Abstract

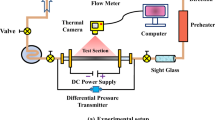

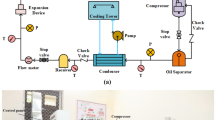

The heat transfer, pressure drop and flow patterns during flow boiling of R407C in a horizontal microfin tube have been investigated. The microfin tube is made of copper with a total fin number of 55 and a helix angle of 15°. The fin height is 0.24 mm and the inner tube diameter at fin root is 8.95 mm. The test tube is 1 m long. It is heated electrically. The experiments have been performed at saturation temperatures between −30°C and +10°C. The mass flux was varied between 25 and 300 kg/m2/s, the heat flux from 20,000 W/m2 down to 1,000 W/m2. The vapour quality was kept constant at 0.1, 0.3, 0.5, 0.7 at the inlet and 0.8, 1.0 at the outlet, respectively. The measured heat transfer coefficient is compared with the correlations of Cavallini et al., Shah as well as Zhang et al. Cavallini’s correlation contains seven experimental constants. After fitting these constants to our measured values, the correlation achieves good agreement. The measured pressure drop is compared to the correlations of Pierre, Kuo and Wang as well as Müller-Steinhagen and Heck. The best agreement is achieved with the correlation of Kuo and Wang. Almost all values are calculated within an accuracy of ±30%. The flow regimes were observed. It is shown, that changes in the flow regime affect the heat transfer coefficient significantly.

Similar content being viewed by others

Abbreviations

- A,B,C,F,S,U,V,Z:

-

Dimensionless constants (–)

- Bo:

-

Boiling number (–)

- Bon:

-

Bond number (–)

- Co:

-

Convection number (–)

- cp :

-

Specific heat capacity (J/kg/K)

- dH :

-

Hydraulic diameter (m)

- di :

-

Diameter from fin tip to fin tip (m)

- dK :

-

Diameter at fin root (m)

- d0 :

-

Reference diameter (m)

- FC :

-

Mixture correction factor (–)

- Emf :

-

Enhancement factor for microfin tubes (–)

- ERB :

-

Convection enhancement factor (–)

- Fr:

-

Froude number (–)

- g:

-

Gravitational acceleration (m/s2)

- G:

-

Mass flux (kg/m2/s)

- G0 :

-

Reference mass flux (kg/m2/s)

- Kf :

-

Pierre’s Boiling number (–)

- L:

-

Length of test section (m)

- M:

-

Molar mass (kg/kmol)

- n:

-

Number of fins (–)

- N:

-

Dimensionless number (–)

- p:

-

Pressure (Pa)

- pr :

-

Reduced pressure (–)

- Pr:

-

Prandtl number (–)

- q, \( \dot{q} \) :

-

Heat flux (W/m2)

- Re:

-

Reynolds number (–)

- Rx:

-

Geometry amplification factor (–)

- t:

-

Fin height (m)

- v:

-

Specific volume (m3/kg)

- w:

-

Velocity (m/s)

- x:

-

Mass-specific vapour quality (–)

- Xtt :

-

Martinelli parameter (–)

- z:

-

Coordinate parallel to the test section (m)

- α:

-

Heat transfer coefficient (W/m2/K)

- β:

-

Helix angle of fins (°)

- γ:

-

Apex angle of fins (°)

- ΔhV :

-

Specific enthalpy of vaporization (J/kg)

- Δp:

-

Pressure drop (Pa)

- ΔTglide :

-

Temperature glide (K)

- η:

-

Dynamic viscosity (Pa s)

- λ:

-

Thermal conductivity (W/m/K)

- ξ:

-

Friction factor (–)

- ρ:

-

Density (kg/m3)

- σ:

-

Surface tension (N/m)

- Φ:

-

Two-phase multiplier (–)

- cal:

-

Calculated

- cv:

-

Convective

- exp:

-

Experimental

- I:

-

Inlet

- l:

-

Liquid

- m:

-

Mean

- nb:

-

Nucleate boiling

- O:

-

Outlet

- plane:

-

Measurement plane

- pure:

-

Pure refrigerant

- S:

-

Saturation

- v:

-

Vapour

References

Spindler K, Müller-Steinhagen H (2006) Heat transfer and pressure drop during flow boiling of R134a and R404A in a microfin tube at low mass fluxes. Paper BOI-24, Proceedings of 13th International Heat Transfer Conference Sydney, Australia

Seo K, Kim Y (2000) Evaporation heat transfer and pressure drop of R-22 in 7 and 9.52 mm smooth/micro-fin tubes. Int J Heat Mass Transf 43:2869–2882

Rollmann P, Spindler K, Müller-Steinhagen H (2010) Wärmeübergang und Druckverlust beim Strömungssieden von Kältemittelgemischen in einem horizontalen innenstrukturierten Rohr. Forschungsrat Kältetechnik e.V. (Hrsg.), final report of AiF project No. 15084, Frankfurt/M

Cavallini A, Del Col D, Doretti L, Longo GA, Rosetto L (1999) Refrigerant vaporisation inside enhanced tubes: A heat transfer model. Heat Technol 17(2):29–36

Thome JR (1996) Boiling of new refrigerants: a state-of-the-art review. Int J Refrig 19(7):435–457

Shah MM (1982) Chart correlation for saturated boiling heat transfer equations and further study. ASHRAE Trans 88(pt. 1):185–196

Zhang X, Ji C, Yuan X (2008) Prediction method for evaporation heat transfer of non-azeotropic refrigerant mixtures flowing inside internally grooved tubes. Appl Therm Eng 28:1974–1983

Thome JR, Kattan N, Favrat D (1997) Evaporation in microfin tubes: a generalized prediction model. Proceedings of the convective flow and pool boiling conference, Kloster Irsee, VII–4

Boissieux X, Heikal MR, Johns RA (2000) Two-phase heat transfer coefficients of three HFC refrigerants inside a horizontal smooth tube, part I: evaporation. Int J Refrig 23:269–283

Pierre B (1964) Flow resistance with boiling refrigerants–Part 1. ASHRAE J 6(9):58–65

Müller-Steinhagen H, Heck K (1986) A simple friction pressure drop correlation for two-phase flow in pipes. Chem Eng Process 20:297–308

Chawla JM (2006) Druckverlust in durchströmten Verdampferrohren. VDI-Wärmeatlas, Springer, Heidelberg, 10. Auflage

Kou CS, Wang CC (1996) Horizontal flow boiling of R22 and R407C in a 9.52 mm micro-fin tube. Appl Thermal Eng 16(8/9):719–731

Acknowledgments

This work was supported by the German Bundesministerium für Wirtschaft (BMWi) through the Arbeitsgemeinschaft industrieller Forschungsvereinigungen (AiF). The project was accompanied by a working party of the Forschungsrat Kältetechnik e.V. (FKT), Frankfurt a. M., Germany. The final report [3] is available at FKT e.V.

Author information

Authors and Affiliations

Corresponding author

Additional information

Dedicated to Prof. Dr.-Ing. Dr.-Ing. E.h. mult. Franz Mayinger on the occasion of his 80th birthday.

Rights and permissions

About this article

Cite this article

Rollmann, P., Spindler, K. & Müller-Steinhagen, H. Heat transfer, pressure drop and flow patterns during flow boiling of R407C in a horizontal microfin tube. Heat Mass Transfer 47, 951–961 (2011). https://doi.org/10.1007/s00231-011-0857-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-011-0857-x