Abstract

Yacón root is a natural source of fructans, which has many potential benefits. Convective drying has been applied to increase the shelf life of yacón roots. However, this processing may lead to detrimental effects on the physicochemical functionality. The drying was investigated using different conditions (drying temperatures of 45 °C, 50 °C and 55 °C at a drying air velocity of 2 m/s and 60 °C at a drying air velocity of 2 m/s, 3 m/s and 4 m/s). The dried samples were compared to the original yacón with regard to their physicochemical properties. From all the properties that were studied, the color of the dried material and the elastic modulus of the reconstituted yacón were the most important properties being minimized respectively. The results of this investigation indicate that the best drying conditions, where the physicochemical properties of the samples are kept closest to the original material, are obtained either by using temperatures of 55 °C and 2 m/s or using higher temperatures but increasing the air velocity.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Improved healthy aspects of food products is a well established trend in the food industry, and one of the identified aspects is the need to enhance the intake of dietary fibers. Dietary fibers are defined as polysaccharides and lignins that are non-digestible in the intestinal tract. These components provide different functional properties when applied in food products as they can modify or improve the texture and shelf life of foods [1].

One of the components of dietary fibers, the inulin-type fructans, has received particular attention due to their ability to interact with the texture properties of food products [2, 3]. Inulin-type fructans are linear poly carbohydrates consisting of β (2 ← 1) fructosyl-fructose linkages [4]. They provide properties such as the ability to increase the absorption of calcium and magnesium [5]. They also present prebiotic properties due to their capacity to stimulate the growth of beneficial and decreasing the growth of harmful bacteria in the intestine [6].

Yacón (Smallanthus sonchifolius) is a natural source of inulin-type fructans, and it grows in the Central Andean regions limiting with the Amazon basin between 1800 and 3500 m above sea level, and it is cultivated especially in countries like Bolivia, Peru, Ecuador, and Argentina. Yacón, a member of the sunflower family (Asteraceae), is a perennial plant that grows up to 1.5 to 2.5 m and produces large tuberous roots. The roots have different tissue colors: white, yellow, orange, and purple depending on the variety of the plant and the region where it grows [7].

Fruits and vegetables that are dried change many quality properties like the loss of vitamins and other nutrients, alterations in color and texture, density and porosity but these losses are highly dependent on the condition and the method of drying [8]. The shrinkage and toughness of the dried product are increased when the drying of the product is extended possibly leading to reducing rehydration capacity [9]. The effect in the rehydration capacity is possibly produced because the water loss creates cracks when leaving the drying material that produces structural damage in the food material [10].

Convection drying is a drying process in which the material receives heat from the air flow. The increase of the temperature in the material is related to the difference between the temperature of the air flow and the surface of the material. Convection drying presents advantages like providing control of the temperature of drying. However, the problem is when the drying reaches a low amount of moisture in the material, the rate of moisture loss begins to decrease and the rest of the drying time that can be long is spent trying to eliminate the last remains of moisture [9].

The objective is to describe the sensitivity of the physicochemical functionality towards the drying parameters of convective drying of yacón.

2 Material and methods

2.1 Preparation of yacón paste

The measurement devices and accessories used during the experiments and their technical specifications are given in Table 1.

Yacón roots with orange tissue were purchased from a local market in the city of La Paz that were cultivated from the region of Sorata, Bolivia on three different months of the year (from April to August). The roots were washed, peeled under distilled water with ascorbic acid for 1 min to avoid oxidation. The material was cut into small pieces and minced in an Oster® blender (Model: 4172–051, Mexico) to obtain a yacón paste. Ascorbic acid (3 g/l disintegrated material) was added as an antioxidant while the root was minced. The yacón paste was stored at -20 °C in many polypropylene containers of 100 mL between 3 and 7 days. To perform the experiments the yacón sample was thawed at room temperature for at least two hours.

2.2 Drying methodology

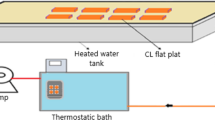

Samples of 100 g of yacón paste were weighed in a Petri dish (diameter = 14 cm, height = 2 cm) and spread. The average thickness of the sample inside the Petri dish was 3 mm. The sample was put into a convective drying tunnel oven according to Skjöldebrand [11] with only the upper surface of the sample in contact with the flow of air (Fig. 1). The relative humidity of the drying chamber is low. It is determined by the humidity in the air outside the cabinet and it becomes between 6 to 13% depending of the drying temperature (45 °C and 60 °C respectively). Six different experiments were carried out for three yacón samples: four at different temperatures (45 °C, 50 °C, 55 °C, 60 °C) with an air velocity of 2 m/s and two experiments with a temperature of 60 °C using different air velocities (3 m/s, 4 m/s). The experiments were run in duplicate.

During each drying procedure, the weight of the sample and sample holder was recorded every minute until the end of the drying process. The end of the drying was established when the sample reached a constant weight. After completed drying, the samples were kept at room temperature completely sealed in polypropylene containers.

The drying rate and the extent of drying were followed by measuring the free moisture representing the amount of moisture present in the void spaces of the sample [12] and is represented by the eq. (1):

Where maq in the sample is the amount of water remaining after drying at a certain time, and mS represents the total solids in the sample that can be found using the dry matter of the undried yacón.

2.3 Characterization of the dried samples of the yacón

2.3.1 Determination of dry matter, water activity and color of the dried samples

For the determination of the dry matter (DM) one gram of the different dried materials obtained was dried in a vacuum oven at 70 °C for 16 h and then weighed to obtain the dry matter of the dried samples. The results are expressed as g dry matter (DM)/100 g sample.

The water activity was measured using a water activity meter (Aqua Lab series 3) with a cooled mirror condensation detector. About one gram of each dried sample was put in a cup (d = 4 cm, h = 1 cm) in a uniform way and applied into the sample drawer of the water activity meter around 4 to 5 min per sample.

The color (CIE Lab color space) of the dried material was measured using a colorimeter (Chromameter CR-400, Konica Minolta) over the homogeneous surface of one gram of dried yacón sample without any treatment. It measures the parameters L*, a* and b* to describe the color. Parameter (L*) expresses the lightness of the sample and changes from dark (0–50) to light (51–100). Parameters (a*) and (b*) do not present specific limits. Parameter (a*) expresses the perceived red/green color balance of the sample; negative values indicate green and positive values indicate red. Parameter (b*) expresses the perceived yellow/blue color balance of the sample, where negative values indicate blue and positive values indicate yellow. For all the characterization of the dried samples, two replicates were used.

2.4 Characterization of the original and reconstituted yacón paste

2.4.1 Reconstitution of the dried samples into a paste

The dried samples were reconstituted with pure water at a volume of 40 mL to the same dry matter (10.85%, 14.43%, and 11.94%) as the raw yacón paste from which they originated. After mixing using a magnetic stirrer, the samples were allowed to equilibrate for approximately one hour at room temperature before any measurements were performed.

2.4.2 Determination of water-insoluble solids and soluble solids of the pastes

Two grams of yacón paste was suspended in 10 mL of distilled water to determine the water-insoluble solids (WIS) of the original and the reconstituted paste. The mix was centrifuged at 3000 x g for 20 min at 20 °C (Allegra X-1512, Beckman Coulter Inc. USA). The supernatant was filtered (paper filter 1F, Munktell Filter AB, Sweden) to recollect any residue in the suspension. The residue was washed out of any sugar repeatedly using distilled water until the washing liquid had a refractive index of about zero. The residue was dried in an oven at 105 °C for 16 h and then weighed. The results are expressed as g WIS/100 g dry matter. The total water-soluble solids (WSS) were determined by drying all the supernatants collected from the water-insoluble solids measurements in an oven at 105 °C for 16 h and then weighed. The results are expressed as g WSS/100 g dry matter and both the determination of WIS and WSS were performed in duplicate.

2.4.3 Particle size distribution of the yacón paste

The particle size distribution (PSD) of the solids of the different yacón pastes (refractive index of the suspension = 1.339) was measured using a laser diffraction analyzer (Malvern Mastersizer Hydro 2000 SM) in the 0.1–1000 μm interval and performed in duplicate. The most common descriptions of the particle size distribution are given as the surface-weighted mean (d32) and the volume-weighted mean (d43). The parameters d32 and d43 are calculated using the following equations:

where i is the index of population and d is the particle diameter of population i.

2.4.4 Rheological properties of the yacón paste

A controlled-stress rheometer (Malvern Kinexus Pro) equipped with a four blade vane geometry (d = 21 mm, height = 45 mm) giving a gap of 3 mm was used to perform the sinusoidal oscillatory tests. The purpose of using the vane geometry is to eliminate the slip phenomenon. The linear viscoelastic region, defined as the initial linear part (LVR) when applying a stress sweep test from 0.02 to 100 Pa at 1 Hz at 20 °C was determined. The measurements were performed in duplicate.

2.4.5 Determination of inulin-type fructans content in the yacón paste

The content of inulin-type fructans in the yacón paste was determined by applying an enzymatic method described by Steegmans et al. [13]. The total content of inulin-type fructans is expressed as g inulin-type fructans/100 g dry matter. The measurements were performed in duplicate.

2.5 Statistical analysis

The results were statistically treated using one-way analysis of variance (ANOVA, p < 0.05) using one of the three design parameters (yacón sample, drying temperature and air velocity). The correlations between properties were determined by using the Pearson correlation coefficient. Principal Component Analysis (PCA) was performed having two principal components showing loading plots and score plots. Minitab® 14.1.0.0 was used for statistical analysis, graphics and data processing. The precision of measurements is estimated from the variation between replicates.

3 Results and discussion

3.1 The drying procedure of yacón

The average drying curves of the samples are shown in Fig. 2.The average standard deviation of each point in the curve varied from 0.2 to 0.8. It can be noted that the higher the temperature, the steeper the drying curves, which is in accordance with the results of drying carrots as given by Prabhanjan et al. [14] and the results of drying tomato slices as given by Coşkun et al. [15].

The time necessary to dry the sample decreased when the drying temperature increased (see Fig. 2). This is because higher temperatures provides larger heat flux, higher water vapor carrying capacity and a larger water vapor activity gradient. The increase of air velocity in the samples at the same temperature (60 °C) also enhances the rate of drying, because air is responsible for the transfer of the heat as well of the evaporating water from the sample during the drying.

Before the drying, the moisture content of the different yacón was around 88%. The moisture content was calculated using the dry matter of the yacón samples. During the drying process the critical moisture concentration was reached after the removal of the majority of water (free moisture ≈ 0). During this latter part of the drying, the removal of hygroscopic moisture begins, but the quantity of the water remaining is usually low. The first section of the drying is faster than after reaching the critical moisture concentration [9]. The moisture content after the drying of yacón samples are between 13% and 4% depending of the drying temperature and air velocity used. By analyzing the drying curves, we can obtain the drying time and the drying rate. The drying rate represents the amount of free moisture per unit of time and is obtained from the first steep slope of the curves given in Fig. 2. The drying time is read off when reaching the critical moisture concentration.

The effects of the drying parameters, such as drying temperature and air velocity, on the drying time and the drying rate can be seen in Tables 2 and 3 using one-way ANOVA.

From the results presented, the drying time is significantly influenced by both the drying temperature and the air velocity. Similar observations were found in studies in which both the air velocity and temperature during the drying had a significant influence on the drying time of garlic slices [16] and bananas [9]. For instance, the drying times of bananas were about 520 and 320 min at 50 °C and 70 °C, respectively, using an air velocity of 3.3 m/s [9]. Comparing these results with the drying time of yacón at 50 °C and 60 °C using 2 m/s, the drying time of yacón is quicker than the drying time of banana when considering that the bananas were dried using a higher air velocity. Prabhanjan et al. [14] obtained a drying time of 390 min at 45 °C and 90 min at 60 °C during convective air drying of carrots at an air velocity of 1.7 m/s and these drying times were significantly lower in comparison with those of yacón achieved in this investigation especially at the higher drying temperatures.

The drying temperature was the only variable that significantly increased the drying rate. The drying rate of the yacon samples were (0.028 min−1 at 50 °C and 0.036 min−1 at 60 °C using an air velocity of 2 m/s) where the drying rate of bananas [9] was lower (0.001 min−1 at 50 °C and 0.003 min−1 at 70 °C using an air velocity of 3.3 m/s). This similar trend was also observed in Mohan [17] and Darıcı [18].

The air velocity helps to reduce the drying time, but its effect is less significant than the temperature. Krokida et al. [19] obtained similar results on the influence of air velocity when drying different types of vegetables.

3.2 Characterization of the dried samples

Dry matter, water activity and color (L*, a* and b*) was performed in yacón samples before drying (Table 4) and from the dried yacón obtained at different drying conditions (Tables 5, 6 and 7).

The initial dry matter of yacón before drying varies between 10.8 and 14.4 g/100 g sample. In Table 5, the dry matter of dried material is about 92 g/100 g for the different samples, which tells us that the dried sample preserves about 8% of internal water after the drying procedure. The water activity, aw, is also low enough for good preservation of the dried samples. The type of yacón significantly influences the water activity, in where yacón 1 had the lowest value. With regard to the color in the different samples of yacón before and after the drying there is an increment in all the parameters (L*, a* and b*) after drying. The increase is higher with regard to the values of a* and b* which is observed in a darker coloration in the dried samples (Fig. 3).

In Table 6, the dry matter of the yacón dried samples increases with temperature, reaching the highest value of 93 g/100 g sample at 60 °C and this effect is significant. Similar effects of the drying temperature on the dry matter have also been seen for the drying of fruits like the Tunisian dates by Borchani et al. [20]. The drying temperature significantly influences the water activity giving the lowest value at the highest temperature. The effect of the temperature on the water activity was similar to that of powders of different date varieties [20].

The color of the dried samples is a visual representation of the effect of the different drying conditions. The drying temperature does not significantly influence lightness (L*) [21], but the yellowness (b*) and redness (a*) is enhanced in the dried samples with drying temperature. The drying of savory leaves by Nikjooy and Hashemi [22] showed there is an effect of rising the temperature on the color of the dry material particularly at the highest temperatures similar to the results obtained here for yacon. After the drying, the samples acquire a strong orange color (high a* and b* values). This change of color might be produced by oxidation, Maillard, and caramelization reactions [23] resulting in the formation of colored substances induced by the high temperatures that are applied to a food product for a longer period.

In Table 7, the dry matter significantly increased by the air velocity, whereas the air velocity did not significantly influence the water activity.

Although the air velocity does not seem to influence the majority of the color parameters significantly except for (b*), there is still a reduction of the drying time on increasing air velocity, thereby lowering the probability of reactions taking place that will change the properties of the color of the sample. This effect of the drying conditions (temperature and air velocity) can be observed in Fig. 4 by analyzing the parameter (a*).

3.3 Characterization of the reconstituted yacón

The three types of fresh yacón used for the drying procedures were characterized by evaluation of the chemical parameters (WIS, WSS, and FOS), structural (particle size d32 and d43) and rheological (elastic modulus) parameters (Table 8).

In Table 8 the physicochemical properties of the yacon before drying is shown. Yacón 1 represents the least amount of water-insoluble solids but has the highest content of fructooligosaccharides, whereas yacón 2 has the largest water insoluble content and the highest elastic module of all the samples. In the case of yacón 1, which has the least amount of water-insoluble solids, the value of the elastic module is the lowest. All the measured properties of the three original yacons were significantly different.

The results of the characterization of the reconstituted yacón prepared from the dried samples obtained from the drying were analyzed in the same way as the original yacón pastes, i.e. chemically, structurally and rheologically. The results were further analyzed using one-way ANOVA to allow us to describe the properties as a function of the design parameters: yacón type, drying temperature and drying air velocity (see Tables 9, 10 and 11).

It is interesting to compare the properties of the dried and reconstituted yacon (Table 9) with the fresh yacon (Table 8). It can be observed that by drying yacon there is a substantial loss in WIS, elastic modulus, and FOS. This is especially pronounced for yacon 2, which after drying has the lowest WIS and elastic modulus among the three tested yacons, whereas the same yacon 2 is the one with the highest WIS and elastic modulus when being fresh. The smallest particles (d32) do not change much on drying, whereas the larger ones (d43) increase somewhat. The reason for this behavior on drying can be due to cellular breakdown and further disintegration of the cellular wall causing mainly a loss in WIS and consistency of the paste.

In Table 10, it can be observed that the amount of water-insoluble solids increased significantly with the drying temperature but decreased again at the highest temperature of 60 °C. Huang et al. [24] found a similar behavior related to the insoluble solids working with the drying of citrus by-products with temperatures of 50 °C, 60 °C and 70 °C. This different behavior at the highest temperature of 60 °C might be produced by a loosening of pectin and cell wall structures that can occur at this high temperature thereby increasing their solubility [24].

Both parameters of the particle size distribution (d32 and d43) are not significantly influenced by the air velocity or by the drying temperature.

The drying temperature has not a significant influence on the rheological behavior. However, it can be observed that amount of water-insoluble solids and elastic modulus change similarly, and the drying temperature significantly influences the WIS. Thus, the temperature has an indirect influence on the loss of texture.

The influence of the air velocity at 60 °C on the physicochemical properties of the reconstituted samples is shown in Table 11. Although the air velocity has no significant influence on the physicochemical properties, there is a tendency that an increase in the air velocity reduces the loss of water-insoluble solids and increases the elastic modulus (this is almost significant).

Figure 5 shows the behavior of the elastic modulus at different drying conditions, where yacón samples at 60 °C and 2 m/s had the lowest value of elastic modulus, but by increasing the air velocity the elastic modulus started to increase again up to the highest level of all the dried samples.

3.4 Relationship between properties

We can analyze the correlation between the physicochemical properties of the dried and reconstituted yacón statistically by using Principal Component Analysis (PCA), and the results are presented in a loading plot and a score plot (Figs. 6 and 7).

There is a positive correlation between water-insoluble solids and elastic modulus using Pearson coefficient correlation (r = 0.940, p = 0.005). Another correlation between water activity and the elastic modulus (r = 0.972, p = 0.001) observed using Pearson coefficient correlation, suggests that with a better network of the yacón suspension the better the water is held in the network.

In the loading plot (Fig. 6), the principal component 1 (PC1) explains 60% of the variation, and the principal component 2 (PC2) explains 22% of the variation, respectively. There are positive correlations between many physicochemical properties, especially between water insoluble solids (WIS) and the elastic modulus. The parameter d43 presents a positive correlation with WIS and elastic modulus, and for the latter, the values of the Pearson coefficient correlation are r = 0.543, p = 0.000, whereas those between d43 and WIS are r = 0.703, p = 0.000. This latter relationship suggests that when WIS and the elastic modulus of the reconstituted paste are higher, the insoluble part is more aggregated (a higher d43).

Analyzing the score plot of the principal component analysis (Fig. 7) and taking into consideration the loading plot, we observe tendencies between the different drying conditions. Most of the samples dried at 55 °C, 2 m/s and at 60 °C, 4 m/s are similar and tend to present high values of the elastic modulus and water-insoluble solids. The samples dried at 60 °C, 2 m/s, which have the lowest value of water-insoluble solids and elastic modulus are dissimilar with the samples dried at 55 °C, 2 m/s and at 60 °C, 4 m/s, and those scores are mostly concentrated in the upper left corner opposite to the high elastic modulus and WIS.

4 Conclusions

Yacón roots have great potential for application in the food industry for its content of fructo oligosaccharides but the high content of water in yacón roots makes it difficult to preserve the root for a longer period of time. Drying is a suitable way to preserve yacón roots as it easily allows for a reduction of the water so a range of water activity of 0.3 to 0.5 is achieved.

According to the results, it is best to dry yacón when aiming for a minimal alteration of the overall physicochemical properties either by using relatively high temperatures of 55 °C and 2 m/s or the highest temperature of 60 °C but then with a higher air velocity of 4 m/s. Evidently, the higher the drying temperature the faster the drying of the yacón and thereby avoiding alterations of the overall physicochemical properties. This does not hold, however, for a drying temperature of 60 °C, where detrimental effects in the properties of yacón occur. Increasing the air velocity from 2 to 4 m/s helps to decrease the detrimental effects in the properties of yacón when a temperature of 60 °C is used.

Besides, by analyzing both the PCA and the Pearson coefficient correlation, it can be observed that many properties in the yacón, i.e. water insoluble solids and elastic modulus, correlate well with each other.

In conclusion, even for the drying conditions that show properties of the dried yacón more similar to the fresh sample, there is always a loss in some of the physicochemical properties of yacón, after drying.

Abbreviations

- FOS:

-

Fructo oligosaccharides

- Xaq :

-

Free moisture

- maq :

-

The amount of water remaining after drying at a certain time

- ms:

-

Total solids in the sample

- DM:

-

Dry matter

- WIS:

-

Water insoluble solids

- WSS:

-

Water soluble solids

- d32 :

-

Surface-weighted mean of the particle size

- d43 :

-

Volume-weighted mean of the particle size

- i:

-

Index of population

- di :

-

Particle diameter of population i

- L:

-

Lightness

- a:

-

Green/red color component

- b:

-

Blue/yellow color component

- aw:

-

Water activity

- F:

-

variation between sample means

- p:

-

Significance

- PC1:

-

Principal Component 1

- PC2:

-

Principal Component 2

References

Yangilar F (2013) The application of dietary fibre in food industry: Structural features, effects on health and definition, obtaining and analysis of dietary fibre: A review. Journal of Food and Nutrition Research 1(3):13–23

Bodner JM, Sieg J (2009) Fiber. In: Tarte R (ed) Ingredients in meat products. Springer, New York, pp 83–109

Castro A, Céspedes G, Carballo S, Bergenståhl B, Tornberg E (2013) Dietary fiber, fructooligosaccharides, and physicochemical properties of homogenized aqueous suspensions of yacón (Smallanthus sonchifolius). Food Res Int 50(1):392–400

Roberfroid MB (2007) Inulin-type fructans: Functional food ingredients. J Nutr 137:2493S–2502S

Sabater-Molina M, Larque E, Torrella F, Zamora S (2009) Dietary fructooligosaccharides and potential benefits on health. J Physiol Biochem 65(3):315–328

Seminario J, Valderrama M, Manrique I (2003) El yacón: Fundamentos para el aprovechamiento de un recurso promisorio. Centro Internacional de la Papa (CIP), Universidad Nacional de Cajamarca, Agencia Suiza para el Desarrollo y la Cooperacion (COSUDE), Lima

Grau A, Rea J (1997) Yacon. Smallanthus sonchifolius (Poepp. & Endl.) H. Robinson. In: M. H, J. H (eds) Andean roots and tuberous roots: Ahipa, Arracacha, Maca and Yacon. Promoting the conservation and use of underulitized crops. International Plant Genetic Resource Institute, Rome, pp 199–256

Sablani SS (2006) Drying of fruits and vegetables: Retention of nutritional/functional quality. Dry Technol 24(2):123–135

Pereira NR, Marsaioli A, Ahrné LM (2007) Effect of microwave power, air velocity and temperature on the final drying of osmotically dehydrated bananas. J Food Eng 81(1):79–87

Krokida MK, Maroulis ZB (1997) Effect of drying method on shrinkage and porosity. Dry Technol 15(10):2441–2458

Skjöldebrand C (1980) Convection oven frying: Heat and mass transfer between air and product. J Food Sci 45(5):1354–1358

Heldman D, Lund DB (2006) Handbook of Food Engineering CRC Press. York, New

Steegmans M, Iliaens S, Hoebregs H (2004) Enzymatic, spectrophotometric determination of glucose, fructose, sucrose, and inulin/oligofructose in foods. J AOAC Int 87(5):1200–1207

Prabhanjan DG, Ramaswamy HS, Raghavan GSV (1995) Microwave-assisted convective air drying of thin layer carots. J Food Eng 25(2):283–293

Coşkun S, Doymaz İ, Tunçkal C, Erdoğan S (2016) Investigation of drying kinetics of tomato slices dried by using a closed loop heat pump dryer. Heat Mass Transf 53(6):1863–1871

Demiray E, Tulek Y (2014) Drying characteristics of garlic (Allium sativum L) slices in a convective hot air dryer. Heat Mass Transf 50(6):779–786

Mohan VPC, Talukdar P (2012) Design of an experimental set up for convective drying: experimental studies at different drying temperature. Heat Mass Transf 49(1):31–40

Darıcı S, Şen S (2015) Experimental investigation of convective drying kinetics of kiwi under different conditions. Heat Mass Transf 51(8):1167–1176

Krokida MK, Karathanos VT, Maroulis ZB, Marinos-Kouris D (2003) Drying kinetics of some vegetables. J Food Eng 59(4):391–403

Borchani C, Besbes S, Masmoudi M, Bouaziz MA, Blecker C, Attia H (2011) Influence of oven-drying temperature on physicochemical and functional properties of date fibre concentrates. Food Bioprocess Technol 5(5):1541–1551

Beigi M (2015) Hot air drying of apple slices: dehydration characteristics and quality assessment. Heat Mass Transf 52(8):1435–1442

Nikjooy S, Hasemi SH (2014) The effect of drying conditions on the color of savory (Satureia hortensis) leaves. International Journal of Agriculture and Crop Sciences 7(5):225–229

Bonazzi C, Dumoulin E (2011) Quality changes in food materials as influenced by drying processes. In: Tsotsas E, Mujumdar AS (eds) Modern drying technology, 1st edn. Wiley-VCH & Verlag GmbH & Co. KGaA, Weinheim, pp 1–20

Huang X, Wang K, Yang F, Yi T (2014) Influence of drying methods on the functional properties of dietary fiber. J Chem Pharm Res 6(6):2887–2894

Acknowledgements

The authors wish to thank the Swedish International Development Cooperation Agency (SIDA/SAREC) for their financial support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Salinas, J.G., Alvarado, J.A., Bergenståhl, B. et al. The influence of convection drying on the physicochemical properties of yacón (Smallanthus sonchifolius). Heat Mass Transfer 54, 2951–2961 (2018). https://doi.org/10.1007/s00231-018-2334-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-018-2334-2