Abstract

The popularity of beer and the complexity of its formation call for simulating and optimizing the operations that take place during brewing in order to reduce energy costs, minimize the consumption of raw materials, maximize the use of equipment, and produce a product of the best possible quality. In recent decades, noteworthy progress has been made in understanding the phenomena occurring in various industrial devices thanks to Computational Fluid Dynamics (CFD). This article is a review of previous attempts to use CFD methods to understand and simulate the processes that accompany individual stages of beer production. Additionally, the paper indicates the possible use of CFD methods for processes that have not been modelled yet in the brewing industry.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Beer is one of the most widely distributed alcoholic beverages in the world. The first mentions of beer production are even 6000 years old and come from ancient Sumer [1]. Over the centuries, this drink has not lost its popularity, as is evident from the historical texts available and more recent statistical data. In 2017, its production reached 1.95 billion hectolitres [2]. As in any branch of industry, it has become necessary to better understand the mechanisms of beer production to simulate and optimize the process. The following solutions are sought: minimization of the amount of waste and maximization of the use of raw materials and available equipment, all of which can translate into higher profits.

The production of beer is made up of the following:

-

mashing that takes place in a mashing tun;

-

lautering—usually in a lauter tun with a false bottom;

-

boiling in a kettle or a suitably adapted mash vat;

-

whirlpooling in the whirlpool separator;

-

cooling in a proper heat exchanger (usually plate type);

-

fermentation in an open or closed fermentation vessel;

-

maturation in a barrel (e.g., after wine or whiskey) or specially designated maturation tank; and

-

pasteurization in proper pasteurization equipment (e.g., in a tunnel pasteurization conveyor).

These can be complemented by the following:

-

carbonating by CO2 or N2 through a sparger;

-

brewers spent hops (BSH) filtration by a mesh filter;

-

so-called cold crash in a cooled fermentation vessel; and

-

in the production of some beer brands (e.g., Berliner Weisse or Lambic) – acidification with lactic acid bacteria.

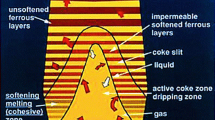

Depending on the brand of beer and the size of the brewery, production may involve operations other than those mentioned above. The basic technological line of beer production is shown in Fig. 1.

The operation of the devices used in the brewery could be simulated and improved through CFD (Computational Fluid Dynamics) methods. CFD by means of iterative solving of the differential equations of heat, mass, and momentum transport, improves more accurate understanding of the physicochemical processes taking place in the apparatus, and then enables their simulations, without the need to perform them physically. For example, knowledge of heat and mass distributions with chemical reactions taken place in apparatus gained by performing CFD simulations of processes like mashing or fermentation compared to experimental results obtained from making different beer flavour profiles could be beneficial in designing and optimising brewing of various types of beer. It could lead to a significant reduction in the time needed to design new flavour profiles for beer and other products from the food industry.

In recent decades, there has been noteworthy progress in the field of understanding the mechanisms that occur in devices thanks to CFD. This also applies to the use of CFD methods in the design and optimization of processes in the food industry [3,4,5]. So far, many papers have been published on the use of CFD techniques in the food industry, e.g., for baking bread [6], drying food products [7], heat flow when sterilizing food [8] or phenomena occurring in prepared beer [9]. This article focusses on a review of the available literature on CFD simulations during individual stages of beer production and shows whether similar processes have already been modelled in other branches of the food industry. The authors also suggest which other articles could be helpful in performing a simulation of processes during beer brewing that have not yet been simulated by using CFD methods.

Mashing

Mashing is a process of mixing and gradually heating ground malt with water to a temperature of around 80 °C. The enzymes contained in malt (mainly α and β amylases) lyse the starch that is present in malt into fermentable sugars (mainly maltose). This process is most effective in a temperature range between 62 and 68 °C, which must be maintained for several dozen minutes. Often, in addition to sugars, proteins, and some of the fats contained in the malt also pass into the liquid phase of the mixture due to rests (e.g., ferulic acid rest, protein rest, saccharification rest) during mashing. The effectiveness of this process depends on temperature, the method of mixing, the ratio of water to grain, the break time, the quality of the raw material, etc. The whole mashing can take up to several hours. Due to the complexity of this process and the specificity of its occurrence in the brewing and distilling industries, no attempt has yet been made to model it with CFD software. Simulations of similar processes, for example, tea bag brewing [10, 11], coffee brewing [12] resveratrol extraction [13] or brown coal wax extraction [14] have been made. During tea brewing, compounds such as theine or essential oils are extracted from the solid phase (leaves) to the hot liquid phase (water). The models proposed by Dhekne et al. [10] and Lian et al. [11] can also be applied in the design of mashing due to the similarity of the extraction of compounds in the liquid phase from the solid phase. Simulations carried out by Moroney et al [12], Turgut et al. [13] and Wang et al. [14] may also give tips on how to model grain distribution and the impact of heat movement on extraction. The following models were applied in the articles: k-epsilon (momentum) [10], laminar (momentum) [14], Euler–Euler (multiphase) [12]. For CFD calculations, most commonly ANSYS Fluent [10,11,12] or COMSOL Multiphysics software [13, 14] were chosen. 'Reactive Pellet Bed' in the Chemical Reaction Engineering Module [13] and the CFD Module were used in articles with the COMSOL software [13, 14]. Because of the absence of articles, any coupled CFD models with FEM (finite element method) or DEM (discrete element method) have not been implemented yet to describe the mashing process. Researchers suggest that using CFD-FEM could simulate for example the forces affecting on the agitator in the mashing vat. Also, CFD-DEM method could be appropriate to simulate the fluid (wort) and solid (malt) movement and interactions during mashing, however, it brings the necessity of a detail description of solid phase. For an exact description of physicochemical properties of malt or BSG such as thermal conductivity, specific heat, thermal diffusivity or size distribution, the following articles could deliver necessary correlations [15,16,17,18,19,20,21,22]. Because of the continuous increase in the computing power, the continuous development of CFD software and the great popularity of research on beer and the use of waste generated in its production, papers on the application of CFD methods to model mashing are highly likely to be published.

Lautering

After the mashing is complete, the liquid phase is separated from the solid phase by means of filtration in a lauter tun with a false bottom. The liquid phase (wort) is funnelled to the kettle to boil with the addition of hops (or other spices), while the remaining solid phase, the so-called brewers spent grains (BSG) is treated as a by-product that could be appropriately valorised [23,24,25]. So far, no articles dealing with lautering CFD simulation in the beer production process have been published. In the food industry, CFD methods have been applied to optimize milk filtration [26, 27] in water purification [28, 29] and in device design like gas–solid–liquid separator hollow-fiber filter [30, 31].

One of the key aspects necessary to model filtration is knowledge of the characteristics of the solid phase, including the shape and size of the filtered particles [32]. Because of the specificity of the flow of fluids filtered through the filter cake, it is also necessary to know the resistances and particle–particle, and particle–fluid interactions. Research has shown that dry spent grains are characterised by sphericity φ = 0.78 ± 0.10, Sauter diameter ds = 5.85 ± 0.14 mm and true density 1386 ± 4 kg/m3 [21]. Warpala and Pandiella [20] examined the particle size distribution of the malt used to make a beer. The average malt grain used in this article has a length of 7.9 mm, a thickness of 3.1 mm, and a width of 3.6 mm. The paper points out that the roll gap between a mill has a crucial effect on the particle size distribution. The roll speed does not appear to have a noticeable effect. de Moura and Mathias [22] also checked how moisture-od milled malt effect on mean particle size and distribution. The results showed that the mean diameter of the particles depends on the moisture of the malt during milling, for dry malt the ds was 1.35 ± 0.15 mm and changed in: 10% moisture − 1.02 ± 0.20 mm, 20% moisture − 1.24 ± 0.16 mm, 30% moisture − 1.50 ± 0.13 mm, 40% moisture − 1.66 ± 0.12 mm and 50% moisture − 1.66 ± 0.13 mm, respectively. The articles mentioned could be helpful in describing the solid phase for both mashing and lautering.

Puderbach et al. [33] used the CFD-DEM (Computational Fluid Dynamics with the Discrete Element Method) together with the LBM (Lattice–Boltzmann Method) to determine the conditions for the formation of the filter cake and to estimate the individual interactions between the phases on the basis of pressure filtration of silica glass from. Hund et al. [34] also performed simulations with the CFD-DEM method, to study the formation of particle bridges over the pores of the filter body during the formation of filter cake. Both Puderbach et al. [33] and Hund et al. [34] point out the high accuracy of the method in relation to the experimental data. Research on the properties of BSG and currently used CFD models is a good starting point for modelling filtration in beer production.

Boiling

After lautering, the wort is introduced into the vat, where the boiling step takes place. During this stage, hops or other spices are added to impart flavour or bitterness. Sometimes, sugar or malt extract is also mixed in to increase sugar content.

So far, no focus has been placed on modelling boiling water or other liquid mixtures in processes occurring in the food industry. In some CFD-related articles, boiling water is present as a heat carrier, for example, when sterilizing asparagus in brine [35] or cooking rice [36]. In such papers, modelling a boiling liquid is often nothing more than assuming the boundary condition of the wall Twall = 373 K. This approach does not require simulating a boiling medium (environment) but allows you to focus on the material (system) considered.

CFD techniques have modelled cooking for:

Till now, articles using the CFD-FEM method to describe boiling phenomena in food industry have not been published yet. The authors suggest that this approach could optimize the apparatus construction to eliminate dead zones and intensify mass and heat exchange between a boiling liquid and solid wall. Currently to perform boiling simulations, Euler–Euler [42, 44] or Volume of Fluid (VOF) [43] models with different extensions are being used. To describe bubble flow, the Algebraic Interfacial Area Density (AIAD) and Generalised-Two-Phase (GENTOP) models could be implemented in CFD calculations. More information about the models can be found here [44]. The bubble diameter distribution could be predicted with the Sy model [41]. The lack of articles on CFD analysis of boiling systems in the food industry may indicate the need to research their dynamics. Shopska et al. [46] point out that CFD methods could be helpful in simulating wort flow in the boiling kettle.

In opposition to CFD calculations, empirical models of boiling could be implemented to describe the boiling heat transfer phenomena. S.C.P. Cheung et al. examined empirical boiling models at subcooled flow boiling in vertical channels at low pressures [47]. The researchers pointed out that predictions of some combinations of empirical correlations compared well with the axial measured data while other combinations were found to provide a better agreement with the local measured data. However, not one single combination was able to provide satisfactory results for both the entire axial and local conditions. This problem could be solved by CFD modelling. Because of the opportunity to simulate both local conditions by proper dense mesh with simultaneous calculations for the whole apparatus, the obtained results could be better due to empirical ones. Nevertheless, the correctness of the CFD results, if possible, should first be provided by experimental data. Fortunately, continuing development of numerical methods could give a satisfactory result with good trust level, also without the need to perform experiments and could be used to optimize the apparatus before the construction process begins.

Whirlpool

After boiling, the hops and proteins must be separated from the wort. This is most often done through a whirlpool that consists of introducing the wort into a swirling motion in a tun. The forces acting on the suspended solid particles in the wort cause them to migrate into the formation funnel, making them relatively easy to remove. Most articles on whirlpool modelling have been published by Marek Jakubowski and his co-workers [48,49,50,51,52]. The order of publication of the papers well reflects the approach that should be adopted when modelling CFD. Initially, the researchers focused on modelling in two-phase mixing in 2D geometry to learn how the tank axis cone and secondary whirls are formed. [48]. The article confirms that the most favourable ratio of the discharge head to the diameter of a vessel is 1: 1. The applied 3D model was then confirmed by PIV (Particle Image Velocimetry) tests while dimensionless numbers were presented, which can be used to reflect the dynamics of a two-phase system (gas–liquid) [49]. Furthermore, the researchers propose various modifications to the whirlpool tank to improve the formation of the funnel necessary for the subsequent separation of solids. In the next article, a modification of the conditions in the form of a two-sided injection of liquid into the tank was proposed to symmetrize the flow, again improving funnel formation [50]. Figure 2 presents the results of the sample simulation of a whirlpool during the stages of single- and two-sided filling [50]. Another study showed the benefits of pulsatile filling over the classic filling of a regular tank and a whirlpool separator [51]. The latest 2020 paper extends the proposed model by a solid phase. Research suggests that results in a reasonable computational time and more consistent with those provided by experiments were obtained for the VOF (Volume of Fluid) model [52]. Researchers point out the difficulties of the discrete phase model (DPM) in simulating sedimentation, while CFD-DEM and DPM showed problems with the modelling of turbulence, which were also very time consuming [52]. All of the above-mentioned papers indicate high accuracy of CFD simulations in relation to the data from the experiments. The approach and models applied by Jakubowski's team can be used to model other processes accompanying beer brewing. They may be particularly important in the context of modelling mashing because of the similarities between whirlpool and mashing, that is, the presence of a three-phase system and mixing.

Results of the simulation of a whirlpool during the stage of: a single-sided filling (full view of the stage for 140 s) b single-sided filling (45 s); c whirling with a tank with single-sided filling (140 s); d two-sided filling (7 s); e whirling with a tank with two-sided filling (65 s) [50]

Cooling

Before beginning fermentation, the wort must be brought to a temperature suitable for yeast inoculation. Too high of a temperature can cause the death of yeast cells, while leaving the wort warm increases the risk of infection. A heat exchanger reduces the time necessary to add yeast. Toapanta-Ramos et al. conducted a simulation in Ansys Fluent 2019 software of beer cooling with a helical heat exchanger [53]. In principle, the medium that flows through the cooler is the cooled wort with a temperature of 70 °C, while the external cooling medium is water with a temperature of 15 °C. The wort was assumed to have a temperature of less than 25 °C, making the addition of yeast to the ales possible. Authors used k-epsilon RNG model to describe the turbulence in heat exchanger. Studies indicate that the final temperature of the wort is much more influenced by the value of the flow rate of the wort than the change in the inlet temperature of the coolant. Research such as this enables a better understanding of heat exchange and leads to a better efficiency in the cooling of the wort.

Cooling is also often used after fermentation and before bottling to facilitate yeast removal. Yuan et al. simulated the cooling of beer in a conical bottom tank using five cooling jackets [54]. The entire was cooled with ammonia from a temperature of 10 to – 1 °C for approximately 9600 min. The physicochemical properties of beer were determined experimentally. The simulation was carried out with the Fluent 6.1 software, and its results were compared with the temperatures taken from five different locations in the simulated reservoir. It transpired that the temperature of the simulated reservoir corresponded quite well with the observed results. They also presented the temperature profiles, velocities, and heat transfer coefficients yielded by simulation. It appears that the temperature profile during the process changes along the axis of the tank but remains constant along the radius. The velocity profile of the fluid in the tank is not a regular flow along the axis or the wall. The results show a much more complex motion with local vortices. The values of the heat transfer coefficients for the tank walls remain at a constant level of approximately 10 W/m2·K throughout the cooling. The exception here is the penetration coefficients for the walls located at the conical bottom. Their values are about an order higher for the first 22 h of cooling, after which they decrease to a value of about 60 W/m2 K for 34 h. Additionally, at the conical bottom, the velocity gradient values at the wall were greater than zero, unlike in the upper part of the tank. This could have been influenced by the local geometry of the tank and a more favourable ratio of the cooling surface to the cooled liquid. This is confirmed by the fact that, in the case of convection, heat exchange is more efficient than in the case of conduction in liquids. Researchers suggest that the actual velocity profile in the tanks could translate into more efficient beer cooling.

Many articles have been devoted to CFD simulation of cooling because it is so common in the food industry. Ajani et al. [55] collected publications on CFD modelling of refrigeration. The researchers described the most important problems in both cooling design and current approaches to solving them with CFD calculations. Researchers show that the most commonly used models to calculate velocity are laminar, standard k-ε and shear stress transport (SST) k-ω [55]. More details regarding applicability of CFD methods for the food industry could be found in the research article [55]. They point to the computational fluid dynamics tool as an inexpensive and innovative approach to designing and optimising the operation of devices. They also expose the great flexibility of CFD simulation: from the design of large-scale apparatus to the analysis of cooling in a single product or package. The conclusions published by the researchers and the list of the most frequently applied models can also be used to simulate cooling also more efficiently in brewing.

Fermentation

Fermentation converts the sugars contained in beer by yeast into alcohol, carbon dioxide, esters, or other compounds. It is especially important to include the dynamics of the system resulting from metabolic changes in microorganisms. CFD methods, because of their high accuracy of calculations and growing interest in the use of microorganisms for the production of biofuels and other bioproducts, are able to accelerate fermentation. Simulations were also performed considering gaseous, liquid, and solid phase flows in the form of microorganisms for microalgae in photobioreactors (PBRs) [56]. The Eulerian–Eulerian model used in the work enabled the simulation of the velocity profiles of each phase with high accuracy, with the maximum relative error in relation to the experimental results not exceeding 18.2%. Furthermore, the simulation helped to detect dead zones in the reactor, which could be eliminated by considering the results obtained using the created model. Other articles also indicate the possibility of applying CFD software to modify equipment used in biological processes for better process efficiency [57]. The assumed approach may prove useful in modelling beer fermentation, in particular, turbulent fermentation. During this stage, the yeast creates local fluctuations in the depth of the beer, rapidly producing CO2.

Due to the sedimentation of yeast, tanks with a conical bottom are most often used for wine and beer fermentation, which facilitates the subsequent separation of yeast from the beverage. [58] examined how the shape of the fermenter affects the time required for a uniform distribution of nutrients (e.g., diammonium phosphate—DAP) in wine. An even distribution of nutrients throughout the tank volume is particularly important. This prevents the formation of undesirable products that alter the taste and aroma of wine or beer. The best mixing results in industrial fermenters with a capacity of 10 m3 were obtained in tanks with a conical bottom (60º cone angle), while the worst results were obtained for tanks with a low slope or without cone. The average mixing speed in time 0 < t< 180 s for fermenters with a conical bottom oscillated around the value of ~0.15 m/s, while for tanks with a flat bottom– ~0.03 m/s. It was observed that the flow induced by the formation of CO2 bubbles during middle fermentation significantly improves the mixing due to the presence of forced convection in relation to the early phase of fermentation. Researchers suggested that their results can be used to optimise tank shapes, implement cooling, and control other process parameters. This article may be helpful in modelling beer fermentation due to the similarity in the structure of the tanks used and the same species of yeast (Saccharomyces cerevisiae).

CFD has been used in both the design and optimization of bioreactors themselves. Table 1 provides an overview of articles that describe CFD to model various fermentation processes.

The articles in Table 1 present the use of CFD methods to model fermentation. Biofuel production is increasingly being simulated by computational fluid dynamics methods [63]; still, there are few articles describing CFD simulations of fermentation. Most of the research mentioned above focusses on modelling the mixing that takes place in fermenters to improve the production of a product such as biohydrogen, biogas, or lactic acid [57, 59, 63, 65]. Furthermore, it is worth noting the high overlap of the simulation results with the experimental results [65, 67, 69] while CFD software is indicated as a reasonable and economical tool to determine the nature of flows in the reactors [61]. The lack of articles on the simulation of beer fermentation may indicate another area for the application of CFD techniques in brewing.

Pasteurization

Pasteurization is widely used in the food industry to microbiologically stabilize products. It consists in keeping the product at a sufficiently high temperature to destroy or deactivate microorganisms and enzymes without decreasing its nutritional value. The efficiency of the process is measured in the so-called pasteurization units (PU). This is the sterilization effect observed for 1 min at the reference temperature (Tref). This effect increases exponentially with increasing temperature, depending on the value of the thermal resistance coefficient (Z). The formula for defining PU for beer is as follows:

For beer, with the elimination of S. cerevisiae, the Tref and Z values are 60 °C and 6.94, respectively.

In the case of beer, the pasteurization of both the bottle and the can was analysed with CFD [70, 71]. In both studies, values above 15 PU were checked, which means that the beer obtained adequate microbiological stability.

Bhuvaneswari et al. analysed the pasteurization of strong beer (7% ABV, alcohol by volume) from United Brewery Pvt. Ltd. available in stores [70]. Both the pasteurization of stationary beer in a water bath (60 °C for 1800 s) and tunnel pasteurization were simulated. Figure 3 presents the tunnel pasteurization scheme [70]. During the process, beer goes through seven stages: preheating at 22 °C for 6 min, heating at 32 °C for 6 min, heating at 65 °C for 14 min, pause at 60 °C for 6 min, precooling at 40 °C for 10 min, cooling at 32 °C for 7 min, and final cooling at 22 °C for 6 min [70]. The simulation results were compared with the experimental results of the temperature measurements for three different bottle heights. The researchers pointed to the high accuracy of the calculations carried out for both stationary pasteurization and tunnel pasteurization. For a standing bottle, the beer temperature in the entire volume was 60 °C after approximately 1140 s and it was demonstrated that the slowest heating zone was the beer at the bottom of the bottle. Data collected during tunnel pasteurization simulation show that a total pasteurization value of 17 PU was obtained for the beer tested, proving the microbiological stability of the product. Figure 4 presents the temperature profiles of bottled beer in different tunnel pasteuriser zones at different time intervals.

Schematic diagram of tunnel pasteurizer [70]

Temperature profiles (a–m) of bottled beer in different tunnel pasteurizer zones at different time intervals [70]

Augusto et al. analysed the effect of can orientation on pasteurization efficiency [71]. The simulation was carried out for a can with an initial temperature of 25 °C and a volume of 375 ml in a water bath at a temperature of 60 °C. The physicochemical values of beer were assumed to be the same as those of water at the same temperature. Simulations were carried out for a can standing on the standard way (with the lid "up"), an inverted can, and a can lying on the wall. The pasteurization time was 1300 s to achieve 15 PU in the entire can. Simulations allow us to conclude that the orientation of the can has no effect on the quality or the time of pasteurization. Simulations, however, allow one to identify two main flows for both vertical positions: the main (larger) and the smaller, so-called Bernard's cell. It is characterised by a flow in the opposite direction to the main flow. The assumption that the physical properties of the modelled fluid are equal to the parameters of water may cast doubt on the results obtained for beers significantly different in rheological properties from water, in particular for beers with high extract.

The literature also provides other examples of pasteurization modelling. Table 2 presents pasteurization phenomena modelled in various branches of the food industry.

The researchers listed in Table 2 highlight the high precision of the CFD software with respect to the experimental data [73,74,75,76]. Taking into account the variety of cases considered so far and the widespread use of pasteurization in the food industry, it can be expected that CFD simulations will be used more and more often to improve this process, for example, in the case of designating an effective Pasteurization Unit [78, 85] or SHZ [76, 77, 79, 84]. Furthermore, CFD testing of pasteurization can bring about greater microbiological stability of food products, and thus increase their safety [81]. Two articles have been published on the pasteurization of beer in bottles and cans in tunnel pasteurizers. In the brewing industry, pasteurization is performed on flow pasteurizers. Beer in such devices is heated while flowing through the heat exchanger in the entire volume until the appropriate temperature is reached, and then it is cooled down. Beer is often used as a coolant to preheat it before actual pasteurization. Such devices use energy more efficiently compared to tunnel pasteurizers but are more expensive. CFD research could contribute to the design, for example, of heat exchangers for flow pasteurisers, which, in turn, could translate into lower costs for erecting such a device.

Sparger modelling: carbonating beer

Drinks can be saturated with carbon dioxide through the sparger [86] simulated fluid mixing in a bubbler for two different geometries of water delivery. The liquid was introduced into the bubbler perpendicularly (centrally) or radially (tangentially) to the axis of the chamber. The simulation was carried out for three different media flow rates: for water 8, 16 and 32 L/h, and for CO2 2.8, 5.6 and 13.2 L/h [86]—with the use of Ansys CFX v15 software. The results were validated with the experimental results of CO2 bubble size measurements performed on a bubbler available at the University of Parma. The simulation and experimental results confirmed that better mixing results, along with the formation of a more stable water–CO2 mixture, were achieved for the central input. The most favourable results, characterized by the most homogeneous and small bubbles, were produced for the highest flow rates of water and CO2. Researchers suggest that, for a given system, the use of a static turbulator could help improve the mixing quality of the proposed fluids. Research of this type can translate into more effective use of the bubbler in the large-scale production of beer and carbonated beverages.

Conclusions

Currently, the literature offers articles (mainly on gas–liquid systems) that deal with the description and modelling of the processes that occur during beer production by means of CFD techniques. Different texts present stages such as the cooling, pasteurization, or carbonation of beer. Whirlpool is the only solid-state process to have been modelled by CFD techniques. The paper on the solid phase appeared relatively recently, with the remaining text being limited to the study of flow hydrodynamics only for liquid and gas. Processes such as mashing, filtration, boiling, and fermentation of beer have not yet been described. This may be due to their complexity. The influence of the wet solid phase (BSG) (mashing and filtration), the duration of the processes compared to the required small time step and complexity of the momentum, mass and heat transport (mashing), the chemical reactions involved (mashing, boiling, and fermentation) or the properties of biomass (fermentation) have to be taken into consideration while performing CFD simulations of mentioned operations. Also, the complexity of choosing the right multiphase model, the necessity of high computing power to perform a numerical calculation, etc. are nowadays the obstacles to characterize by CFD methods some of the processes that are taking place during brewing. That is why, currently, there are no significant numbers of articles describing CFD simulation of mashing, filtration, boiling, and fermentation for brewing. Although publications on whirlpooling and areas other than brewing show that the currently available models and solutions can be used to present the phenomena occurring in analogous processes with quite good accuracy. The popularity of beer and research on its intermediates may contribute to a better understanding of the parameters of BSG and S. cerevisiae, which can be applied in CFD simulations. The development of computational fluid dynamics methods, the constant demand for improved apparatus operation, and the complexity of the processes described give space for greater use of CFD simulation in the brewing industry.

The articles presented above demonstrate the application of computational fluid dynamics methods in simulating and optimizing processes that occur in many branches of the food industry. The high accuracy of the simulation in relation to the experimental data makes CFD modelling helpful in understanding the mechanisms governing the modelled processes, which can translate into a safer and more optimal use of materials, apparatuses, and energy in the food (and brewing) industry.

Data availability

Data sharing is not applicable to this article as no new data were created or analyzed in this study.

References

Jackowski M, Trusek A (2018) Non-alcoholic beer production–an overview. Polish J Chem Technol 20:32–38

Jackowski M, Semba D, Trusek A et al (2019) Hydrothermal Carbonization of Brewery’s Spent Grains for the Production of Solid Biofuels. Beverages 5:12. https://doi.org/10.3390/beverages5010012

Norton T, Sun DW (2006) Computational fluid dynamics (CFD)-an effective and efficient design and analysis tool for the food industry: A review. Trends Food Sci Technol 17:600–620. https://doi.org/10.1016/j.tifs.2006.05.004

Scott G, Richardson P (1997) The application of computational fluid dynamics in the food industry. Trends Food Sci Technol 8:119–124. https://doi.org/10.1016/S0924-2244(97)01028-5

Xia B, Sun D-W (2002) Applications of computational fluid dynamics (CFD) in the food industry: a review. Comput Electron Agric 34:5

Chhanwal N, Tank A, Raghavarao KSMS, Anandharamakrishnan C (2012) Computational Fluid Dynamics (CFD) Modeling for Bread Baking Process-A Review. Food Bioproc Tech 5:1157–1172. https://doi.org/10.1007/s11947-012-0804-y

Malekjani N, Jafari SM (2018) Simulation of food drying processes by Computational Fluid Dynamics (CFD); recent advances and approaches. Trends Food Sci Technol 78:206–223. https://doi.org/10.1016/j.tifs.2018.06.006

Ghani AGA, Farid MM, Chen XD (2003) A computational and experimental study of heating and cooling cycles during thermal sterilization of liquid foods in pouches using CFD. Proc Inst Mech Eng, Part E: J Process Mech Eng 217:1–9. https://doi.org/10.1243/09544080360562936

Lee WT, Kaar S, O’Brien SBG (2018) Sinking bubbles in stout beers. Am J Phys 86:250–256. https://doi.org/10.1119/1.5021361

Dhekne PP, Patwardhan AW (2021) CFD model for transient flow fields around teabag during tea infusion. Food and Bioprod Process 130:79–91. https://doi.org/10.1016/j.fbp.2021.09.006

Lian G, Astill C (2002) Computer simulation of the hydrodynamics of teabag infusion. Food and Bioprod Process: Transact Inst Chem Eng, Part C 80:155–162. https://doi.org/10.1205/096030802760309179

Moroney KM, O’Connell K, Meikle-Janney P et al (2019) Analysing extraction uniformity from porous coffee beds using mathematical modelling and computational fluid dynamics approaches. PLoS One 14:1–24. https://doi.org/10.1371/journal.pone.0219906

Turgut SS, Feyissa AH, Baltacıoğlu C et al (2020) Extraction simulation of porous media by CFD: Recovery of trans-resveratrol from grape cane by pressurised low polarity water system. Chem Eng Process-Process Intensif 148:107779. https://doi.org/10.1016/j.cep.2019.107779

Wang Y, Herdegen V, Repke JU (2016) Numerical study of different particle size distribution for modeling of solid-liquid extraction in randomly packed beds. Sep Purif Technol 171:131–143. https://doi.org/10.1016/j.seppur.2016.07.013

Alagusundaram K, Jayas DS, Muir WE, White NDG (1991) Thermal conductivity of bulk barley, lentils, and peas. Transact ASAE 34:1784–1788

Lapczynska-Kordon B, Zaremba A, Kempkiewicz K (1994) Thermal characteristics of barley and oat. Int Agrophys 8:2

Markowski M, Białobrzewski I (2013) Bulk thermal conductivity of malting barley. Ind Crops Prod 42:369–372. https://doi.org/10.1016/j.indcrop.2012.06.017

Ropelewska E (2018) Relationship of thermal properties and ergosterol content of barley grains. J Cereal Sci 79:328–334. https://doi.org/10.1016/j.jcs.2017.11.018

Bala BK, Woods JL (1991) Physical and thermal properties of malt. Dry Technol 9:1091–1104. https://doi.org/10.1080/07373939108916735

Warpala IWS, Pandiella SS (2000) Grist fractionation and starch modification during the milling of malt. Food Bioprod Process: Transact Inst Chem Eng, Part C 78:85–89. https://doi.org/10.1205/096030800532789

Barrozo MAS, Borel LDMS, Lira TS, Ataíde CH (2019) Fluid dynamics analysis and pyrolysis of brewer’s spent grain in a spouted bed reactor. Particuology 42:199–207. https://doi.org/10.1016/j.partic.2018.06.001

de Moura FP, Mathias TRDS (2018) A comparative study of dry and wet milling of barley malt and its influence on granulometry and wort composition. Beverages. https://doi.org/10.3390/beverages4030051

Jackowski M, Niedźwiecki Ł, Jagiełło K et al (2020) Brewer’s spent grains—valuable beer industry by-product. Biomolecules 10:1–18. https://doi.org/10.3390/biom10121669

Jagiełło K, Uchańska O (2020) Wysłodziny browarnicze jako alternatywne źródło energii. Zeszyty Energetyczne VII:441–450

Jagiełło K, Hińcz W, Kaczorowska W et al (2022) Properties of activated carbon obtained from brewers spent grains. Biomass Convers Biorefin. https://doi.org/10.1007/s13399-022-02964-6

Brans G, Schroën CGPH, Van Der Sman RGM, Boom RM (2004) Membrane fractionation of milk: State of the art and challenges. J Memb Sci 243:263–272. https://doi.org/10.1016/j.memsci.2004.06.029

Springer F, Carretier E, Veyret D et al (2011) Numerical and experimental methodology for the development of a new membrane prototype intended to microfiltration bioprocesses. Application to milk filtration. Chem Eng Process: Process Intensif 50:904–915. https://doi.org/10.1016/j.cep.2011.07.009

Stahl S, Leipert C, Nirschl H (2013) The cleanability of particle loaded woven filter media in solid-liquid separation. Sep Purif Technol 110:196–201. https://doi.org/10.1016/j.seppur.2013.02.003

Naukkarinen T, Nikku M, Turunen-Saaresti T (2019) CFD-DEM simulations of hydrodynamics of combined ion exchange-membrane filtration. Chem Eng Sci 208:115151. https://doi.org/10.1016/j.ces.2019.08.009

Hao FL, Shen MW (2021) Development, simulation, and laboratory test of novel gas-solid-liquid separator for UASB/EGSB reactor of wastewater treatment. J Environ Chem Eng 9:105217. https://doi.org/10.1016/j.jece.2021.105217

Wu SE, Lin YC, Hwang KJ et al (2018) High-efficiency hollow fiber arrangement design to enhance filtration performance by CFD simulation. Chem Eng Process-Process Intensif 125:87–96. https://doi.org/10.1016/j.cep.2018.01.003

Li B, Zhang H, Saranteas K, Henson MA (2022) A rigid body dynamics model to predict the combined effects of particle size and shape on pressure filtration. Sep Purif Technol 278:119462. https://doi.org/10.1016/j.seppur.2021.119462

Puderbach V, Schmidt K, Antonyuk S (2021) A coupled CFD-DEM model for resolved simulation of filter cake formation during solid-liquid separation. Processes. https://doi.org/10.3390/pr9050826

Hund D, Lösch P, Kerner M et al (2020) CFD-DEM study of bridging mechanisms at the static solid-liquid surface filtration. Powder Technol 361:600–609. https://doi.org/10.1016/j.powtec.2019.11.072

Dimou A, Yanniotis S (2011) 3D numerical simulation of asparagus sterilization in a still can using computational fluid dynamics. J Food Eng 104:394–403. https://doi.org/10.1016/j.jfoodeng.2011.01.002

Jayamini HPA, Weliwita JA, Narayana M, et al (2021) Study of moisture transport in rice cooking. MERCon 2021 - 7th International Multidisciplinary Moratuwa Engineering Research Conference, Proceedings 240–244. https://doi.org/10.1109/MERCon52712.2021.9525735

Bhuvankar P, Dabiri S (2020) Numerical simulation of sliding bubbles in saturated flow boiling. Chem Eng Sci 228:115919. https://doi.org/10.1016/j.ces.2020.115919

Shoghl SN, Bahrami M, Moraveji MK (2014) Experimental investigation and CFD modeling of the dynamics of bubbles in nanofluid pool boiling. Int Commun Heat Mass Transfer 58:12–24. https://doi.org/10.1016/j.icheatmasstransfer.2014.07.027

Stojanović A, Belošević S, Crnomarković N et al (2021) Heat Transfer To a Boiling Liquid-Numerical Study. J Serbian Soc Comput Mech 15:177–185. https://doi.org/10.24874/jsscm.2021.15.01.12

Liu Y, Olewski T, Véchot LN (2015) Modeling of a cryogenic liquid pool boiling by CFD simulation. J Loss Prev Process Ind 35:125–134. https://doi.org/10.1016/j.jlp.2015.04.006

Colombo M, Fairweather M (2016) Accuracy of Eulerian-Eulerian, two-fluid CFD boiling models of subcooled boiling flows. Int J Heat Mass Transf 103:28–44. https://doi.org/10.1016/j.ijheatmasstransfer.2016.06.098

Krepper E, Rzehak R, Lifante C, Frank T (2013) CFD-modelling of subcooled boiling. Kerntechnik 78:43–49. https://doi.org/10.3139/124.110311

Jouhara H, Fadhl B, Wrobel LC (2016) Three-dimensional CFD simulation of geyser boiling in a two-phase closed thermosyphon. Int J Hydrog Energy 41:16463–16476. https://doi.org/10.1016/j.ijhydene.2016.02.038

Setoodeh H, Shabestary AM, Ding W et al (2022) CFD-modelling of boiling in a heated pipe including flow pattern transition. Appl Therm Eng 204:117962. https://doi.org/10.1016/j.applthermaleng.2021.117962

Chien NB, Choi K, il, Oh JT, (2015) Experiment and CFD Simulation of Boiling Heat Transfer Coefficient of R410A in Minichannels. Int J Air-Cond Refrig 23:1–9. https://doi.org/10.1142/S2010132515500327

Shopska V, Denkova-Kostova R, Kostov G (2022) Modeling in Brewing—A Review. Processes 10:267

Cheung SCP, Vahaji S, Yeoh GH, Tu JY (2014) Modeling subcooled flow boiling in vertical channels at low pressures - Part 1: Assessment of empirical correlations. Int J Heat Mass Transf 75:736–753. https://doi.org/10.1016/j.ijheatmasstransfer.2014.03.016

Jakubowski M, Diakun J (2007) Simulation investigations of the effects of whirlpool dimensional ratios on the state of secondary whirls. J Food Eng 83:106–110. https://doi.org/10.1016/j.jfoodeng.2006.12.025

Jakubowski M, Sterczyska M, Matysko R, Poreda A (2014) Simulation and experimental research on the flow inside a whirlpool separator. J Food Eng 133:9–15. https://doi.org/10.1016/j.jfoodeng.2014.02.011

Jakubowski M, Wyczalkowski W, Poreda A (2015) Flow in a symmetrically filled whirlpool: CFD modelling and experimental study based on Particle Image Velocimetry (PIV). J Food Eng 145:64–72. https://doi.org/10.1016/j.jfoodeng.2014.08.009

Jakubowski M, Stachnik M, Sterczyńska M et al (2019) CFD analysis of primary and secondary flows and PIV measurements in whirlpool and whirlpool kettle with pulsatile filling: Analysis of the flow in a swirl separator. J Food Eng 258:27–33. https://doi.org/10.1016/j.jfoodeng.2019.04.003

Stachnik M, Jakubowski M (2020) Multiphase model of flow and separation phases in a whirlpool: Advanced simulation and phenomena visualization approach. J Food Eng 274:109846. https://doi.org/10.1016/j.jfoodeng.2019.109846

Toapanta-Ramos F, González-Rojas L, Calero E et al (2020) Numerical Study of a Helical Heat Exchanger for Wort Cooling in the Artisanal Beer Production Process. Revista Facultad de Ingenieria 29:e11632

Yuan Y, Xu Y, Liu X (2009) CFD modeling of subcooling process for beer fermentation liquid. Asia-Pacific J Chem Eng 4:99–106. https://doi.org/10.1002/apj.216

Ajani CK, Zhu Z, Sun DW (2021) Recent advances in multiscale CFD modelling of cooling processes and systems for the agrifood industry. Crit Rev Food Sci Nutr 61:2455–2470. https://doi.org/10.1080/10408398.2020.1809992

Calvo F, Bula A, Di Mare L, Garcia S (2017) CFD simulation of multiphase (liquid–solid–gas) flow in an airlift column photobioreactor. Acta Mech 228:2413–2427. https://doi.org/10.1007/s00707-017-1828-1

Das S, Sarkar S, Chaudhari S (2018) Modification of UASB reactor by using CFD simulations for enhanced treatment of municipal sewage. Water Science and Technology 77:766–776. https://doi.org/10.2166/wst.2017.584

Schmidt D, Velten K (2016) Numerical simulation of bubble flow homogenization in industrial scale wine fermentations. Food and Bioproducts Processing 100:102–117. https://doi.org/10.1016/j.fbp.2016.06.008

Ding J, Wang X, Zhou XF et al (2010) CFD optimization of continuous stirred-tank (CSTR) reactor for biohydrogen production. Bioresour Technol 101:7005–7013. https://doi.org/10.1016/j.biortech.2010.03.146

Novak M, Trontel A, Slavica A et al (2017) Computational fluid dynamic (CFD) modeling of simultaneous extraction and fermentation process in a single sugar beet cossette. Eurobiotech J 1:18–26

Ri PC, Ren NQ, Ding J et al (2017) CFD optimization of horizontal continuous stirred-tank (HCSTR) reactor for bio-hydrogen production. Int J Hydrogen Energy 42:9630–9640. https://doi.org/10.1016/j.ijhydene.2017.02.035

Haringa C, Deshmukh AT, Mudde RF, Noorman HJ (2017) Euler-Lagrange analysis towards representative down-scaling of a 22 m3 aerobic S. cerevisiae fermentation. Chem Eng Sci 170:653–669. https://doi.org/10.1016/j.ces.2017.01.014

Wang J, Xue Q, Guo T et al (2018) A review on CFD simulating method for biogas fermentation material fluid. Renew Sustain Energy Rev 97:64–73. https://doi.org/10.1016/j.rser.2018.08.029

Pessoa DR, Finkler ATJ, Machado AVL et al (2019) CFD simulation of a packed-bed solid-state fermentation bioreactor. Appl Math Model 70:439–458. https://doi.org/10.1016/j.apm.2019.01.032

Spann R, Glibstrup J, Pellicer-Alborch K et al (2019) CFD predicted pH gradients in lactic acid bacteria cultivations. Biotechnol Bioeng 116:769–780. https://doi.org/10.1002/bit.26868

Miller KV, Block DE (2020) A review of wine fermentation process modeling. J Food Eng. https://doi.org/10.1016/j.jfoodeng.2019.109783

Shu L, Yang M, Zhao H et al (2019) Process optimization in a stirred tank bioreactor based on CFD-Taguchi method: A case study. J Clean Prod 230:1074–1084. https://doi.org/10.1016/j.jclepro.2019.05.083

Li J, Zou J, Wei X (2022) Modeling of CSTR flow field for Agaricus bisporus residue fermentation based on CFD numerical simulation. Environ Sci Pollut Res. https://doi.org/10.1007/s11356-022-23388-9

Du YH, Tong LL, Wang Y et al (2022) Development of a kinetics-integrated CFD model for the industrial scale-up of DHA fermentation using Schizochytrium sp. AIChE J. https://doi.org/10.1002/aic.17750

Bhuvaneswari E, Anandharamakrishnan C (2014) Heat transfer analysis of pasteurization of bottled beer in a tunnel pasteurizer using computational fluid dynamics. Innov Food Sci Emerg Technol 23:156–163. https://doi.org/10.1016/j.ifset.2014.03.004

Augusto PED, Pinheiro TF, Cristianini M (2010) Using Computational Fluid-Dynamics (CFD) for the evaluation of beer pasteurization: effect of orientation of cans. Ciencia e Tecnologia de Alimentos 30:980–986. https://doi.org/10.1590/S0101-20612010000400022

Jun S, Puri VM (2005) 3D milk-fouling model of plate heat exchangers using computational fluid dynamics. Int J Dairy Technol 58:214–224. https://doi.org/10.1111/j.1471-0307.2005.00213.x

Kiziltaş S, Erdoǧdu F, Koray Palazoǧlu T (2010) Simulation of heat transfer for solid-liquid food mixtures in cans and model validation under pasteurization conditions. J Food Eng 97:449–456. https://doi.org/10.1016/j.jfoodeng.2009.10.042

Augusto PED, Cristianini M (2011) Numerical simulation of packed liquid food thermal process using computational fluid dynamics (CFD). Int J Food Eng. https://doi.org/10.2202/1556-3758.2418

Bottani E, Ferretti G, Manfredi M, Vignali G (2013) Modeling and thermo-fluid dynamic simulation of a fresh pasta pasteurization process. Int J Food Eng 9:327–339. https://doi.org/10.1515/ijfe-2013-0036

Cordioli M, Rinaldi M, Copelli G et al (2015) Computational fluid dynamics (CFD) modelling and experimental validation of thermal processing of canned fruit salad in glass jar. J Food Eng 150:62–69. https://doi.org/10.1016/j.jfoodeng.2014.11.003

Lee MG, Yoon WB (2014) Developing an effective method to determine the deviation of F value upon the location of a still can during convection heating using CFD and subzones. J Food Process Eng 37:493–505. https://doi.org/10.1111/jfpe.12107

D’Addio L, di Natale F, Budelli A, Nigro R (2014) CFD simulation for the pasteurization of fruit puree with pieces. Chem Eng Trans 39:1699–1704. https://doi.org/10.3303/CET1439284

Shafiekhani S, Zamindar N, Hojatoleslami M, Toghraie D (2016) Numerical simulation of transient temperature profiles for canned apple puree in semi-rigid aluminum based packaging during pasteurization. J Food Sci Technol 53:2770–2778. https://doi.org/10.1007/s13197-016-2249-1

Lespinard AR, Badin EE, Santos MV, Mascheroni RH (2019) Computational fluid dynamics analysis on natural convective heating of bottled liquid food during pasteurization: Effect of container orientation. J Food Process Eng. https://doi.org/10.1111/jfpe.12995

de Albuquerque CD, Curet S, Boillereaux L (2019) A 3D-CFD-heat-transfer-based model for the microbial inactivation of pasteurized food products. Innov Food Sci Emerg Technol 54:172–181. https://doi.org/10.1016/j.ifset.2019.04.007

Lazaar M, Boughanmi H, Bouadila S, Jarraya M (2021) Parametric study of plate heat exchanger for eventual use in a solar pasteurization process designed for small milk collection centers in Tunisia. Sustain Energy Technol Assess 45:101174. https://doi.org/10.1016/j.seta.2021.101174

Erdogdu F, Topcam H, Altin O et al (2021) Computational modeling of axial rotation for the evolution of temperature in horizontal toroidal cans under pasteurization conditions. Food Bioprod Process 130:106–120. https://doi.org/10.1016/j.fbp.2021.09.007

Jahanbakhshian N, Hamdami N (2021) Numerical simulation of heat and mass transfer during heating and cooling parts of canned-green-olive pasteurization. J Food Process Eng 44:1–12. https://doi.org/10.1111/jfpe.13909

Dammann A, Schwarzer K, Müller U, Schneider J (2011) Flash pasteurization of beer - A critical review. BrewingScience 64:32–40

Rinaldi M, Cordioli M, Barbanti D, Dall’Aglio M, (2016) Study and Optimization of a CO2 Sparger for Carbonated Beverages and Beer by Means of CFD Modeling. Int J Food Eng 12:867–873. https://doi.org/10.1515/ijfe-2016-0083

Funding

This research did not receive external funding.

Author information

Authors and Affiliations

Contributions

Conceptualization, KJ, WL; writing—original draft preparation, KJ; writing—review and editing, WL; visualization, KJ; supervision, WL; all authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors confirm that there are no conflicts of interest.

Compliance with ethics requirements

This article does not contain any studies with human or animal subject.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Jagiełło, K., Ludwig, W. Towards computational fluid dynamics applications in brewing process. Eur Food Res Technol 250, 361–373 (2024). https://doi.org/10.1007/s00217-023-04401-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-023-04401-y