Abstract

Yarrowia lipolytica has found many biotechnological applications. The species has a number of regulatory mechanisms to maintain cellular homeostasis, enabling biomass growth in complex media. The aim of this study was to evaluate the use of Y. lipolytica yeast as a platform for the simultaneous management of several industrial by-products and the production of microbial lipids with application potential in the chemical and food industries. Batch cultures of KKP 379 strain were conducted in media with post-frying rapeseed oil (PFO) and a by-product of curd cheese production—acid whey. To evaluate the potential of Yarrowia as a nutraceutical, quantitative and qualitative analyses of microbial sterols were carried out along with an assessment of the biomass mineral composition. It was indicated that the composition and content of sterols varied depending on the phase of cell growth in batch culture. During culture in medium with 20% (v/v) whey and 50 g/L PFO, the cellular lipid content reached 39% (w/w). The highest amount of sterols per dry biomass (7.38 mg/g) and cellular lipids (21.08 mg/g) was recorded after 38 h of culture. The dominant was ergosterol 12.10 mg/g (57%). In addition, the composition of carbon and nitrogen sources in the medium affected the content of selected elements in biomass, indicating that substrate modification can be a tool for manipulating the composition of yeast cells. The results of the study showed that the selection of waste substrates is an important factor in regulation of the cellular lipid accumulation efficiency, as well as the content of certain sterols.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Despite the fact that currently there is enough food for about 7 billion people, almost 1 billion people suffer from malnutrition or hunger due to the unequal distribution of wealth and poverty [67]. The challenge is not only to feed the 10 billion people predicted by 2050, but also how to do this in a sustainable way, taking into account losses in biodiversity, soil erosion, climate change, pollution and greenhouse gas emissions [20]. The ability of microorganisms classified as oleaginous to accumulate above-average amounts of lipids called single cell oils (SCOs) in their cells has made them the subject of much research. Current trends continue to focus on obtaining these valuable compounds for the oleochemistry, food and feed industries [73].

Considering the human population growth, increasing demand for new sustainable nutrients, significant amounts of household and industrial wastes produced, microbiological disposal of them with simultaneous obtaining of value-added products is justified. Therefore over the last years, SCOs extraction from cells of oleaginous microorganisms by culture in waste media has been repeatedly discussed [22, 36,37,41, 75, 75,76,80, 4]. The ability of Y. lipolytica species to biosynthesize microbial lipids under growth conditions in a variety of low-cost waste media e.g. grease, salad oil, crude glycerol, olive-mill wastewater, palm oil mill effluents, waste cooking oil, tuna wash processing wastewater, molasses, brine, urea, lard, mutton tallow, beef tallow and poultry fat have been reported in the literature [2, 3, 13, 15, 24, 35, 39, 42, 65, 70, 71, 78, 79, 81, 83].

Due to the possibility to achieve high biomass densities with rapid cell growth, which is essential for efficient production of SCOs, the yeast species Yarrowia lipolytica is considered to be the best studied microbial producer of bioproducts [36]. The yeast biomass of Y. lipolytica is not only a source of proteins, lipids, mainly unsaturated fatty acids (UFA) and carbohydrates, but also other bioactive compounds like minerals, vitamins or enzymes, [28, 33]. The U.S. Food and Drug Administration (FDA) has given the species Generally Recognized As Safe (GRAS) status. As well as, the European Food and Safety Authority (EFSA) has declared it safe for food and feed [51, 85]. Unique biological capabilities like natural adaptability to various extreme growth environment conditions with limited nutrients, extreme pH values (2.5–8), salinity (up to 12%), temperatures (2–32 °C), tolerance to metal ions (zinc and copper sulphate, cobalt, cadmium, nickel) and ability to degrade both hydrophilic and hydrophobic substrates make the species a promising tool fitting into the concept of circular economy with great potential to be a part of solution for the global waste problem [1, 6].

Whey as a leachate after casein precipitation in the cheese-making process is a by-product of the dairy industry with still untapped potential. Annual worldwide whey output is 162 million tons, of which 75% is reused in Europe and less than 50% in the rest of the world. Acid whey contains more ash and fewer whey proteins compared to sweet whey, which complicates its industrial application, but at the same time creates opportunities as a substrate for microorganisms cultivation [37, 45, 71]. Among the industrial by-products particularly stimulating the process of microbial lipid accumulation, waste cooking oils stand out as a waste carbon source allowing to obtain oil-rich biomass with high efficiency. Y. lipolytica accumulated SCOs as high as 47% of cell dry mass [80]. More and more methods of processing and disposing of WCOs are being developed, but still the most common practices are based on landfilling which is associated with the risk of leakage into the environment. In a worse scenario, WCOs are illegally reused for food purposes posing serious risks to human health [19, 43, 84].

The approach of using Y. lipolytica yeast as a platform to manage industrial waste and by-products could have both environmental and economic benefits resulting in new value-added products such as microbial lipids. In the study, batch cultures of Y. lipolytica KKP 379 yeast were carried out in media with post-frying rapeseed oil (PFO) and acid whey. A concept for the simultaneous utilization of those wastes has been proposed. PFO was a waste carbon source for yeast and cold-pressed rapeseed oil was used for comparative purposes. On the other hand, the use of whey was aimed at reducing water consumption in the process of growing oleaginous microorganisms, for which it was the main source of nitrogen. The effect of waste substrates on the lipid content of cell dry matter was evaluated. To highlight the potential of the microbial products, the lipid profile of the extracted SCOs was characterized and mineral analysis of the biomass cultured in the waste substrates has been carried out to evaluate their potential as nutraceuticals. In addition, for the first time a qualitative and quantitative analysis of microbial sterols from media containing both plant and animal substrates were conducted.

Materials and methodology

Microorganisms

The material for the study was a wild strain Y. lipolytica KKP 379 from the Collection of Industrial Microorganisms Cultures belonging to Institute of Agricultural and Food Biotechnology (IAFB, Warsaw, Poland). The strain was stored in 20% (v/v) glycerol solution in YPG medium (yeast extract 1%, peptone 2%, glucose 2%) at − 20 °C.

Wastes

The waste post-frying rapeseed oil, in which cod fillets were fried at 170 °C in full immersion, came from a fish processing company in Podlaskie Voivodeship, Poland. Fatty acids (FA) composition of waste was myristic acid (C14:0) 0.36%; palmitic acid (C16:0) 3.78%; stearic acid (C18:0) 7.95%, oleic acid (C18:1) 60.92%; linoleic acid (C18:2) 14.93%; linolenic acid (C18:3) 6.18%; arachidic acid (C20:0) 4.15%; behenic acid (C22:0) 1.51%; erucic acid (C22:1) 0.05%; nervonic acid (C24:1) 0.09%. The acid whey was the residue from the production of curd cheese after the complete curdling of cow's milk from a local manufacturer in Podlaskie Voivodship, Poland.

Physicochemical analysis of whey

pH was measured with Elmetron pH-meter (Zabrze, Polska). The dry mass of whey was determined using a Radwag MAC 50/NH moisture analyzer (Radwag, Radom, Poland) at a temperature of 105 °C. The lipid content was determined by the extraction-weight method. Lipids were extracted twice with n-hexane which was vacuum evaporated. The amount of fat extracted was calculated by relating the weight of the extracted lipids to the volume of whey used in the process. The protein content of whey was determined by the formol method based on the ability of formaldehyde to block the amino groups of proteins. This determination was carried out in two stages. The first was to neutralize the whey with a standard solution of sodium hydroxide in the presence of phenolphthalein. The second consisted in adding formaldehyde to the whey, as a result of which hydrogen ions from ε-amino groups were released and titration of the released hydrogen ions with a 0.1 M NaOH solution. The amount of amino groups that have been bound to the formalin were calculated (1 mL of 0.1 M NaOH corresponded to the content of 1.92 g of protein in 100 g of sample).

Culture conditions

Inoculum culture was provided in YPG medium at 28 C for 24 h with a rotation amplitude of 140 rpm. Batch cultures of the strain were carried out in four medium variants in a BIOFLO 3000 laboratory bioreactor from New Brunswick Scientific (New Jersey, USA) at 28 °C (inoculum 0.025% (v/v)). During culture, the temperature, pH and oxygenation of the medium were monitored. The relative degree of oxygenation of at least 30% of the initial oxygen concentration was maintained by adjusting with compressed air at an overflow of 100 dm3/h/L of medium and a variable stirring speed in the range of 300–600 rpm. The base for all growth media was a mineral medium with the following composition: Na2HPO4, 2.5 g/L; MgSO4, 1.5 g/L; CaCl2, 0.15 g/L; FeSO4 × H2O, 0.16 g/L; MnCl2 × 4H2O, 0.08 g/L; ZnSO4, 0.02 g/L. The culture variants differed in carbon sources (50 g/L) in the form of cold-pressed rapeseed oil or post-frying rapeseed oil, the content of (NH4)2SO4 and KH2PO4 and the addition of acid whey which was used to replace part of the water in the culture media (Table 1). Kinetic parameters of Y. lipolytica batch culture were calculated according to Fabiszewska et al. [16].

General analytical techniques

Biomass concentration in medium was determined based on cell dry weight (CDW) measured by thermogravimetric method. Cells were harvested by centrifugation (8000 rpm, 10 min) washed with redistilled water and dried at 105 °C. Dried samples of yeast biomass were crushed and homogenized in a mortar. Total C, N and S contents were determined by dry combustion (Vario MacroCube, Elementar, Germany). Total content of P, K, Na, Ca, Mg, Fe, Al, Mn, Cu, Zn, Ni, Pb, Cr, V, Sr, Ba, Ti and Zr was measured by inductively coupled plasma atomic emission spectrometry—ICP-OES (Avio 200, Perkin Elmer, Waltham, MA, USA) after samples digestion in a mixture of HNO3 and HCl (3:1 v/v) using the microwave digestion system (Milestone Ethos Up, Sorisole, Italy). Microbial lipids were extracted from dry biomass using a Soxhlet apparatus; n-hexane was used as a solvent. The residual oil was extracted from 30 mL of medium by double straight extraction with portions of n-hexane. Next, after evaporation of the solvent by distillation under reduced pressure of 360 mbar (Buchi Rotavapor R-200 evaporator, Flawil, Switzerland), residual oil weight was measured.

Determination of cellular lipid composition

FA composition was analyzed by FAME gas chromatography. To generate volatile FA derivatives, the lipid samples were esterified with BF3 (boron trifluoride) solution in methanol, according to the ISO method [27]. Measurements were made using a YL6100 GC chromatograph equipped with a flame ionization detector (FID) and a BPX70 capillary column of 0.25 mm i.d. × 60 m in length and a layer thickness of 0.25 μm. The temperature program was as follows: 60 °C (5 min) to 180 °C (10 °C/min), 180 °C to 230 °C (15 min) (3 °C/min), injector temperature: 225 °C; detector temperature: 250 °C; injection volume: 2 µL. Nitrogen was used as the carrier gas. FAs were identified by retention time values compared to the standards.

Oil samples or standards were weighed and dissolved in 2 mL of hexane. 100 µL of 5α-cholestane (10.5 mg/25 mL chloroform) was added as an internal standard. Measured compounds were derivatized with 0.5 mL of 2 M KOH in methanol for 1 h. 1 mL of upper layer was collected carefully and transferred to a glass vial, evaporated in a stream of nitrogen and 100 µL of silylating reagent (BSTFA + TMCS, 99:1) and 100 µL pyridine were added. The prepared sample was shaken and left for 24 h at room temperature to fulfill derivatization process. 0.2 mL of hexane was added and the trimethylsilyl ether sterols content was analyzed. The separation of sterol derivatives was performed with GC coupled with mass spectrometer Shimadzu-QP-2010S and capillary column ZB-5 ms (30 m × 0.25 mm × 0.25 μm) stationary phase (5%—phenyl-arylene, 95%—dimethylpolysiloxane). Column temperature procedure: initial 60 °C (3 min) to 250 °C (temperature rate 15 °C/min), 250 °C to 310 °C (10 min) (temperature rate 3 °C/min). Carrier gas was helium with the flow 0.7 mL/min. Interface temperature of GC–MS was 250 °C. The ionization energy was 70 eV. The Total Ion Current (TIC) was used to detect sterols (m/z ranged 100–600). The qualitative analysis of trimethylsilyl ether was made on the basis of a comparison of their retention time with retention time of available standards and mass spectra as well as literature data. The internal standard 5α-cholestane was used to quantify sterols. Results were presented in mg/g of oil. Each sample was analyzed in duplicate [12].

Statistical analysis

Statistical analyses of the results were performed using Statistica 13.0 set plus soft-ware (Statsoft, Cracow, Poland). Determination of fatty acid composition and sterols content was performed of repeated measurements with one-way ANOVA followed by Tukey’s multiple comparison test and p-value ≤ 0.05 were considered to be statistically significant.

Results and discussion

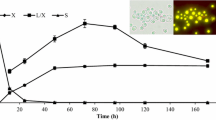

The oleaginous Y. lipolytica KKP 379 strain was cultured in 4 variants of media (Fig. 1) with hydrophobic carbon sources post-frying rapeseed oil (PFO) and conventional cold-pressed rapeseed oil (CPO). It was investigated how the waste nature of the substrates yeast growth and the quality of microbiological products: biomass and cellular lipids. The concept presented in the current paper assumed the use of whey as a diluent for the culture medium ingredients in order to replace a part of tap water.

Changes in the oxygenation of the medium, pH, biomass concentration of Y. lipolytica KKP 379 and content of residual lipid carbon sources in media with A cold-pressed rapeseed oil (CPO-0), B cold-pressed rapeseed oil and 30% addition of acid whey (CPO-0.3), C post-frying rapeseed oil and 20% addition of acid whey (PFO-0.2) and D post-frying rapeseed oil and 30% addition of acid whey (PFO-0.3)

Whey composition is influenced by many factors, e.g., lactation phase, method of breeding cattle or storage of milk [59]. It consists of about 93% water and contains 55% of the nutrients present in milk and about 20% of the total protein content. Its yellow-green color is due to the presence of riboflavin (vitamin B12). The main component of whey is lactose, the content of which varies around 70–75% of the total dry matter [29, 52]. Nevertheless, lactose content in the whey was irrelevant in the present study, because Y. lipolytica yeast are not capable of lactose utilization [28]. Since wild type strains do not assimilate lactose, a major carbon source in whey, a secreted β-galactosidase was introduced into engineered Y. lipolytica yeast strain what allowed to achieve rapid total conversion of all carbon sources in acid whey, producing 6.61 g/L of fatty acids [47]. Lactose was an insignificant source of carbon in yeast culture and hydrophobic compounds constituted only 0.2% m/v (Table 2.) The main source of carbon utilized by Y. lipolytica yeast was PFO or CPO. Still, the whey could be considered as additional nitrogen source as proteins constituted 1.4% m/v in the solution.

Batch cultures of Y. lipolytica in waste-based media

The CPO-0.3 culture with cold-pressed rapeseed oil and 30% acid whey addition had the highest biomass concentration, 37.44 g/L after 62 h of incubation (Fig. 1B). After 10 h, the cells entered an exponential growth phase resulting in a biomass concentration of 5.88 g/L. In second day of cultivation, the biomass production reached 29.22 g/L. The strain used the hydrophobic carbon source efficiently from the beginning of the culture period. Its initial concentration in medium was reduced from 50 to 24.67 g/L within the first 16 h. Until 38 h, the cells utilized the entire pool of carbon source available in the medium. The best result of biomass growth may have been related to the higher addition of whey, which contains not only nitrogen, but also phosphorus and other components necessary for growth. In addition, the medium was enriched with ammonium sulphate and potassium phosphate. The yield of microbial lipid biosynthesis in CPO-0.3 medium was 11.86% and the highest lipid concentration was noticed (4.44 g/L) (Table 2). The biomass concentration was nearly 40% lower (44 g/L) (Fig. 1A) after 62 h incubation of yeast in CPO-0 medium without the addition of whey, compared to the CPO-0.3 culture, corresponds to the result obtained after 38 h. The lag phase lasted 15 h, according to the medium oxygenation decrease. A significant increase in biomass concentration was noticed between 38 and 48 h, from 6.44 to 20.78 g/L. The cells utilized the lower amount of CPO. The content of the carbon source decreased to 21.22 g/L after 38 h. Finally, 5.23 g/L of oil remained unused by the cells in the medium. During culture, the yeast cells accumulated 3.83 g/L of storage lipids, which corresponds to 15.07% of dry cell weight.

The next two medium variants contained a waste PFO and an addition of acid whey at the level of 20 and 30%. The ammonium sulfate was lacking in the medium and whey was the only nitrogen source. The addition of the source of phosphorus was decreased compared to the media with CPO. The culture conditions resulted in a lower dry cell mass. After 62 h of growth in PFO-0.2 and PFO-0.3 medium, the biomass concentration was 12.2 g/L and 9.89 g/L, respectively (Fig. 1C, D). Lag phase in both cultures lasted about 10 h. The extended culture time of PFO-0.3 variant resulted in a final biomass concentration of 22.1 g/L. The yeast efficiently utilized the lipid carbon source, reducing its content in the medium to 14.45 g/L after 24 h of incubation. The uninhibited yeast growth was observed, following which the yeast utilized the entire available pool of waste substrate. As opposed to the PFO-0.2 culture where the residual oil concentration amounted 30.22 g/L what reflected in limited growth potential. The disruption in yeast growth may have been caused by the depletion of the medium in nitrogen, which resulted from the lower proportion of whey in the medium. The yeast was unable to dispose of the entire carbon source. There can be seen a significant difference between culture provided in PFO-0.2 and PFO-0.3 medium (Fig. 1C, D). For yeast grown in post-frying oil with 30% whey medium the culture period was prolonged up to 90 h. At 60 h similar biomass concentrations have been achieved for variants C and D. pH was also not diverse as well as oxygen concentration profile. However, the difference could be noticed in residual oil content. Waste oil was fully utilized at 90 h in PFO-0.3 medium.

The differences in the efficiency of cellular lipid accumulation between culture variants were also noticeable. For PFO-0.2 and PFO-0.3 medium, changes in microbial lipid content during the culture process were analyzed (Table 3). The highest amount of lipids in the biomass from the PFO-0.3 medium occurred at the 16th hour of culture (30.77%), and decreased in the following hours. After 24 h of culture, the biomass contained 23.58% lipids, after 62 h—15.79%, and after 90 h—9.17%, corresponding to a final lipid concentration of 2.02 g/L. Higher SCO yields in PFO-0.2 medium could be explained by higher C:N ratio. Whey was considered as nitrogen source and its higher content lowered C:N ratio. It can be concluded that due to nitrogen content in whey its usage in growth medium is limited.

Regardless of the culture variant, a degradation of storage lipids in cells was noticeable. Biodegradation of previously synthesized lipids is a known process for oleaginous yeast. SCO are synthesized under carbon source excess. During growth of microorganisms carbon source is usually depleted and as a consequence storage metabolites are reused for purposes of growth and cell metabolism. This phenomenon was reported previously [78]. It has been also described for Y. lipolytica yeast cultured in glycerol medium when citric acid production was accompanied by storage lipids turnover and remarkable biosynthesis of glycolipids, sphingolipids and phospholipids [11, 46]. Not only Y. lipolytica but also Rhodosporidium toruloides revealed reconsumption of synthesized lipid metabolites [64]. Transfer of lipids from the neutral lipid fraction to fat-like compounds was also observed in this work.

In PFO-0.2 medium, yeast cells efficiently accumulated storage lipids even at the early stages of culture (Table 3). The storage lipid content in dry cells mass after 16 h of incubation was 24.61%. Subsequently, a further increase in the proportion of cellular lipids was observed until the end of the culture. After 24 h, the efficiency increased to 30.77%, and after 38 h to 35.0%. Finally, as a result of 62 h of the cultivation, the cellular lipid content of Y. lipolytica grown in PFO-0.2 medium reached the highest result among the four culture variants (38.79%).

Our experiment showed that in media containing whey and ammonium sulfate as an additional nitrogen source, the biosynthesis of cellular lipids was significantly reduced (Fig. 1, Table 3). The observations that were made are consistent with those in the experiment of Takin et al. (2015). The use of whey in culture medium requires the elimination of additional sources of phosphorus and nitrogen. As a result of Y. lipolytica culture in acid whey, it was proven that potassium phosphate as an additional phosphorus source at all concentration levels (0–2 g/L) significantly reduced the yield of lipid accumulation. It is well known that whey as a by-product of cheese making process is rich in phosphorus [71]. Excess of this element significantly reduces lipid accumulation in oleaginous yeast, as proven by the authors of the previous study. Through the approach of limiting the supplementation of nitrogen as well as phosphorus in the mineral medium with PFO, it was possible to increase the lipid content of Y. lipolytica to 47.5%. This proved that simultaneous limitation of both ingredients promoted lipid accumulation in cells [79].

The growth of yeast biomass was hindered in a medium with a lower addition of whey (PFO-0.2), but the conditions assumed favored efficient lipid accumulation at level 3.84 g/L (Table 3). The maximum lipid yield (Lmax) was similar to the result achieved for CPO-0 culture (3.83 g/L). According to the previous reports, higher concentrations of ammonium sulfate in whey media significantly reduced lipid production, which is why no additional nitrogen supplementation was used in the PFO-0.2 culture. In the experiment of Taskin et al. [71] a lipid concentration of 3.16 g/L was also obtained in the medium without additional nitrogen source. For a maximum lipid yield of 4.29 g/L, as well as lipid content (58%), the researchers cultured a selected strain of a wild-type strain of Y. lipolytica isolated from soil samples in whey medium with the addition of lactose as an additional carbon source for 120 h. Lopes et al. [39] achieved a significant amount of microbial lipids in the medium (3 g/L) with an accumulation efficiency of 48% by culturing Y. lipolytica in a medium based on waste cooking oils, a result similar to those cited in the literature. Wierzchowska et al. [80] by limiting nitrogen and phosphorus in the culture medium also increased the proportion of SCO in biomass to 48%. Unfortunately, the composition of the medium reduced the concentration of lipids in the substrate to 0.37 g/L. There have been many experiments [25, 26, 31, 83], demonstrating that under conditions of mineral limitation and simultaneous unrestricted access to carbon, oleaginous yeast accumulate greater amounts of lipids in cells. The current experiment is another example supporting this assumption. The maintenance of cellular lipid content at high levels in the PFO-0.2 culture can be explained by the constant access of cells to carbon in the medium with the simultaneous reduction or depletion of the nitrogen source. In contrast to the PFO-0.3 culture, by having a higher proportion of whey in the medium, the yeast had better access to nitrogen and its growth was uninhibited. The hydrophobic carbon source was fully utilized for the growth needs, which did not promote the accumulation of storage lipids.

Whey composition is influenced by many factors, e.g. lactation phase, method of breeding cattle or storage of milk [59]. It consists of about 93% water and contains 55% of the nutrients present in milk and about 20% of the total protein content. Its yellow-green color is due to the presence of riboflavin (vitamin B12). The main component of whey is lactose, the content of which varies around 70–75% of the total dry matter [29, 52]. Nevertheless, lactose content in the whey was irrelevant in the present study, because Y. lipolytica yeast are not capable of lactose utilization [28]. Since wild type strains do not assimilate lactose, a major carbon source in whey, a secreted β-galactosidase was introduced into engineered Y. lipolytica yeast strain what allowed to achieve rapid total conversion of all carbon sources in acid whey, producing 6.61 g/L of fatty acids [47]. The concept presented in the current paper assumed the use of whey as a diluent for the culture medium ingredients in order to replace a part of tap water. Lactose was an insignificant source of carbon in yeast culture (Table 2) and hydrophobic compounds constituted only 0.2% m/v. The main source of carbon utilized by Y. lipolytica yeast was waste rapeseed oil. Still, the whey could be considered as additional nitrogen source as proteins constituted 1.4% m/v in the solution.

Fatty acid composition and sterol content of microbial lipids

The fatty acid profile is essential to assess the SCOs quality. In the current study, oleic (C18:1), linoleic (C18:2), palmitic (C16:0) and stearic (C18:0) acids were the mainly fatty acids, regardless of the medium variant (Table 4). The predominance of the unsaturated fraction was detected in all extracted SCOs, particularly C18:1 (41.67–71.60%) and C18:2 (14.74–18.41%) acids. Linolenic acid was noted in each sample, with the highest percentage in SCO from PFO-0.3 culture (4.83%). Analyses showed that SCO samples from cultures with PFO and whey had an increased proportion of C16:0 acid compared to the media with CPO, PFO-0.3–17.09% and PFO-0.2–19.22%. The highest percentage of unsaturated fatty acids (UFA—87.66%) was detected in SCO from CPO-0 medium without whey. In contrast, the highest percentage of saturated fraction was found in cellular lipids from PFO-0.2 culture (SFA—40.28%). It should be mentioned that the composition of lipids extracted from the biomass is related to the composition of the substrates used in the cultures. The post-frying waste used in the current experiment was composed of 76% UFAs [15]. For all SCOs samples, the proportion was similar except for the PFO-0.2 culture, where UFAs accounted for only 59.71%. In commercial CPO, the content of C16:0 ranges from 3.97 to 5.30% [7, 32, 48], and C18:0 is from 1.10 to 2.14% [82]. In general, the composition is dominated by UFAs, C18:1 (56.2–70.01%) [48, 60] and C18:2 (7.74–20.54%) [62, 82] similarly to the samples of microbial lipids in our study. In contrast, bovine milk fat consists primarily of the saturated fraction, C16:0 (23.6–31.4%), C18:0 (10.4–14.6%) and C14:0 (9.1–11.9%), while the unsaturated C18:1 content ranges from 14.9 to 22.0% [44, 50].

SCOs from the cultures with hydrophobic animal wastes such as chicken or goat tallows are characterized by an increased proportion of SFAs, compared to microbial lipids obtained from the cultures containing vegetable fats including waste cooking oils. The microbial lipids derived from this type of substrate were dominated by saturated C16:0, 55% for chicken tallow and 43% for goat tallow. Interestingly, in the presence of pork lard, the ratio of unsaturated to saturated acids in SCO was higher than the composition of the waste substrate would indicate, C18:1 (35–53%) and C16:0 (25–48%) were predominantly accumulated in cells [39, 55, 56]. What should be added, the KKP 379 yeast strain cells accumulated proportionally free fatty acids from carbon source and slight differences could be observed for their content in cellular lipids and waste oil medium. Culture conditions do not significantly influence the fatty acids profile in lipids extracted from Y. lipolytica cells which usually reflect the fatty acids composition in waste oil [16, 14].

Very long chain fatty acids (VLCFAs) with 20 or more carbon atoms (C20:0, C20:1, C22:1, C24:1) were present in cellular lipids from all Y. lipolytica cultures variants in the current study. VLCFAs are usually found in small amounts in microbial oils of wild-type strains. The exception was a sample of cellular lipids from PFO-0.2 cultures, C20:0 FA accounted for 9.68% of all fatty acids. It is also necessary to add that in the post-frying waste profile, VLCFAs accounted for 7.59%, (C20:0–6.91%, C22:0–0.68%), but C22:1 and C24:1 acids were not detected [15]. The biosynthesis of VLCFAs may be associated with the elongation of C16–C18 FAs with fewer carbon atoms to C20–C26 FAs [17, 58]. Part of the fatty acids can be assimilated from the substrate, in connection with the “leaky-hose pipe model”, some intermediates of acyl-CoAs can be released from β-oxidation. PFO also contained the mentioned fatty acids, but in different proportions. This indicates other possible strain-dependent modifications promoting VLCFAs accumulation. Gajdoš et al. [17] reported the presence of arachidic (C20:0), eicosenoic (C20:1), behenic (C22:0) and lignoceric (C24:0) VLCFAs less than 3% of the total fatty acid in Y. lipolytica W29 wild strain. Moreover, a Y. lipolytica YL10 mutant capable of producing large amounts of VLCFAs especially erucic acid has been constructed to convert waste cooking oil (WCO) and crude glycerol to VLCFAs [17]. In another study, VLCFAs accounted for 34% of all fatty acids in the biomass of the YL53 mutant [18]. In the Fabiszewska et al. [16] study, fish industry waste was used to grow the wild KKP 379 strain, as in the current study. The carbon source for the cells was fish waste oil from the industrial smoking process. VLCFAs such as C20:0, C20:1, C22:1, C24:1 were present in the cell oils. In addition, the authors noted the contribution of C20:5 (eicosapentaenoic acid) and C22:6 (docosahexaenoic acid) which underscores the value of the unexploited potential of waste and by-products of the food industry [16]. Controlling the fatty acid profile of microbial lipids by selecting substrates with different more or less saturated fractions seems to be a promising solution giving the possibility of obtaining oils with a variety of compositions possible to design. SCO is a promising substrate in biodiesel synthesis and an alternative strategy for plant oils based on non-food sources. Dairy wastewater was efficiently used in Chlorella vulgaris microalgae culture with high biomass and lipid yield for biogas purposes [8]. Carota et al. [5] investigated 18 strains of oleaginous yeasts in Ricotta cheese whey as a growth medium. Cryptococcus curvatus NRRL Y-1511 turned out to be a promising candidate for biodiesel productions and the oil synthesized in cells resembled that of the Jatropha oil [5]. Good candidates for the synthesis of storage lipids constituted non-conventional oleaginous yeast C. curvatus ATCC 20509 and Papiliotrema laurentii NRRL Y-2536 grown in second cheese whey (main by-product in Mizithra cheese) supplemented with condensed cheese whey-derived lactose [76].

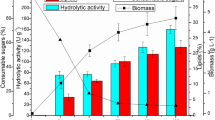

In cellular lipid samples from cultures with cold-pressed oil, post-frying rapeseed oil and acid whey, six major sterols were identified (Tables 5, 6, 7). Comparing the analyzed samples, β-sitosterol (2.17–47.57%), campesterol (9.74–40.15%), and stigmasterol (1.47–15.48%), phytosterols typical of vegetable oils, were identified. Microbial metabolites such as ergosterol (4.24–62.53%), dehydroergosterol (1.40–14.01%) and the animal membrane component cholesterol (0.2–14.84%) were also present (Table 6). Finally, the highest sterol content of 12.96 mg/g was found in lipid samples from yeast cells cultured in CPO-0.3 medium (Table 7), where ergosterol accounted for more than half (7.08 mg/g). In addition to the regulation of phospholipids and sphingolipids, the change in sterol composition is the main mechanism for maintaining membrane homeostasis [23, 66, 77]. As a stress response, sterols can be stored as steryl esters in lipid particles, free forms as a component of membrane structures, or secreted by cells into the medium [38, 69].

The content of cellular sterols from PFO-0.2 medium was analyzed during culture time. With the start of the culture process, sterol content increased. The highest amount of sterols both in terms of the amount of dry biomass (7.38 mg/g) (Table 5) and cellular oil extracted (21.08 mg/g) was recorded after 38 h (Table 7). The dominant compound was ergosterol 12.10 mg/g. During the following hours, the ergosterol content significantly decreased for the oil sample extracted from biomass cultured at 46 h and after 62 h (6.69 mg/g and 1.49 mg/g respectively) (Table 7).

Sterols, similar to FA, perform a regulatory function in the global fluidity and permeability of the cell membrane. Cells are able to increase the synthesis of sterols and saturated fatty acids (SFA) as an attempt to adapt the cell to environmental conditions. More UFA and less sterols increase the fluidity of the phospholipid bilayer structure [21, 53]. Therefore, the main role of ergosterol as a fungal equivalent of cholesterol is to stabilize the cell and protect it from harmful stress factors such as hypoxia, osmotic pressure or toxic components presence in medium [38, 69]. Disruption of cell integrity is associated with membrane modification, as well as metabolic disorders, which hinders biomass growth and reduces cell survival [54, 63]. As it is well known, acetyl-CoA is essential for cellular metabolism including ergosterol and microbial lipid biosynthesis. Therefore, the reduction of sterols between 38 and 62 h with in PFO-0.2 culture with simultaneous efficient accumulation of cellular lipids may be explained by the competitiveness of lipogenesis and the ergosterol biosynthesis pathway, which starts with the condensation of two acetyl-CoA molecules. It is worth adding, that for yeast overproduction of ergosterol, access to oxygen is also a critical issue [38, 54]. Culture conditions may have led to changes in membrane structure. Manipulating the content of individual sterols is an effective method of yeast adaptation [77]. Yeast mutually converts steryl esters and free sterols depending on culture conditions [69, 72]. During Y. lipolytica yeast culture in media with a lipid carbon source, conversion from steryl esters stored in lipid particles to free sterols was observed to protect cell membranes from interference by hydrophobic substrates. In glucose medium, the opposite correlation was found [69]. According to the literature, Y. lipolytica biomass in lipid media contained more ergosterol in both free and ester forms than in glucose media. In addition, cells cultured with glucose were more susceptible to sterol depletion as a consequence of stress [68, 69].

In the authors’ previous study, higher sterol contents were achieved in microbial lipid samples. Y. lipolytica lipid samples from fed-batch cultures with molasses as well as PFO contained 68.4 mg/g oil and 8.34 mg/g oil of sterols, respectively. In molasses-based cultures, the high content of total sterols and especially ergosterol (60.16 mg/g oil) was explained by pretreatment of the substrate. Acid hydrolysis of molasses resulted in increased osmotic pressure of the growth medium [78]. Culture mode also may have influenced differences in sterol content between cultures. Ta et al. [69] suggested that cells cultured in media with peptone and amino acid additives are more resistant to sterol depletion.

The sterol content of conventional vegetable oils depends on many factors. For example, [34] proved that temperature conditioning of rapeseed increased sterol content by 16% compared to cold-pressed oils. The sterol content of all analyzed rapeseed oils ranged from 5.9 to 8.2 mg/g. Similarly, in the study by [61], the analyzed rapeseed oil samples contained 5.7–6.6 mg/g of total sterols. Based on literature reports describing the composition of vegetable oils, it is important to emphasize the potential of SCOs as a source of bioactive compounds such as sterols, the content of which was similar or higher with intensified biosynthesis of yeast ergosterol compared to conventional oils. Moreover, the unique properties of SCOs are related to the possibility of quality profiling through substrate regulation.

Ergosterol as provitamin D has been extensively studied for its positive effects behind the human body. The basis of the theory on the health-promoting effects of ergosterol was the great importance of vitamin D for the functioning of the entire body, such as bone health or the proper functioning of the cardiovascular and immune system, but also fertility [9, 30]. In vitro studies have demonstrated selective cytotoxicity of a combination of ergosterol and lipophilic triphenylphosphonium cations (TPP+) between healthy gastric endothelial cells (GES) and cancer cells, as well as inhibitory effects on breast (MCF-7) and liver (HepG2) cancer cells [57]. Additionally, research by Tiwari et al. [74] highlighting the promising role of bioactive components including ergosterol as nutraceuticals against COVID-19 seems extremely interesting. Therefore, SCOs with high ergosterol content could be a natural nutraceutical formula.

Mineral composition of Y. lipolytica biomass

Y. lipolytica biomass is considered a carrier of many nutrients, which accounts for its potential as an enrichment ingredient in the human diet, especially for vegetarians, vegans or athletes. This oleaginous species is not only a source of primarily UFAs, protein, sterols, but also B vitamins and minerals [28]. We investigated how waste substrates affected the mineral composition of biomass from individual cultures with CPO, PFO and acid whey (Table 8). Biomass from CPO-0 substrate had the highest contents of N, K, S, Ca, Cr, Ni, V, Co, Sr and Li. There were no significant differences in the contents of Ti (1.80–8.12 mg/kg), Pb (0.88–1.63 mg/kg) and Al (26.75–62.2 mg/kg) between samples from all of the culture variants.

A favorable feature of Y. lipolytica biomass is its low sodium concentration [10, 28]. The biomass obtained from cultures with PFO-0.2 (1.12 g/kg) and PFO-0.3 (0.40 g/kg) had a significantly lower sodium content compared to CPO-0 and CPO-0.3 media, but also to the results presented by Czech et al. [10], where Na—12.81–19.38 g/kg. Czech et al. [10] analyzed the effects of feeding piglets with Y. lipolytica yeast biomass cultured on glycerol derived from rapeseed biofuel production. At the same time, the biomass of strain KKP 379 contained more P, Mg, Zn, Fe, Mn than the biomass produced from waste glycerol. [10, 49]. Sodium content was higher in biomass samples from cultures with CPO. The highest amount of Na was found for biomass grown in CPO-0.3 medium (71.62 g/kg).

The opposite trend was observed for Mn and Zn, whose content was higher in biomass cultured in PFO medium. Biomass samples from cultures with acid whey contained significantly more P (16.47–17.16 g/kg). Surprisingly, the yeast biomass from the culture with 30% whey contained less calcium compared to the other two cultures. The composition of the medium in the PFO-0.2 culture resulted in biomass samples with the highest contents of Mg (6.08 g/kg), Cu (5.96 mg/kg) and Ba (2.27 mg/kg).

Overall, yeast biomass cultured in medium with whey and CPO or PFO contained more K, P, Mg, Zn and Fe compared to the biomass of Saccharomyces cerevisiae yeast in the Czech et al. [10] study, which contained K—1.34 g/kg, P—10.02 g/kg, Mg—1.48 g/kg, Zn—30.93 mg/kg and Fe—101.07 mg/kg. In the study, the authors demonstrated that Y. lipolytica yeast produced with waste glycerol is a good source of minerals, including Ca (3.04–5.48 g/kg), Zn (57.97–82.57 mg/kg), Na (12.81–19.38 g/kg), Mn (12.03–18.21 mg/kg), S (3.53–6.21 g/kg), K (19.10–25.14 g/kg) and Mg (1.82–2.04 g/kg). 82–2.04 g/kg, as well as valuable amino acids (tyrosine, tryptophan, leucine, lysine, valine or glycine), and can be successfully applied instead of the commonly used yeast S. cerevisiae [10].

Comparing the results with the authors previous study, KKP 379 strain grown in molasses medium contained more Cr, N, S and Cu. However, biomass was less abundant in minerals such as Na, P Ca, Mg, Fe and Al compared to acid whey media, which underscores the potential of the dairy industry by-product in Y. lipolytica biomass production [78].

Conclusions

In the face of the growing human population and the increasing amount of industrial waste, the search for sustainable solutions aimed at both waste utilization and meeting the nutritional needs of people seems to be one of the most important challenges of modern food science. The nutritional value of unconventional yeasts, such as Y. lipolytica, is still not fully understood. Once again, it has been proven that in a culture where it is possible to obtain a high concentration of biomass, it is not possible to obtain a high yield of microbial oil. During cell division, unlimited access to a source of nitrogen is necessary, the limitation of which promotes the accumulation of storage lipids. It seems reasonable to start work on continuous culture, in which it would be possible to collect the biomass characterized by a high concentration of microbial oil.

Meanwhile, this work is also the first in which both the mineral composition of oleaginous yeast biomass and the quantitative and qualitative assessment of sterols were simultaneously described. It was indicated that the composition and content of sterols in microbial lipids depending on the phase of cell growth in batch culture. In turn, the substrates in the culture medium affected the content of selected elements, which indicates that modification the culture medium may be a tool of manipulating the yeast cell composition. This provides opportunities to profile the quality of Y. lipolytica yeast biomass, as well as the extracted oil. It is currently known that SCO can be a substitute for vegetable oils in terms of fatty acid profile. However, the present study proves the competitiveness of SCOs by highlighting their unique profile and content of valuable bioactive components like sterols.

In addition, the results of the experiment confirmed that the choice of waste substrates is a regulator of the cellular lipid accumulation efficiency, as well as the content of certain sterols. As can be seen, both vegetable and animal waste can be used in many ways in oleaginous yest cultures. There is a clear trend in the use of oily wastes for the SCOs production, as well as yeast biomass. Highlighting the yeast's excellent job of valorizing troublesome fats, intracellular lipids can be used in many ways, such as the production of substitutes for different vegetable oils, where the sourcing of them may be costly, consuming time and resources. It is possible to control the culture process in such a way as to obtain the most valuable microbial products, e.g. for food purposes.

Data availability

The data generated during the current study are available from the corresponding author upon reasonable request.

References

Bao W, Li Z, Wang X, Gao R, Zhou X, Cheng S et al (2021) Approaches to improve the lipid synthesis of oleaginous yeast Yarrowia lipolytica: a review. Renew Sustain Energy Rev 149:111386. https://doi.org/10.1016/j.rser.2021.111386

Bednarski W, Adamczak M, Kowalewska-Piontas J, Zadernowski R (1994) Biotechnological methods for the up-grading and modification of animal waste fats. Acta Biotechnol 14(4):387–393. https://doi.org/10.1002/abio.370140412

Brabender M, Hussain MS, Rodriguez G, Blenner MA (2018) Urea and urine are a viable and cost-effective nitrogen source for Yarrowia lipolytica biomass and lipid accumulation. Appl Microbiol Biotechnol 102:2313–2322. https://doi.org/10.1007/s00253-018-8769-z

Caporusso A, Capece A, De Bari I (2021) Oleaginous yeasts as cell factories for the sustainable production of microbial lipids by the valorization of agri-food wastes. Fermentation 7(2):50

Carota E, Crognale S, D’Annibale A, Gallo AM, Stazi SR, Petruccioli M (2017) A sustainable use of Ricotta cheese whey for microbial biodiesel production. Sci Total Environ 584–585:554–560. https://doi.org/10.1016/j.scitotenv.2017.01.068

Carsanba E, Papanikolaou S, Erten H (2018) Production of oils and fats by oleaginous microorganisms with an emphasis given to the potential of the nonconventional yeast Yarrowia lipolytica. Crit Rev Biotechnol 38(8):1230–1243. https://doi.org/10.1080/07388551.2018.1472065

Chew SC (2020) Cold-pressed rapeseed (Brassica napus) oil: chemistry and functionality. Food Res Int 131:108997. https://doi.org/10.1016/j.foodres.2020.108997

Choi H-J (2016) Dairy wastewater treatment using microalgae for potential biodiesel application. Environ Eng Res. https://doi.org/10.4491/eer.2015.151

Cito G, Cocci A, Micelli E, Gabutti A, Russo GI, Coccia ME, Franco G, Serni S, Carini M, Natali A (2020) Vitamin D and male fertility: an updated review. World J Men’s Health 38(2):164. https://doi.org/10.5534/wjmh.190057

Czech A, Smolczyk A, Ognik K, Kiesz M (2016) Nutritional value of Yarrowia lipolytica yeast and its effect on growth performance indicators n piglets. Ann Anim Sci 16(4):1091–1100. https://doi.org/10.1515/aoas-2016-0034

Daskalaki A, Vasiliadou IA, Bellou S, Tomaszewska-Hetman L, Chatzikotoula C, Kompoti B, Papanikolaou S, Vayenas D, Pavlou S, Aggelis G (2018) Data on cellular lipids of Yarrowia lipolytica grown on fatty substrates. Data Brief 21:1037–1044. https://doi.org/10.1016/j.dib.2018.10.116

Derewiaka D, Stepnowska N, Bryś J, Ziarno M, Ciecierska M, Kowalska J (2019) Chia seed oil as an additive to yogurt. Grasas Aceites 70(2):e302–e302. https://doi.org/10.3989/gya.0705182

Dobrowolski A, Mituła P, Rymowicz W, Mirończuk AM (2016) Efficient conversion of crude glycerol from various industrial wastes into single cell oil by yeast Yarrowia lipolytica. Biores Technol 207:237–243

Fabiszewska A, Misiukiewicz-Stępień P, Paplińska-Goryca M, Zieniuk B, Białecka-Florjańczyk E (2019) An insight into storage lipid synthesis by Yarrowia lipolytica yeast relating to lipid and sugar substrates metabolism. Biomolecules 9(11):685. https://doi.org/10.3390/biom9110685

Fabiszewska A, Wierzchowska K, Nowak D, Wołoszynowska M, Zieniuk B (2022) Brine and post-frying oil management in the fish processing industry—a concept based on oleaginous yeast culture. Processes 10(2):294. https://doi.org/10.3390/pr10020294

Fabiszewska AU, Zieniuk B, Kozłowska M, Mazurczak-Zieniuk PM, Wołoszynowska M, Misiukiewicz-Stępień P, Nowak D (2021) Studies on upgradation of waste fish oil to lipid-rich yeast biomass in Yarrowia lipolytica batch cultures. Foods 10(2):436. https://doi.org/10.3390/foods10020436

Gajdoš P, Hambalko J, Slaný O, Čertík M (2020) Conversion of waste materials into very long chain fatty acids by the recombinant yeast Yarrowia lipolytica. FEMS Microbiol Lett 367(6):fnaa042. https://doi.org/10.1093/femsle/fnaa042

Gajdoš P, Urbaníková V, Vicenová M, Čertík M (2022) Enhancing very long chain fatty acids production in Yarrowia lipolytica. Microb Cell Fact 21(1):138. https://doi.org/10.1186/s12934-022-01866-6

Gao Z, Ma Y, Liu Y, Wang Q (2022) Waste cooking oil used as carbon source for microbial lipid production: promoter or inhibitor. Environ Res 203:111881. https://doi.org/10.1016/j.envres.2021.111881

Ghazani SM, Marangoni AG (2022) Microbial lipids for foods. Trends Food Sci Technol 119:593–607. https://doi.org/10.1016/j.tifs.2021.10.014

Girardi Piva G, Casalta E, Legras JL, Tesnière C, Sablayrolles JM, Ferreira D et al (2022) Characterization and role of sterols in Saccharomyces cerevisiae during white wine alcoholic fermentation. Fermentation 8(2):90. https://doi.org/10.3390/fermentation8020090

Gottardi D, Siroli L, Vannini L, Patrignani F, Lanciotti R (2021) Recovery and valorization of agri-food wastes and by-products using the non-conventional yeast Yarrowia lipolytica. Trends Food Sci Technol 115:74–86. https://doi.org/10.1016/j.tifs.2021.06.025

Guo L, Pang Z, Gao C, Chen X, Liu L (2020) Engineering microbial cell morphology and membrane homeostasis toward industrial applications. Curr Opin Biotechnol 66:18–26. https://doi.org/10.1016/j.copbio.2020.05.004

Hamimed S, Barkaoui T, Trabelsi I, Landoulsi A, Chatti A (2021) High-performance biological treatment of tuna wash processing wastewater using Yarrowia lipolytica. Environ Sci Pollut Res 28:1545–1554. https://doi.org/10.1007/s11356-020-10586-6

Hoarau J, Petit T, Grondin I, Marty A, Caro Y (2020) Phosphate as a limiting factor for the improvement of single cell oil production from Yarrowia lipolytica MUCL 30108 grown on pre-treated distillery spent wash. J Water Process Eng 37:101392. https://doi.org/10.1016/j.jwpe.2020.101392

Huang X, Luo H, Mu T, Shen Y, Yuan M, Liu J (2018) Enhancement of lipid accumulation by oleaginous yeast through phosphorus limitation under high content of ammonia. Biores Technol 262:9–14. https://doi.org/10.1016/j.biortech.2018.04.063

ISO 5509; Animal and Vegetable Fats and Oils—Preparation of Methyl Esters of Fatty Acids. International Organization for Standardization: Geneva, Switzerland, 2001

Jach ME, Malm A (2022) Yarrowia lipolytica as an alternative and valuable source of nutritional and bioactive compounds for humans. Molecules 27(7):2300. https://doi.org/10.3390/molecules27072300

Jelicic I, Božanic R, Trawnik L (2008) Whey-based beverages—a new generation of dairy products. Mljekarstvo 58(3):257–274. https://www.researchgate.net/publication/228631581

Jiang Q, Zhang M, Mujumdar AS (2020) UV induced conversion during drying of ergosterol to vitamin D in various mushrooms: effect of different drying conditions. Trends Food Sci Technol 105:200–210. https://doi.org/10.1016/j.tifs.2020.09.011

Kolouchová I, Maťátková O, Sigler K, Masák J, Řezanka T (2016) Lipid accumulation by oleaginous and non-oleaginous yeast strains in nitrogen and phosphate limitation. Folia Microbiol 61:431–438. https://doi.org/10.1007/s12223-016-0454-y

Konuskan DB, Arslan M, Oksuz A (2019) Physicochemical properties of cold pressed sunflower, peanut, rapeseed, mustard and olive oils grown in the Eastern Mediterranean region. Saudi J Biol Sci 26(2):340–344. https://doi.org/10.1016/j.sjbs.2018.04.005

Kothri M, Mavrommati M, Elazzazy AM, Baeshen MN, Moussa TA, Aggelis G (2020) Microbial sources of polyunsaturated fatty acids (PUFAs) and the prospect of organic residues and wastes as growth media for PUFA-producing microorganisms. FEMS Microbiol Lett 367(5):fnaa028. https://doi.org/10.1093/femsle/fnaa028

Kraljić K, Škevin D, Pospišil M, Obranović M, Neđeral S, Bosolt T (2013) Quality of rapeseed oilproduced by conditioning seeds at modest temperatures. J Am Oil Chemists' Soc 90(4):589–599

Lan WU, Gang GE, Jinbao WAN (2009) Biodegradation of oil wastewater by free and immobilized Yarrowia lipolytica W29. J Environ Sci 21(2):237–242. https://doi.org/10.1016/S1001-0742(08)62257-3

Lazar Z, Liu N, Stephanopoulos G (2018) Holistic approaches in lipid production by Yarrowia lipolytica. Trends Biotechnol 36(11):1157–1170. https://doi.org/10.1016/j.tibtech.2018.06.007

Lievore P, Simões DR, Silva KM, Drunkler NL, Barana AC, Nogueira A, Demiate IM (2015) Chemical characterisation and application of acid whey in fermented milk. J Food Sci Technol 52:2083–2092. https://doi.org/10.1007/s13197-013-1244-z

Liu JF, Xia JJ, Nie KL, Wang F, Deng L (2019) Outline of the biosynthesis and regulation of ergosterol in yeast. World J Microbiol Biotechnol 35:1–8. https://doi.org/10.1007/s11274-019-2673-2

Lopes M, Gomes AS, Silva CM, Belo I (2018) Microbial lipids and added value metabolites production by Yarrowia lipolytica from pork lard. J Biotechnol 265:76–85. https://doi.org/10.1016/j.jbiotec.2017.11.007

Lopes M, Miranda SM, Alves JM, Pereira AS, Belo I (2019) Waste cooking oils as feedstock for lipase and lipid-rich biomass production. Eur J Lipid Sci Technol 121(1):1800188. https://doi.org/10.1002/ejlt.201800188

Lopes M, Miranda SM, Costa AR, Pereira AS, Belo I (2022) Yarrowia lipolytica as a biorefinery platform for effluents and solid wastes valorization–challenges and opportunities. Crit Rev Biotechnol 42(2):163–183. https://doi.org/10.1080/07388551.2021.1931016

Louhasakul Y, Cheirsilp B, Prasertsan P (2016) Valorization of palm oil mill effluent into lipid and cell-bound lipase by marine yeast Yarrowia lipolytica and their application in biodiesel production. Waste Biomass Valoriz 7:417–426. https://doi.org/10.1007/s12649-015-9451-7

Ma Y, Shen Y, Liu Y (2020) Food waste to biofertilizer: a potential game changer of global circular agricultural economy. https://doi.org/10.1021/acs.jafc.0c02210

MacGibbon AKH (2020) Composition and structure of bovine milk lipids. In: Advanced dairy chemistry, volume 2: lipids. pp 1–32. https://doi.org/10.1007/978-3-030-48686-0_1

Macwan SR, Dabhi BK, Parmar SC, Aparnathi KD (2016) Whey and its utilization. Int J Curr Microbiol App Sci 5(8):134–155. https://doi.org/10.20546/ijcmas.2016.508.016

Makri A, Fakas S, Aggelis G (2010) Metabolic activities of biotechnological interest in Yarrowia lipolytica grown on glycerol in repeated batch cultures. Biores Technol 101(7):2351–2358. https://doi.org/10.1016/j.biortech.2009.11.024

Mano J, Liu N, Hammond JH, Currie DH, Stephanopoulos G (2020) Engineering Yarrowia lipolytica for the utilization of acid whey. Metab Eng 57:43–50. https://doi.org/10.1016/j.ymben.2019.09.010

McDowell D, Elliott CT, Koidis A (2017) Characterization and comparison of UK, Irish, and French cold pressed rapeseed oils with refined rapeseed oils and extra virgin olive oils. Eur J Lipid Sci Technol 119(8):1600327. https://doi.org/10.1002/ejlt.201600327

Merska M, Czech A, Ognik K (2015) The effect of yeast Yarrowia lipolytica on the antioxidant indices and macro-and microelements in blood plasma of turkey hens. Pol J Vet Sci 18(4):709–714. https://doi.org/10.1515/pjvs-2015-0092

Pacheco-Pappenheim S, Yener S, Heck JM, Dijkstra J, van Valenberg HJ (2021) Seasonal variation in fatty acid and triacylglycerol composition of bovine milk fat. J Dairy Sci 104(8):8479–8492. https://doi.org/10.3168/jds.2020-19856

Panel EB (2018) Update of the list of QPS-recommended biological agents intentionally added to food or feed as notified to EFSA 8: suitability of taxonomic units notified to EFSA until March 2018. EFSA J 16(7):5315. https://doi.org/10.2903/j.efsa.2018.5315

Pires AF, Marnotes NG, Rubio OD, Garcia AC, Pereira CD (2021) Dairy by-products: a review on the valorization of whey and second cheese whey. Foods 10(5):1067. https://doi.org/10.3390/foods10051067

Qi Y, Liu H, Chen X, Liu L (2019) Engineering microbial membranes to increase stress tolerance of industrial strains. Metab Eng 53:24–34. https://doi.org/10.1016/j.ymben.2018.12.010

Qian YD, Tan SY, Dong GR, Niu YJ, Hu CY, Meng YH (2020) Increased campesterol synthesis by improving lipid content in engineered Yarrowia lipolytica. Appl Microbiol Biotechnol 104(16):7165–7175. https://doi.org/10.1007/s00253-020-10743-4

Radha P, Narayanan S, Chaudhuri A, Anjum S, Thomas DL, Pandey R, Ramani K (2023) Synthesis of single-cell oil by Yarrowia lipolytica MTCC 9520 utilizing slaughterhouse lipid waste for biodiesel production. Biomass Convers Biorefinery. https://doi.org/10.1007/s13399-020-01132-y

Radha P, Suhazsini P, Prabhu K, Jayakumar A, Kandasamy R (2020) Chicken tallow, a renewable source for the production of biosurfactant by Yarrowia lipolytica MTCC9520, and its application in silver nanoparticle synthesis. J Surfactants Deterg 23(1):119–135. https://doi.org/10.1002/jsde.12357

Ren W, Wu J, Wang J, Wang H, Han Y, Lin Y, Bu M (2023) Mitochondria-targeted ergosterol peroxide derivatives: synthesis, anticancer properties and their preliminary mechanism of inhibiting MCF-7 cell proliferation. J Braz Chem Soc. https://doi.org/10.21577/0103-5053.20230054

Rigouin C, Croux C, Borsenberger V, Ben Khaled M, Chardot T, Marty A, Bordes F (2018) Increasing medium chain fatty acids production in Yarrowia lipolytica by metabolic engineering. Microb Cell Fact 17:1–12. https://doi.org/10.1186/s12934-018-0989-5

Rocha-Mendoza D, Kosmerl E, Krentz A, Zhang L, Badiger S, Miyagusuku-Cruzado G, García-Cano I (2021) Acid whey trends and health benefits. J Dairy Sci 104(2):1262–1275. https://doi.org/10.3168/jds.2020-19038

Różańska MB, Kowalczewski PŁ, Tomaszewska-Gras J, Dwiecki K, Mildner-Szkudlarz S (2019) Seed-roasting process affects oxidative stability of cold-pressed oils. Antioxidants 8(8):313. https://doi.org/10.3390/antiox8080313

Rękas A, Siger A, Wroniak M, Ścibisz I, Derewiaka D, Anders A (2017) Dehulling and microwavepretreatment effects on the physicochemical composition and antioxidant capacity of virgin rapeseed oil. J Food Sci Technol 54:627–638

Rękas A, Wroniak M, Szterk A (2016) Characterization of some quality properties and chemical composition of cold-pressed oils obtained from different rapeseed varieties cultivated in Poland. Polish J Nat Sci 31(2):249–261

Sandoval NR, Papoutsakis ET (2016) Engineering membrane and cell-wall programs for tolerance to toxic chemicals: beyond solo genes. Curr Opin Microbiol 33:56–66. https://doi.org/10.1016/j.mib.2016.06.005

Sarantou S, Stoforos NG, Kalantzi O, Papanikolaou S (2020) Biotechnological valorization of biodiesel-derived glycerol: trials with the non-conventional yeasts Yarrowia lipolytica and Rhodosporidium sp. Carbon Resour Convers 4:61–75. https://doi.org/10.1016/j.crcon.2020.12.006

Sarris D, Rapti A, Papafotis N, Koutinas AA, Papanikolaou S (2019) Production of added-value chemical compounds through bioconversions of olive-mill wastewaters blended with crude glycerol by a Yarrowia lipolytica strain. Molecules 24(2):222. https://doi.org/10.3390/molecules24020222

Sezgin E, Levental I, Mayor S, Eggeling C (2017) The mystery of membrane organization: composition, regulation and roles of lipid rafts. Nat Rev Mol Cell Biol 18(6):361–374. https://doi.org/10.1038/nrm.2017.16

Sharma P, Dwivedi S, Singh D (2016) Global poverty, hunger, and malnutrition: a situational analysis. Biofortification of food crops. pp 19–30. https://doi.org/10.1007/978-81-322-2716-8_2

Ta TMN, Cao-Hoang L, Romero-Guido C, Lourdin M, Phan-Thi H, Goudot S et al (2012) A shift to 50 °C provokes death in distinct ways for glucose-and oleate-grown cells of Yarrowia lipolytica. Appl Microbiol Biotechnol 93:2125–2134. https://doi.org/10.1007/s00253-011-3537-3

Ta TMN, Romero-Guido C, Phan TH, Tran HD, Dinh HT, Waché Y (2022) Encapsulation of flavours into Yarrowia lipolytica active yeast cells. Fluorescence study of the lipid droplets morphology and steryl/sterol balance during the shock. AIMS Biophysics 9(3):257–270. https://doi.org/10.3934/biophy.2022022

Tan KH, Gill CO (1985) Batch growth of Saccharomycopsis lipolytica on animal fats. Appl Microbiol Biotechnol 21(5):292–298. https://doi.org/10.1007/BF00252707

Taskin M, Saghafian A, Aydogan MN, Arslan NP (2015) Microbial lipid production by cold-adapted oleaginous yeast Yarrowia lipolytica B9 in non-sterile whey medium. Biofuels Bioprod Biorefin 9(5):595–605. https://doi.org/10.1002/bbb.1560

Taylor FR, Parks LW (1978) Metabolic interconversion of free sterols and steryl esters in Saccharomyces cerevisiae. J Bacteriol 136(2):531–537. https://doi.org/10.1128/jb.136.2.531-537.1978

Thevenieau F, Nicaud JM (2013) Microorganisms as sources of oils. Oilseeds Fats Crops Lipids 20(6):D603. https://doi.org/10.1051/ocl/2013034

Tiwari A, Singh G, Choudhir G, Motiwale M, Joshi N, Sharma V, Srivastava RK, Sharma S, Tutone M, Singour PK (2022) Deciphering the potential of pre and pro-vitamin D of mushrooms against Mpro and PLpro proteases of COVID-19: an in silico approach. Molecules 27(17):5620. https://doi.org/10.3390/molecules27175620

Tomás-Pejó E, Morales-Palomo S, González-Fernández C (2021) Microbial lipids from organic wastes: outlook and challenges. Biores Technol 323:124612. https://doi.org/10.1016/j.biortech.2020.124612

Vasilakis G, Karayannis D, Massouras T, Politis I, Papanikolaou S (2022) Biotechnological conversions of mizithra second cheese whey by wild-type non-conventional yeast strains: production of yeast cell biomass, single-cell oil and polysaccharides. Appl Sci 12:11471. https://doi.org/10.3390/app122211471

Walker C, Ryu S, Trinh CT (2019) Exceptional solvent tolerance in Yarrowia lipolytica is enhanced by sterols. Metab Eng 54:83–95. https://doi.org/10.1016/j.ymben.2019.03.003

Wierzchowska K, Pakulska A, Derewiaka D, Piasecka I, Zieniuk B, Nowak D, Fabiszewska A (2022) Concept of batch and fed-batch cultures of Yarrowia lipolytica as a valuable source of sterols with simultaneous valorization of molasses and post-frying rapeseed oil. Appl Sci 12(24):12877. https://doi.org/10.3390/app122412877

Wierzchowska K, Zieniuk B, Fabiszewska A (2021) Use of non-conventional yeast Yarrowia lipolytica in treatment or upgradation of hydrophobic industry wastes. Waste Biomass Valoriz 13:757–779. https://doi.org/10.1007/s12649-021-01516-9

Wierzchowska K, Zieniuk B, Nowak D, Fabiszewska A (2021) Phosphorus and nitrogen limitation as a part of the strategy to stimulate microbial lipid biosynthesis. Appl Sci 11(24):11819. https://doi.org/10.3390/app112411819

Wonganu B, Kongruang S, Charoensakdi R (2021) Statistical design and optimization of nutritional value production by an oleaginous yeast Yarrowia lipolytica cultured in industrial–waste molasses. E3S Web Conf 302:02022. https://doi.org/10.1051/e3sconf/202130202022

Wroniak M, Rękas A (2016) Nutritional value of cold-pressed rapeseed oil during long term storage as influenced by the type of packaging material, exposure to light & oxygen and storage temperature. J Food Sci Technol 53:1338–1347. https://doi.org/10.1007/s13197-015-2082-y

Wu S, Hu C, Jin G, Zhao X, Zhao ZK (2010) Phosphate-limitation mediated lipid production by Rhodosporidium toruloides. Biores Technol 101(15):6124–6129. https://doi.org/10.1016/j.biortech.2010.02.111

Zhao N, Li B, Li H, Li G, Wu R, Hong Q et al (2021) The potential co-benefits for health, economy and climate by substituting raw coal with waste cooking oil as a winter heating fuel in rural households of northern China. Environ Res 194:110683. https://doi.org/10.1016/j.envres.2020.110683

Zieniuk B, Fabiszewska A (2019) Yarrowia lipolytica: a beneficious yeast in biotechnology as a rare opportunistic fungal pathogen: a minireview. World J Microbiol Biotechnol 35:1–8. https://doi.org/10.1007/s11274-018-2583-8

Funding

The study was financially supported by sources of the Ministry of Education and Science within funds of the Institute of Food Sciences of Warsaw University of Life Sciences (WULS), for scientific research.

Author information

Authors and Affiliations

Contributions

KW: conceptualization, methodology, formal analysis, investigation, data curation, writing—original draft preparation, visualization. DD: methodology, investigation. BZ: methodology, investigation, writing—review and editing. DN: methodology, investigation, resources, and supervision. AF: methodology, formal analysis, investigation, resources, writing—review and editing, and supervision.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Compliance with Ethics requirements

This article does not contain any studies with humans and animal subjects.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wierzchowska, K., Derewiaka, D., Zieniuk, B. et al. Whey and post-frying oil as substrates in the process of microbial lipids obtaining: a value-added product with nutritional benefits. Eur Food Res Technol 249, 2675–2688 (2023). https://doi.org/10.1007/s00217-023-04322-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-023-04322-w