Abstract

Computational fluid dynamics (CFD) is a tool for modelling and simulating processes in many industries. It is usually used as a choice to solve problem involving flow of fluids, heat transfer, mass transfer and chemical reaction. Moreover, it has also found application in the optimization of processes in branches of the food industry, including bread baking, cooling beef roast, or spray drying. CFD has enormous potential and many opportunities to improve the quality and safety of food products, as well as to reduce the costs of production and the use of machines and production equipment. In addition, empirical models only permit data to be extracted at a limited number of locations in the system (where sensors and gauges are placed). CFD allows the designer to examine any location in the region of interest, and interpret its performance through a set of thermal and flow parameters. Computer simulations are the future of every field of science, and the presented overview provides the latest information on experts and experiences related to CFD application in food production. Despite some disadvantages, such as the need to have a large reserve of computing power, the development of digital and IT technologies will make this problem insignificant in the nearest future. Then the CFD will become an indispensable element in the design of equipment and technological lines in the food industry.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Computational fluid dynamics (CFD) is a tool for modelling and simulating processes commonly used in industry. CFD integrates the disciplines of fluid mechanics, mathematics and computer science. CFD is dedicated to the fluids in motion, which physical characteristics can be described through mathematical equations. To solve the equations, they are converted into computer programmes or software packages using computer programming languages. Despite the combination of three different domains, only one person, who obtains more or less some subsets of the knowledge of each discipline, is demanded. Computational fluid dynamics is a powerful tool that is employed in many fluid engineering applications. In many industries such as aviation and automotive, CFD is an integral part of the product development process and production technology [1,2,3]. In the case of food technology, it is possible to use CFD simulations for modelling, inter alia, thermal and mechanical processes. This is due to the process optimization and development of technology that focus on safety, quality and cost reduction.

CFD simulations have a significant advantage over empirical experiments. Conventional experiments allow the analysis of data only from a limited number of places in the system (where sensors and metres are located). CFD simulations, on the other hand, allow researchers to explore any location in a region of interest and interpret its performance using multiple thermal and flow parameters. In addition, using classical experiments and tests to obtain the necessary engineering data for design is much more costly. Simulations allow engineers to model different process conditions. In addition, many flow and heat transfer processes cannot be easily tested in the laboratory. CFD simulation gives you the ability to theoretically simulate any physical state. This method allows for great control over the physical process and provides the ability to isolate specific phenomena for research. An additional advantage is the fact that many simulations can be performed in a much shorter time than by conducting laboratory tests. Input data and any modifications can be made early in the process design process [4,5,6].

This review aims to present the latest advanced application of CFD in various branches of food industry (including thermal and non-thermal processing) and experiences of scientists using CFDs in the food science.

Simulation of thermal processing of food products

Heat exchangers

A heat exchanger is an apparatus that enables the heat transferring from a flowing fluid (medium) to another flowing fluid through either direct or indirect contact. In direct heat exchangers, heat transfer occurs through direct contact between the cold and hot streams. The exchange factors can be two immiscible liquids, gas and liquid, and solid and liquid. Mixed heat exchangers are a special case, in which the heat exchange process takes place through direct contact, as a result of mixing factors, although the heat exchange process itself is treated as a side effect. In indirect heat exchangers, the exchange of energy is the result of the indirect contact of hot and cold streams. This type of heat exchange is used in recuperators and regenerators [7]. Heat exchangers are used in many food processes for applications such as heating and cooling. CFD was widely used to compare heat exchanger configurations [8], investigate tubular heat exchangers [9,10,11], fouling dynamics [12], designing easy-to-clean processing equipment [13] and the possibility of using plate exchangers in a solar pasteurization process [14].

CFD has found application in many areas of research of different types of heat exchangers: improper distribution of fluid flow, contamination, pressure drop and thermal analysis in the design and optimization phase. In simulations of processes with the use of heat exchangers, various turbulence models are used, e.g. standard k-ε, realizable k-ε, RNG k-ε and SST k-ω. Speed–pressure coupling schemes such as Semi-Implicit Method for Pressure Linked Equations (SIMPLE), Semi-Implicit Method for Pressure Linked Equations-Consistent (SIMPLEC), Pressure-Implicit with Splitting of Operators (PISO) are used to perform the simulation. In most cases, simulations give results in good agreement with experimental studies in the range of 2% to 10%. Unfortunately, there are exceptional cases in which the differences reach even 36%. For large deviations, user-defined subroutines specific to the design problem are necessary. The reliability of CFD results has reached the point where it has become an integral part of all design processes, leading to the elimination of the need for prototyping [15,16,17,18].

The studies conducted by Piepiórka-Stepuk and Diakun (2014) show that the design of the plate surface is a key issue in the development of heat exchangers. This work allowed to simulate the distribution of fluid flow velocity in the channel between heat exchanger plates with different surface shapes. The results show that the velocity field and streamlines flavour the use of panels with a corrugated surface. The velocity distribution in the duct between the heat exchanger plates is an important parameter of the cleaning efficiency of a damaged system. The results indicate that different channel flow conditions can cause non-uniform cleaning in place (CIP) conditions [19]. Similar analyses were carried out on the example of heat exchangers in the paper by Piepiórka-Stepuk and Jakubowski [20]. Numerical calculations using the finite volume method (FVM) using the ANSYS CFX programme were used in these studies. The calculations identified areas on the plates where insufficient flow could cause cleaning problems. Based on the results of this work, it was shown that different flow rates in adjacent channels between the heat exchanger plates can not only cause non-uniform cleaning conditions in the CIP system, but also affect the thermal treatment of the product.

Lazaar et al., (2021) proposed to design a solar pasteurization system for small milk collection centres in Tunisia. The system consisted of solar water collector system, plate heat exchangers and an absorption chiller. This system allowed minimizing the amount of rejected milk during transport process from the producer to the factory. A numerical study was conducted to evaluate the behaviour of the mass and heat transfer through plate heat exchangers. CFD simulations were validated by experimental performances. In this work, geometry was simplified by eliminating structures which are unaffected by flow to reduce the number of nodes. For turbulent flow simulation, the realizable k-ε turbulence model was adopted for calculation process. For the pressure–velocity coupling, the method of “Pressure–Velocity Coupling” was used. Numerical results showed that the turbulence depended on the angle of plate corrugations inclination. The plate heat exchanger efficiency varied depending on the inlet temperature of the hot water and its flow rate. Maximal efficiency of 80% was reached for the inlet temperature of 80 ℃ and a flow rate of 386 l/h [14].

In Perone et al., (2021), study of CFD analysis of a tubular heat exchanger used for olive paste conditioning was carried out to evaluate the influence of the inlet conditions of the olive paste on thermal and hydrodynamic behaviour within it. The heat-exchanger-based olive paste conditioning could improve the process of olive oil extraction. The heat exchanger consists of a tube-in-tube module. The inner tube was fed with olive paste, while the jacket was filled of hot water. The main aim was to predict the heat transfer and pressure drop in the paste side of the exchanger. Temperature and pressure drop were estimated. CFD simulation proved very useful in identifying the main factors affecting the optimization of the heat exchanger [11].

The main aim of Dekhil et al., (2020) research was to investigate thermal behaviour of three configurations of heat exchangers for sensible thermal energy storage. One of the heat exchangers is commonly used in the agri-food industry and was used in this study as the reference against which the other two configurations were compared. The reference exchanger was made up of two fluid coils embedded in an aluminium cylindrical conductive element. The other two exchangers were derived by a partial substitution of the conductive element with a confined heat transfer fluid. Thermal properties and storage performance of heat exchangers were analyzed. The study showed that a controlled distribution of the conductive material by a confined heat transfer fluid at constant compactness and coils heat transfer surface led to an achievement of material saving compared to the reference configuration and increased the energy reserve without decrease in the heat transfer kinetics [8].

Córcoles et al., (2020) used CFD to simulate the heat transfer process in a tube with a curved elbow. Commercially available fruit juice was used as a non-Newtonian fluid in laminar regime. The numerical model was validated using water as the heat transfer fluid. The difference between outlet temperature and inlet temperature was higher for the laminar simulation than for the turbulent one. The highest viscosity was found at the centre of the pipe and the lowest values were showed at the wall. Pseudoplastic condition of the juice explains this behaviour. These results may lead to improving the heat transfer process [9].

Sannad et al., (2022) paper focussed on the fouling of milk which takes place during thermal treatments using a plate heat exchanger. Minimizing this process could make heat exchanging process more efficient. A mathematical model of the steady state was established for the flow. The model accounted for constant and turbulent flows between two parallel plates in the presence of the porous medium. The accuracy of the model was validated by comparison with previously published data. The simulation results showed a good reliability of the developed code for laminar and turbulent regimes [12].

Dehydration

Drying is a multidisciplinary unit operation, which for centuries has been responsible for extending the shelf life of food products and for shaping sensory features. Apart from the classic (convection) drying methods, many innovative drying processes are simulated, which are individually selected for the raw material being processed [21]. These include: spray drying, fluidized bed drying (FBD), freeze drying, microwave-assisted drying processes or super-heated steam drying processes. Each of these techniques requires an individual technological solution [22].

Spray drying of food products is a process often simulated in CFD that includes atomization, spray-air contact and separation of dried products [23]. CFD simulation tools for spray drying are now frequently used because measurements of air flow, temperature, particle size and humidity in the drying chamber are very difficult and expensive to obtain in large-scale dryers. Accurately selecting the dose of heat and optimizing the process parameters are very important in this case due to the nutritional value of the product. An incorrectly carried out process may result in a decrease in the nutritional value due to the breakdown of thermolabile substances, e.g. degradation of some vitamins and unsaturated fatty acids. In addition, too high a dose of heat supplied to the sprayed product with a very large surface area can cause the formation of compounds harmful to human health. Among them, for example, polycyclic aromatic hydrocarbons (PAHs) that may be formed during the production of milk in infant powder. Optimization using CFD also translates into economic benefits. Providing the optimal dose of heat necessary to carry out the process allows you to reduce energy consumption during drying. In the case of simulation of this process, the two most general two-phase modelling frames are used: the Eulerian–Eulerian and the Eulerian–Lagrangian methods. In the Eulerian–Eulerian frame, the dispersed phase is treated as a continuous phase. On the other hand, in the Eulerian–Lagrangian particle tracking approach, the gas phase is modelled using the standard Eulerian approach and the spray is represented by a number of discrete computational ‘particles’ [23,24,25]. Benavides-Morán et al. (2021) used CFD to simulate air movement during the spray-drying process of a formulation of guava juice. The study implements the two-phase Euler–Lagrange model for simulating gas–particle interactions. The Lagrange method used by the authors made it possible to calculate the trajectories of the particles, starting from the circumference of the spraying nozzle and ending with the walls of the dryer and the lower outlet. The CFD model used allowed for the simulation of the particle size distribution, analysis of temperature and humidity during the process, and consequently the evaluation of the drying efficiency [26].

Among the many innovative drying methods, many CFD simulations focus on modelling the transformations associated with freeze drying [27]. There are many scientific reports on the mathematical models used in this type of simulation or the design of individual components of the device, such as capacitors, chambers and heat exchangers [28,29,30,31,32,33,34,35]. There are even calculations available in the literature aimed at reducing the loss of heat during the dehydration of food products [36]. However, there is very little information available about the simulation process of freeze-drying food products. Li et al. (2007) developed and validated a CFD model based on foil sublimation for the sublimation drying process of apple cubes. They showed values of tortuosity and internal resistance coefficient are critical for process simulation [33]. In addition, a novel model was developed to illustrate the effect of hot water blanching on freeze-drying characteristics and product quality [37].

CFD simulations also found application in the design of the fluidized bed drying process (FBD) [38,39,40]. Mu et al. (2021) applied CFD in the simulation of sago pith waste (SPW) using FBD [41]. This method was also used in simulating the drying of pistachios, tea leaves, soybean and many other foods [42,43,44,45,46]. In addition, Xiao et al. (2012) developed a CFD model and performed a simulation of super-heated steam fluidized bed drying process [47]. In addition, CFD has also found application in simulating the drying of by-products from distillation operations [48]. Moreover Ranjbaran and Zare (2012) developed a CFD model of microwave-assisted FBD using two-fluid Eulerian model and their results were verified on the basis of empirical experience with soybeans, and Angula et al. (2019) found the use of CFD in the simulation of the drying process of food products using solar energy [49, 50].

Using incorrect parameter values, wrong chosen model or boundary conditions are among the typical researchers’ errors. Usage errors can exist in the geometry, grid generation and post-processing software, in addition to the CFD set-up. Among other material properties, thermal conductivity air flow velocity and temperature drying should be taken into account during CFD drying simulation [51]

Sterilization and pasteurization

Sterilization and pasteurization are one of the essential ways of thermal processing food. The primary purpose is inactivation of microorganisms, toxins and enzymes which can lead to food decaying. Sterilization and pasteurization are also used for foods shelf life extending. The main parameter of these processes is temperature but time and the chemical and physical properties of products are also important, in particular the shape and position of the slowest heating zone. Conditions of thermal processes should be strictly determined so the germs are inactivated and the food quality is not compounded [52].

CFD was used in many researches where the aim was to determinate the best parameters for these processes. Bhuvaneswari and Anandharamakrishnan (2014) used CFD to determinate the temperature distribution pattern inside bottled beer during pasteurization. Unlike in earlier published works, the actual thermophysical properties of beer were used. Further, the simulation prediction was validated with experimental measurements. The results of this study signified that using the actual thermophysical properties lead to close correlation between the predictions and experimental measurements [53].

The ability of using CFD in beer manufacturing was also used to evaluate the effect of packaging orientation during pasteurization of beer packed in aluminium cans. The temperature profile and convection current velocity along the process and the variation of the pasteurization units were evaluated in relation to time. Cans positioned in conventional, inverted and a horizontal way were considered. The temperature and velocity profiles were similar to those presented in the literature. The position of package did not result in process improvement [54].

The aim of Lespinard and Mascheroni (2014) study was to develop a model that allows the prediction of the effect of package orientation on temperature distribution, flow pattern, position of slowest heating zone, processing time and quality changes in tomato puree during pasteurization. The lowest processing time was observed for the package positioned horizontally and there was no difference between time process for packages positioned in conventional and inverted way. Consequently, reduction of processing time in the horizontal position resulted in decrease of quantity losses [55].

Pasteurization in aluminium cans is also used in orange juice manufacturing. Jing et al. (2013) used CFD to improve the pasteurization process. The input data included juice parameters, i.e.: density ρ = 1026 kg/m3, the specific heat capacity Cp = 3880 J/ kgK, the thermal conduction k = 0.596 W/mK and density of heat flow rate a = 600 W/m2K.

Authors used different equations applied in numerical computation to simulate pasteurization process.

Equation of mass conservation (continuity equation)

Equation of energy conservation in the X direction

Equation of energy conservation in the Y direction

Equation of energy conservation in the Z direction

Equation of energy conservation

Control equation

where u, v, w is the velocity of flow in X, Y, Z direction during pasteurization, respectively, and ρ is the pressure in the infinitesimal flow. FX, FY and FZ are the micro unit volume force. τxx, τxy, τxz are the components of the infinitesimal body surface viscous stress xy xz xx, respectively. Cp is the specific heat capacity of the juice, k is the heat transfer coefficient and ST is the dissipative term of viscous force to the juice. T, φ and S are the thermodynamic temperature, universal variable, generalized source, respectively. Unfortunately, the work did not include the reaction kinetics of bacterial spores simulated by CFD.

Simulations in three different temperatures (85 ℃, 88 ℃, 90 ℃) were conducted and the temperature field for each of them was obtained. After comparing measurements with experimental data, the simulation model was improved and optimal computational model was obtained. The discrepancies resulted from the fact that with the progress of the process, there was a slight movement of the fluid particles. Even the velocity was very low, while the dynamic viscosity of the fluid was very low, the fluid's Reynolds number increased rapidly, and the flow properties would likely change from laminar flow to transient flow, and possible turbulence would occur. Thus, the laminar flow equation is no longer suitable for unstable pasteurization of orange juice. The results showed that the wall temperature varied continuously, which was different from the expected result. This was due to the fact that the convection force of the oil was much weaker than that of any other fluid. The wall temperature varied according to the formula: T = − 0.0004t2 + 0.1387t + 70.512 (where T is temperature and t is time). The laminar equation was replaced by the k–ε equation, and the coefficient Cµ changed during heating [56].

Ghani et al. (2000) used CFD to simulate the process of sterilization. The study presented the profiles of temperature and bacteria concentration in a pouch filled with viscous liquid food during thermal sterilization. In the study, natural convection that occurs during sterilization in a pouch heated from all sides was simulated. The results showed different temperature profiles during sterilization process which highlight the migration of the slowest heating zone. Moreover, the dependency of concentration of alive bacteria on the temperature distribution was shown [57]. The work assumes that the rate of bacterial inactivation is consistent with the first-order kinetics. The reaction rate constant is a function of temperature and is usually described by Arrhenius equation (Eq. 6).

Accurate kinetic parameters such as reaction rate constants and activation energy were required to predict quality changes during food processing. In food engineering, decimal reduction time is most commonly used. The relationship between the reaction rate constant and the decimal reduction time (D) is calculated according to Eq. 7.

In the simulation, the value of the decimal reduction time at 121 ℃ for Clostridium botulinum was 0.1 min, and the value of activation energy was 30 × 104 J mol−1. The reaction rate constant kT was calculated using Eq. 6. Equation (7) was used to calculate the A constant of Arrhenius equation (A = 2.5 × 1011 s−1).

C concentration in Eq. (8)—mass balance for bacteria, was taken as the dimensionless percent bacterial concentration defined as the ratio of the actual value to the initial bacterial concentration (multiplied by 100).

The boundary conditions used: T = Tw = 121℃, u = 0, v = 0 and w = 0 at top, bottom and side walls. The initial conditions used: T = Tref = 20 ℃, C = Co = 100, u = 0, v = 0 and w = 0.

CFD was also used in the simulation of heat transfer and liquid flow during the sterilization of large particles in a cylindrical vertical can. Natural convection heating was simulated and three dimensional equations of mass, momentum and energy conservation were solved. The results show a good agreement between simulated and measured temperatures in both liquid and particles [58].

In Azar's et al., (2020) study, conductive heat transfer was investigated during sterilization in canned celery stew. A CFD model was developed and validated to predict the temperature profiles and determine the slowest heating zone. The temperature profile was obtained and recorded experimentally at the point where the coldest thermal point was expected. CFD models were compared with experimental data and the root mean square error (RMSE) was calculated. It showed a good fit between both methods. Using these results, the retort setting for stew sterilization was readjusted towards the process optimisation [59].

Cooking and baking

CFD computer simulation enables the use of innovative solutions in the process of baking and cooking food products. It has found a very wide application in the optimisation of the baking process [60]. In order for the simulation to reflect the real baking process, it is necessary to implement the mechanism of evaporation and condensation as well as the influence of latent heat during the phase change of water. Thanks to CFD, baking can be optimized with the use of the classic combi-steamer which is intended for small-scale production or devices with continuous operation (tunnel ovens) [61,62,63,64,65]. Such solutions allow, among other things, to predict the degree of starch gelatinisation during baking [66].

Similarly, the roasting process of meat and other meat products can be simulated, and moisture transport can be analyzed using Flory–Rehner theory [67]. The above-mentioned theory describes mass transport driven by swelling pressure gradients and relates to water holding capacity (WHC). It was also used in the work of van der Sman (2013), where poultry WHC changes during the treatment process in a tunnel kiln were described with the use of many different factors (including salt and pH) [68]. Szpicer et al. (2022) in his work optimized the roasting process of beef based on the degree of protein denaturation and weight loss in the convection-steam oven [69]. On the other hand, Chen et al. (2011) optimized the baking process of hamburgers depending on the temperature and pressure in the oven chamber. Moreover a simulation of heat and mass transfer model can be used to predict content of acrylamide formation (among others in French fries) or for developing a heat treatment procedure for meat products to inactivate microorganisms such as Escherichia coli O157:H7 [70,71,72]. In addition, Cordioli et al., (2016) raised a very interesting topic on heat transfer by conduction. Their study was used to analyze the effect of gelatinization of modified starch on heat transfer in food systems [73].

Many researchers are focussing their experience with simulating heat treatment for the roasting process. The experiment of Oliveros et al. (2017) focussed on the analysis of the effect of porosity of coffee beans on the prediction of heat and mass transfer parameters during roasting based on simulation. It was observed that porosity influences the rate of heat and moisture loss during roasting, and the obtained results allow for optimizing the processing of food products that require roasting with hot air, such as grains or seeds [74]. A similar experiment was carried out by Alonso-Torres et al. (2013), they developed a model for roasting coffee beans on the basis of which it is possible to analyze the temperature and humidity distribution. Such 3D simulations are crucial to better understand the roasting process at the individual bean level [75]. Bopape et al. (2016) presented research on the coffee roasting process based on the Schwartzberg model [76]. Based on this experiment, the influence of heat transfer parameters on the roasting profile was investigated. On the other hand, the often used single-bean CFD simulations are often not sufficient and do not reflect the changes in the volume of the raw material during roasting [77]. The use of positron emission particle tracking (PEPT) is innovative and enables the tracking of particles inside the chamber of the device. This solution characterizes the particle dynamics of the coffee beans in the fountain bed roasting device as a function of the changing air-to-bean ratio, and can be used to improve existing heat and mass transfer patterns when roasting the coffee beans [78]. Another solution was used by Agyei-Agyemang et al. (2022) who simulated the roasting process of peanuts [79]. In this case, a 3D hot plate roaster model was used and its structure was modified to include a diverse number of heat sources to predict the temperature distribution during the process.

Cooling and refrigeration

The CFD simulations used in air flow calculations are an increasingly used practice in the design of refrigeration and freezing systems in the food industry. One of the main parameters determining the microclimate surrounding food products is temperature. To limit changes in food quality, it is essential to select the correct refrigerant and cooling equipment throughout the cold chain [80]. Flow simulations have been used in the design of both conventional home appliances, professional gastronomic appliances and large industrial freezing appliances [81,82,83] and in the case of a very wide range of food products, including fish, meat and meat products, fruits and vegetables [84,85,86,87].

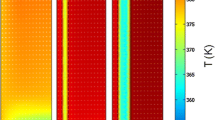

Among the basic reports on the use of CFD, food cooling modelling, classic refrigeration devices operating on the basis of forced convection, serving, among others, cooling of beef carcasses or optimization of pre-cooling conditions (thermal and aerodynamic tests) in chamber cooling [88, 89]. On the other hand, the innovative devices used to simulate food freezing, scientists are increasingly analyzing the temperature distribution during fluidisation or quasi-hydrofluidisation (HF) [90]. Moreover, Stebel et al. (2022) investigated the effects of various refrigerants (ethanol–glycerol solution and ethanol–glucose solution) used in hydrofluidisation during freezing of the macroscopic particle model (MPM) [91]. Their experiment showed that the type of liquid had little effect on the heat transfer coefficient (HTC), but it did affect the behaviour of the food samples. Another novel solution used by researchers is the use of 3D CFD simulations for spray freezing in cold gas. Such a mathematical model made it possible to solve the problem of the accumulation of a layer of ice at the outlet of the nozzle and to increase the efficiency by increasing the diameter of the outlet of the chamber (from 20 to 57%) [92].

A wide range of CFD tools allows not only to optimize the cooling and freezing process in terms of efficiency, but also the time and amount of energy received. During the process of freezing food products, ice crystals are formed, the size of which is of particular importance for the physical properties after defrosting. This topic was examined by Miller et al. (2011) who simulated the ice crystallization in ice cream manufacturing. They analyzed the process of dynamic freezing of model sucrose solutions that takes place in a scraped-surface heat exchanger (SSHE) [93]. This study describes the effect of multiphase, phase change and shear caused by scraping on ice crystal nucleation and growth kinetics.

However, the cold chain is not only about the process of receiving energy, it is also about storage. CFD is suitable, among others, for simulating the sorption and storage stability of dried food products during cold storage [94]. There are also reports of heat distribution during transport using refrigerated trucks [95]. In the report, Moureh and Flick (2004) improved and optimized air distribution system in refrigerated vehicles to reduce temperature differences across the entire palletised load [96]. In addition to the above-mentioned solutions, numerical calculations are also used, and the efficiency of anti-fog coatings in refrigerated display cases is simulated [97]. Among the storage studies in which CFD was used for simulation is the analysis of the maturation conditions of traditional sheep cheeses. In the work of Alvarenga et al. (2021), a simulation was developed to test environmental conditions (i.e. humidity and temperature) for the physicochemical and microbiological properties of the product [98].

Smoking

Smoking is a food processing method that involves submission of food to indirect or direct action of smoke generated during combustion of wood chips. This process is used for food preservation on account of the fact that it causes inactivation of microorganisms and endogenous enzymes liable for food spoilage. Furthermore, it is also imparting sensory characteristics in food. Smoking can be applied to many food products but is mainly used for meat, fish, vegetables and fruits. It should be noted that despite the widespread use of this method, it is characterized by ineffective smoke fume consumption. During the food smoking process, only 10% of smoke is effectively used and the remaining amount is emitted into the atmosphere. It is also important that during wood combustion, harmful compounds such as polycyclic aromatic hydrocarbons can be released into food [99, 100]. Taking this into account, it is necessary to improve the utilization of smoke and reduce the generation of hazardous compounds in the process.

A significant problem, in addition to the inefficient use of smoke, is the uneven smoke flow through the smoke chamber, which causes defects in food. It may cause two main defects: the product is not sufficiently smoked or is cured too much. To solve the problem of technological defects, CFD was used to optimize the construction of smoking chambers [101]. Single truck smoking machine was a simulation model and four geometric variants were analyzed: an empty chamber and chamber filled with batches of spherical and cylindrical hams and an elongated shape loin. Analysis was conducted using the Ansys Mechanical APDL. Significant flow irregularities and areas with higher and lower concentrations of smoke were revealed. This can indicate the areas where smoke propagation may not be sufficient which can deteriorate the realization of process. Data obtained from the analysis can provide a basis for improving the process.

The purpose of study was to create models for the construction of smoke supply and distribution nozzles inside the smoke chamber. Models of empty smoking chamber and chamber filled with oval product batch and its discretization were conducted with the use of Ansys Mechanical APDL [102]. Basic design model (classical feed nozzle arrangement) and the proposed solution (modified feed nozzle design: nozzles up to 15 cm long from the floor) were compared. The compared distributions of flow velocities in the smoking chambers in both design variants showed significant variation, which indicated the occurrence of a lack of symmetry in the flow despite the uniform distribution of inlet nozzles. The obstructions found in the form of individual batch pieces clearly indicate the problem of uneven propagation of the smoke, and thus the possibility of technological defects, such as under-smoking or over-smoking with a classic feed nozzle arrangement. Comparing the results of tracing the trajectory lines of the smoke particles in a chamber with a classical (base input) feed nozzle design with the batch, one can find the occurrence of so-called "dead spaces" of smoke concentration. The occurrence of "dead spaces" confirms the thesis of unfavourable conditions for the propagation of the smoke in such a feed nozzle arrangement, which may further translate into the finished product. A different situation can be observed in the chamber, where modified feed nozzles have been proposed (their length up to 15 cm from the floor). The proposed layout of the feed nozzles highlights a more favourable movement of the smoke both at the bottom and in the centre of the smoke chamber, which improves the concentration and propagation conditions of the smoke. Taking into account the data obtained, it is possible to significantly improve the conditions for the realization of smoking in the form of a longer contact of the smoke with the processed product.

The purpose of study was to investigate the temperature distribution inside a gas heated oven, to simulate hot gases flow under actual operating conditions and then to compare the predictions with the experiments results [103]. The flow of heat was described using continuity and momentum equations. The energy equation was required because temperature interest and turbulence modelling were also involved to calculate the average kinetic viscosity. Analyzed models were conducted using Ansys Programme. Validation study between numerical method and experimental study has been conducted and the temperature difference was approximately 4%. It was stated that, using CFD, it would be possible to find flow problems, and thereby improve the smoking process.

Simulation of mechanical processes in CFD in food industry

Mixing

Mixing is a primary process in food manufacturing. It is commonly used in many different departments of food industry. This process can go off in and of itself, for example, in components diffusion or forced as a consequence of conveying exterior energy. Mixing consists in mutual relocating of different particles of environment towards obtaining or sustaining the homogeneity. The main purpose of mixing is to make the composition of two- or multi-component mixtures uniform [104].

CFD was used to simulate homogenisation [105], solid mixing [106], mixing of Newtonian [107] and viscoelastic fluids [108]. It was also used to design an industrial mixer for fluid foods [109].

In Jiang et al. (2019) study, there were two CFD models developed based on high-pressure homogenizer [105]. The homogeneous cavity geometry model A was simplified to a 2D model without circumferential flow, while model B was a 3D model. It was determined that the mathematical model B was more consistent with the actual homogenization process. The investigated parameters were homogenization pressure, ratio of oil to water and temperature. Comparing the optimal parameter combination from experimental data and from numerical simulation it was observed that the data were not entirely consistent. Inconsistency was owed to addition of emulsifiers during the homogenization process which can promote breaking of emulsions and prevent polymerization. Another cause of that was severe mass transfer and heat transfer that occurred during homogenization. However, despite that, the mathematical model and analysis method of the B model were consistent with the actual homogenization process. It was proven that numerical simulation methods have a great influence on the guidance of the homogenization process and can provide an important reference in the development and use of homogenizers.

Kenche et al. (2013) paper presented a numerical study of the gas and solid dynamics in an internally circulating fluidized bed for which, despite being an intensive research area, are no design rules that can be used to quantitatively predict the solid mixing in a specific system for a stated set of operating parameters. The flow structure was investigated in terms of spatial distribution of gas and solid flow. It was shown that complete lateral and vertical solid mixing can be achieved in a similar time (5 s). The investigated operating velocities did not affect the solid mixing and solid flux [106].

In Connelly and Valenti-Jordan (2008) study, CFD was used to gain greater understanding of the mixing action of the planetary pin mixer. Both local and global measures of mixing were evaluated using particle tracking. Mixing of highly viscous Newtonian corn syrup was simulated. Segregation scale, length of stretch and efficiency were used to evaluate the mixer. It was shown that the planetary mixer does not experience as much axial mixing as cross-sectional mixing over the same time span. It was observed that some pin positions are more efficient than others [107].

Mixing characteristics of complex non-Newtonian fluid in a cylindrical vessel without baffles were determined in Ameur’s (2018) study. The effect of the impeller design was explored. The study was focussed on the determination of flow patterns, cavern size and power consumption for various shapes of cuts in the blade of impeller. In terms of both cavern size and power consumption, the best compromise allowed selecting the impellers with V-cuts or W-cuts in blades as the most efficient [108].

Ferretti et al. (2013) work focussed on discontinuous vertical fluid mixing systems for food fluid with particles. The main aim of the study was to identify some structural and physical parameters that have the strongest influence on the performance of the mixing process to obtain useful indications for the design of mixing systems. Different mixer designs were analyzed using CFD, and key performance indicators were obtained. The significance of the influence of input parameters such as position of the rotor, fluid viscosity and aspect ratio was assessed. To verify the accuracy of the results obtained, a preliminary validation has been performed showing a good agreement between simulation results and experimental data [109].

Forming and extrusion

Forming the shape of food products is an indispensable element of food design. To meet the expectations of customers, production plants use innovative mechanical solutions to shape sweets, confectionery, bakery products and much more.

CFD is also used to simulate the extrusion process. Emin et al. (2021) performed a numerical analysis on the profile of thermal and mechanical stresses during the process of extrusion of plasticized starch. The results of their work showed that the maximum stresses arise at the ends of the extruder screws, and their consequence is local overheating of the raw material. CFD analysis allowed the tracking of molecules and the study of stresses, thus optimizing the process. It is surprising that the increase in the speed of rotation of the extruder screw causes a decrease in mechanical stress. It is related to the decrease of the matrix viscosity [110]. This is due to starch fragmentation with higher mechanical stresses generated before the simulated zone (i.e. end of the extruder). Therefore, although the screw speed and the corresponding shear rates are higher, the resulting maximum shear stresses can be much lower [111].

A similar study was carried out by Sarghini et al., (2016) in which a numerical simulation of pasta extrusion was performed. Using the local Taylor expansion, they proposed a model based on semolina moisture and temperature during shear. The proposed solution allows to precisely design an innovative extrusion nozzle based on reverse engineering [112].

Studies using a single-screw extruder simulation were also conducted by Singh and Muthukumarappan (2017). They analyzed the rheological properties during the isothermal flow of high-protein cake based on white soy flakes. Among the analyzed substitutes, the following process conditions were taken into account: screw speed, barrel temperature and the content of white soy flakes. The above-mentioned simulations were consistent with the results of empirical research and were used to optimize the extrusion process [113].

Among the rheological tests analyzed with the use of CFD, reference should also be made to the work of Hicks et al. (2012). They simulated the local shear flow behaviour of bread dough with CFD. The predictions showed that the dough remained fairly undamaged near the centreline of the flow field as the critical strain limit for failure was not reached, suggesting that the process model should include a viscoelastic element. In addition, the geometry provides extremely high shear rates, which highlighted the usefulness of CFD in identifying unstable process regions and the need for a model that takes into account such conditions [114].

In Tagliavini et al. (2018), a CFD simulation of a co-rotating twin screw extruder was carried out. The modelling was to validate the rheological profile of starch dough formed into snacks. The first stage of this study was to verify the rheological parameters of corn and tapioca dough calculated on the basis of mathematical models with experimental analyses. After validation, a CFD 3D simulation was performed reproducing the flow in the first part of the twin screw extruder (feed zone). The developed model allows for the examination of many different operating parameters of the device and various geometries of machine screws, predicting changes in the rheological properties of the product [115].

Completely different solutions were considered in their work by Latif et al. (2020) who carried out a CFD simulation of mechanical juicing from cassava leaves. Among the input data, the impact of, inter alia, the diameter of the nozzle and the rotational speed of the screw determined the efficiency of the process. The process was optimized and based on it, it was possible to calculate the amount of protein in cassava leaves, cake, juice sediment and juice supernatant [116].

Food 3D printing

3D printing, also known as additive layer manufacturing, is a kind of rapid prototyping technology which has a great potential in food manufacturing processes. This technique provides numerous advantages for the food industry such as capacities to customize complex shapes and eliminate time-consuming and labour-intensive processes. Mathematical modelling in food printing was applied to investigate 3D printing properties of potato starch composite gels [117], rice paste [118], other cereal grains [119] and to compare syringe-based and screw-based printers [120].

Based on previous studies, Cui et al. (2022) hypothesized that xanthan gum might play a similar role in structuring starch composite gel in 3D printing composites as sodium alginate, as it is also a common thickening agent. They analyzed geometric accuracy, rheological properties, water state distribution and microscopy images of products made for composites with added various amounts of sodium alginate, xanthan gum and both of the substances. CFD was used to model the printing process. The best geometric accuracy was shown in gel with added both agents (2.5%/2.5% w/w). The mathematical model explained the non-uniformity of velocity distribution in the flow channel due to the varied diameter, which led to jet expansion during printing process [117].

The objective of Guo et al. (2019) study was to compare two different kinds of extrusion-based food printing methods in fluid characteristics and printing profile. CFD simulations were validated by a printing experiment. Analysis of the simulated model suggested that the screw-based food printer had complex fluid characteristics while syringe based showed simpler properties. Furthermore, experimental data suggested that the screw-based printer was not suitable for extruding the inks with high viscosity [120].

In Oyinloye and Yoon (2021) study, CFD was utilized to investigate the deposition process and printability of rice paste. The suitability for 3D printing rice paste was formed from rice-to-water ratio 100:80. Controlling the ambient temperature at 47 ± 5 ℃ contributed to improving the sample’s structural stability. The viscoelastic simulation showed that the nozzle diameter affected the flow properties of the printed material in both residual stress and overall deformation of the sample. CFD analysis showed significant advantage in optimizing the operating parameters for printing rice paste [118].

Guo et al. (2020) investigated the possibility of using black rice, job’s tear seeds, mung bean, brown rice and buckwheat gels for 3D printing. CFD was used to analyze how easy or difficult a material of interest can be successfully printed. The printing performance of the gels was evaluated by CFD and printing experiments. Mathematical simulations and printing experiments data were consistent. CFD simulations gave realistic understanding of the extrusion flow behaviour of grain gels [119].

Other applications

Clean room condition

Air-borne microbial contamination is one of the main reasons for the shortened use-by date. The consequence of this is food waste and economic losses for both food producers and consumers. The use of CFD in the design of catering rooms and food processing halls allows the use of an appropriate food safety management that will ensure the highest microbiological safety [121]. This challenge was undertaken by the researchers such as Zand et al. (2022) who analyzed the application of a partial protection strategy based on filtering fan units (FFU) [122]. The FFU strategy with air velocity of 0.3 m/s resulted in a significant reduction of the relative pollution (99.94%). A numerical model for assessing the air exchange system for microbiological quality was also assessed in a food processing clean room [123]. The pollutant removal efficiency is strongly related to the position of the pollutant source and does not change significantly as the air change rate (ACH) changes. A similar issue was discussed in the Rouaud and Havet (2005) publication. The purpose of their work was to develop a methodology and correctly design air distribution using CFD in clean rooms and to optimize the organization of the process [124].

Crystallization

Meng et al. (2021) study focussed on improvizing circulation and mixing of the massecuite and reducing the energy loss in the cane sugar continuous crystallization system. The developed CFD model was based on the continuous crystallization system of a sugarcane mill in China and verified with the actual operation data. The calculated entropy production and pressure drop of the system were used as indices for assessing the performance of the system. CFD simulations were conducted in the parametric experiment platform and produced a collection of data. Then the data-driven model was employed for regression of the relations between key parameters and indices. CFD simulation with the optimized parameters reduced entropy and pressure drop [125].

In Srinivasan (2022) paper, a three-stage solidification model for food droplets has been implemented in a CFD code. Additional simulations were made in which crystallization behaviour of the cocoa butter droplets in relation to the droplet size, ambient air temperature and the relative drop-gas velocity was investigated. It was found that the crystallization time is exponentially related to droplet size. It increased with the ambient temperature but decreased with the relative drop-gas velocity. The results suggested operating at the extreme values of the process parameters to minimize the crystallization time [126].

Rezvanivand Fanaei et al. (2021) designed a TVC (thermal vapour compressor) and simulated to recover waste vapour streams and reuse them in the crystallization of sugar. CFD was used to simulate the flows. The effect of motive steam pressure on the entrainment ratio and compressor ratio was simulated. Thermodynamics parameters such as static pressure, temperature, velocity, Mach number and mass ratios of motive steam and suction were assessed. It was suggested that the designed TVC could be mounted in the crystallization section. Additionally, it would be counted as a beneficial process to reduce energy and fuel consumption and serve environmental concerns [127].

Filling and food packaging

In the work of Venturelli et al. (2018), the main aim was to investigate the predictive capabilities of numerical simulation for addressing the actual operation of the hydraulic system of filling machines for beverage packaging process. The lumped and distributed parameter approach was compared to the full CFD simulation of the filling system. The accuracy of results was assessed in the case of Newtonian and non-Newtonian fluids. Water and tomato were used as operational fluids. When considering water, the results obtained by the lumped and distributed parameter numerical model and the simulation proved to be very similar. Conversely, when addressing a non-Newtonian fluid, the results proved to be significantly different [128].

Jałowiecka and Makowski (2020) paper comprised numerical simulations of two filling methods. First method involved dosing with a pipe placed over the free liquid surface of a fully filled bottle while the second method covered filling with a pipe located near the bottom. The influence of rheological properties and surface tension was considered. Following conducted simulations, the negative impact of dosing the liquid from a high position was observed in comparison to the results from simulations of method 2. The authors suggested that a better approach to fill such large bottles would be introducing a moveable nozzle over the bottom of the bottle and rising it with the increasing height of the free liquid surface. This method would also have small risk of contamination of the label area or the area of the bottom neck, just like dosing the liquid from a high position [129].

Wu et al. (2019) study unveiled how package design, package position on a pallet, package stacking pattern and cold chain scenarios affect the cooling kinetics and fruit quality evolution for every single fruit inside a pallet. For this purpose, the virtual cold chain methodology was applied to large ensembles of fruit, which relies on CFD simulations. There were three packaging designs evaluated for citrus fruit. The Supervent package outperformed the Standard and Opentop packaging by providing the overall fastest and most uniform cooling. The methodology enabled authors to identify, for a certain cold chain, which box on the pallet the customer should choose to have the longest shelf life or which box the retailer should sell first. Concerning the cold chain scenarios, forced-airflow pre-cooling was the fastest to bring down the temperature after harvest. The “ambient loading” scenario, where citrus fruit are loaded at ambient temperatures in the container, proved to be a worthy alternative [130].

In Olatunji et al. (2020) paper, a new tool was developed that was capable of rapidly generating the geometry of a fruit stack. The tool took a size and weight distribution of fruit and simulated the effect of gravity and friction forces to form a realistic stack. The tool-generated stacks were validated against computer tomography (CT) scans of real fruit stacks and found to be similar, except that in the CT scans, the presence of an internal polyliner appeared which was not simulated in the stacking tool. A conjugated heat transfer and airflow CFD model was, therefore, able to be produced quickly and without the need for manual construction of the model geometry. The CFD model showed that most of the airflow during a forced-air cooling operation passed through the headspace and that airflow pathway through the channel was more sinuous than previous studies have predicted, due to the realistic polyliner shape [131].

The major CFD models and features used in each of the discussed applications areas in food industry are presented in Table 1.

Advantages and disadvantages of CFD simulation in food technology

CFD calculations have the views of extremely complex, time-consuming simulations that require powerful machines and a broad knowledge of physical processes, numerical methods, programming, heat and mass transport, and of course fluid mechanics itself [52]. All these elements are necessary to model physical phenomena and then simulate them, and the knowledge in this field itself translates into the accuracy of the results, simulation time or the sensitivity of the simulation to the input data. Modelling is a way of recording physical phenomena using the language of mathematics, so it requires extensive knowledge of the phenomenon, then knowledge of the physical equations that describe them, transforming them into a computer language, writing a programme based on them, examining whether the proposed models describe the phenomenon well or even create your own model to describe reality. An additional problem is working with simulated biological material whose properties change during the process [24]. Factors such as basic composition, water loss from the product or protein denaturation will have a significant impact on numerous parameters, including: specific heat (Cp) or thermal conductivity (λ) [69]. In addition to thermal changes resulting from heat treatment, the mechanical properties of the product often also change, such as volume changes resulting from thermal shrinkage or building a spongy structure of the product, as is the case when baking bread [133, 134].

An additional difficulty is the lack of ready-made solutions for most food products. This applies to the designs themselves as well as the thermal and mechanical properties. It is often necessary to determine these parameters from tables and equations. Fluid mechanics is crucial in food technology, and due to its apparent chaotic nature, it is the greatest challenge for people who describe reality with mathematics. Nowadays, where satisfactory results can be obtained up to several hours for a moderately complex problem, and commercial software is user-friendly, where the meshing process is automated, boundary conditions are assigned with the mouse on the CAD model, it is not necessary to implement the phenomenon models by hand. Then you only need to select them from the list of available models, and the visualization takes a fraction of the time. Currently, CFD calculations mainly support the design process, thanks to which it can be easily determined whether the design assumptions can be met and in which direction the design changes would take place. Built-in optimization algorithms and parametric tests alone can improve the product. In addition, the currently available computers have very high computing power, which reduces the simulation time. The number of mesh elements results in the quality of the results; however, with further densification, the results do not change significantly. The most basic and accurate way to evaluate mesh quality is to refine the mesh until a critical result such as the maximum stress in a specific location converges: meaning that it does not change significantly as the mesh is a refinement. Equation 9 can be used to select the size of the grid element.

where v is maximum velocity in the domain, dt is time step (defined in solver) and dx is your typical mesh size. This number should be close to 1 to ensure accuracy and numerical stability. To sum up, the algorithms that create a mesh and the increased computing power in conjunction with the parametric test allow to obtain, in a relatively short time, appropriate results and trends in changing the phenomena under the influence of changes in geometry or boundary conditions. Moreover, in a CFD simulation, it is not just the final results that count. The generated charts, for which CFD simulations are known, are an extremely important thing related to simulations due to their accuracy and 3D visualization [135]. The final result of the simulation is not individual values, but the entire calculated fields of velocity, temperature, density and pressure. These fields illustrate how the device works and allow you to observe how changes in parameters affect the tested sample.

There are many types of CFD simulation software on the market today. They are characterized by different functions and can be used to simulate various types of processes (Table 2).

There is a wide field of possibilities for further use of CFD in the food industry. So far, few articles have been published on the simulation of the development of the amount of microorganisms in food products. Such an application would be used, for example, in the selection of sterilization and pasteurization parameters, which are particularly important for improving durability and increasing food safety. Also there is a lack of research on the transportation of food products, especially vegetables and fruits, where appropriate transport conditions significantly affect shelf life and quality. Additionally, there are also few new reports on the smoking process, where it is possible to improve the design of devices to allow better use of smoke. It is also necessary to develop CFD in the simulation of the synthesis of chemical compounds during heating, such as polycyclic aromatic hydrocarbons (PAH) and other unfavourable compounds to food. This is especially necessary for equipment used in large-scale smoked food enterprises. The above examples illustrate gaps in research that can be filled using CFD, allowing the method to realize its full potential in the food industry.

Conclusion

CFD is a powerful tool used in many branches of the food industry. CFD has become crucial for understanding physical phenomena of 2D and 3D geometries. It is used at every stage of production, from preparation and processing of raw materials to packing the finished product. Simulations of flows, temperature distribution and mechanical changes during processing significantly affect the selection of window sills and process optimization. It is increasingly used for scaling up, optimizing and designing processes in food technology. 3D modelling made it possible to reduce the time and costs associated with the construction of prototypes of food processing machines and devices. This type of software in the hands of a qualified operator will allow machine manufacturers to meet the requirements of food processors, including reducing losses during production, increasing the efficiency of the process or reducing energy consumption. It is assumed that CFD will become an indispensable element in the design of equipment and technological lines in the food industry. Despite some disadvantages, such as the need to have a large reserve of computing power, the development of technology will make this problem insignificant over time.

Availability of data and material

The authors declare availability of data and material.

Code availability

Not applicable.

Abbreviations

- Biological:

-

Chemical and microbiological

- SPW:

-

Sago pith waste

- PAH:

-

Polycyclic aromatic hydrocarbons

- FBD:

-

Fluidized bed drying

- CFD:

-

Computational fluid dynamics

- PEPT:

-

Positron emission particle tracking

- HF:

-

Hydrofluidization

- MPM:

-

Macroscopic particle model

- HTC:

-

Heat transfer coefficient

- RMSE:

-

Root mean square error

- SSHE:

-

Scraped-surface heat exchanger

- FFU:

-

Filtering fan units

- TVC:

-

Thermal vapour compressor

- CT:

-

Computer tomography

- IT:

-

Information technology

- HPC:

-

High-performance computing

- RAS:

-

Reynolds-averaged simulation

- LES:

-

Large eddy simulation

- DES:

-

Detached eddy simulation

- MRF:

-

Multiple reference frames

- AMI:

-

Arbitrary mesh interface

- MEP:

-

Mechanical, electrical and plumbing

- FVM:

-

Finite volume method

- CIP:

-

Cleaning in place

- RANS:

-

Reynolds-averaged Navier Stokes

- EEM:

-

Eulerian–Eulerian model

- SST:

-

Shear stress transport

- DO:

-

Discrete ordinates

- RTE:

-

Radiative transfer equation

- RANS:

-

Reynolds-averaged Navier–Stokes

- DPM:

-

Discrete phase model

- MPM:

-

Macroscopic particle model

- RNG:

-

Re-normalization group

- SIMPLE:

-

Semi-Implicit Method for Pressure Linked Equations

- SIMPLEC:

-

Semi-Implicit Method for Pressure Linked Equations-Consistent

- PISO:

-

Pressure-Implicit with Splitting of Operators

- Λ:

-

Conduction coefficient (W/(m⋅K))

- C p :

-

Specific heat (J/kgk)

References

Tu J (2019) Computational fluid dynamics a practical approach, 3rd edn. Elsevier Ltd, Amsterdam

Ajani CK, Zhu Z, Sun DW (2021) Recent advances in multiscale CFD modelling of cooling processes and systems for the agrifood industry. Crit Rev Food Sci Nutr 61:2455–2470. https://doi.org/10.1080/10408398.2020.1809992

Wang H, Yan X, Li D et al (2021) Recent advances in computational fluid dynamics simulation of flotation: a review. Asia-Pac J Chem Eng 16:1–29. https://doi.org/10.1002/apj.2704

Versteeg HK, Malalasekera W (2007) An introduction to parallel computational fluid dynamics, 2nd edn. Pearson Education Limited, Harlow

Jagadale P, Chawdhary AB (2021) Computational fluid dynamics, an overview. Int Res J Eng Technol 8:1817–1821

Stachnik M, Jakubowski M (2020) Multiphase model of flow and separation phases in a whirlpool: Advanced simulation and phenomena visualization approach. J Food Eng 274:109846. https://doi.org/10.1016/j.jfoodeng.2019.109846

Kakac S, Liu HH (2002) Heat exchangers selection, rating, and thermal design, 2nd edn. CRC Press, Boca Raton

Dekhil MA, Simo Tala JV, Bulliard-Sauret O, Bougeard D (2020) Development of an innovative heat exchanger for sensible heat storage in agro-food industry. Appl Therm Eng 177:115412. https://doi.org/10.1016/j.applthermaleng.2020.115412

Córcoles JI, Marín-Alarcón E, Almendros-Ibáñez JA (2020) Heat transfer performance of fruit juice in a heat exchanger tube using numerical simulations. Appl Sci. https://doi.org/10.3390/app10020648

Arsana IM, Putra YRR, Sari HN et al (2020) Optimized hydraulic diameter and operating condition of tube heat exchanger for food industry—a numerical study. J Mech Eng Res Dev 43:329–338

Perone C, Romaniello R, Leone A et al (2021) CFD analysis of a tubular heat exchanger for the conditioning of olive paste. Appl Sci 11:1–19. https://doi.org/10.3390/app11041858

Sannad M, Zaza A, El Hammami Y et al (2022) A numerical simulation under milk fouling in a plate heat exchanger in the presence of a porous medium. J Adv Res Fluid Mech Therm Sci 91:1–17. https://doi.org/10.37934/arfmts.91.1.117

Jensen BBB, Friis A, Bénézech T et al (2005) Local wall shear stress variations predicted by computational fluid dynamics for hygienic design. Food Bioprod Process 83:53–60. https://doi.org/10.1205/fbp.04021

Lazaar M, Boughanmi H, Bouadila S, Jarraya M (2021) Parametric study of plate heat exchanger for eventual use in a solar pasteurization process designed for small milk collection centers in Tunisia. Sustain Energy Technol Assess 45:101174. https://doi.org/10.1016/j.seta.2021.101174

Aslam Bhutta MM, Hayat N, Bashir MH et al (2012) CFD applications in various heat exchangers design: a review. Appl Therm Eng 32:1–12. https://doi.org/10.1016/j.applthermaleng.2011.09.001

Georgiadis MC, Macchietto S (2000) Dynamic modelling and simulation of plate heat exchangers under milk fouling. Chem Eng Sci 55:1605–1619. https://doi.org/10.1016/S0009-2509(99)00429-7

Grijspeerdt K, Hazarika B, Vucinic D (2003) Application of computational fluid dynamics to model the hydrodynamics of plate heat exchangers for milk processing. J Food Eng 57:237–242. https://doi.org/10.1016/S0260-8774(02)00303-5

Jun S, Puri VM (2006) A 2D dynamic model for fouling performance of plate heat exchangers. J Food Eng 75:364–374. https://doi.org/10.1016/j.jfoodeng.2005.03.064

Piepiórka-Stepuk J, Diakun J (2014) Numerical analysis of fluid flow velocity between plates channel of heat exchanger by different surface configuration in reference to the effects of cleaning. Ital J Food Sci 26:210–220

Piepiórka-Stepuk J, Jakubowski M (2013) Numerical studies of fluid flow in flat, narrow-gap channels simulating plate heat exchanger. Chem Process Eng Inz Chem i Proces 34:507–514. https://doi.org/10.2478/cpe-2013-0041

Babu AK, Kumaresan G, Antony Aroul Raj V, Velraj R (2020) CFD studies on different configurations of drying chamber for thin-layer drying of leaves. Energy Sources Part A Recover Util Environ Eff 42:2227–2239. https://doi.org/10.1080/15567036.2019.1607935

Malekjani N, Jafari SM (2018) Simulation of food drying processes by Computational Fluid Dynamics (CFD); recent advances and approaches. Trends Food Sci Technol 78:206–223. https://doi.org/10.1016/j.tifs.2018.06.006

Kuriakose R, Anandharamakrishnan C (2010) Computational fluid dynamics (CFD) applications in spray drying of food products. Trends Food Sci Technol 21:383–398. https://doi.org/10.1016/j.tifs.2010.04.009

Jamaleddine TJ, Ray MB (2010) Application of computational fluid dynamics for simulation of drying processes: a review. Dry Technol 28:120–154. https://doi.org/10.1080/07373930903517458

Anandharamakrishnan C (2007) Computational fluid dynamics in food processing, 1st edn. Springer, London

Benavides-Morán A, Cubillos A, Gómez A (2021) Spray drying experiments and CFD simulation of guava juice formulation. Dry Technol 39:450–465. https://doi.org/10.1080/07373937.2019.1708382

Ehlers S, Friess W, Schroeder R (2021) Impact of chamber wall temperature on energy transfer during freeze-drying. Int J Pharm 592:120025. https://doi.org/10.1016/j.ijpharm.2020.120025

Zadravec M (2022) Determination of pressure resistance of a partially stoppered vial by using a coupled CFD-0D model of lyophilization. Eur J Pharm Biopharm 175:53–64. https://doi.org/10.1016/j.ejpb.2022.04.010

Kshirsagar V, Tchessalov S, Kanka F et al (2019) Determining maximum sublimation rate for a production lyophilizer: computational modeling and comparison with ice slab tests. J Pharm Sci 108:382–390. https://doi.org/10.1016/j.xphs.2018.10.061

Nakagawa K, Ochiai T (2015) A mathematical model of multi-dimensional freeze-drying for food products. J Food Eng 161:55–67. https://doi.org/10.1016/j.jfoodeng.2015.03.033

Petitti M, Barresi AA, Marchisio DL (2013) CFD modelling of condensers for freeze-drying processes. Sadhana Acad Proc Eng Sci 38:1219–1239. https://doi.org/10.1007/s12046-013-0155-z

Barresi AA, Marchisio DL (2018) Computational Fluid Dynamics data for improving freeze-dryers design. Data Br 19:1181–1213. https://doi.org/10.1016/j.dib.2018.05.141

Li S, Stawczyk J, Zbicinski I (2007) CFD model of apple atmospheric freeze drying at low temperature. Dry Technol 25:1331–1339. https://doi.org/10.1080/07373930701438907

Barresi AA, Rasetto V, Marchisio DL (2018) Use of computational fluid dynamics for improving freeze-dryers design and process understanding. Part 1: modelling the lyophilisation chamber. Eur J Pharm Biopharm 129:30–44. https://doi.org/10.1016/j.ejpb.2018.05.008

Ramachandran RP, Akbarzadeh M, Paliwal J, Cenkowski S (2018) Computational fluid dynamics in drying process modelling—a technical review. Food Bioprocess Technol 11:271–292. https://doi.org/10.1007/s11947-017-2040-y

Masud MH, Islam T, Joardder MUH et al (2019) CFD analysis of a tube-in-tube heat exchanger to recover waste heat for food drying. Int J Energy Water Resour 3:169–186. https://doi.org/10.1007/s42108-019-00032-w

Wang HO, Fu QQ, Chen SJ et al (2018) Effect of hot-water blanching pretreatment on drying characteristics and product qualities for the novel integrated freeze-drying of apple slices. J Food Qual. https://doi.org/10.1155/2018/1347513

Aziz H, Ahsan SN, De Simone G et al (2022) Computational modeling of drying of pharmaceutical wet granules in a fluidized bed dryer using coupled CFD-DEM approach. AAPS PharmSciTech 23:1–19. https://doi.org/10.1208/s12249-021-02180-x

Faizal M, Seri SM, Al-Hafiz M, Raghavan VR (2012) CFD studies on velocity distribution of air in a swirling fluidized bed. Adv Mater Res 468–471:25–29. https://doi.org/10.4028/www.scientific.net/AMR.468-471.25

Pérez Cortés SA, Aguilera Carvajal YR, Vargas Norambuena JP et al (2021) Modeling a fluidized bed dryer through computational fluid dynamics and the discrete element method. Chem Eng Technol 44:1567–1577. https://doi.org/10.1002/ceat.202100134

Mu A, Abdul I, Tantiyani N, Ali B (2021) Computational fluid dynamics simulation of fluidized bed dryer for sago pith waste drying process computational fluid dynamics simulation of fluidized bed dryer for sago pith waste drying process. J Kejuruter 33:239–248. https://doi.org/10.17576/jkukm-2021-33(2)-09

Shadidi B, Chayjan RA (2022) Full Research Paper Mass transfer simulation of pistachio nuts using computational fluid dynamic (CFD) during fluid bed drying. Iran Food Sci Technol 17:103–119. https://doi.org/10.22067/ifstrj.2021.70119.1038

Azmir J, Hou Q, Yu A (2020) CFD-DEM study of the effects of food grain properties on drying and shrinkage in a fluidised bed. Powder Technol 360:33–42. https://doi.org/10.1016/j.powtec.2019.10.021

Haron NS, Zakaria JH, Mohideen Batcha MF (2017) Recent advances in fluidized bed drying. IOP Conf Ser Mater Sci Eng. https://doi.org/10.1088/1757-899X/243/1/012038

Yohana E, Tauviqirrahman M, Mahawan MI, Mulqi MS Al (2020) Investigating the Effect of Inlet Velocity on Temperature Distribution and Solid Volume Fraction in Fluidized Bed Dryer using CFD. In: Prasetiawan D, Hartanto H, Nurmasitah S (eds) Proceedings of the 7th Engineering International Conference on Education, Concept and Application on Green Technology (EIC 2018). SCITEPRESS–Science and Technology Publications, Semarang, pp 21–28

Da Silva FRGB, De Souza M, Da Costa AM, de S, et al (2012) Experimental and numerical analysis of soybean meal drying in fluidized bed. Powder Technol 229:61–70. https://doi.org/10.1016/j.powtec.2012.06.008

Xiao Z, Zhang F, Wu N, Liu X (2012) CFD modeling and simulation of superheated steam fluidized bed drying process. In: Li D, Chen Y (eds) Computer and ComputingTechnologies in agriculture VI. Springer, Zhangjiajie

Ramachandran RP, Akbarzadeh M, Paliwal J, Cenkowski S (2017) Three-dimensional CFD modelling of superheated steam drying of a single distillers’ spent grain pellet. J Food Eng 212:121–135. https://doi.org/10.1016/j.jfoodeng.2017.05.025

Ranjbaran M, Zare D (2012) CFD modeling of microwave-assisted fluidized bed drying of moist particles using two-fluid model. Dry Technol 30:362–376. https://doi.org/10.1080/07373937.2011.642913

Angula JP, Inambao F, Africa S (2019) Computational fluid dynamics in solar drying. Int J Mech Eng Technol 10:259–274

Rindang A, Panggabean S, Wulandari F (2019) CFD analysis of temperature drying chamber at rotary dryer with combined energy. J Phys Conf Ser. https://doi.org/10.1088/1742-6596/1155/1/012037

Xia B, Sun DW (2002) Applications of computational fluid dynamics (CFD) in the food industry: a review. Comput Electron Agric 34:5–24. https://doi.org/10.1016/S0168-1699(01)00177-6

Bhuvaneswari E, Anandharamakrishnan C (2014) Heat transfer analysis of pasteurization of bottled beer in a tunnel pasteurizer using computational fluid dynamics. Innov Food Sci Emerg Technol 23:156–163. https://doi.org/10.1016/j.ifset.2014.03.004

Augusto PED, Pinheiro TF, Cristianini M (2010) Using Computational Fluid-Dynamics (CFD) for the evaluation of beer pasteurization: effect of orientation of cans. Ciência e Tecnol Aliment 30:980–986. https://doi.org/10.1590/s0101-20612010000400022

Lespinard AR, Mascheroni RH (2014) Using computational fluid-dynamics (CFD) for the evaluation of tomato puree pasteurization: effect of orientation of bottle. In: COMSOL Conference. Curitiba, Brazil, pp 1–7

Jing X, Lin YY, Wang JF et al (2013) Theoretical study of temperature distribution though pasteurization for orange juice based on 3D CFD simulation. Adv Mater Res 740:242–248. https://doi.org/10.4028/www.scientific.net/AMR.740.242

Ghani AGA, Farid MM, Chen XD (2000) Numerical simulation of 3-D pouch during sterilization using computational fluid dynamics (CFD). Food Process Eng, pp 1–4

Rabiey L, Flick D, Duquenoy A (2007) 3D simulations of heat transfer and liquid flow during sterilisation of large particles in a cylindrical vertical can. J Food Eng 82:409–417. https://doi.org/10.1016/j.jfoodeng.2007.02.011

Azar AB, Ramezan Y, Khashehchi M (2020) Numerical simulation of conductive heat transfer in canned celery stew and retort program adjustment by computational fluid dynamics (CFD). Int J Food Eng. https://doi.org/10.1515/ijfe-2019-0303

Chhanwal N, Tank A, Raghavarao KSMS, Anandharamakrishnan C (2012) Computational fluid dynamics (CFD) modeling for bread baking process—a review. Food Bioprocess Technol 5:1157–1172. https://doi.org/10.1007/s11947-012-0804-y

Tank A, Chhanwal N, Indrani D, Anandharamakrishnan C (2014) Computational fluid dynamics modeling of bun baking process under different oven load conditions. J Food Sci Technol 51:2030–2037. https://doi.org/10.1007/s13197-012-0736-6

Adamic RM (2012) CFD and heat transfer model of baking bread in a tunnel oven. ETD Arch 3:1–210

Wong SY, Zhou W, Hua J (2007) CFD modeling of an industrial continuous bread-baking process involving U-movement. J Food Eng 78:888–896. https://doi.org/10.1016/j.jfoodeng.2005.11.033

Khatir Z, Paton J, Thompson H et al (2012) Computational fluid dynamics (CFD) investigation of air flow and temperature distribution in a small scale bread-baking oven. Appl Energy 89:89–96. https://doi.org/10.1016/j.apenergy.2011.02.002

Feyissa AH, Gernaey KV, Adler-Nissen J (2013) 3D modelling of coupled mass and heat transfer of a convection-oven roasting process. Meat Sci 93:810–820. https://doi.org/10.1016/j.meatsci.2012.12.003

Therdthai N, Zhou W, Adamczak T (2004) Simulation of starch gelatinisation during baking in a travelling-tray oven by integrating a three-dimensional CFD model with a kinetic model. J Food Eng 65:543–550. https://doi.org/10.1016/j.jfoodeng.2004.02.018

van der Sman RGM (2007) Moisture transport during cooking of meat: An analysis based on Flory-Rehner theory. Meat Sci 76:730–738. https://doi.org/10.1016/j.meatsci.2007.02.014

van der Sman RGM (2013) Modeling cooking of chicken meat in industrial tunnel ovens with the Flory-Rehner theory. Meat Sci 95:940–957. https://doi.org/10.1016/j.meatsci.2013.03.027

Szpicer A, Wierzbicka A, Półtorak A (2022) Optimization of beef heat treatment using CFD simulation: Modeling of protein denaturation degree. J Food Process Eng. https://doi.org/10.1111/jfpe.14014

Chen H, Marks BP, Murphy RY et al (2011) Modeling and simulation of hamburger cooking process using finite difference and CFD methods. Int J Ind Chem 2:1–12

Chan DS (2020) Computer simulation with a temperature-step frying approach to mitigate acrylamide formation in French fries. Foods. https://doi.org/10.3390/foods9020200

Huang L (2012) A simplified method for numerical simulation of gas grilling of non-intact beef steaks to eliminate Escherichia coli O157:H7. J Food Eng 113:380–388. https://doi.org/10.1016/j.jfoodeng.2012.07.003