Abstract

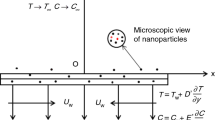

To optimize the distillation process and evaluate evaporation in the production of titanium sponge using the magnesiothermic method, it is necessary to study the microchannel evaporation process of titanium sponge. Combining the kinetic theory, heat transfer theory and augmented Young–Laplace equation, we established an analysis model for titanium sponge micropores and predicted the heat and mass transfer characteristics of the microchannel evaporation meniscus. The model considered the influence of a series of factors such as superheat, wall temperature and channel inclination on heat and mass transfer characteristics of titanium sponge pores. The results show that a high wall temperature and superheat do not necessarily enhance the heat and mass transfer performance of the matrix material and fluid, and the inclination angle of the microchannel has negligible effects on the overall evaporation. In addition, according to the calculation results, the semi-empirical relationship of Nusselt number is obtained. The well uniformity between the numerical calculation results and the fitted results is confirmed through verification.

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding author, upon reasonable request.

Abbreviations

- A :

-

Hamker constant, J

- C pl :

-

Specific heat at constant pressure, J/(kg∙K)

- D :

-

Characteristic length, m

- h fg :

-

Lateral heat of evaporation, J/kg

- h lv :

-

Heat transfer coefficient, W/(m2∙K)

- D :

-

Characteristic length, m

- L :

-

Microchannal length, m

- m " :

-

Evaporation mass flux, kg/(m2∙s)

- N u :

-

Nusselt number

- p :

-

Pressure, Pa

- P r :

-

Prandtl number

- R e :

-

Reynolds Number

- q " :

-

Heat flux, W/m2

- T :

-

Temperature, K

- u :

-

Velocity along x-axis, m/s

- x :

-

X-direction, m

- r :

-

R-direction, m

- δ :

-

Liquid layer thickness, m

- δ 0 :

-

Non-evaporating layer thickness, m

- δ ' :

-

The first derivative of the film thickness with respect to the x-direction

- δ ” :

-

The second derivative of the film thickness with respect to the x-direction

- δ ′” :

-

The third derivative of the film thickness with respect to the x-direction

- v :

-

Kinematic viscosity, m2/s

- μ :

-

Dynamic viscosity, Ns/m2

- ρ :

-

Density, kg/m3

- σ :

-

Surface tension coefficient, N/m

- Γ :

-

Mass flow rate, kg/(m∙s)

- κ :

-

Curvature, m−1

- c :

-

Capillary

- d :

-

Disjoining

- l :

-

Liquid

- lv :

-

Liquid-vapor interface

- v :

-

Vapor

- w :

-

Wall

References

Hu X, Luo F, Lin J, Wang M, Li X (2022) Dynamic material flow analysis of titanium sponge in China: 2000–2019. J Clean Prod 371:p133704

Nahar MM, Ma B, Guye K, Chau QH, Padilla J, Iyengar M, Agonafer D (2021) Microscale evaporative cooling technologies for high heat flux microelectronics devices: Background and recent advances. Appl Therm Eng 194:117109

Derjaguin B (1957) Optical study of the adsorption and surface condensation of vapours in the vicinity of saturation on a smooth surface. Proc 2nd Int Cong Surf Activ 2:145–152

Potash M, Wayner PC (1972) Evaporation from a two-dimensional extended meniscus. Int J Heat Mass Transf 15:1851–1863

Schrage RW (1953) A Theoretical Study of Interface Mass Transfer Columbia University Press, New York

Wayner P Jr, Kao Y, LaCroix L (1976) The interline heat-transfer coefficient of an evaporating wetting film. Int J Heat Mass Transf 19:487–492

Schonberg J, Wayner P Jr (1992) Analytical solution for the integral contact line evaporative heat sink. J Thermophys Heat Transf 6:128–134

Wayner P Jr (1979) Effect of thin film heat transfer on meniscus profile and capillary pressure. AIAA J 17:772–776

Kou ZH, Bai ML (2011) Effects of wall slip and temperature jump on heat and mass transfer characteristics of an evaporating thin film. Int Commun Heat Mass Transf 38:874–878

Lim E, Hung YM (2015) Thermophysical phenomena of working fluids of thermocapillary convection in evaporating thin liquid films. Int Commun Heat Mass Transf 66:203–211

Kou ZH, Lv HT, Zeng W, Bai ML, Lv JZ (2015) Comparison of different analytical models for heat and mass transfer characteristics of an evaporating meniscus in a micro-channel. Int Commun Heat Mass Transf 63:49–53

Wang H, Garimella SV, Murthy JY (2007) Characteristics of an evaporating thin film in a microchannel. Int J Heat Mass Transf 50:3933–3942

Dwivedi R, Singh PK (2018) Decisive influence of nanofluid on thin evaporating meniscus. In Thermophysics: 23rd international meeting of thermophysics. AIP Conference Proceedings 1988:020043. https://doi.org/10.1063/1.5047637

Dwivedi R, Singh PK (2019) Numerical analysis of an evaporating thin film region: Enticing influence of nanofluid. Numer Heat Tranf A-Appl 75:56–70

Wang H, Garimella SV, Murthy JY (2008) An analytical solution for the total heat transfer in the thin-film region of an evaporating meniscus. Int J Heat Mass Transf 51:6317–6322

Dwivedi R, Pati S, Singh PK (2020) Combined effects of wall slip and nanofluid on interfacial transport from a thin-film evaporating meniscus in a microfluidic channel. Microfluid Nanofluid 24:1–17

Biswal L, Som SK, Chakraborty S (2011) Thin film evaporation in microchannels with interfacial slip. Microfluid Nanofluid 10:155–163

Zhao J-J, Duan Y-Y, Wang X-D, Wang B-X (2013) Effect of nanostructured roughness on evaporating thin films in microchannels for wenzel and Cassie-Baxter states. J Heat Transfer 135:041502

Zhao JJ, Duan YY, Wang XD, Wang BX (2011) Effect of nanofluids on thin film evaporation in microchannels. J Nanopart Res 13:5033–5047

Shkarah AJ, Bin Sulaiman MY, bin Hj Ayob MR, (2015) Analytical Solutions of Heat Transfer and Film Thickness with Slip Condition Effect in Thin-Film Evaporation for Two-Phase Flow in Microchannel. Math Probl Eng 2015:369581

Abdullaev R, Agazhanov AS, Khairulin A, Samoshkin D, Stankus S (2022) Thermophysical Properties of Magnesium in Solid and Liquid States. J Eng Thermophys 31:384–401

Abdullaev R, Khairulin R, Kozlovskii YM, Agazhanov AS, Stankus S (2019) Density of magnesium and magnesium-lithium alloys in solid and liquid states. Trans Nonferrous Met Soc China 29:507–514

Mills KC (2002) Recommended values of thermophysical properties for selected commercial alloys: Mg Pure Magnesium. Woodhead Publishing Limited, Cambridge, England

Lu J, Yang S, Rong Z, Pan G, Ding J, Liu S, Wei X, Wang W (2021) Thermal properties of KCl–MgCl2 eutectic salt for high-temperature heat transfer and thermal storage system. Sol Energy Mater Sol Cells 228:111130

Zhang F, Du Y, Liu S, Jie W (2015) Modeling of the viscosity in the AL–Cu–Mg–Si system: Database construction. Calphad 49:79–86

Bera TK, Biswas SK, Rajan K, Nagaraju J (2014) Projection Error Propagation-based regularization (PEPR) method for resistivity reconstruction in electrical impedance tomography (EIT). Measurement 49:329–350

Wang W, Wu F, Yu Q, Jin H (2018) Experimental investigation of titanium tetrachloride in pool boiling heat transfer. Int J Heat Mass Transf 122:1308–1312

Hanchak MS, Vangsness MD, Byrd LW, Ervin JS (2014) Thin film evaporation of n-octane on silicon: Experiments and theory. Int J Heat Mass Transf 75:196–206

Lay JH, Dhir VK (1995) Shape of a Vapor Stem During Nucleate Boiling of Saturated Liquids. J Heat Transfer 117:394–401

Dhavaleswarapu HK, Garimella SV, Murthy JY (2009) Microscale Temperature Measurements Near the Triple Line of an Evaporating Thin Liquid Film. J Heat Transfer 131:061501

Funding

The author acknowledges the financial supported by GuiZhou Provincial Science and Technology Projects [grant numbers QKHJC-ZK 2021-YB 261 and QKHJC 2019-1406], the National Natural Science Foundation of China [grant number 51874108], the Talent Projects of Guizhou University [grant number GDPY 2019-20].

Author information

Authors and Affiliations

Contributions

Chengqi Zhang: Investigation, Methodology, Formal analysis, Writing - Original Draft. Wenhao Wang: Supervision, Validation, Writing - Review & Editing, Funding acquisition. Hui Yuan: Writing - Original Draft. Fuzhong Wu: Conceptualization, Project administration, Funding acquisition. Xiangwei Hui: Validation. Ming Qi: Validation. Sen Yang: Validation.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, C., Wang, W., Yuan, H. et al. Thin-film evaporation characteristics of molten magnesium and magnesium chloride in a microchannel of titanium sponge. Heat Mass Transfer 59, 2241–2254 (2023). https://doi.org/10.1007/s00231-023-03411-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-023-03411-6