shear rate (γ r ), true shear stress (τ r ), and true viscosity (η r ) were determined, the relationship between true viscosity and (1/T) was studied for PLA70 blend and the flow activation energy at a constant shear stress (E τ ) and a constant shear rate (E γ ) was determined. The mechanical property measurements were performed at room temperature. Stress at break and strain at break were determined. The results showed that PLA/PS blend exhibited a typical shear-thinning behavior over the range of the studied shear rates, and the viscosity of the blend decreased with increasing PLA content. Also it was found that no equal-viscosity temperature exists between PLA and PS. The mechanical results showed immiscibility between PLA and PS in the blend.

Similar content being viewed by others

References

Lunt J (1998) Larg-scale production, properties and commercial applications of poly lactic acid polymers. Polym Degrad Stab 59:145–152

Ishida S, Nagasaki R, Chino K, Dong T, Inoue Y (2009) Toughening of poly(l-lactide) by melt blending with rubbers. J Appl Polym Sci 113:558–566

Sarazin P, Li G, Orts W, Favis B (2008) Binary and ternary blends of polylactide, polycaprolactone and thermoplastic starch. Polymer 49:599–609

Wang N, Yu J, Chang P, Ma X (2008) Influence of formamide and water on the properties of thermoplastic starch/poly(lactic acid) blends. Carbohydr Polym 71:109–118

Wang N, Yu J, Ma X (2008) Preparation and characterization of compatible thermoplastic dry starch/poly(lactic acid). Polym Compos 29:551–559

Wang N, Yu J, Ma X (2007) Preparation and characterization of thermoplastic starch/PLA blends by one-step reactive extrusion. Polym Inter 56:1440–1447

Wang N, Yu J, Chang P, Ma X (2007) Influence of citric acid on the properties of glycerol-plasticized dry starch (DTPS) and DTPS/Poly(lactic acid) blends. Starch 59:409–417

Huneault M, Li H (2007) Morphology and properties of compatibilized polylactide/thermoplastic starch blends. Polymer 48:270–280

Bhatia A, Gupta R, Bhattacharya S, Choi H (2007) Compatibility of biodegradable poly (lactic acid) (PLA) and poly (butylenes succinate) (PBS) blends for packaging application. Korea-Australia Rheo J 19:125–131

Lee S, Lee JW (2005) Characterization and processing of Biodegradable polymer blends of poly(lactic acid) with poly(butylene succinate adipate). Korea-Australia Rheo J 17:71–77

Ren J, Fu H, Ren T, Yuan W (2009) Preparation, characterization and properties of binary and ternary blends with thermoplastic starch, poly(lactic acid) and poly(butylene adipate-co-terephthalate). Carbohydr Polym 77:576–582

Yeh JT, Tsou CH, Huang CY, Chen KN, Wu CS, Chai WL (2009) Compatible and crystallization properties of poly(lactic acid)/poly(butylene adipate-co-terephthalate) blends. J Appl Polym Sci 116:680–687

Coltelli MB, Maggiore ID, Bertoldo M, Signori F, Bronco S, Ciardelli F (2008) Poly(lactic acid) properties as a consequence of poly(butylene adipate-co-terephthalate) blending and acetyl tributyl citrate plasticization. J Appl Polym Sci 110:1250–1262

Xiao H, Lu W, Yeh JT (2008) Crystallization behavior of fully biodegradable poly(lactic acid)/poly(butylene adipate-co-terephthalate) blends. J Appl Polym Sci 112:3754–3763

Li Y, Shimizu H (2009) Improvement in toughness of poly(l-lactic acid) (PLLA) through reactive blending with acrylonitrile–butadiene–styrene copolymer (ABS): morphology and properties. Eur Polym J 45:738–746

Bourmaud A, Pimbert S (2008) Investigations on mechanical properties of poly(propylene) and poly(lactic acid) reinforced by miscanthus fibers. Composites A 39:1444–1454

Reddy N, Nama D, Yang Y (2008) Polylactic acid/polypropylene polyblend fibers for better resistance to degradation. Polym Degrad Stab 39:233–241

Anderson KS, Hillmyer MA (2004) The influence of block copolymer microstructure on the toughness of compatibilized polylactide/polyethylene blends. Polymer 45:8809–8823

Schlemmer D, Sales M, Resck IS (2009) Degradation of different polystyrene/thermoplastic starch blends buried in soil. Carbohydr Polym 75:58–62

Schlemmer D, Oliveira ER, Sales M (2007) Polystyrene/theromoplastic starch blends with different plasticizer, preparation and thermal characterization. J Therm Anal Calorim 87:635–638

Pimentel T, Duraes J, Drummond A, Schlemmer D, Falcao R, Sales M (2007) Preparation and characterization of blends of recycled polystyrene with cassava starch. J Mater Sci 42:7530–7536

Mihai M, Huneault M, Favias B (2007) Foaming of polystyrene/thermoplastic starch blends. J Cell Plast 43:215–236

Tadmor Z, Gogos CG (2006) Principles of polymer processing. Wiley, New Jersey

Han CD (2007) Rheology and processing of polymeric materials (Polymer Processing). Oxford University Press, New York

Bagley EB (1957) End corrections in the capillary flow of polyethylene. J Appl Phys 28:624–627

Sinthavathavorn W, Nithitanakul M, Grady B, Mangaraphan R (2009) Melt rheology and die swell of PA6/LDPE blends by using lithium ionomer as a compatibilizer. Polym Bull 63:23–35

Lenk RS (1978) Polymer rheology. Applied Science Publishers Ltd, London

Ebewele RO (2000) Polymer science and technology. CRC Press LLC Publication, Florida

Biresaw G, Carriere CJ (2004) Compatibility and mechanical properties of blends of polystyrene with biodegradable polyesters. Composites A 35:313–320

Acknowledgment

The authors are indebted to Kreem Industrial Establishment for the aid in designing of SHAM EXDRUDER 25D.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hamad, K., Kaseem, M. & Deri, F. Rheological and mechanical properties of poly(lactic acid)/polystyrene polymer blend. Polym. Bull. 65, 509–519 (2010). https://doi.org/10.1007/s00289-010-0354-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-010-0354-2