Abstract

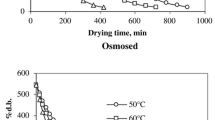

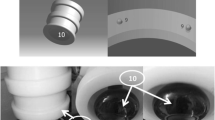

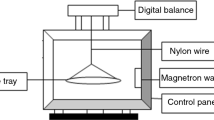

The major target of this study was to investigate the influences of osmotic dehydration, microwave power and slice thickness on drying phenomena of Turkish red meat (watermelon) radish. Two different thin layer thicknesses were used as 3 and 6 mm and samples dried at 72, 269 and 356 W real microwave powers. NaCl was osmotic solution at a concentration of 6% and slices were waited during 120 min at 25 °C for the pre-treatment. The drying data was fitted to 24 mathematical models available in literature and best equations were determined. The results indicated that, pre-treatment application shortened processing time remarkably. Sigmoid, cubic and rational models showed the best performances in all experiments for describing drying kinetics. The estimated effective moisture diffusivities were ranged between 4.44 × 10−7-5.56 × 10−6 and 3.86 × 10−7-2.52 × 10−6 m2 s−1 for 3 and 6 mm slices respectively. The activation energies were calculated as in the gap of 2.77 and 10.61 W g−1 and increased with decreasing slice thickness, however enhanced in presence of osmotic application. The suggested process conditions are 72 W and 6 mm slice thickness without any pre-treatment in order to obtain a well-qualified product.

Similar content being viewed by others

Abbreviations

- a, b, c, d:

-

Drying coefficients (−).

- Deff :

-

Effective moisture diffusivity (m2 s−1).

- D0 :

-

Arrhenius constant (m2 s−1).

- Ea :

-

Activation energy (W g−1).

- F:

-

Function of independent variable (−).

- k:

-

Drying constant (min−1).

- K:

-

Slope (−).

- M:

-

Mass of sample after dehydration (g).

- Ma :

-

Moisture content at any time (gwater g−1dry matter).

- Me :

-

Equilibrium moisture content (gwater g−1dry matter).

- MRexp,i :

-

Experimental moisture ratio at i (−).

- MRpre,i :

-

Predicted MR at i (−).

- Mo :

-

Initial moisture content (gwater g−1dry matter).

- MR:

-

Moisture ratio (−).

- m:

-

Mass of solid in sample after osmotic dehydration or weight of slice (g).

- m0 :

-

Initial mass of solid in sample (g).

- μ:

-

Bessel function (−).

- N:

-

Number of experimental data (−).

- n:

-

Number of positive terms (−).

- P:

-

Microwave power level (W).

- Pr :

-

Real microwave power (W).

- r:

-

Radius (m).

- RMSE:

-

Root mean square error (−).

- R2 :

-

Determination coefficient (−).

- SG:

-

Solid gain (−).

- t:

-

Time (s).

- WL:

-

Water loss (−).

- WR:

-

Weight reduction (−).

- w:

-

Uncertainty (W, g, min, m2 s−1, W g−1 or -).

- χ2 :

-

Chi square (−).

- y:

-

Independent variable (−).

- z:

-

Number of constant in model (−).

References

Coogan RC, Wills RBH (2002) Effect of drying and salting on the flavour compound of Asian white radish. Food Chem 77(3):305–307. https://doi.org/10.1016/S0308-8146(01)00350-8

Lee JH, Kim HJ (2009) Vacuum drying kinetics of Asian white radish (Raphanus sativus L.) slices. LWT-Food Sci Technol 42:180–186. https://doi.org/10.1016/j.lwt.2008.05.017

Deepika K, Gayathri V (2015) Optimization of process parameters on osmotic dehydration of radish slices using response surface methodology (RSM). Int J Pharm Sci Bus Manag 3:1–10

Herman-Lara E, Martínez-Sánchez CE, Pacheco-Angulo H, Carmona-García R, Ruiz-Espinosa H, Ruiz-López I (2013) Mass transfer modeling of equilibrium and dynamic periods during osmotic dehydration of radish in NaCl solutions. Food Bioprod Process 91:216–224. https://doi.org/10.1016/j.fbp.2012.10.001

Turkish Statistical Institute (2019). Statistics of vegetative production, red radish. Web page: https://biruni.tuik.gov.tr/medas/?kn=92&locale=tr Access date: 01.12.2019

Manchali S, Murthy KNC, Patil BS (2012) Crucial facts about health benefits of popular cruciferous vegetables. J Funct Foods 4:94–106. https://doi.org/10.1016/j.jff.2011.08.004

Goyeneche R, Roura S, Ponce A, Vega-Gálvez A, Quispe-Fuentes I, Uribe E, Di Scala K (2015) Chemical characterization and antioxidant capacity of red radish (Raphanus sativus L.) leaves and roots. J Funct Foods 16:256–264. https://doi.org/10.1016/j.jff.2015.04.049

Kumar C, Karim MA (2019) Microwave-convective drying of food materials: a critical review. Crit Rev Food Sci Nutr 59:379–394. https://doi.org/10.1080/10408398.2017.1373269

Feng H, Yin Y, Tang J (2012) Microwave drying of food and agricultural materials: basics and heat and mass transfer modeling. Food Eng Rev 4:89–106. https://doi.org/10.1007/s12393-012-9048-x

Sadeghi M, Mirzabeigi Kesbi O, Mireei SA (2013) Mass transfer characteristics during convective, microwave and combined microwave-convective drying of lemon slices. J Sci Food Agric 93:471–478. https://doi.org/10.1002/jsfa.5786

Zarein M, Samadi SH, Ghobadian B (2015) Investigation of microwave dryer effect on energy efficiency during drying of apple slices. J Saudi Soc Agric Sci 14:41–47. https://doi.org/10.1016/j.jssas.2013.06.002

Süfer Ö, Sezer S, Demir H (2017) Thin layer mathematical modeling of convective, vacuum and microwave drying of intact and brined onion slices. J Food Process Preserv 41:e13239. https://doi.org/10.1111/jfpp.13239

Lee D, So JD, Jung HM, Mo C, Lee SH (2018) Investigation of drying kinetics and color characteristics of white radish strips under microwave drying. J Biosyst Eng 43(3):237–246. https://doi.org/10.5307/JBE.2018.43.3.237

Chavan UD, Amarowicz R (2012) Osmotic dehydration process for preservation of fruits and vegetables. J Food Res 1(2):202–209. https://doi.org/10.5539/jfr.v1n2p202

Yadav AK, Singh SV (2014) Osmotic dehydration of fruits and vegetables: a review. J Food Sci Technol 51(9):1654–1673. https://doi.org/10.1007/s13197-012-0659-2

Madamba PS (2003) Thin layer drying models for osmotically pre-dried young coconut. Dry Technol 21:1759–1780. https://doi.org/10.1081/DRT-120025507

Torringa E, Esveld E, Scheewe I, Van Den Berg R, Bartels P (2001) Osmotic dehydration as a pre-treatment before combined microwave-hot-air drying of mushrooms. J Food Eng 49:185–191. https://doi.org/10.1016/S0260-8774(00)00212-0

Sagar VR, Suresh Kumar P (2010) Recent advances in drying and dehydration of fruits and vegetables: a review. J Food Sci Technol 47:15–26. https://doi.org/10.1007/s13197-010-0010-8

Azimi-Nejadian H, Hoseini SS (2019) Study the effect of microwave power and slices thickness on drying characteristics of potato. Heat Mass Transf 55(10):2921–2930. https://doi.org/10.1007/s00231-019-02633-x

Dasore A, Konijeti R, Puppala N (2019) Experimental investigation and mathematical modeling of convective drying kinetics of white radish. Front Heat Mass Transf 13:21. https://doi.org/10.5098/hmt.13.21

Liu Z, Song Y, Guo Y, Wang H, Liu J (2016) Optimization of pulsed electric field pretreatment parameters for preserving the quality of Raphanus sativus. Dry Technol 34(6):692–702. https://doi.org/10.1080/07373937.2015.1070859

AOAC (1990). AOAC method no 985.29. Official methods of analysis. 15th ed. Arlington: Association of Official Analytical Chemists

Buffler CR (1992). Microwave cooking and processing. New York Van Nostrand Reinhold, ISBN-10-0442008678, New York

Alam MS, Singh A (2010) Optimization of osmotic dehydration process of aonla fruit in salt solution. Int J food Eng 6(1):article 4. https://doi.org/10.2202/1556-3758.1476

Akgun NA, Doymaz I (2005) Modelling of olive cake thin-layer drying process. J Food Eng 68(4):455–461. https://doi.org/10.1016/j.jfoodeng.2004.06.023

Al-Harahsheh M, Al-Muhtaseb AH, Magee TRA (2009) Microwave drying kinetics of tomato pomace: effect of osmotic dehydration. Chem Eng Process Process Intensif 48:524–531. https://doi.org/10.1016/j.cep.2008.06.010

Kassem AS, Shokr AZ, El-Mahdy AR, Aboukarima AM, Hamed EY (2011) Comparison of drying characteristics of Thompson seedless grapes using combined microwave oven and hot air drying. J Saudi Soc Agric Sci 10:33–40. https://doi.org/10.1016/j.jssas.2010.05.001

Bruce DM (1985) Exposed-layer barley drying: three methods fitted to new data up to 150°C. J Agric Eng Res 32:337–347. https://doi.org/10.1016/0021-8634(85)90098-8

Page GE (1949). Factors influencing the maximum rates of air drying shelled corn in thin layers (M.S. thesis). Purdue, USA: Department of Mechanical Engineering, Purdue University

Overhults DG, White HE, Hamilton HE, Ross IJ (1973) Drying soybean with heated air. Trans ASAE 16:112–113. https://doi.org/10.13031/2013.37459

Antal T, Figiel A, Kerekes B, Sikolya L (2011) Effect of drying methods on the quality of the essential oil of spearmint leaves (Mentha spicata L.). Dry Technol 29(15):1836–1844. https://doi.org/10.1080/07373937.2011.606519

Midilli A, Kucuk H, Yapar ZA (2002) A new model for single-layer drying. Dry Technol 20(7):1503–1513. https://doi.org/10.1081/DRT-120005864

Ghazanfari A, Emami S, Tabil LG, Panigrahi S (2006) Thin-layer drying of flax fiber: II. Modeling drying process using semi-theoretical and empirical models. Dry Technol 24(12):1637–1642. https://doi.org/10.1080/07373930601031463

Erbay Z, Icier F (2010) A review of thin-layer drying of foods: theory, modeling, and experimental results. Crit Rev Food Sci Nutr 50(5):441–464. https://doi.org/10.1080/10408390802437063

Henderson SM, Pabis S (1961) Grain drying theory I: temperature effect on drying coefficient. J Agric Eng Res 6:169–174

Karathanos VT (1999) Determination of water content of dried fruits by drying kinetics. J Food Eng 39:337–344. https://doi.org/10.1016/S0260-8774(98)00132-0

Togrul IT, Pehlivan D (2004) Modelling of thin layer drying kinetics of some fruits under open-air sun drying process. J Food Eng 65:413–425. https://doi.org/10.1016/j.jfoodeng.2004.02.001

Henderson SM (1974) Progress in developing the thin-layer drying equation. Trans ASAE 17:1167–1172

Wang CY, Singh RP (1978) Use of variable equilibrium moisture content in modelling rice drying. Trans ASAE 11:668–672

Corzo O, Bracho N, Pereira A, Vasquez A (2008) Weibull distribution for modelling air drying of coroba slices. LWT-Food Sci Technol 41:2023–2028. https://doi.org/10.1016/j.lwt.2008.01.002

Sharma GP, Prasad S (2004) Effective moisture diffusivity of garlic cloves undergoing microwave-convective drying. J Food Eng 65:609–617. https://doi.org/10.1016/j.jfoodeng.2004.02.027

Dalvand MJ, Mohtasebi SS, Rafiee S (2012) Determining the influence of drying conditions on EHD drying process. J Agric Biol Sci 7:396–401

Thompson TL, Peart RM, Foster GH (1968) Mathematical simulation of corn drying - a new model. Trans ASAE 11:582–586

Vega-Gálvez A, Notte-Cuellob E, Lemus-Mondaca R, Zura L, Miranda M (2009) Mathematical modelling of mass transfer during rehydration process of Aloe vera (Aloebarbadensis Miller). Food Bioprod Process 87(4):254–260. https://doi.org/10.1016/j.fbp.2008.10.004

Haghi AK, Angiz FZ (2007). Heat and mass transfer in thermal drying of wool: a theoretical approach. 5th Asia-Pasific drying conference Hong Kong: Japan, 443-448

Lemus-Mondaca R, Miranda M, Grau AA, Briones V, Villalobos R, Vega-Gálvez A (2009) Effect of osmotic pretreatment on hot air drying kinetics and quality of chilean papaya (Carica pubescens). Dry Technol 27(10):1105–1115. https://doi.org/10.1080/07373930903221291

Hii CL, Law CL, Cloke M (2009) Modeling using a new thin layer drying and product quality of cocoa. J Food Eng 90(2):191–198. https://doi.org/10.1016/j.jfoodeng.2008.06.022

Sripinyowanich J, Noomhorm A (2011) A new model and quality of unfrozen and frozen cooked rice dried in a microwave vibro-fluidized bed dryer. Dry Technol 29(7):735–748. https://doi.org/10.1080/07373937.2010.535399

Noomhorn A, Verma LR (1986) Generalized single-layer rice drying models. Trans Am Soc Agric Eng 29(2):587–591

Doymaz I (2006) Thin-layer drying behaviour of mint leaves. J Food Eng 74:370–375. https://doi.org/10.1016/j.jfoodeng.2005.03.009

Goyal RK, Kingsly ARP, Manikantan MR, Ilyas SM (2007) Mathematical modelling of thin layer drying kinetics of plum in a tunnel dryer. J Food Eng 79:176–180. https://doi.org/10.1016/j.jfoodeng.2006.01.041

Doymaz I (2011) Thin-layer drying characteristics of sweet potato slices and mathematical modelling. Heat Mass Transf 47:277–285. https://doi.org/10.1007/s00231-010-0722-3

Sarimeseli A (2011) Microwave drying characteristics of coriander (Coriandrum sativum L.) leaves. Energy Convers Manag 52:1449–1453. https://doi.org/10.1016/j.enconman.2010.10.007

Mota CL, Luciano C, Dias A, Barroca MJ, Guiné RPF (2010) Convective drying of onion: kinetics and nutritional evaluation. Food Bioprod Process 88:115–123. https://doi.org/10.1016/j.fbp.2009.09.004

Dadali G, Ozbek B (2008) Microwave heat treatment of leek: drying kinetic and effective moisture diffusivity. Int J Food Sci Technol 43:1443–1451. https://doi.org/10.1111/j.1365-2621.2007.01688.x

Alibas I (2014) Mathematical modeling of microwave dried celery leaves and determination of the effective moisture diffusivities and activation energy. Food Sci Technol 34:394–401. https://doi.org/10.1590/s0101-20612014005000030

Erbay Z, İçier F (2010) Thin layer drying behaviors of olive leaves (Olea europaea L.). J Food Process Eng 33:287–308. https://doi.org/10.1111/j.1745-4530.2008.00275.x

Coogan RC, Wills RBH (2008) Flavour changes in Asian white radish (Raphanus sativus) produced by different methods of drying and salting. Int J Food Prop 11(2):253–257. https://doi.org/10.1080/10942910701298093

Lech K, Figiel A, Michalska A, Wojdyło A, Nowicka P (2018). The effect of selected fruit juice concentrates used as osmotic agents on the drying kinetics and chemical properties of vacuum-microwave drying of pumpkin. J food Qual 1-11. https://doi.org/10.1155/2018/7293932

Grajales-Lagunes A, Cabrera-Ruız L, Gutıérrez-Mıcelı F, Ruız-Cabrera MA, Dendooven L, Abud-Archıla M (2019) Anthocyanins from blackberry (Rubus fructicosus L.) impregnated in yam bean (Pachyrhizus erosus (L.) Urb.) by osmotic dehydration. Food Sci Technol 39(4):922–929. https://doi.org/10.1590/fst.15618

Tan M, Chua KJ, Mujumdar AS, Chou SK (2007) Effect of osmotic pre-treatment and infrared radiation on drying rate and color changes during drying of potato and pineapple osmotic pre-treatment and infrared radiation. Dry Technol 19(9):2193–2207. https://doi.org/10.1081/DRT-100107494

Maskan M (2000) Microwave/air and microwave finish drying of banana. J Food Eng 44(2):71–78. https://doi.org/10.1016/S0260-8774(99)00167-3

Süfer Ö, Palazoğlu TK (2019) A study on hot air drying of pomegranate: kinetics of dehydration, rehydration and effects on bioactive compounds. J Therm Anal Calorim 137(6):1981–1990. https://doi.org/10.1007/s10973-019-08102-1

Calín-Sanchez Á, Figiel A, Szarycz M, Lech K, Nuncio-Jáuregui N, Carbonell-Barrachina ÁA (2014) Drying kinetics and energy consumption in the dehydration of pomegranate (Punica granatum L.) arils and rind. Food Bioprocess Technol 7:2071–2083. https://doi.org/10.1007/s11947-013-1222-5

Keneni YG, Hvoslef-Eide AKT, Marchetti JM (2019) Mathematical modelling of the drying kinetics of Jatropha curcas L. seeds. Ind Crop Prod 132:12–20. https://doi.org/10.1016/j.indcrop.2019.02.012

Demiray E, Seker A, Tulek Y (2017) Drying kinetics of onion (Allium cepa L.) slices with convective and microwave drying. Heat Mass Transf 53(5):1817–1827. https://doi.org/10.1007/s00231-016-1943-x

İlter I, Akyıl S, Devseren E, Okut D, Koç M, Ertekin FK (2018) Microwave and hot air drying of garlic puree: drying kinetics and quality characteristics. Heat Mass Transf 54:2101–2112. https://doi.org/10.1007/s00231-018-2294-6

Kipcak AS, Doymaz İ (2020). Microwave and infrared drying kinetics and energy consumption of cherry tomatoes. Chem Ind Chem Eng Q (Accepted) https://doi.org/10.2298/CICEQ190916039K

Jebri M, Desmorieux H, Maaloul A, Saadaoui E, Romdhane M (2019) Drying of Salvia officinalis L. by hot air and microwaves: dynamic desorption isotherms, drying kinetics and biochemical quality. Heat Mass Transf 55:1143–1153. https://doi.org/10.1007/s00231-018-2498-9

Kipcak AS (2017) Microwave drying kinetics of mussels (Mytilus edulis). Res Chem Intermed 43(3):1429–1445. https://doi.org/10.1007/s11164-016-2707-4

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of both authors, Özge Süfer declares that there is no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Çınkır, N.İ., Süfer, Ö. Microwave drying of TURKISH red meat (watermelon) radish (RAPHANUS SATIVUS l.): effect of osmotic dehydration, pre-treatment and slice thickness. Heat Mass Transfer 56, 3303–3313 (2020). https://doi.org/10.1007/s00231-020-02930-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-020-02930-w