Abstract

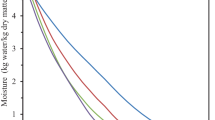

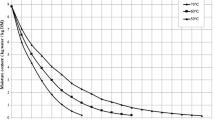

In the present work, the influence of microwave power and samples thickness on drying behavior, moisture diffusivity and energy consumption of potato slices was studied. The slices with thicknesses of 3.5, 5, 7 and 9 mm were dried as mono layers at four different power levels (200, 400, 600 and 800 W). The results showed that the process time was significantly (P < 0.05) decreased with increasing power and decreasing thickness. The curves of moisture removal rate included a short accelerating rate period at the beginning followed by a long falling rate period. Seven thin layer models were practiced to simulate the experimental drying kinetics and the Midilli model showed the best performance. The average values of effective moisture diffusivity were obtained to be in the range of 1.15510−8-6.654 × 10−8 m2 s−1, and increased significantly (P < 0.05) with both of the increasing microwave power and the samples thickness. The average activation energies changed from 1.423 W g−1 to 1.621 W g−1, and decreased with increasing samples thickness. Specific energy consumption for the process were ranged from 0.680 MJ kg−1water to 2.591 MJ kg−1water.

Similar content being viewed by others

Abbreviations

- D:

-

Effective moisture diffusivity (m2 s-1)

- D0 :

-

Arrhenius constant (m2 s-1)

- DR:

-

Drying rate (kg water kg-1dry matter s-1)

- Ea :

-

Activation energy (W kg-1)

- L:

-

Thickness of sample (m)

- m0 :

-

Initial mass of drying sample (kg)

- m:

-

Instantaneous mass of drying sample (kg)

- mw :

-

Mass of removed water (kg)

- M:

-

Moisture content (kg water kg-1dry matter)

- Me :

-

Equilibrium moisture content (kg water kg-1dry matter)

- M0 :

-

Initial moisture content (kg water kg-1dry matter)

- MR:

-

Moisture ratio (-)

- MRexp,i :

-

The i-th experimental moisture ratio (-)

- MRpre,i :

-

The i-th predicted moisture ratio (-)

- \( \overline{MR} \) :

-

Average experimental moisture ratio (-)

- n:

-

Number of observation (-)

- P:

-

Microwave power (W)

- R:

-

Universal gas constant (kJ mol-1 K)

- R2 :

-

Coefficient of determination (-)

- RMSE:

-

Root mean square error (%)

- S:

-

Slope of line (-)

- SEC:

-

Specific energy consumption (kJ kg-1)

- SSE:

-

Sum of squared error (-)

- t:

-

Drying time (s)

- T:

-

Absolute temperature (K)

- φ :

-

Shape dependent constant (-)

References

Torki-Harchegani M, Ghanbarian D, Ghasemi-Pibalouti A, Sadeghi M (2016) Dehydration behaviour, mathematical modelling, energy efficiency and essential oil yield of peppermint leaves undergoing microwave and hot air treatments. Renew Sust Energy Rev 58:407–418

Amiri Chayjan R, Dibagar N, Alaei B (2017) Drying characteristics of zucchini slices under periodic infrared-microwave vacuum conditions. Heat Mass Transf 53:3473–3485

Darvishi H, Mohammadi P, Azadbakht M, Farhudi Z (2018) Effect of different drying conditions on the mass transfer characteristics of kiwi slices. J Agr Sci Tech 20:249–264

Wang J, Xiong YS, Yu Y (2004) Microwave drying characteristics of potato and the effect of different microwave powers on the dried quality of potato. Eur Food Res Technol 219:500–506

Darvishi H, Zarein M, Farhudi Z (2016) Energetic and exergetic performance analysis and modeling of drying kinetics of kiwi slices. J Food Sci Technol 53:2317–2333

Wang J, YS I (2005) Drying characteristics and drying quality of carrot using a two-stage microwave process. J Food Eng 68:505–511

Süfer Ö, Sezar S, Demir H (2017) Thin layer mathematical modeling of convective, vacuum and microwave drying of intact and brined onion slices. J Food Process Preserv. https://doi.org/10.1111/jfpp.13239

Arsalan D, Özcan MM (2010) Study the effect of sun, oven and microwave drying on quality of onion slices. LWT–Food Sci Technol 43:1121–1127

Sutar PP, Prasad S (2007) Modeling microwave vacuum drying kinetics and moisture diffusivity of carrot slices. Dry Technol 25:1695–1702

Harish A, Vivek BS, Sushma R, Monisha J, Krishna Murthy TP (2014) Effect of microwave power and sample thickness on microwave drying kinetics elephant foot yam (Amorphophallus paeoniifolius). Amer J Food Sci Technol 2:28–35

Song XJ, Zhang M, Mujumdar AS, Fan L (2009) Drying characteristics and kinetics of vacuum microwave–dried potato slices. Dry Technol 27:969–974

Dadali G, Apar DK, Özbek B (2007) Microwave drying kinetics of okra. Dry Technol 25:917–924

Demiray E, Tulek Y (2012) Thin-layer drying of tomato (Lycopersicum esculentum Mill. cv. Rio Grande) slices in a convective hot air dryer. Heat Mass Transf 48:841–847

Torki-Harchegani M, Ghasemi-Varnamkhasti M, Ghanbarian D, Sadeghi M, Tohidi M (2016) Dehydration characteristics and mathematical modelling of lemon slices drying undergoing oven treatment. Heat Mass Transf 52:281–289

Hii CL, Law CL, Cloke M (2009) Modeling using a new thin layer drying model and product quality of cocoa. J Food Eng 90:191–198

Sadeghi M, Mirzabeigi Kesbi O, Mireei SA (2013) Mass transfer characteristics during convective, microwave and combined microwave-convective drying of lemon slices. J Sci Food Agric 93:471–478

Beigi M (2016) Influence of drying air parameters on mass transfer characteristics of apple slices. Heat Mass Transf 52:223–2221

Ghanbarian D, Baraani Dastjerdi M, Torki-Harchegani M (2016) Mass transfer characteristics of bisporus mushroom (Agaricus bisporus) slices during convective hot air drying. Heat Mass Transf 52:1081–1088

Ju HY, El-Mashad HM, Fang XM, Pan Z, Xiao HW, Liu YH, Gao ZJ (2016) Drying characteristics and modeling of yam slices under different relative humidity conditions. Dry Technol 34:296–306

Beigi M (2017) Thin layer drying of wormwood (Artemisia absinthium L.) leaves: dehydration characteristics, rehydration capacity and energy. Heat Mass Transf 53:2711–2718

Beigi M (2017) Numerical simulation of potato slices drying using a two-dimensional finite element model. Chem Ind Chem Eng Q 23:431–440

Jahedi Rad S, Kaveh M, Rasooli Sharabiani V, Taghinezhad E (2018) Fuzzy logic, artificial neural network and mathematical model for prediction of white mulberry drying kinetics. Heat Mass Transf 54:3361–3374

Torki-Harchegani M, Ghanbarian D, Sadeghi M (2015) Estimation of whole lemon mass transfer parameters during hot air drying using different modelling methods. Heat Mass Transf 51:1121–1129

Lu L, Tang J, Ran X (1999) Temperature and moisture changes during microwave drying of sliced food. Dry Technol 17:413–432

Dadali G, Özbek B (2008) Microwave heat treatment of leek: drying kinetic and effective moisture diffusivity. Int J Food Sci Technol 43:1443–1451

Amiri Chayjan R, Kaveh M, Khayati S (2015) Modeling drying characteristics of hawthorn fruit under microwave-convective conditions. J Food Process Preserv 39:239–253

Olanipekun BF, Tunde-Akintunde TY, Oyelade OJ, Adebisi MG, Adenaya TA (2015) Mathematical modeling of thin-layer pineapple drying. J Food Process Preserv 39:1431–1441

Darvishi H (2012) Energy consumption and mathematical modeling of microwave drying of potato slices. Agric Eng Int CIGR J 14:94–102

Murthy TPK, Manohar B (2012) Microwave drying of mango ginger (Curcuma amada Roxb): prediction of drying kinetics by mathematical modelling and artificial neural network. Int J Food Sci Technol 47:1229–1236

Onwude DI, Hashim N, Abdan K, Janius R, Chen G (2018) Modelling the mid-infrared drying of sweet potato: kinetics, mass and heat transfer parameters, and energy consumption. Heat Mass Transf 54:2917–2933

Hafezi N, Sheikhdavoodi MJ, Sajadiye SM (2015) The effect of drying kinetic on shrinkage and colour of potato slices in the vacuum- infrared drying method. Int J Agric Food Res 4:24–31

Esehaghbeygi A, Pirnazar K, Sadeghi M (2014) Quality assessment of electro-hydrodynamic and microwave dehydrated banana slices. LWT–Food Sci Technol 55:565–571

Beigi M (2017) Mathematical modelling and determination of mass transfer characteristics of celeriac slices. Period Plytech Chem Eng 61:109–116

Amiri Chayjan R (2012) Modeling some drying characteristics of high moisture potato slices in fixed, semi fluidized and fluidized bed conditions. J Agr Sci Tech 14:1229–1241

Evin D (2011) Microwave drying and moisture diffusivity of white mulberry: experimental and mathematical modelling. J Mech Sci Technol 25:2711–2718

Markowski M, Bondaruk J, Błaszczak W (2009) Rehydration behavior of vacuum-microwave-dried potato cubes. Dry Technol 27:296–305

Srikiatden J, Roberts JS (2006) Measuring moisture diffusivity of potato and carrot (core and cortex) during convective hot air and isothermal drying. J Food Eng 74:143–152

Reyes A, Moyano P, Paz J (2007) Drying of potato slices in a pulsed fluidized bed. Dry Technol 25:581–590

Doymaz I (2011) Thin-layer drying characteristics of sweet potato slices and mathematical modelling. Heat Mass Transf 47:277–285

Nguyen MH, Price WE (2007) Air-drying of banana: influence of experimental parameters, slab thickness, banana maturity and harvesting season. J Food Eng 79:200–207

Darvishi H, Khoshtaghaza MH, Najafi G, Nargesi F (2013) Mathematical modeling of green pepper drying in microwave-convective dryer. J Agr Sci Tech 15:457–465

Beigi M (2018) Effect of infrared drying power on dehydration characteristics, energy consumption, and quality attributes of common wormwood (Artemisia absinthium L.) leaves. J Agr Sci Tech 20:709–718

Barzegar M, Zare D, Stroshine RL (2015) An integrated energy and quality approach to optimization of green peas drying in a hot air infrared-assisted vibratory bed dryer. J Food Eng 166:302–315

Khoshtaghaza MH, Darvishi H, Minaei S (2015) Effects of microwave-fluidized bed drying on quality, energy consumption and drying kinetics of soybean kernels. J Food Sci Technol 52:4749–4760

Soysal Y (2009) Intermittent and continuous microwave-convective air drying of potato (lady rosetta): drying kinetics, energy consumption and product quality. J Agric Machin Sci 5:139–148

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Azimi-Nejadian, H., Hoseini, S.S. Study the effect of microwave power and slices thickness on drying characteristics of potato. Heat Mass Transfer 55, 2921–2930 (2019). https://doi.org/10.1007/s00231-019-02633-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-019-02633-x