Abstract

Plant-based hydrocolloid systems which are mixed with different carbohydrate types are becoming popular due to vegan concerns for both non-food and food industry. In this study, different sugar types (d-allulose and sucrose) at different concentrations (20% and 40%) were used to explore their effects on the gelation and physical properties of agar–agar. For characterization of these agar–agar-based gel systems, in addition to common physical methods (moisture content, water activity, color, hardness, viscosity), novel methods such as TD-NMR relaxometry, and FTIR were also used to get deep insight of the microstructures and water dynamics of the gel systems. Results clearly indicated that sugar type and concentration were vital factors affecting the agar–agar gel properties and dynamics of the system. Utilization of allulose in the gel systems led to formation of less moist and softer agar–agar matrix characterized with longer T2 spin–spin relaxation times. This study will lead to designing new types of vegan agar–agar-based confectionery products such as soft candies that are considered as perfect composite gels.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Hydrocolloids are one of the commonly used ingredients in the food industry to enhance final product quality, to improve food texture [1]. They could function as thickening, gelling agent or stabilizers in different food products. Confectionery gels include high amounts of sugar content such as sucrose and glucose syrup, varying kind of gelling agents like starch or gelatin along with food colorings and flavorings [2]. Although gelatin is one of the most preferred gelling agent in sugar confectionery products with good water solubility, adhesiveness, good transparency, a certain consumer group does not choose to consume it due to its animal origin [3]. At this point, agar could be seen as a perfect plant-based alternative to gelatin for soft candy production.

Agar is extracted from the cell walls of agarophyte red algae and can be divided into two main compounds, agarose, and agaropectin [4]. While agarose is a linear polysaccharide with repeating β-1, 3-linked d-galactose-α-1, 4-linked 3, 6-anhydro-l-galactose disaccharide, agaropectin is a heterogeneous mixture of smaller molecules. Agar forms a thermo-reversible gel proposing a healthier polysaccharide alternative compared to other gelling agents containing higher cholesterol and caloric contents.

Other than vegan concerns, high sugar intake is another recent issue in confectionery industry. There are so many attempts to reduce sugar consumption and the use of low and non-calorie sweeteners instead of sucrose is one of the solutions. However, it is crucial to provide desirable food properties after replacing sucrose. Recently, it has been demonstrated that rare sugar, d-allulose (a type of monosaccharide found in nature in small amounts) has displayed satisfied characteristics depending on rheological and processing properties of the confectionary products, showing positive health effects at the same time [5]. d-Allulose can be naturally found in sugar cane or wheat, as well as in blend of fructose and glucose syrups in trace amounts [6]. d-Allulose (C-3 epimer of fructose) as a rare sugar has 70% sweetness of sucrose at a lower caloric value of 0.39 kcal/g due to the poor digestion and it has been proposed as a sucrose substitute in confectionery products [7]. Since sugar type influences textural features of the food owing to differences in water binding ability, any change in the kind of sugar could affect final quality. Such kind of water, sugar, and polymer interactions could also be examined by time-domain nuclear magnetic resonance (TD-NMR) experiments. The signal in NMR comes from protons in a sample, so the mobility and distribution of protons give information about food internal structure particularly by measuring T2 (spin–spin or transverse relaxation time constant). Water dynamics within hydrogel or other food systems were previously conducted by TD-NMR in the literature [8]. In addition, there are some studies comparing water binding properties of d-allulose with other monosaccharides in confectionery products such as gelatin-based soft candies [5], soy-protein-added pectin gels [9]. However, they mostly focused on complex systems in the presence of gelatin, pectin, and corn syrup, and they have not been studied on vegan-based formulation only in the presence of agar–agar.

The objective of this study was to explore the interaction between d-allulose and agar with the help of NMR relaxometry measurements in the gel matrix. The addition of sucrose and d-allulose into agar gel as a well-defined model system rather than real food was investigated with competing interactions. The results were compared with the sample including sucrose instead of rare sugar at varying ratios. Gel properties were also analyzed in terms of moisture content, water activity, color, Fourier transform infrared spectroscopy (FTIR), and Time-domain (TD) NMR relaxometry experiments.

Materials and methods

Materials

Agar–agar powder was purchased from Smart Kimya with the brand name Tito. Sucrose (Torku, Konya, Turkey) was purchased from a local market in Konya, Turkey. d-Allulose (All-u-Lose) was purchased from Santiva Inc. Downers Grove, IL, USA.

Methods

Preparation of the gel samples

Agar–agar gels including different types of sugar were formulated according to previous study with some modifications [1]. 2% (w/v) of agar–agar was dispersed in distilled water, heated up to 50 °C, and properly mixed during this process. Afterward, different powdered sugars (sucrose or allulose) at fixed concentration (20% w/v for Suc20 or 40% w/v for Suc40) were added to agar–agar dispersion. This final solution again heated up to 95 °C using magnetic stirrer. After reaching this temperature (95 °C), mixtures were poured to molds and waited at room temperature for 24 h. This process is done and processed separately for sucrose and allulose. The formulation table for each gel is shown in below (Table 1).

The mixture poured into the containers is kept at room temperature for 1 h to cool and take shape, then it is placed in the refrigerator and kept in the refrigerator for 1 day.

Viscosity, moisture content, and water activity measurements

Viscosities of the agar (2% w/v) solutions at varying sweetener ratios were determined by Sinewave Vibro Viscometer SV-10/SV-100 (A&D Company Limited, Japan) at room temperature [10]. The principle relied on the exposure of vibration to the samples by two sensor plates covered with gold and oscillated at frequency of 30 Hz having an amplitude of less than 1 mm.

Moisture content of the different formulations of agar–agar gels was measured using a vacuum oven (DAIHAN, Germany) at 70 °C for 4 h. Weight loss from samples was measured and moisture content of each sample was calculated.

Aqualab 4TE (METER Group, Pullman, WA) was used to measure water activities of prepared samples. Experiments was conducted at 25 °C.

Color analysis

Color analysis was performed using a portable spectrophotometer (Ser-lab, Turkey) and L* (brightness), a* (red/green ratio), and b* (yellow/blue ratio) values measured. Total color change \((\Delta E)\) was measured using the following formula:

where L, a, and b represent the values belonging to the sample; L*, a*, and b* are the values of reference material (white paper was used as the reference).

Hardness analysis

Texture measurements were performed by a texture analyzer (Brookfield CT3, USA) after some modifications of the method of Pocan et al. [11]. The gel samples (with the dimensions of 3 cm × 3 cm × 2 cm) were subjected to 50% compression with a cylindrical probe (4 mm in diameter). The parameters were set as: pretest speed 2 mm/s, test speed of 1 mm/s, return speed 4.5 mm/s, and a trigger load of 5.1 g. Hardness values of the gels were discarded from the texture profile curves. Three replicates were taken as an average after the measurements.

FTIR (Fourier transform infrared spectroscopy) analysis

The gel samples with different formulations and the powders of agar, sucrose, and allulose were investigated in Fourier transform infrared spectrometer (Shimadzu QATR-S, Japan) using attenuated total reflectance (ATR) attachment unit to understand molecular interactions. The following parameters were used during the measurements: the range of 600–4000 cm−1 at 4 cm−1 resolution with 32 scans [12]. The measurements were repeated at least twice.

TD-NMR relaxometry experiments

Low field TD-NMR experiments were performed using a 0.5-T (22.40 MHz) bench-top instrument (SpinCore Technologies, Inc., Gainesville, USA) with 10 mm r.f. coil. Carr–Purcell–Meiboom–Gill (CPMG) sequence was used for T2 measurements with parameters of 1000 us echo time, repetition delay of 5 s, 8 scans, and 500 number of echo. Mono-exponential fitting was conducted on the relaxation curves using MATLAB.

Statistical analysis

Analysis of variance (ANOVA) was conducted on all the quantitative measurements using Minitab Version 16 (Minitab Ltd. Co., Coventry, UK). Generalized linear models were applied to see the effect of sugar type and sugar concentration on the analyzes. A Tukey test was assessed to determine the significance difference of means between groups at the 5% significance level (p < 0.05).

Results and discussion

Moisture content

Moisture content (MC) is considered as an important quality indicator for most of the gel type of foods such as soft candies [5]. In literature, there are also various studies examining the water holding capacities and syneresis behavior of hydrocolloid systems containing agar and different type of sugars [1, 13]. In this present study, moisture content of agar-agar gels containing different types of sugar was also measured to indicate the effect of distinct sugars on agar-agar gel matrix and results are shown in Table 2.

According to the results, the highest moisture content (70.56%) was found for the control gel containing no sugar in its formulation whereas the lowest moisture content (33.45%) was found for the Alu40 agar-agar gel containing 40% allulose in its formulation. Significant changes were also observed among the formulations (p < 0.05) considering both sugar type (sucrose and allulose) and sugar concentrations (20% and 40%). Such distinct results might have stemmed from the different hydration behaviors of different sugars used in the agar gel formulations. In the previous studies, water binding abilities (hydration behavior) of different type of sugar molecules were examined and the highest rate was found for the sucrose and decreased in the order of sucrose > glucose > fructose > allulose. As Tas et al. [14] mentioned in this study, allulose has the lowest hydration rate compared to the other sugar types. This “low hydration capacity” of allulose was also observed in our present study leading to Alu40 samples’ low moisture content compared to its counterparts. It was hypothesized that, due to low water binding ability of allulose, Alu40 sample might have not absorbed moisture leading to leave more free water to the environment. This phenomenon also resulted in the formation of weak and soft gel formation as it will be further discussed on the upcoming “Hardness” section. In addition, hardness and moisture data were found to be highly correlated (Pearson’s correlation coefficient = 0.74, p < 0.05).

Referring to results shown in Table 2, it was observed that, as the sugar concentration increased, moisture content decreased significantly (p < 0.05) for each type of gel containing same type of sugar. Similar results were also observed in previous studies. Maurer et al. [13] examined the impact of sucrose and fructose on the physical properties of agarose hydrogels and they found that when the fructose or sucrose concentration was increased from 20 to 40%, moisture content decreased dramatically.

Water activity (a w)

As well as moisture content, water activity (aw) is another important quality parameter that is highly affected by the presence of sugars, sweeteners, and humectants that are found in gel systems and food products [5]. Water activity is also directly related with the stability of the samples as mentioned in previous studies [5]. As seen in Table 3, water activity of the gel samples did not change significantly (p > 0.05) among the formulations containing different type and concentration of sugar. Regarding the different water binding abilities of sucrose and allulose as mentioned in previous section, normally we expect distinct water activities for each agar-agar gel type. However, contrary to our expectation, such differences in water activities were not observed and very similar values were obtained as seen in Table 3. This outcome might have stemmed from stable gel matrices of agar-agar. Due to the formation of stable agar gel matrices, all gels might have preserved their stability and because of this, water activities of these samples might not have shown significant changes. Similar results were also obtained in previous studies examining the effect of allulose on gelatin-based soft candies which are considered as perfect composite gel systems [5]. Considering the similarities in gelation mechanism of gelatin and agarose (main component of agar), obtaining similar water activities for the agar gels that are formulated for this present study could be considered as an expected result.

Color analysis

Color is an important parameter to understand the food products and gels quality [15]. During the processes requiring heating, some reactions such as gelatinization, denaturation, Maillard or caramelization might take place and color changes could be used to quantify the extent of these reactions [15]. In this present study, color analysis was performed for all samples and lightness (L*), redness (a*), yellowness (b*), and total color change (ΔE) values were reported as seen in Table 4.

Significant changes were not observed in the lightness of the samples and similar L* values were found for all the samples (p > 0.05). On the other hand, for the redness, lowest a* values were found for the Suc20 and similar values were detected for the remaining samples. The most prominent results were obtained considering yellowness (b*) values of the samples. As seen in Table 4, the lowest b value was found for the Suc20 while the highest one was obtained for the Alu40 sample (p < 0.05). This observed increment for the b* value is most probably related with the enhanced caramelization rate of allulose (known as a very reactive sugar) as indicated in the previous studies [5, 9, 16]. Pocan et al. [16] examined the effect of allulose syrup on Turkish delights and they found increased color values which is considered as the sign of enhancement in caramelization reaction. In another study, the reactivity of allulose in caramelization reactions was explored, and it was illustrated that allulose is a highly reactive sugar compared to glucose and sucrose during caramelization reactions [17]. Regarding our present study, since Alu40 is the sample containing the highest amount of allulose, the highest yellowness (b*) value for this sample could be considered as an expected result.

Viscosity

Agar is the only polymer utilized in this study as a hydrophilic, plant-based gelling agent. It is composed of two fractions, agarose which is main source for gelling ability and agaropectin which has potential to enhance gelation [18]. Agar undergoes two-step gelation mechanism, first following initial helix formation and then aggregation of the helices [1]. The helices could be stabilized by forming hydrogen bonding with water following aggregation together. The junction zones linked through the helical parts are responsible for creating a 3D gel network. Herein, besides hydrocolloid, the order of each ingredient addition is crucial criteria during the preparation of solutions. Ellis et al. [18] demonstrated that inhomogeneous and poor gel structure could be obtained if sucrose was added before agar especially at higher than 50% to dissolve in water. For that reason, agar was first exposed to complete dissolution in water with the help of high temperature and it eliminated the mentioned probability in the present study.

The effect of sugar addition and type of sugar on viscosity was displayed on Table 5. All the samples were measured before the gelation and cooling process as in the form of polymer solution. In addition, control which was 2% agar solution before gelation appeared as the lowest viscous solution. That is why it gave closer result with pure water under the same conditions. Likewise, the presence of sucrose was assigned with the rise in viscosity as compared to control and fructose added agar (1 wt%) fluid gels in the literature [18]. Overall, the viscosity increased in the order of control ~ Suc20 < Alu20 < Alu40 ~ Suc40 in our measurements. Furthermore, both sugar type and sugar concentration affected the resistance to flow, significantly (p < 0.05). While sucrose and d-allulose reflected a remarkable difference in viscosity at low concentrations, they began to give similar values at higher concentrations (40%). Ellis et al. [18] similarly mentioned their close gelation outcomes independent from sugar concentration. This is meaningful because they used very high amount of sugar at around 60 wt%. Theoretically, hydrogen bonding between agarose and sucrose could be strengthened by equatorial –OH groups, n (e-OH), thereby yield higher viscosity than control. From the other perspective, d-allulose has one more –OH group than sucrose, leading to more hydrogen bonding and higher water solubility [19]. Its effect could be clearly seen at low sugar concentrations, but its dominant effect disappears after an optimum point. In our study, 40% concentration was seen above saturated level for available hydroxyl groups so both sugar types performed high similarity (Table 5).

Hardness

Hardness as the first bite force is one of the prominent factors in soft gels identifying the maximum force (N) required for the penetration of probe during the first compression [20]. In particular, confectionery gels (pectin gels, etc.) are evaluated taking the hardness values of sucrose-added gels as a reference for consumer acceptability [9]. Table 6 summarized our hardness results giving the highest data in sample Suc20 (p < 0.05). On the other side, control gel gave the lowest value as two times less than Alu40 which was the second softest gel. Addition of sugar resulted in harder texture in agar gels compared to the control sample prepared by the same agar concentration (2% w/v). As control gel (sugar free sample) gave the lowest value in hardness, sugar added gels gave very high hardness values. On the behalf of sugar concentration, it was found that softer structure was valid at higher amount of sugar. Interestingly, Alu20 gave hardness as high as Suc40 pointing out very striking softening effect of allulose.

There are several factors influencing gel texture mainly listed as compression rate, number of compression cycle, exposed gel surface area, gel matrix composition, etc. [4]. For instance, very fast compression speed causes extensive fracture and crack formation in the gels. Second, water or sugar release might occur depending on polysaccharide and sugar type during the mechanical deformation at varying rates [4]. As a result, all the parameters were kept as constant during the measurements to see only the effect of gel composition on agar gel texture.

The addition of d-allulose considerably weakened the gel hardness compared to sucrose addition into the gels (p < 0.05). This was an expected finding owing to the nature of d-allulose showing relatively lower water binding ability than sucrose [9]. Addition of sugar to hydrocolloid matrix at constant polymer concentration makes less available water for the polymer. Sugar molecules begin to compete with the polymer (agar in this study) for free water to generate hydrate shells and make polymer–sugar interactions via hydrogen bonds at the same time [1]. Regarding sugar type, d-allulose is not as good as sucrose in this behavior. d-Allulose is a monosaccharide known as a C-3 epimer of d-fructose having same molecular weight [19]. However, their existing forms differ at equilibrium as β-pyranose ring form in d-fructose whereas α-furanose ring in d-allulose, in aqueous solutions at 30 °C. On the other hand, sucrose is a disaccharide including d-glucose and d-fructose. It was reported that hydrogen bonding between sugar molecules and agar polymer chains as well as the number of junction zones within the polymer chains were strengthened in the presence of sucrose [1]. Correspondingly, the role of sucrose as a “linker” leads to stronger gel network followed by stiffer gel texture. Nevertheless, it is not likely in the addition of d-allulose. The reason behind that is mostly related to hindering effect of allulose on gelation ability of agar. Since allulose could not show high tendency to absorb water within the matrix, there could be still free water around the environment which could not allow strong gelation process. This observation is also consistent with the moisture content results giving less moist gels with the increase in allulose concentration.

Similar results were also observed in the study of Pocan et al. (2018) displaying decreasing hardness value from 7 N to around 3 N at allulose amount changing from 0 to 40% in gelatin-based soft candies. However, this might not be the only effect characterizing texture results. For instance, Ates et al. [9] reported an opposite trend in soy-protein-added pectin gels sweetened by d-allulose. The inclusion of protein molecule into gel network emerged different responses in other mechanisms developed within the gel (e.g., Maillard reaction); hence, it indirectly affected other gel features, as well.

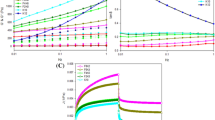

FTIR analysis

FTIR spectroscopy enables the assessment of microstructural characterization and intermolecular interactions between the molecules as a fingerprint method [12]. FTIR spectra of selected gels and each ingredient used during gel preparation are illustrated in Fig. 1. For hydrogels, FTIR is very favorable for the confirmation of the monomers, interactions between functional groups, reacted and unreacted parts and crosslinkers [21]. As reported in the study of Qari and Haider [22], agar powder gave distinct peaks at around 3340 cm−1 (for O–H, N–H, C–H groups), broadened peak at around 2900 cm−1 (–CH2 stretching vibrations), small peak at around 2400 cm−1 corresponding to C≡C, C≡N bonds, at 1674 cm−1 indicating carboxyl groups, another broad peak at around 1388 cm−1 for C–N, N=O bonds, a rough peak at 1172 cm−1 (for S=O) and lastly very characteristic peak at 1064 cm−1 associated with polysaccharides for C–H groups [22, 23]. The peak around 3330 cm−1 assigned for –OH band was observed in all the samples [24]. After gelation of agar, the absorption band at 3330 cm−1 of the gels displayed a sharper increase as compared to agar powder due to water hydration resulting in the increase in OH groups (Fig. 1b). Notably, intensity of the proposed peak was reduced in the order of Alu40 > control > Suc40 emphasizing higher available free water in allulose gels. This was also confirmed by moisture and hardness findings as discussed before. Sugars should be evaluated from different aspects such as in relation to volumetric density of hydrogen bonding sites between biopolymer and water-sugar solution. Volumetric density of hydrogen bonds for the interaction could be described as the difference between the number and molar volume of available hydroxyl groups for intermolecular interactions [19]. Sucrose is superior at this point exhibiting higher molar volume and effective hydroxyl groups at amorphous state. However, this might have modified upon gelation.

The gelation process additionally caused loss of the peaks laying between 700 and 1400 cm−1. However, they were not lost within the aforenoted range in sugar added gels.

For the sugars, intense bands were located at around 3300 cm−1 assigned for OH stretching, 2900 cm−1, 2400 cm−1, 1000 cm−1 attributed to C–O stretching, and at around 700 cm−1 assigned to C–H deformation [25]. They slightly shifted to the left in d-allulose powder like the fructose spectra. Upon gelation of agar polymer chains in the presence of sugars, the peaks located at around 2900 cm−1 were disappeared. Interestingly, a new peak at around 2300 cm−1 originated in allulose incorporated gels. Conversely, this peak was existing in sucrose powder, but it was lost after gelation in sucrose-added agar gels (Fig. 1).

The results supported the unique nature of each molecule and different gelation mechanisms within intrinsic polymeric network.

Time-domain (TD) NMR relaxometry

Low field time-domain (TD) NMR relaxometry is a non-invasive novel analysis method that is widely used to characterize the complex nature of food systems and hydrogels [26]. To understand the polymer–polymer and polymer–water interactions within the gel systems, T2 relaxation time constant which is also known as spin–spin relaxation time is generally utilized as mentioned in the previous studies [5, 12, 15, 26, 27]. T2 relaxation times measured through TD-NMR relaxometry are also generally used to investigate the gelation process of hydrocolloids and their interactions with water [28]. As well as understanding the water interactions of hydrocolloid blends, T2 (spin–spin) relaxation times were also used to understand the effect of d-allulose substitution on polymer–water interactions of starch-based [15], gelatin-based [5], and pectin-based [9] soft candy products which are also considered as perfect composite gel systems. Since T2 (spin–spin) relaxation times obtained through TD-NMR relaxometry are very helpful to identify water uptake and polymer–water and polymer–polymer interactions in gel systems [29], in this study, mono-exponential T2 relaxation times were also used to characterize gelation behaviors and water dynamics of sucrose- and allulose-containing (20% and 40%) agar–agar gels and results are shown in Table 7.

As seen in Table 7, compared to the control sample containing only agar–agar (117.36 ms), addition of different type of sugars at different concentrations affected notably T2 relaxation times of the samples. When T2 relaxation times compared at the fixed 20% concentration, sucrose- and allulose-containing gels demonstrated significantly different results (p < 0.05) and it was observed that T2 of allulose-containing ones (Alu20) reduced significantly. The reason behind this phenomenon can be explained with the different hydration behavior resulting in totally different water competition properties of allulose and sucrose. As mentioned in the previous sections, allulose has lower hydration rate and less water absorbing capacity compared to sucrose. As a result, polymer (agar)–water interactions increased leading to overall decrease in T2 of Alu20 gels. On the other hand, as it was reported by Russ et al. [1], interactions between sugar molecules and agar polymer chains as well as the number of junction zones within the polymer chains were strengthened in the presence of sucrose leading to decrease in agar–water interactions and increase in available free water in the environment finally resulting in overall increase in T2 relaxation time of the Suc20 gel. In addition, viscosity has also dominant effect which leads to significant decrease in T2 of Alu20 compared to Suc20 because as mentioned in “Viscosity” part, Alu20 has a notably higher viscosity compared to Suc20. Interestingly, at the higher concentration (40%), totally different scenario is valid for the Suc40 and Alu40 samples and significantly longer T2 relaxation times were found for the Alu40 (113.88 ms) compared to its counterpart (86.91 ms) although their viscosities have very similar value. Herein, it was hypothesized that, at 40% concentration, intermolecular interactions might have changed compared to 20% concentration leading to different relaxation behavior of the samples. Most probably, in the presence of higher amount of allulose, more free water was accumulated in the environment resulting in weak gelation process leading to formation of less moist and softer gels compared to its sucrose-containing counterpart (Suc40). These relaxation results of the gels were also confirmed with the FTIR analysis as mentioned in previous section since in the FTIR spectra, the intensity of the proposed peak was reduced in the order of Alu40 > control > Suc40 indicating higher amount of available free water in Alu40 gels. These results were found in concordance with the previous studies. For example, mono-exponential T2 relaxation times of allulose-containing pectin gels were found to be longer compared to its sucrose-containing counterparts [9, 30]. Similarly, for the gelatin gels, longer T2 relaxation times were obtained as the allulose substitution increased in the formulations due to weak water absorption capacity of allulose [5].

Apart from these findings, according to the Pearson correlation results, strong negative correlation was observed between the viscosity and T2 relaxation times (r = −0.89, p < 0.05) indicating T2 relaxation time can be utilized to monitor viscosity changes in agar–agar gels including different type of sugars.

Conclusion

This study was built on designing agar–agar-based gels containing different types of sugar (d-allulose and sucrose) at different concentrations (20% and 40%) and exploring the effect of these sugars on the physical and gelling properties of agar–agar.

Results obtained through this study indicated that using sucrose or allulose at different concentrations (20% or 40%) remarkably changed the moisture content, viscosity, hardness, and color values of the gels compared to control sample containing only agar–agar in its formulation. On the other hand, water activities of sugar containing gels did not change remarkably compared to the control one. In addition, it was revealed that TD-NMR relaxometry and FTIR spectra could be used together to investigate the changing water dynamics and microstructure of the agar–agar gel systems when different type of sugars was included in the formulations. Results clearly indicated that less moist and softer gels were obtained when allulose was added to the formulation leading to longer T2 relaxation time. It was also found that viscosity and T2 mono-exponential times are inversely correlated (r = −0.89, p < 0.05) enabling researchers to utilize low-field TD-NMR relaxometry to monitor the viscosity changes of agar–agar-based gels.

To conclude, due to totally different hydration properties of allulose and sucrose, physical properties and water dynamics, thereby relaxation behavior, of the agar–agar gels changed drastically compared to control one when these sugars included in the formulations at different concentrations (20% and 40%). Authors believe that this study will pave the way for designing vegan agar–agar-based confectionery products such as soft candies that are considered as perfect composite gels. Further research on the subject could be focused on the characterization of these agar–agar-based vegan soft candies and monitoring the changes in the properties of gels when the corn syrup was included in the formulations.

Data availability

Data are available from corresponding authors upon reasonable request.

References

Russ N, Zielbauer BI, Vilgis TA (2014) Impact of sucrose and trehalose on different agarose-hydrocolloid systems. Food Hydrocoll 41:44–52. https://doi.org/10.1016/j.foodhyd.2014.03.020

Ilhan E, Poçan P, Kruk D et al (2022) Water dynamics in starch based confectionery products including different types of sugar. Molecules 27:1–10

Konar N, Gunes R, Palabiyik I, Toker OS (2022) Health conscious consumers and sugar confectionery: present aspects and projections. Trends Food Sci Technol 123:57–68. https://doi.org/10.1016/j.tifs.2022.02.001

Wang Z, Yang K, Brenner T et al (2014) The influence of agar gel texture on sucrose release. Food Hydrocoll 36:196–203. https://doi.org/10.1016/j.foodhyd.2013.09.016

Pocan P, Ilhan E, Oztop MH (2019) Effect of d-psicose substitution on gelatin based soft candies: a TD-NMR study. Magn Reson Chem 57:661–673. https://doi.org/10.1002/mrc.4847

Xia Y, Cheng Q, Mu W et al (2021) Research advances of d-allulose : an overview of physiological. Foods 10:1–21

Pocan P, Ilhan E, Florek-Wojciechowska M et al (2021) Exploring the water mobility in gelatin based soft candies by means of fast field cycling (FFC) nuclear magnetic resonance relaxometry. J Food Eng 294:110422. https://doi.org/10.1016/j.jfoodeng.2020.110422

Kirtil E, Oztop MH (2016) 1H nuclear magnetic resonance relaxometry and magnetic resonance imaging and applications in food science and processing. Food Eng Rev 8:1–22. https://doi.org/10.1007/s12393-015-9118-y

Ates EG, Ozvural EB, Oztop MH (2020) Understanding the role of d-allulose and soy protein addition in pectin gels. J Appl Polym Sci 138(8):49885. https://doi.org/10.1002/app.49885

Tokita M, Nishinari K (2000) Gels: structures, properties, and functions fundamentals and applications. Springer, Berlin

Pocan P, Knapkiewicz M, Rachocki A, Oztop MH (2021) Detection of authenticity and quality of the Turkish delights (Lokum) by means of conventional and fast field cycling nuclear magnetic resonance relaxometry. J Agric Food Chem 69:12089–12101. https://doi.org/10.1021/acs.jafc.1c00943

Cikrikci S, Oztop MH, Mert B (2018) Development of pH sensitive alginate/gum tragacanth based hydrogels for oral insulin delivery. J Agric Food Chem 66(44):11784–11796. https://doi.org/10.1021/acs.jafc.8b02525

Maurer S, Junghans A, Vilgis TA (2012) Impact of xanthan gum, sucrose and fructose on the viscoelastic properties of agarose hydrogels. Food Hydrocoll 29:298–307. https://doi.org/10.1016/j.foodhyd.2012.03.002

Tas O, Ertugrul U, Grunin L, Oztop MH (2022) Investigation of the hydration behavior of different sugars by time domain-NMR. Foods 11(8):1148. https://doi.org/10.3390/foods11081148

Ilhan E, Pocan P, Ogawa M, Oztop MH (2020) Role of ‘d-allulose’ in a starch based composite gel matrix. Carbohydr Polym 228:115373. https://doi.org/10.1016/j.carbpol.2019.115373

Pocan P, Grunin L, Oztop MH (2022) Effect of different syrup types on Turkish delights (Lokum): a TD-NMR relaxometry study. ACS Food Sci Technol 2(12):1819–1831. https://doi.org/10.1021/acsfoodscitech.2c00222

Ertugrul U, Tas O, Namli S, Oztop MH (2021) A preliminary investigation of caramelisation and isomerisation of allulose at medium temperatures and alkaline pHs: a comparison study with other monosaccharides. Int J Food Sci Technol 56(10):5334–5339. https://doi.org/10.1111/ijfs.15128

Ellis AL, Mills TB, Norton IT, Norton-Welch AB (2019) The effect of sugars on agar fluid gels and the stabilisation of their foams. Food Hydrocoll 87:371–381. https://doi.org/10.1016/j.foodhyd.2018.08.027

Bolger AM, Rastall RA, Oruna-Concha MJ, Garcia JR (2021) Effect of d-allulose, in comparison to sucrose and d-fructose, on the physical properties of cupcakes. Lwt 150:111989. https://doi.org/10.1016/j.lwt.2021.111989

Apostolidis E, Kioupis D, Kakali G et al (2021) Effect of starch concentration and resistant starch filler addition on the physical properties of starch hydrogels. J Food Sci 86(12):5340–5352. https://doi.org/10.1111/1750-3841.15954

Emir AA, Erunsal SC (2022) Impact of oleuropein on LCD-based stereolithography-assisted fabrication of 3D printed PEGDMA hydrogels. Eur Polym J 180:111592. https://doi.org/10.1016/j.eurpolymj.2022.111592

Qari R, Haider S (2021) Agar extraction, physical properties, FTIR analysis and biochemical composition of three edible species of red seaweeds Gracilaria corticata (J. Agardh), Gracilaria dentata (J. Agardh) and Gracilariopsis longissima (S. G. Gmelin). Pak J Sci Ind Res 64(3):263–273. https://doi.org/10.52763/PJSIR.BIOL.SCI.64.3.2021.263.273

Huang JW, Chang JJ, Yang RH, Chen CH (2019) Agarose dispersed liquid crystals as a soft sensing platform for detecting mercuric ions in water. Res Chem Intermed 45:5409–5423. https://doi.org/10.1007/s11164-019-03978-y

Xiao Q, Ye S, Zhang Y, Chen J, Chen F, Weng H, Xiao A (2022) Gel properties transition from mono-succinylation to cross-linking of agar by attemperation with succinic anhydride. Food Chem 381:132164. https://doi.org/10.1016/j.foodchem.2022.132164

Guven B, Durakli-Vellioglu S, Boyaci İH (2019) Rapid identification of some sweeteners and sugars by attenuated total reflectance-Fourier transform infrared (ATR-FTIR), near-infrared (NIR) and Raman spectroscopy. Gida J Food 44:274–290

Ozel B, Cikrikci S, Aydin O, Oztop MH (2017) Polysaccharide blended whey protein isolate-(WPI) hydrogels: a physicochemical and controlled release study. Food Hydrocoll 71:35–46. https://doi.org/10.1016/j.foodhyd.2017.04.031

Ozel B, Aydin O, Oztop MH (2020) In vitro digestion of polysaccharide including whey protein isolate hydrogels. Carbohydr Polym 229:115469. https://doi.org/10.1016/j.carbpol.2019.115469

Ozel B, Uguz SS, Kilercioglu M et al (2016) Effect of different polysaccharides on swelling of composite whey protein hydrogels: a low field (LF) NMR relaxometry study. J Food Process Eng 40(3):e12465. https://doi.org/10.1111/jfpe.12465

Cikrikci Erunsal S (2023) Evaluation of multicomplex systems on pomegranate concentrate loaded alginate hydrogels by low-field NMR relaxometry: physicochemical characterization and controlled release study. J Food Sci Technol 60:1960–1969. https://doi.org/10.1007/s13197-023-05730-2

Ates EG, Ozvural EB, Oztop MH (2021) In vitro digestibility of rare sugar (d-allulose) added pectin–soy protein gels. Int J Food Sci Technol 56:3421–3431. https://doi.org/10.1111/ijfs.14966

Acknowledgements

The authors would like to thank Prof. Mecit Halil Oztop for the use of TD-NMR relaxometry that is found in his laboratory at Middle East Technical University (METU). Authors are also thankful to Zikrullah Bölükkaya for his help during NMR relaxometry experiments.

Funding

Open access funding provided by the Scientific and Technological Research Council of Türkiye (TÜBİTAK).

Author information

Authors and Affiliations

Contributions

Pelin Pocan and Sevil Cikrikci Erunsal: writing—original draft, methodology, investigation, data analysis, conceptualization, formal analysis, validation. Pelin Pocan and Sevil Cikrikci Erunsal: writing—reviewing and editing.

Corresponding author

Ethics declarations

Competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Compliance with ethics requirements

This study does not contain any studies with human participants or animal subjects.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Poçan, P., Çıkrıkcı Erünsal, S. Exploring the effect of sucrose and d-allulose addition on the gelling ability and physical properties of agar–agar vegan gels. Eur Food Res Technol 250, 2245–2254 (2024). https://doi.org/10.1007/s00217-024-04534-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-024-04534-8