Abstract

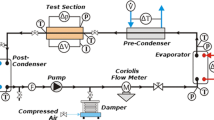

Experimental investigations were conducted to analyze the evaporation heat transfer of R407c inside a horizontal microfin (trapezoidal-shaped) Cu-tube. The experiments were performed in equipment specifically designed and fabricated for phase change analysis, with a test section consisting of a 1m long Cu-tube with an outer diameter of 9.52 mm and a recirculating water heating system. The following test parameters were used: a heat flux of 5-85 kW.m-2, mass flux of 20-350 kg.m-2.s-1, vapor quality range of 0.03-0.667, and saturation temperature of 283.15-313.15 K. The novel aspect of this study is the newly designed microfin tube with helix and apex angles of 22° and 48°, fin height of 0.22 mm, and a total of 60 fins. Following experimental analysis, flow boiling heat transfer coefficients rise with mass flux, vapor quality, lower saturation temperature, hydraulic diameter, and heat flux. The experimental outcomes were also compared with established correlations. The error range for the experimental data was found to be within \(\pm 25\%\), which shows that the data are accurate to a high level of 95%. Besides that, correlations of evaporation heat transfer through a 9.52 mm horizontal round microfin tube were established by using the interpolation technique in LINGO software to anticipate the internal evaporator heat transfer coefficient as a consequence of saturation temperature. At saturation temperatures of 283.15 K and 293.15 K, the new correlation can predict most of the previous experimental results within \(\pm 20\%\) the error margin.

Similar content being viewed by others

Availability of data and materials

The datasets used and/or analyzed during the current study are available from the corresponding author upon reasonable request.

Abbreviations

- \(A_{in}\) :

-

The evaporator test tube inner surface area, [m2]

- \(A_{out}\) :

-

The evaporator test tube outer surface area, [m2]

- \(Bo\) :

-

Boiling number

- \(c_{p}\) :

-

Specific heat at constant pressure, [kJ.kg-1.K-1]

- \(c_{v}\) :

-

Specific heat at constant volume, [kJ.kg-1.K-1]

- \(D\) :

-

The evaporator test tube diameter, [mm]

- \(f\) :

-

Friction factor

- \(F{}_{h}\) :

-

Fin height, [mm]

- \(F_{\alpha }\) :

-

Factor accounting for tube inclination in Eq. (10)

- \(G\) :

-

Mass flux, [kg.m-2.s-1)]

- \(H\) :

-

Refrigerant enthalpy, [kJ.kg-1]

- \(h\) :

-

Heat transfer coefficient, [kW.m-2. K-1)]

- \(h_{fg}\) :

-

Latent heat of vaporization, [kJ.kg-1]

- \(I\) :

-

Current, [A]

- \(k\) :

-

Refrigerant thermal conductivity, [kW.m-1. K-1)]

- \(L\) :

-

Length, [mm]

- \(M\) :

-

Molecular weight, [kg.kmol-1]

- \(m\) :

-

Mass flow rate, [kg.s-1]

- \(N\) :

-

Number of dataset

- \(n_{f}\) :

-

Number of fins

- \(Nu\) :

-

Nusselt number

- \(p\) :

-

Pressure, [kPa]

- \(p_{c}\) :

-

Critical pressure, [kPa]

- \(\Pr\) :

-

Prandtl number

- \(Q\) :

-

Heat flow rate, [W]

- \(q\) :

-

Heat flux, [kW.m-2]

- \({\text{Re}}\) :

-

Reynolds number

- \(T\) :

-

Temperature, [K]

- \(T_{c}\) :

-

Critical temperature, [ K]

- \(V\) :

-

Voltage, [V]

- \(x\) :

-

Vapor quality

- \(X_{tt}\) :

-

Martinelli parameter

- \(\alpha\) :

-

Apex angle, [o]

- \(\beta\) :

-

Helix angle, [o]

- \(\delta\) :

-

Ratio of hydraulic diameter

- \(\mu\) :

-

Dynamic viscosity, [µPa.s-1]

- \(\rho\) :

-

Density, [kg.m-3]

- \(\sigma\) :

-

Surface tension, [mN.m-1]

- \(Ana\) :

-

Analytical

- \(avg\) :

-

Average

- \(b\) :

-

Bulk

- \(Cal\) :

-

Calculated

- \(Exp\) :

-

Experimental

- \(h\) :

-

Hydraulic

- \(in\) :

-

Inside

- \(l\) :

-

Liquid

- \(lt\) :

-

Latent heat

- \(out\) :

-

Outside

- \(ph\) :

-

Pre heater

- \(ref\) :

-

Refrigerant

- \(sat\) :

-

Saturation

- \(sn\) :

-

Sensible heat

- \(t\sec\) :

-

Test section

- \(v\) :

-

Vapor

- \(w\) :

-

Water

- \(APE\) :

-

Absolute precision error

- \(ASHRAE\) :

-

American Society of Heating, Refrigerating and Air-Conditioning Engineers

- \(CFC\) :

-

Chlorofluorocarbon

- \(CoC\) :

-

Coefficient of correlation

- \(GWP\) :

-

Global warming potential

- \(HCFC\) :

-

Hydrochlorofluorocarbon

- \(HFC\) :

-

Hydrofluorocarbon

- \(HF\) :

-

Heat flux, [kW.m-2]

- \(HTC\) :

-

Heat transfer coefficient, [kW.m-2. K-1)]

- \(LMTD\) :

-

Log-mean temperature difference

- \(MAE\) :

-

Mean absolute error

- \(MF\) :

-

Mass Flux

- \(MSE\) :

-

Mean square error

- \(NIST\) :

-

National institute of standards and technology

- \(ODP\) :

-

Ozone layer depletion

- \(RMSD\) :

-

Root mean square deviation error

References

Lavin JG (1963) Heat Transfer to Refrigerants Boiling Inside Plain Tubes and Tubes with Internal Turbulators, PhD Thesis, University of Michigan

Lavin JG, Young EH (1965) Heat transfer to evaporating refrigerants in two phase flow. Am Inst Chem Eng J 11:1124–1132

Fujie Y, Ohta H, Innami T, Kimura H, Nakayama N, Yanagidi T (1977) Heat Transfer Pipe, US Patents #4044;797, Assigned to Hitachi, Ltd

Webb RL (1994) Principles of Enhanced Heat Transfer. John Wiley and Sons, New York

Zurcher O, Thome JR, Favrat D (1998) In-tube flow boiling of R-407C and R407C/oil mixtures. Part I: Microfin tube HVAC&R Res 4(4):347–372

Wellsandt S, Vamling L (2005) Evaporation of R407C and R410A in a horizontal herringbone microfin tube: heat transfer and pressure drop. Int J Ref 28(6):901–911

Targanski W, Cieslinski J (2007) Evaporation of R407C/oil mixtures inside corrugated and micro-fin tubes. App Therm Engg 27:2226–2232

Rollmann P, Spindler K, Müller-Steinhagen H (2011) Heat transfer, pressure drop and flow patterns during flow boiling of R407C in a horizontal microfin tube. Heat Mass Trans 47(8):951–961

Filho EPB, Barbieri PEL (2011) Flow boiling performance in horizontal microfinned copper tubes with the same geometric characteristics. Exp Therm Fluid Sci 35:832–840

Jiang GB, Tan JT, Nian QX, Tang SC, Tao WQ (2016) Experimental study of boiling heat transfer in smooth/micro-fin tubes of four refrigerants. Int J Heat Mass Trans 98:631–642

Diani A, Rossetto L (2019) R513A flow boiling heat transfer inside horizontal smooth tube and microfin tube. Int J Ref 107:301–314

Wang Z, Luo L, Xia X, He N, Peng D, Wu S (2020) Experimental study on flow boiling heat transfer and pressure drop of R245fa/R141b mixture in a horizontal microfin tube. Int J Ref 118:72–83

Deb S, Kanade PM, Pal S, Das AK (2022) Influence of horizontal enhanced tube on flow boiling heat transfer characteristics of environmentally friendly refrigerant R-407c. Matls Today: Proces 62(6):3178–3182

Kumar A, Das DC, Das P (2022) Significance of surface morphology of materials on flow boiling heat transfer using R-407c. Matls Today: Proces 62:3122–3128

Deb S, Kanade PM, Das M, Das DC, Pal S, Das R, Das AK (2023) Flow Boiling Heat Transfer Characteristics over Horizontal Smooth and Microfin Tubes: An Empirical Investigation Utilizing R407c. Int J Therm Sci 188:108239

Kumar A, Das, D C, Das P (2023) Parametric variation studies of experimental flow boiling heat transfer phenomena using R407c inside an enhanced tube. Heat Mass Trans 1-11

Thome JR (1990) Enhanced Boiling Heat Transfer. Hemisphere, New York

Thome JR (2004) Engineering Data Book III, Wolverine Tube Inc. Copenhagen amendment to the Montreal Protocol, 5 Nov. 1992

Copenhagen amendment to the Montreal Protocol, 5 Nov. 1992

Aprea C, Greco A (2003) Performance evaluation of R22 and R407c in a vapor compression plant with reciprocating compressor. App Therm Engg 23:215–227

Bitzer (2007) Refrigerant Report, Bitzer International, thirteenth ed. 71065, Sindelfingen, Germany

Diani A, Rossetto L (2018) Experimental analysis of refrigerants flow boiling inside small sized microfin tubes. Heat Mass Trans 54:2315–2329

Deb S, Pal S, Das DC, Das M, Das AK, Das R (2020) Surface wettability change on TF nanocoated surfaces during pool boiling heat transfer of refrigerant R-141b. Heat Mass Trans 56:3273–3287

Das DC, Ghosh K, Sanyal D (2021) Scale analysis for water jet impingement over a horizontal flat plate under film boiling configuration. Heat Mass Trans 57:1211–1221

Kazerooni R B, Bakhtiarpour M A, Noghrehabadi A (2022) Experimental study of flow boiling heat transfer in horizontal rifled tube. Heat Mass Trans 1–11

Chen JC (1966) Correlation for boiling heat transfer to saturated fluids in convective flow. Ind Eng Chem Process Des Develop 5(3):322–329

Shah MM (1982) Chart correlation for saturated boiling heat transfer equations and further study. ASHRAE Trans 88(1):185–196

Gungor KE, Winterton RHS (1987) Simplified general correlation for saturated flow boiling and comparisons of correlations with data. Chem Eng Res Des 65:148–156

Liu Z, Winterton RHS (1991) A general correlation for saturated and subcooled flow boiling in tubes and annuli, based on a nucleate pool boiling equation. Int J Heat Mass Trans 34(11):2759–2766

Bejan A, Kraus AD (2003) Heat Transfer Handbook. J Wiley, New York

Kandlikar SG (1990) A general correlation for saturated two-phase flow boiling heat transfer inside horizontal and vertical tubes. J Heat Transfer 112(1):219–228

Kandlikar SG (1991) A model for correlating flow boiling heat transfer in augmented tubes and compact evaporators. J Heat Transfer 113(4):966–972

Cavallini A, Del Col D, Doretti L, Longo GA, Rossetto L (1999) Refrigerant vaporization inside enhanced tubes: a heat transfer model. Heat Technol 17(2):29–36

Thome JR, Kattan N, Favrat D (1999) Evaporation in microfin tubes: a generalized prediction model. Proc Int Eng Found 3:239–245

Chamra LM, Mago PJ (2007) Modelling of evaporation heat transfer of pure refrigerants and refrigerant mixtures in microfin tubes. Proc Instn Mech Engr C: J Mech Eng Sci 221(4):443–447

Kattan N, Thome JR, Favrat D (1998) Flow boiling in horizontal tubes: part 3 - development of a new heat transfer model based on flow pattern. J Heat Transfer 120(1):156–165

Zhang X, Ji C, Yuan X (2008) Prediction method for evaporation heat transfer of non-azeotropic refrigerant mixtures flowing inside internally grooved tubes. App Therm Engg 28(14-15):1974–1983

Rollmann P, Spindler K (2010) Warmeübergang und Druckverlust beim Stromungssieden von R407C - Vergleich verschiedener Korrelationen, in: Deutscher K€alte- und Klimatechnischer Verein (Ed.), Deutsche Kalte-Klima-Tagung 2010 Magdeburg II.1

Yun R, Kim Y, Seo K, Young Kim H (2002) A generalized correlation for evaporation heat transfer of refrigerants in micro-fin tubes. Int J Heat Mass Transf 45(10):2003–2010

Del Col D, Webb R, Narayanamurthy R (2002) Heat transfer mechanisms for condensation and vaporization inside a microfin tube. J Enhan Heat Transf 9(1):25–37

Murata K, Hashizume K (1993) Forced convective boiling of non azeotropic refrigerant mixtures inside tubes. J Heat Trans T ASME 115(3):680–689

Momoki S, Yu J, Koyama S, Fujii T, Honda H (2011) A correlation for forced convective boiling heat transfer of refrigerants in a microfin tube. Trans Japan Soc Refri Air Cond Engg 12:177–184

Mehendale S (2018) A new heat transfer coefficient correlation for pure refrigerants and near-azeotropic refrigerant mixtures flow boiling within horizontal microfin tubes. Int J Ref 86:292–311

Lemmon EW, Huber ML, McLinden MO (2018) NIST Standard Reference Database 23, NIST Reference Fluid Thermodynamic and Transport Properties, REFPROP, Version 9.0. Standard Reference Data Program, National Institute of Standards and Technology, Gaithersburg, MD

Moffat RJ (1988) Describing the uncertainties in experimental results. Exp Therm Fluid Sci 1(1):3–17

Chen X, Li W, Sun Z, Ren Y, Liu F, Xu JL (2019) Correlation of evaporation heat transfer inside 8.8 mm and 7.14 mm horizontal round micro-fin tubes. Heat Transfer Engg 40(3-4):320–329

He G, Zhou S, Li D, Cai D, Zou S (2018) Experimental study on the flow boiling heat transfer characteristics of R32 in horizontal tubes. Int J Heat Mass Trans 125:943–958

Zhang J, Wang J, He Y, Liu L, Li W, Tang W, Ayub Z (2022) R410A flow boiling coefficient in horizontal annular channels of enhanced tubes, Part II: Heat transfer. Int J Ref 137:43–50

Longo GA, Mancin S, Righetti G, Zilio C (2021) Comparative analysis of microfin vs smooth tubes in R32 and R410A boiling. Int J Ref 131:515–525

Wang W, Ho JY, Leong KC, Wong TN (2022) Experimental Study of Flow Boiling and Condensation in Tubes with Pin-Fin and Metallic Foam Structures. Heat Transfer Engg 43(12):991–1007

Padovan A, Del Col D, Rossetto L (2011) Experimental study on flow boiling of R134a and R410A in a horizontal microfin tube at high saturation temperatures. App Therm Engg 31(17–18):3814–3826

da Silva Lima RJ, Quibén JM, Thome JR (2019) Flow boiling heat transfer characteristics in horizontal, three-dimensional enhanced tubes. Energies 12(5):927

Silva Lima, da R J, Quibén J M, Thome J R, (2009) Flow boiling in horizontal smooth tubes: New heat transfer results for R-134a at three saturation temperatures App Therm Engg 29(7):1289–1298

Koyama SH, Yu J, Momoki S, Fujii T, Honda H (1995) Forced convective flow boiling heat transfer of pure refrigerants inside a horizontal microfin tube. In: Proc Convec Flow Boiling Int Conf Banff Canada

Behabadi MA, Mohseni SG, Razavinasab SM (2011) Evaporation heat transfer of R-134a inside a microfin tube with different tube inclinations. Exp Therm Fluid Sci 35(6):996–1001

Lallemand M, Branescu C, Haberschill P (2001) Coefficients d’échange locaux au cours de l’ébullition du R22 et du R407C dans des tubes horizontaux, lisse ou micro-aileté. Int J Ref 24(1):57–72

Passos JC, Kuser VF, Haberschill P, Lallemand M (2003) Convective boiling of R-407c inside horizontal microfin and plain tubes. Exp Therm Fluid Sci 27(6):705–713

Rollmann P, Spindler K (2016) New models for heat transfer and pressure drop during flow boiling of R407C and R410A in a horizontal microfin tube. Int J Therm Sci 103:57–66

Tang W, Li W (2018) A new heat transfer model for flow boiling of refrigerants in micro-fin tubes. Int J Heat Mass Trans 126:1067–1078

Funding

The corresponding author declares on behalf of all co-authors that no funds, grants, or other support were received during the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

Sandipan Deb- Experimentation, Formal analysis, Data curation, Validation, Writing - original draft. Mantu Das- Mathematical Modelling, Validation, Formal analysis, Writing - original draft. Dipak Chandra Das- Methodology, Formal analysis. Sagnik Pal- Methodology, Formal Analysis, Review, and Editing. Ranjan Das- Writing - review & editing, Supervision. Ajoy Kumar Das- Conceptualization, Writing - review & editing, Supervision.

Corresponding author

Ethics declarations

Conflicts of Interest

Regarding the publication of the present paper, the authors hereby state that no sort of conflict of interest is associated with this work.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Deb, S., Das, M., Das, D.C. et al. Evaluation of flow boiling heat transfer in horizontal circular trapezoidal-shaped microfin tube. Heat Mass Transfer 59, 1931–1947 (2023). https://doi.org/10.1007/s00231-023-03374-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-023-03374-8