Abstract

During drying herbs, the aim is to preserve their bioactive properties and characteristic aroma, which requires choosing a drying method and parameters that minimize degradation. In this study, the effects of convection and vacuum drying methods on peppermint (Mentha piperita L.), sweet basil (Ocimum basilicum L.), and lemon balm (Melissa officinalis L.) were compared. Fresh herb leaves were dried at 35 °C (using both methods) with an airflow of 0.5 m·s−1 for convection (CONV) and with reduced pressure (300 mbar) for the vacuum method (VAC). Physical and chemical properties were measured (color measurement in the L*a*b* system, weight loss, profile of volatile compounds, total phenolic content (TFC), total flavonoid content (TFC), and total antioxidant activity (TAA)). After drying, a reduction in the brightness of the leaf color and the proportion of red color was observed in most replicates (e.g., for peppermint—control sample L* = 43.11, CONV sample L* = 40.21, VAC sample L* = 37.30). Water evaporated by varying degrees depending on the herb species and the drying method as follows:. The TPC of peppermint was 332.44 mg gallic acid equivalent (GAE)/100 g of sample for CONV and 451.38 for VAC; for sweet basil sequentially: 80.59 and 105.63 GAE/100 g; for lemon balm 248.31 and 314.41 GAE/ 100 g. TFC of peppermint was 244.12 mg quercetin/100 g of sample for CONV and 261.92 for VAC; sweet basil sequentially: 76.91 and 83.31 mg quercetin/100 g; lemon balm 186.50 and 203.87 mg quercetin/100 g. The TAA of peppermint was 84.28% for convection drying, 87.49% for vacuum drying, and sweet basil, it was 20.35% and 47.35% sequentially, and for lemon balm, it was 87.67% and 89.69%. The vacuum method was statistically more effective in preserving the polyphenols and flavonoids in the herbs. Different drying methods also affected the volatile compounds recognized in dried herbs using the Electronic Nose.

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Avoid common mistakes on your manuscript.

Introduction

The shelf life of food and raw materials is closely related to their water content. Various methods of preservation are used in food technology, which is based on the regulation of water activity, and one of them is its removal, i.e., drying [1]. The main goals of reducing water activity are to prevent microbial growth, inhibit enzyme activity, oxidation, and nutrients, and prevent non-enzymatic reactions, thus extending the shelf life of the product with minimal quality losses [2]. Herbs are highly vulnerable to the drying process, which, in addition to preserving their valuable features (like anthocyanin or polyphenols), can also damage them or reduce the attractiveness of the final product by affecting color, texture, and aroma [3]. Ensuring the safety and maintaining the quality of herbs necessitates the development of highly effective preservation methods. The study focuses on plants from the Lamiaceae family, which comprises a vast array of over 7000 species. Specifically, the selected herbs are widely utilized in the Central and Eastern European region, where Poland is a leading importer and exporter of herbs in their fresh and dried states [4, 5]. Despite belonging to the same botanical family, chosen herbs exhibit considerable morphological diversity, rendering them ideal subjects for investigating the impact of various drying techniques on their composition and properties.

Peppermint (Mentha piperita L.) is a perennial plant that can reach a height of up to 90 cm. Due to its crossbreeding capabilities, it offers producers opportunities to obtain unique flavor profiles. There are numerous species of peppermint in nature, thanks to the ease of natural hybridization [6]. The essential oil content of peppermint leaves typically averages around 1.50% [7]. It comprises over 30 identified components, including menthol, menthone, neomenthol, and iso-menthone [8]. Peppermint is not only valued for its flavor but also for its potential health benefits. It is known for its soothing and calming effects on the digestive system, making it a popular choice for relieving indigestion and stomach discomfort. The menthol component in peppermint provides a cooling sensation and is often used in topical products to alleviate muscle aches and headaches [9].

Sweet basil (Ocimum basilicum L.) is an annual plant growing between 30 and 90 cm height. The herb, harvested during the early flowering stage, is the primary source of the herbal (oil) raw material. The leaves, harvested before turning pink or yellow during flowering, are commonly used for seasoning. To minimize essential oil loss, they can be naturally dried or dried in a controlled environment at temperatures up to 35 °C. The oil content of sweet basil, known for its clove-like aroma, varies from 0.10 to 0.25% in the herb itself [10] and can reach up to 1.50% in the leaves. Other identified constituents include α-pinene, β-pinene, methyl chavicol, 1,8-cineol, linalool, ocimene, borneol, geraniol, β-caryophyllene, and n-cinnamate [11]. Sweet basil is a culinary herb with cultural and symbolic significance in various cuisines. It is commonly used in Mediterranean, Thai, and Italian cuisine, adding a distinctive aroma and flavor to pasta, pesto, salads, and sauces. In addition to its culinary uses, sweet basil has been used in traditional medicine for its potential health benefits [12]

Lemon balm (Melissa officinalis L.) is a herbaceous perennial plant with a height ranging from 20 to 150 cm and a distinctive citrus aroma [13]. It has been known and appreciated since ancient times in Southern Europe, where the Ancient Greeks and Romans used it for medicinal purposes. In the Middle Ages, its popularity spread across the continent due to the influence of herbal orders, and it eventually gained recognition worldwide [14]. The main components of lemon balm essential oil, according to Ilić et al. [15], are geranial, neral, piperitenone oxide, and caryophyllene oxide, which make up approximately 1.54–2.15% of the oil. Lemon balm is often associated with promoting relaxation, reducing stress, and supporting healthy sleep patterns. It is also used topically in skincare products due to its potent antimicrobial and antioxidant properties. Lemon balm’s lemony scent and mild flavor make it famous for herbal teas, infused beverages, and culinary applications [16].

In modern industry, herbs are used not only as a whole part, but special attention is paid to the individual active compounds that can be extracted from them. The most important groups that are isolated and used are antioxidants, such as flavonoids, terpenoids, lignans, sulfides, polyphenols, carotenoids, coumarins, saponins, sterols, curcuminoids, and phthalides [17, 18].

In food production, phenols and flavonoids enrich and improve food products' flavor, aroma, and color. They also contribute to increasing the nutritional value of food and act as natural preservatives to prevent the growth of pathogens. In medicine, phenols and flavonoids assist in treating and preventing various diseases. These bioactive compounds have been studied for their potential therapeutic effects and are often incorporated into pharmaceutical formulations. In pharmacology and cosmetology, phenols and flavonoids serve as valuable sources of active substances. They are utilized as formulation enhancers and can be found in various skincare and cosmetic products. Additionally, phenols and flavonoids are commonly used as ingredients in dietary supplements, owing to their potential health-promoting properties [19, 20].

The simplest way to expedite the drying process is to increase the temperature at which it occurs. In the case of valuable and sensitive raw materials, the solution is to use a vacuum, which will ensure the efficiency of the process with the possibility of significantly lowering the temperature in the drying chamber [21]. By lowering the boiling point of water at low pressure, it is possible to carry out the drying process faster, at a lower temperature, and with a higher quality of the final product than conventional drying [22]. The heat energy is delivered by contact with the raw material through the trays on which it is spread [23]. Other methods that can be carried out with the vacuum chamber are microwave-vacuum drying, sublimation (freeze-drying), and combined methods [24]. Unconventional drying methods can also be economically viable due to the reduced use of thermal energy [25]. Herbs essential oils are mixes of volatile compounds (VOCs) naturally found in plants, with heavy aromas (often attractive to humans) and various capabilities, such as antibacterial, antiviral, antifungal, or insecticidal activity [26]. The drying method, temperature, time, vacuum level or airflow rate, and amount of moisture evaporated during drying affect the composition and content of VOCs in herbs essential oil. Also, the age of a particular plant, its origin, harvesting, growing conditions, and storage affect the baseline composition of volatile compounds in the fresh raw and the obtained dehydrated material [27, 28]. The advancement of electronic and sensory technology has led to the emergence of the electronic nose (e-nose) as a replacement for traditional sensory evaluation methods in food analysis. In recent years, a novel approach called fast GC e-nose, combining headspace analysis, electronic nose, and gas chromatography, has been successfully developed to characterize aroma compounds in different food products. This technique enables rapid and non-destructive analysis of volatile components, providing valuable insights into the composition of aromas. Its use in the analysis of dried herbs is an approach that eliminates classic sensory analysis and allows for the acceleration and automation of product evaluation processes. In this study, the applicability of it in deciding on the choice of method for drying raw material was tested [29]. During drying, there may be an increase and decrease in the concentration of volatiles in the essential oil, the formation of new compounds, or a loss of them. The noted new volatile compounds after drying could be an effect of oxidation or release of compounds from cell walls degraded by the drying process. Hydrolysis of glycosylated forms may also occur since, in plant cells, not all volatile compounds have a free form, contributing to the release of new compounds [27].

Considering the importance of the market for dried spices, a study was conducted to compare the effects of drying methods on the leaves of popular herbs from one family, yet with different morphological structures of the lamina. Determining this effect on physicochemical characteristics will make it possible to establish which drying method is better at preserving each species’ valuable and consumer-relevant properties.

Materials and methods

Plant material

Fresh leaves of potted herbs: peppermint (Mentha piperita L.; PM), sweet basil (Ocimum basilicum L.; SB), and lemon balm (Melissa officinalis L.; LB) were used for the study. Leaves used were harvested at a fully mature stage. The fresh samples were manually collected, sorted, and washed thoroughly under running water to remove dirt and other extraneous matter. The excess water was drained, and the samples were separated into test groups. The samples were then immediately subjected to drying. The material for the study came from a hydroponic culture near Warsaw (Baziółka, Grodzisk Mazowiecki, Poland).

Treatments

The leaves were collected manually and spread on drying trays in a single layer, without contact with each other, with each species separately. Convection drying (CONV) was performed in a laboratory hot-air dryer (BINDER FP 115 Classic Line, Tuttlingen, Germany) with air flow 0.5 m·s−1 at a temperature of 35 °C [30]. Convection drying (CONV) was performed in a laboratory hot-air dryer (BINDER FP 115 Classic Line, Tuttlingen, Germany) with airflow 0.5 m·s −1 at a temperature of 35 °C [30] for 24 h. Vacuum drying (VAC) was performed in a laboratory vacuum dryer Memmert VO500 (Schwabach, Germany) with contact heating at 35 °C and a pressure of 300 mbar for 24 h. The initial moisture content of samples was determined using the oven method at 105 °C for 24 h. The fresh herb leaves without any drying treatment were considered as control. The fresh herb leaves without any drying treatment were considered as control.

Color measurement

Instrumental measurements of leaves’,color parameters were made three times for each herb species, before and after each drying method. Measurements were made in 7 replicates for each sample and carried out with a Konica Minolta Chroma Meter Cr-400 (Tokyo, Japan) colorimeter, working in CIELab color space (L*a*b*) using the reflection method. A D65 light source, an 8-mm measuring head, and a standard 2° observer were used. Before measurements, the colorimeter was calibrated on a white standard with parameters L* = 98.45, a* = − 0.10, and b* = − 0.13. Based on the averaged values obtained, they were calculated using Eq. (1) coefficient of the overall difference in color between samples [31]:

where ΔL*—a difference in brightness (between control and convection/vacuum dried samples), Δa*—a difference in the color parameter green–red, Δb*—a difference in the color parameter blue–yellow. An accepted criterion for interpretation of calculated ΔE: 3.5 < ∆E < 5—a clear color difference is noticed; 5 < ∆E—observer notices two different colors.

The assessment of browning [BI] was carried out by calculating the following formula [32]:

where: \(x=\frac{{a}^{*}+1.75\bullet {L}^{*}}{5.645\bullet {L}^{*}+{a}^{*}-3.012\bullet {b}^{*}}\)

Weight loss

The weight of herbs’ leaves was measured by a laboratory weighing balance (RADWAG PS 6000/C/1 electronic balance, Radom, Poland). The weight loss was calculated according to Eq. (3):

where WLt—weight loss (%), Wf—the weight of fresh herbs before drying, Wd—the weight of dried herbs

The control samples' weight loss was determined by 24 h oven drying at 105 °C.

Preparation of ethanolic extracts

Extractions were necessary to assess herb samples' antioxidant activity and phenolic and flavonoid content.

The dried herbs were ground in a laboratory grinder (FW135 ChemLand, Poland). Samples of 0.6 g each were weighed, and 15 mL of 80% ethanol (Sigma Aldrich Inc., USA) was added. The samples were extracted at room temperature for 30 min in a rotary shaker (MyLab SLRM-3, NanoEnTek Inc., Seongnam, Korea) and next centrifuged for 10 min at 18 rpm × 1000 (MPW-251, MPW Med. Instruments, Warsaw, Poland) [33]. The supernatant was filtered through paper filters before measurements.

Total phenolic content (TPC)

The phenolic compounds’ content (TPC) was determined by the Folin–Ciocalteu (F–C) method [34]. To 0.1 mL of every extract, 6.0 mL of distilled water and 0.5 mL of F–C reagent (Sigma Aldrich Inc., USA) were added. After 3 min, 1.5 mL of saturated sodium carbonate of 200 mg/mL concentration (Sigma Aldrich Inc., USA) and 1.9 mL distilled water were added. The mixture was stored for 30 min in the water bath (WNB 7 Memmert, Germany) at a temperature of 40 °C. Absorbance was measured spectrophotometrically at the wavelength of 760 nm (TecanSpark™ 10 M, Männedorf, Switzerland). TPC was expressed as an equivalent gallic acid (GA) based on the prepared calibration curve. The results were provided as an average from two repeats in mg GA equivalent per 100 g of the sample.

Total flavonoid content (TFC)

Total flavonoid content (TFC) was determined with hydrated aluminum chloride [35]. 3.5 mL of 2% aqueous AlCl3·6H2O solution was added to 0.5 mL of ethanol extract, then mixed and incubated at room temperature for 10 min. A control sample was without extract addition (the sample was replaced with ethanol). The absorbance was measured at 430 nm wavelength (Tecan Spark™ 10 M Männedorf, Switzerland). The results were provided as an average from two repeats as mg quercetin/100 g (fresh weight).

Total antioxidant activity (TAA)

The anti-radical activity of the dried herbs was measured as a reductive capacity referred to 2,2-diphe-nyl-1-picrylhydrazyl—DPPH (Sigma Aldrich Inc., USA) [36]. For this purpose, 0.5 mL of ethanol extract was added to 3 mL of ethanol DPPH solution (0.6 mmol/L). The mixture was mixed for 30 s and put for 20 min in a dark place at room temperature. Absorbance was measured at the wavelength of 517 nm (Tecan Spark™ 10 M, Männedorf, Switzerland). As a reference solution, ethanol with 800 g/L concentration was used. A control sample was prepared without extract addition (the sample was replaced with ethanol). Measurements were carried out two times. The total antioxidant activity (TAA) expressed as a percentage of DPPH radical reduction was calculated according to Eq. (4):

where TAA is the total antioxidant activity and Abs is the measured absorbance.

Electronic nose analysis

The volatile compounds’ profiles of herbs were analyzed using Heracles II Electronic Nose (Alpha M.O.S., Toulouse, France) with two columns of different polarity (MXT-5 nonpolar and MXT-1701 polar) connected to two flame ionization detectors (FID) [37]. The main volatile compounds in the samples were recognized based on Kovats retention indexes and to identify the volatile compounds were used the AroChemBase database. Samples of fresh and dried herbs were placed in 20 mL headspace vials. Immediately after weighing, the vials were capped with a silicone-teflon rubber cap. The weighed amount for fresh samples was 0.08 g, and for the dried—0.04 g. Three replicates were prepared for each. The static headspace analysis (SHS) method was used. The incubation time of the samples was 5 min at 65 °C, and the vials were mixed at 250 rpm. The injection volume was 2500 μl; the injector temperature was 200 °C. The initial oven temperature was 40 °C for 3 s, then increased by 4 °C/s to 270 °C and held at 270 °C for 30 s. The detector’s temperature was 270 °C. The analysis time was 93 s. Hydrogen was used as a carrier gas. All samples were run in triplicate from a single vial. The method was calibrated with a mixture of n-hexane to n-hexadecane alkanes (Restek).

Statistical analysis

A one-way analysis of variance (ANOVA) and least significant difference (LSD) test was used to establish the significance of differences between the means at p < 0.05. Statistical analysis was conducted with Statistica 13.3 (StatSoft, Tulsa, USA).

Results and discussion

Color measurement

Health-promoting aspects and culinary suitability are the main qualities that consumers look for when choosing herbs. One of the essential parameters they use to assess whether a product meets these expectations is its color. Meanwhile, the drying process intended to protect herbs and help preserve their post-harvest quality simultaneously affects this characteristic [38]. The measured color parameters for fresh (control samples) peppermint were: L* = 43.11, a* = − 16.19, b* = 18.89; for sweet basil: L* = 44.17, a* = − 15.16, b* = 18.91; and for lemon balm: L* = 46.00, a* = − 19.23, b* = 28.13.

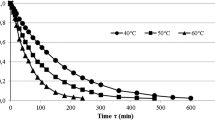

The brightness (L*) of lemon balm and sweet basil leaves did not change significantly after vacuum drying, while peppermint leaves brightness did not change after convection drying (Table 1; Fig. 1). Where significant changes occurred, they consisted of a decrease in brightness. The L* decrease of dried peppermint leaves compared to fresh leaves when vacuum and convection drying were used [39] confirmed also. Similar results were obtained by Rababah et al. [40], where oven drying at 40 °C significantly reduced the L* parameter for peppermint and lemon balm leaves. Kawo et al. [41] reported a decrease in the brightness of sweet basil leaves after oven drying.

The parameter a* determines the proportion of green (negative) and red (positive) color. Its changes are correlated with the degradation of chlorophyll a, which is sensitive to changes in temperature and water content and which, in the case of green-leaved plants, is responsible for their attractive fresh color in particular [34, 38]. During the measurements, it was proven that drying contributed to a significant increase in the a* parameter, i.e., a decrease in the intensity of the sample’s green color. That was probably related to drying browning caused by enzymatic and non-enzymatic reactions. Enzymatic browning occurs due to the oxidation of phenolic compounds by the enzyme polyphenol oxidase, which produces brown pigments called o-quinones. Maillard reactions, caramelization, and ascorbic acid oxidation can cause non-enzymatic browning. In addition, it is also affected by water activity, temperature, pH, and product composition [43]. In the case of peppermint and lemon balm, this parameter was less affected by the convection method (peppermint a* = − 9.25 and lemon balm a* = − 7.00). In contrast, in the case of sweet basil, the vacuum method achieved a lower result, more similar to fresh leaves (a* = − 13.43), which was not significantly different from the control sample. The decrease in the proportion of green color in the leaves of herbs in the Lamiaceae family during oven drying was also confirmed in two studies by Śledź and Witrowa-Rajchert [42] and Śledź et al. [44].

Measurements of the b* parameter (the proportion between yellow and blue color) came out similar to those for the a* parameter, and the only sample that did not differ significantly from the control sample was vacuum-dried sweet basil. In the rest of the cases, significant decreases in the proportion of yellow color were observed, as also shown by Arslan et al. [45] for sun-dried and oven-dried herbs at 50 °C. A decrease in b* values in lemon balm leaves during convection drying was also shown by Argyropoulos and Müller [46]. ΔE parameter shows that every dried sample color compared to fresh one observer notices as two different colors. Only the difference between the control sample and the vacuum-dried basil was < 5, indicating a clear color difference to the observer. This means that drying by both methods in most cases had an observer-noticeable effect on the appearance of the dried product (Fig. 1). Browning index (BI) (Table 1) was significantly higher for convection-dried (29.35) peppermint than vacuum-dried (25.31) and for vacuum-dried (35.29) sweet basil compared to convection-dried (27.22). In both cases, the sample with the lower BI was not statistically significantly different from the BI calculated for the fresh samples. For dried lemon balm both drying methods, BI decreased significantly. This was probably due to the high value of the b* parameter in the fresh sample which affected its BI and the subsequent destruction during drying of carotenoids and chlorophyll b, which are largely responsible for the yellow color of lemon balm [47].

Drying causes changes in the color of herb leaves (browning) that are visible to the observer, as well as a decrease in the value of the L* parameter—depending on the species of herb, vacuum drying (sweet basil) or convection drying (lemon balm and peppermint) had less of an effect on darkening—but the smallest changes overall were recorded in most cases for vacuum-dried sweet basil.

Assessment of herb weight loss

The water content of herb leaves can be affected by natural (variety, ripening, origin, and growth conditions) and processing factors (harvesting, storage, and preparation methods). To ensure the spice's microbiological safety and shelf life, the water content after drying should be < 10% [26]. The measurements showed that the convection drying parameters used resulted in a weight loss of 85.13% for the mint samples. It was not statistically significantly different from the weight loss of the control sample (85.66%). A lower weight loss of peppermint was caused by vacuum drying (76.09%), as was that of sweet basil (63.39%) (Table 2).

The differences in weight loss, which in the drying process is due to water evaporation, between species are due to the morphological structure of their leaf tissue. It is probably due to differences in morphological structure and more accessible water transport in the tissues (e.g., lemon balm than sweet basil) or differences in the epidermal permeability. The results of Altay et al. [48] also show that removing water from sweet basil is problematic. Even at a much higher temperature (55 °C) than that used in this work in the convection method, with faster airflow (1.5 m/s) and similar process time, the water content remains relatively high (about 20.00%). Calín-Sánchez et al. [42] also identify the vacuum method and its variations as the most effective in removing water from plant raw materials due to forming more pores than other methods, facilitating evaporation.

Determination of chemical parameters

Polyphenols and flavonoids are environmentally sensitive compounds, so preserving herbs, which are important parts, by drying them at increased temperature will partially degrade them. Choosing a method that least destroys these compounds is an important step for maintaining the quality of herbs [49]. Total polyphenols content was statistically significantly higher for each herb species after vacuum drying than convection drying. Vacuum-dried peppermint had the richest extract (451.38 mg GAE/100 g of sample), while convection-dried sweet basil had the lowest polyphenols content (80.59 mg GAE/100 g of sample) (Table 3). Hayat [50] obtained a similar result and found that convection drying significantly lowered the polyphenol content (to 405.70 mg GAE/100 of the sample) of peppermint leaves more than the unconventional microwave method he chose. Similar results were obtained for total flavonoid content, whereas a statistically higher sum showed samples dried by vacuum. The richest flavonoid was vacuum-dried peppermint (261.92 mg quercetin/100 g of sample), and the lowest content had sweet basil (83.39 mg quercetin/100 g of sample). Higher flavonoid content in peppermint, when dried under less stressful conditions (50 °C vs. 90 °C), was also recorded by Uribe et al. [51].

Phenols, which include flavonoids, represent the major constituents within the group of natural antioxidants present in herbs. These bioactive compounds, alongside other plants’ secondary metabolites, such as terpenoids and phenolic acids, collectively determine the overall antioxidant activity of a given herb species. The synergistic effect of these diverse compounds contributes to the herb's ability to scavenge free radicals, inhibit oxidative stress, and protect against cellular damage caused by reactive oxygen species. This comprehensive array of secondary metabolites reflects the herb's adaptive response to environmental stressors and is a vital defense mechanism [52]. The most favorable drying method should be selected to preserve the highest possible content of these. It was found that herbs dried by the vacuum method had a statistically significantly higher (p < 0.05) ability to reduce the free radical DPPH. For peppermint, the reduction was 87.49%; for sweet basil, 47.35%; and the lemon balm, 89.60%. A similar result was in the research by Djamila et al. [53] of drying peppermint using the oven method at 50 °C received, where the inhibition of the sample was more than 80%. This was statistically lower than that of the 800 W microwave drying method compared to it in that study.

Volatile compounds’ (VOCs) profile

Consumers expect specific aroma characteristics from plant products, based on which, among other factors, they judge their quality. Herbs owe their intense aromas to volatile compounds (VOCs) which are sensitive to temperature rise, i.e., their aroma can change due to the most popular method of preservation, drying. Therefore, it is important to use drying methods that affect the composition of VOCs as little as possible [54, 55]. A total of 44 volatile compounds were found in the VOCs profile (Table 4). The dominant groups were esters (10 compounds) and terpenes (19 compounds). These groups of compounds are responsible for the characteristic aroma of herbs. The profile of volatile compounds changed during the drying process, which is visualized in Fig. 2. Principal component analysis (PCA) performed for each of the groups shows changes in the VOCs profile during drying. Figure 2A shows changes in the Euclidian distance adopted as conventional odor units differentiating the chromatographic profiles of the analyzed groups. The profiles of volatile compounds of fresh basil and vacuum-dried lemon balm were the most distant from each other; the distance was 355 units. This was due to the presence of different compounds in both groups.

Changes in the profile of volatile compounds. A—assessment of changes in the profile of volatile compounds in fresh herbs—peppermint (PM), basil (SB), lemon balm (LB) and after drying by convection (PMC, LBC, SBC) and vacuum (PMV, LBV, SBV) methods; B—PCA score plot of volatile compounds profile of peppermint; C—PCA score plot of volatile compounds profile of basil; D—PCA score plot of volatile compounds profile of lemon balm

The smallest differences in the profile of volatile compounds during drying were observed for mint (PM); range of changes from 25 to − 62 (87 units). Score plot is shown on Fig. 2B. More than 98% of total variability is explained by the first two components (PC1 and PC2). A total of 28 volatile compounds were found in the fresh peppermint. The profile of fresh mint volatile compounds was formed by alcohols (3 compounds), aldehydes (3 compounds), esters (8 compounds), one ketone and 13 compounds from the terpene group (details in Table 4). In an analysis fresh peppermint by Kizil [56] they identified (+)-menthol, menthol, neomenthol, and cineol as the main components. Aflatuni [57] showed the presence of α-pinene, sabinene, β-pinene, micrene, limonene, 1.8-cyneol, cis-p-ment-2-en-1-ol, menthofuran, menthone, menthol, pulegone, piperitone, menthyl acetate, β-bourbonene, γ-cadinene, and β-caryophyllene. This study confirms the content of such VOCs in fresh peppermint. Partial loss of volatile compounds occurs during drying, 3-octanol and (Z)-2-octenal were not recognized in mint after drying. By analyzing the relative percentage of the terpenes peak areas (the main components of the essential oil (OE)) in the total area of all peaks from the chromatographic analysis of a mint sample, the process of changes in volatile compounds can be traced. The sum of the relative peak areas of all terpenes in fresh mint was 81.2%, in convection-dried mint 64.8%, and in vacuum-dried mint 71.32%. The obtained results suggest that the vacuum drying process ensures greater OE retention in mint than convection drying. On the other hand, it was noticed that compounds absent in fresh mint samples appeared in dried mint samples. This concerned linalool and methyl 2-methylbutanoate. Guo et al. [58], while drying mint in different temperature conditions, also noticed that mint dried at 35ºC showed, among others, linalool and borneol absent in fresh mint. The rationale for this observation was the intact cellular structure in fresh mint, which inhibited the release of some volatile compounds. On the other hand, a mild increase in temperature destroys the cell membrane and supports the process of releasing especially those compounds that have a lower boiling point.

The greatest differences in the profile of volatile compounds during drying (Fig. 2A) were observed for lemon balm (LB); range of changes from − 135 to 105 (240 units). This change concerns the differences in the profiles between fresh and dried lemon balm. Score plot is shown on Fig. 2D. Almost 100% of total variability is explained by the first two components (PC1 and PC2). This graph shows the similarity of the volatile compound profiles of convectively and vacuum-dried lemon balm. A total of 23 different volatile compounds were found in the fresh lemon balm. The profile of volatile compounds of fresh lemon balm consisted of alcohols (3 compounds), aldehydes (4 compounds), esters (6 compounds), one ketone and 10 compounds from the terpene group (details in Table 4). Geranial and geraniol are volatile compounds that were reported by Waheed [13] as one of the main components of fresh lemon balm oil. Jalal et al. [59] study reported that the main components were citronellal, isogeraniol, geranyl acetate, nerol acetate, caryophyllene, and β-caryophyllene oxide. After convection and vacuum drying, 18 and 17 compounds were found in lemon balm, respectively (details in Table 4). A decrease in the share of terpenes in dried lemon balm in relation to fresh lemon balm was observed, using the sum relative share of the terpenes peaks areas in the total areas of all the chromatographic profile peaks. The relative share of terpenes in VOCs of the profile for fresh lemon balm was approx. 95%, for convectively dried lemon balm approx. 51% and for vacuum dried lemon balm approx. 88%. These results indicate that vacuum drying of melissa is the recommended method. Khalid et al. [60] studied the effect of drying methods on the content of OE and volatile compounds in lemon balm. Researchers found significant differences in the content of volatile compounds in lemon balm depending on the method of drying. During sun drying, shade drying and oven drying at 40ºC, reduced content of volatile compounds in lemon balm was obtained from approx. 19% to approx. 14% respectively. The loss of OE compounds was explained by the structure of the lemon balm leaf and the proximity of the oil cells to the leaf surface.

Changes in the volatile compound profile (Fig. 2A) during basil drying (SB) were 105 units (− 230 to − 125). Score plot is shown on Fig. 2C. More than 96% of total variability is explained by the first two components (PC1 and PC2). A total of 22 volatile compounds were found in the fresh basil. The profile of volatile compounds of fresh basil consisted of alcohols (3 compounds), aldehydes (3 compounds), esters (4 compounds), 11 compounds from the terpene group as well as anethol and dodecane. 17 compounds were found in convectively and vacuum-dried samples (details in Table 4). The volatile compounds in fresh sweet basil leaves were similar to what is shown in Shahrajabian et al. [11] review where α-pinene, β-pinene, methyl chavicol, 1,8-cyneol, linalool, ocymene, borneol, geraneol, β-caryophyllene, and n-cinnamate were appointed. The analysis of the share of terpenes in the chromatographic profile showed that the sum of the relative peak areas of all terpenes in fresh basil was approx. 94%, in convection dried basil approx. 60%, and in vacuum dried basil approx. 66%. Kerekes et al. [61], who studied the effect of drying methods on the quality of dried basil, also used changes in the area of peak fields from gas chromatography analyzes to assess changes in volatile compounds. The researchers found that vacuum drying compared to hot-air drying reduced the loss of linalool and camphor, but increased the loss of eucalyptol.

The method that caused lower losses of volatile compounds during the drying of mint, lemon balm and basil turned out to be the vacuum drying method. Reducing the pressure allows the water to evaporate at a lower temperature and speeds up the drying time, which makes it particularly beneficial when drying herbs [51].

Conclusions

The study proved that convection drying affects the raw material differently than vacuum drying. Weight loss depends on the morphological structure of the leaf, and in the case of sweet basil, it was lower for the vacuum method (63.39% compared to 73.24% for convection). Both drying methods lowered the brightness of the leaves’ color (L*) and caused browning (a*). Samples obtained by vacuum method had statistically significantly higher polyphenols (e.g., peppermint: 332.44 mg GAE/100 g of sample weight for convection and 451.38 mg GAE/100 g for vacuum) content and higher flavonoid content (peppermint: 244.12 mg of quercetin/100 g of sample for convection and 261.92 mg for vacuum) than convection-dried ones. Likewise, TPC, TFC and total antioxidant activity was statistically higher in vacuum-dried samples (peppermint: 84.28% of DPPH inhibition for convection and 87.49% for vacuum). The volatile compound profile of the herbs also varied depending on the drying method used. The obtained results permit to recommend vacuum drying as a better method for preserving herbs’ biochemical features unlike the convection method.

Availability of data and material

The authors declare the availability of data and material.

References

Bassey EJ, Cheng JH, Sun DW (2021) Novel nonthermal and thermal pretreatments for enhancing drying performance and improving quality of fruits and vegetables. Trends Food Sci Technol 112:137–148. https://doi.org/10.1016/j.tifs.2021.03.045

Guiné RPF (2018) The drying of foods and its effect on the physical-chemical, sensorial and nutritional properties. Int J Food Eng 4:93–100. https://doi.org/10.18178/ijfe.4.2.93-100

Pandiselvam R, Tak Y, Olum E, Sujayasree OJ, Tekgül Y, Çalışkan Koç G, Kaur M, Nayi P, Kothakota A, Kumar M (2021) Advanced osmotic dehydration techniques combined with emerging drying methods for sustainable food production: Impact on bioactive components, texture, color, and sensory properties of food. J Texture Stud 53:737–762. https://doi.org/10.1111/jtxs.12643

Li B, Cantino D, Olmstead RG, Bramley GLC, Xiang CL, Ma ZH, Tan YH, Zhang DX (2016) A large-scale chloroplast phylogeny of the Lamiaceae sheds new light on its subfamilial classification. Sci Rep 6(1):34343. https://doi.org/10.1038/srep34343

The European market potential for fresh herbs | CBI. (n.d.). Retrieved June 8, 2023, from https://www.cbi.eu/market-information/fresh-fruit-vegetables/fresh-herbs/market-potential

Kiełtyka-Dadasiewicz A, Lis K, Kubat-Sikorska A (2018) Analiza zapachu wybranych odmian mięty (Mentha sp.) Smell analysis of selected mint (Mentha sp.) cultivars. Herbalism 1(4):52. https://doi.org/10.32094/HERB-2018-05

Edwards SE, Rocha I, Williamson EM, Heinrich M (2015) Phytopharmacy: an evidence-based guide to herbal medicinal products. Wiley

Zhao H, Ren S, Yang H, Tang S, Guo C, Liu M, Tao Q, Ming T, Xu H (2022) Peppermint essential oil: its phytochemistry, biological activity, pharmacological effect and application. Biomed Pharmacother 154:113559. https://doi.org/10.1016/j.biopha.2022.113559

Nayak P, Kumar T, Gupta AK, Joshi NU (2020) Peppermint a medicinal herb and treasure of health: a review. J Pharmacogn Phytochem 9(3):1519–1528

Pushpangadan P, George V (2012) Basil. In: Peter K (ed) Handbook of herbs and spices, vol 1. Woodhead Publishing. https://doi.org/10.1533/9780857095671.55

Shahrajabian MH, Sun W, Cheng Q (2020) Chemical components and pharmacological benefits of Basil (Ocimum basilicum): a review. Int J Food Prop 23(1):1961–1970. https://doi.org/10.1080/10942912.2020.1828456

Bączek K, Kosakowska O, Gniewosz M, Gientka I, Węglarz Z (2019) Sweet Basil (Ocimum basilicum L.) productivity and raw material quality from organic cultivation. Agronomy 9(6):279. https://doi.org/10.3390/agronomy9060279

Waheed K, Nawaz H, Hanif MA, Rehman R, Ogunwande IA (2020) Lemon balm. Medicinal plants of South Asia. Elsevier. https://doi.org/10.1016/B978-0-08-102659-5.00035-5

Ravindran PN, Shylaja MR (2012) Introduction spices: definition, classification, history, properties and uses. In: Ravindran PN (ed) The encyclopedia of herbs and spices, vol 1. CABI, p XXI–XXIII

Ilić ZS, Milenković L, Tmušić N, Stanojević L, Stanojević J, Cvetković D (2022) Essential oils content, composition and antioxidant activity of lemon balm, mint and sweet basil from Serbia. LWT 153:112210. https://doi.org/10.1016/j.lwt.2021.112210

Shakeri A, Sahebkar A, Javadi B (2016) Melissa officinalis L.—a review of its atraditional uses, phytochemistry and pharmacology. J Ethnopharmacol 188:204–228. https://doi.org/10.1016/j.jep.2016.05.010

Embuscado ME (2015) Spices and herbs: natural sources of antioxidants—a mini review. J Funct Foods 18:811–819. https://doi.org/10.1016/j.jff.2015.03.005

Tran N, Pham B, Le L (2020) Bioactive compounds in anti-diabetic plants: from herbal medicine to modern drug discovery. Biology 9(9):252. https://doi.org/10.3390/biology9090252

Leja KB, Czaczyk K (2016) The industrial potential of herbs and spices—a mini review. Acta Scientiarum Polonorum Technologia Alimentaria 15(4):353–368. https://doi.org/10.17306/J.AFS.2016.4.34

Ulewicz-Magulska B, Wesolowski M (2019) Total phenolic contents and antioxidant potential of herbs used for medical and culinary purposes. Plant Foods Hum Nutr 74(1):61–67. https://doi.org/10.1007/s11130-018-0699-5

Parikh D (2015) Vacuum drying: basics and application. Chem Eng 122(4):48–54

Pankyamma V, Mokam SY, Debbarma J, Rao BM (2019) Effects of microwave vacuum drying and conventional drying methods on the physicochemical and microstructural properties of squid shreds. J Sci Food Agric 99(13):5778–5783. https://doi.org/10.1002/jsfa.9846

Brennan JG (2011) Evaporation and dehydration. In: Grandison AS, Brennan JG (eds) Food processing handbook. Wiley, pp 77–130. https://doi.org/10.1002/9783527634361.ch3

Reis RF (2014) Introduction to low pressure processes. In: Richter-Reis F (ed) Introduction to low pressure processes. SpringerBriefs in applied sciences and technology. Springer, pp 1–6. https://doi.org/10.1007/978-3-319-08207-3_1 (Issue 9783319082066)

Menon A, Stojceska V, Tassou SA (2020) A systematic review on the recent advances of the energy efficiency improvements in non-conventional food drying technologies. Trends Food Sci Technol 100:67–76. https://doi.org/10.1016/j.tifs.2020.03.014

Caputo L, Amato G, de Bartolomeis P, de Martino L, Manna F, Nazzaro F, de Feo V, Barba AA (2022) Impact of drying methods on the yield and chemistry of Origanum vulgare L essential oil. Sci Rep 12(1):3845. https://doi.org/10.1038/s41598-022-07841-w

Chua LYW, Chong CH, Chua BL, Figiel A (2019) Influence of drying methods on the antibacterial, antioxidant and essential oil volatile composition of herbs: a review. Food Bioprocess Technol 12(3):450–476. https://doi.org/10.1007/s11947-018-2227-x

Thamkaew G, Sjöholm I, Galindo FG (2021) A review of drying methods for improving the quality of dried herbs. Crit Rev Food Sci Nutr 61(11):1763–1786. https://doi.org/10.1080/10408398.2020.1765309

Yu D-X, Guo S, Wang J-M, Yan H, Zhang Z-Y, Yang J, Duan J-A (2022) Comparison of different drying methods on the volatile components of ginger (Zingiber officinale Roscoe) by HS-GC-MS coupled with fast GC E-Nose. Foods 11:1611. https://doi.org/10.3390/foods11111611

Abaas I, Hamzah M, Majeed A (2013) Analysis with evaluation of drying temperature on essential oil content of Achillea frayrantissima L. and Artemisia herb-alba L. Int J Pharm Pharm Sci 5(3):913–914

Mokrzycki W, Tatol M (2011) Color difference ΔE—a survey. Mach Graph Vis 20(4):383–411

Nalawade SA, Ghiwari GK, Hebbar HU (2019) Process efficiency of electromagnetic radiation (EMR)-assisted hybrid drying in spearmint (Mentha spicata L). J Food Process Pres. https://doi.org/10.1111/jfpp.14190

Radzki W, Sławińska A, Jabłońska-Ryś E, Gustaw W (2014) Antioxidant capacity and polyphenolic content of dried wild edible mushrooms from Poland. Int J Med Mushrooms 16(1):65–75. https://doi.org/10.1615/INTJMEDMUSHR.V16.I1.60

Singleton VL, Rossi JA (1965) Colorimetry of total phenolics with phosphomolybdic-phosphotungstic acid reagents. Am J Enol Viticult 16(3):144–158

Zhishen J, Mengcheng T, Jianming W (1999) The determination of flavonoid contents in mulberry and their scavenging effects on superoxide radicals. Food Chem 64(4):555–559. https://doi.org/10.1016/S0308-8146(98)00102-2

Okawa M, Kinjo J, Nohara T, Ono M (2001) DPPH (1,1-diphenyl-2-picrylhydrazyl) radical scavenging activity of flavonoids obtained from some medicinal plants. Biol Pharm Bull 24(10):1202–1205. https://doi.org/10.1248/bpb.24.1202

Pogorzelska-Nowicka E, Hanula MM, Brodowska-Trębacz M, Górska-Horczyczak E, Jankiewicz U, Mazur T, Marcinkowska-Lesiak M, Półtorak A, Wierzbicka A (2021) The effect of cold plasma pretreatment on water-suspended herbs measured in the content of bioactive compounds, antioxidant activity, volatile compounds and microbial count of final extracts. Antioxidants 10:1740. https://doi.org/10.3390/antiox10111740

Złotek U, Szymanowska U, Rybczyńska-Tkaczyk K, Jakubczyk A (2020) Effect of jasmonic acid, yeast extract elicitation, and drying methods on the main bioactive compounds and consumer quality of lovage (Levisticum officinale Koch). Foods 9(3):323. https://doi.org/10.3390/foods9030323

Rubinskienė M, Viškelis P, Dambrauskienė E, Viškelis J, Karklelienė R (2015) Effect of drying methods on the chemical composition and colour of peppermint (Mentha × piperita L) leaves. Zemdirbyste-Agric 102(2):223–228. https://doi.org/10.13080/z-a.2015.102.029

Rababah TM, Al-U’Datt M, Alhamad M, Al-Mahasneh M, Ereifej K, Andrade J, Altarifi B, Almajwal A, Yang W (2015) Effects of drying process on total phenolics, antioxidant activity and flavonoid contents of common mediterranean herbs. Int J Agric Biol Eng 8(2):145–150. https://doi.org/10.3965/j.ijabe.20150802.1496

Kwao S, Al-Hamimi S, Damas MEV, Rasmusson AG, Gómez Galindo F (2016) Effect of guard cells electroporation on drying kinetics and aroma compounds of Genovese basil (Ocimum basilicum L.) leaves. Innov Food Sci Emerg Technol 38:15–23. https://doi.org/10.1016/j.ifset.2016.09.011

Śledź M, Witrowa-Rajchert D (2012) Influence of microwave-convective drying of chlorophyll content and colour of herbs. Acta Agrophys 19(4):865–876

Calín-Sánchez Á, Lipan L, Cano-Lamadrid M, Kharaghani A, Masztalerz K, Carbonell-Barrachina ÁA, Figiel A (2020) Comparison of traditional and novel drying techniques and its effect on quality of fruits. Veg Aromatic Herbs Foods 9(9):1261. https://doi.org/10.3390/foods9091261

Śledź M, Nowacka M, Wiktor A, Witrowa-Rajchert D (2013) Selected chemical and physico-chemical properties of microwave-convective dried herbs. Food Bioprod Process 91(4):421–428. https://doi.org/10.1016/j.fbp.2013.02.010

Arslan D, Özcan MM, Mengeş HO (2010) Evaluation of drying methods with respect to drying parameters, some nutritional and colour characteristics of peppermint (Mentha x piperita L). Energy Convers Manag 51(12):2769–2775. https://doi.org/10.1016/j.enconman.2010.06.013

Argyropoulos D, Müller J (2014) Kinetics of change in colour and rosmarinic acid equivalents during convective drying of lemon balm (Melissa officinalis L). J Appl Res Med Arom Plants 1(1):e15–e22. https://doi.org/10.1016/j.jarmap.2013.12.001

Loranty A, Rembiałkowska E, Rosa EAS, Bennett RN (2010) Identification, quantification and availability of carotenoids and chlorophylls in fruit, herb and medicinal teas. J Food Compos Anal 23(5):432–441. https://doi.org/10.1016/j.jfca.2010.01.007

Altay K, Hayaloglu AA, Dirim SN (2019) Determination of the drying kinetics and energy efficiency of purple basil (Ocimum basilicum L) leaves using different drying methods. Heat Mass Transfer 55(8):2173–2184. https://doi.org/10.1007/s00231-019-02570-9

Ammendola M, Haponska M, Balik K, Modrakowska P, Matulewicz K, Kazmierski L, Lis A, Kozlowska J, Garcia-Valls R, Giamberini M, Bajek A, Tylkowski B (2020) Stability and anti-proliferative properties of biologically active compounds extracted from Cistus L after sterilization treatments. Sci Rep 10(1):6521. https://doi.org/10.1038/s41598-020-63444-3

Hayat K (2020) Impact of drying methods on the functional properties of peppermint (Mentha piperita L) leaves. Sci Lett 8(1):6–42

Uribe E, Marín D, Vega-Gálvez A, Quispe-Fuentes I, Rodríguez A (2016) Assessment of vacuum-dried peppermint (Mentha piperita L.) as a source of natural antioxidants. Food Chem 190:559–565. https://doi.org/10.1016/j.foodchem.2015.05.108

Yeshi K, Crayn D, Ritmejerytė E, Wangchuk P (2022) Plant secondary metabolites produced in response to abiotic stresses has potential application in pharmaceutical product development. Molecules 27(1):313. https://doi.org/10.3390/molecules27010313

Djamila B, Fatima Zohra K, Lahcene K, Zohra RF (2021) Drying methods affect the extracts and essential oil of Mentha aquatica L. Food Biosci 41:101007. https://doi.org/10.1016/j.fbio.2021.101007

Ali MM, Hashim N, Abd Aziz S, Lasekan O (2020) Principles and recent advances in electronic nose for quality inspection of agricultural and food products. Trends Food Sci Technol 99:1–10. https://doi.org/10.1016/j.tifs.2020.02.028

Baietto M, Wilson A (2015) Electronic-nose applications for fruit identification ripeness and quality grading. Sensors 15(1):899–931. https://doi.org/10.3390/s150100899

Kizil S, Ha N, Tolan V, Kilinç E, Yüksel U (2010) Mineral content, essential oil components and biological activity of two mentha species (M. piperita L., M. spicata L.). Turk J Field Crops 15(2):148–153

Aflatuni A (2005) The yield and essential oil content of mint (Mentha sp) in Northern Ostrobothnia. University of Oulu

Guo H-L, Chen Y, Xu W, Xu M-T, Sun Y, Wang X-C, Wang X-Y, Luo J, Zhang H, Xiong Y-K (2022) Assessment of drying kinetics, textural and aroma attributes of mentha haplocalyx leaves during the hot air thin-layer drying process. Foods 11:784. https://doi.org/10.3390/foods11060784

Jalal Z, el Atki Y, Lyoussi B, Abdellaoui A (2015) Phytochemistry of the essential oil of Melissa officinalis L growing wild in Morocco: preventive approach against nosocomial infections. Asian Pac J Trop Biomed 5(6):458–461. https://doi.org/10.1016/j.apjtb.2015.03.003

Khalid AK, Wenli H, Weiming C (2008) The effects of harvesting and different drying methods on the essential oil composition of lemon balm (Melissa officinalis L). J Essent Oil Bear Plants 11(4):342–349. https://doi.org/10.1080/0972060X.2008.10643639

Kerekes B, Antal T, Kovács Z (2019) Effect of various drying methods on the volatile oil composition of basil leaves. Hung Agric Eng 35:39–44. https://doi.org/10.17676/HAE.2019.35.39

Funding

Research financed by Polish Ministry of Science and Higher Education within funds of Institute of Human Nutrition Sciences, Warsaw University of Life Sciences (WULS), for scientific research.

Author information

Authors and Affiliations

Contributions

Conceptualization MZ. Investigation KŻ, EGH, and AO. Methodology MK and MZ. Writing—original draft preparation KŻ and AO. Writing—review and editing MK and MZ.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

There were no experiments in the study.

Consent to participate

All authors have read and agreed to the published version of the manuscript.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Żbik, K., Górska-Horczyczak, E., Onopiuk, A. et al. Vacuum and convection drying effects on volatile compounds profile and physicochemical properties of selected herbs from Lamiaceae family. Eur Food Res Technol 249, 2569–2581 (2023). https://doi.org/10.1007/s00217-023-04309-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-023-04309-7