Abstract

The aim of the paper was to determine the potential of using grape must and unconventional yeasts in the beer production process. Samples were fermented using non-Saccharomyces yeasts (Dekkera bruxellensis 3429, Wickerhamomyces anomalus MG971261, Kluyveromyces lactis MG971263), and Saccharomyces cerevisiae Safale US-05 was used as a control. Grape must was pasteurized and, together with wort, volumetrically introduced into fermentation flasks for fermentation. Mass changes taking place during the process were analyzed. Real extract, alcohol content, free amino nitrogen (FAN) content, titratable acidity, color, and sugar profile were determined in obtained beers. The obtained results have proven that the tested non-Saccharomyces yeasts can adapt to fermentation conditions, just like S. cerevisiae Safale US-05, and can be used to produce beer-wine hybrid alcoholic beverages. The yeast K. lactis MG971263 produced a greater amount of alcohol in beers compared to other yeast strains. There were no significant differences in the color of the obtained beers and in the degree of FAN utilization during the fermentation process. The unconventional yeasts used are capable of producing beers without and with the addition of grape must with parameters similar to beers obtained using S. cerevisiae Safale US-05.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Beer is a very popular low-alcohol drink that has many health benefits if it is consumed in small amounts. The healthiest beers are those that are unpasteurized and unclarified, with a shelf life of about 21 days. They are mainly made from four raw materials: malt, hops, water and yeast. Compared to other alcoholic beverages, beer contains a lot of nutrients, such as phosphorus, magnesium, calcium, potassium, and a small amount of sodium. It is also a source of mineral salts and B vitamins (B1, B2, PP, and B12) derived from malt and yeast. In addition, the drink contains greater amounts of protein than other alcohols, as well as biologically active antioxidant compounds [1, 2].

People's palates are becoming more and more refined, which makes consumers look for new taste sensations. This is also the case with brewing, winemaking, and distilling products. Therefore, in recent years, producers have expanded their offer and more and more fruit beers have been appearing on the market [3]. To meet customer expectations, brewers and winemakers have entered a new dimension of alcohol, creating an innovative combination of beer and wine. The hybrid of these two drinks has appeared on the market relatively recently, and at first, it did not win the hearts of consumers. A small group of gourmets tasted the product, and only with time did it gain wider recognition. The combination of these alcohols comes from Italy. Italian Grape Ale (IGA) is such a composition. It is usually light beer with an addition of grapes, must, pulp, marc, or raisins, which is fermented with top fermentation brewing or winemaking yeast. When producing such a drink, the most important thing is to keep the balance between the taste of beer and wine.

In recent years, due to the changing market, more and more innovative products that meet the highest consumer requirements have been being created. Negative perception of non-Saccharomyces is changing due to the growing interest in these yeasts and increasingly more detailed knowledge of their properties. They have been proven to have a positive effect on the flavor of the final product [4]. Yeasts not belonging to the genus Saccharomyces are genetically diverse microorganisms with high potential for use in the production of fermented beverages. They produce large amount of aromas, i.e., esters and higher alcohols. Their fermentation activity occurs with a small amount of oxygen, which in turn leads to a decrease in ethanol concentration and an increase in biomass. The performance of each yeast species is influenced by pH, oxygen and nutrient availability, and the presence of other microorganisms [5, 6].

Yeasts not belonging to the genus Saccharomyces give an opportunity to create a completely new product. Due to the production of a wide range of compounds that positively affect the organoleptic quality of beers and wines, such yeasts cannot be overrated [5]. C. zemplinina showed a suitable fermentative behavior for the production of lager and ale beers. It is also interesting that the species is unable to ferment maltose which is the main sugar in malt wort, thanks to which it produces beer with a specific aroma and with a reduced ethanol content [4]. The yeast species Hanseniaspora uvarum can produce esters that impart fruity notes to final product. Additionally, combined with S. cerevisiae, it produces greater amounts of higher alcohols than monocultures S. cerevisiae. The yeast species T. delbrueckii can affect acidity by producing large amounts of lactic and succinic acid. The species produces aromatic esters like ethyl lactate and 2-phenylethyl acetate in greater amounts than monocultures S. cerevisiae. Non-Saccharomyces can also be used to produce beer with reduced alcohol content or non-alcoholic beer. De Francesco et al. [7] have confirmed the usefulness of Saccharomycodes ludwigii and Zygosaccharomyces rouxii for production of beer with a lower ethanol content [5]. It is certain that the use of S. cerevisiae in mixed cultures with different species of non-Saccharomyces affects the shelf life and sensory profile of alcoholic drinks [6]. Yeasts not belonging to the genus Saccharomyces are drawing more and more attention due to their fermentation properties [4].

The aim of the paper was to determine the potential of using grape must and unconventional yeasts in the beer production process. Samples were fermented using non-Saccharomyces yeasts (Dekkera bruxellensis 3429, Wickerhamomyces anomalus MG971261, Kluyveromyces lactis MG971263) and Saccharomyces cerevisiae Safale US-05 was used as a control. Unconventional strains were selected based on their natural occurrence in certain alcoholic fermentations and their prior use in winemaking. Grape must was pasteurized and, together with wort, volumetrically introduced into fermentation flasks for fermentation. Mass changes taking place during the process were analyzed. Real extract, alcohol content, free amino nitrogen (FAN) content, titratable acidity, color, and sugar profile were determined in obtained beers.

Materials and methods

Materials

The yeast strains Saccharomyces cerevisiae Safale US-05, Dekkera bruxellensis 3429, Wickerhamomyces anomalus MG971261, and Kluyveromyces lactis MG971263 from the own collection of the Department of Fermentation Technology and Microbiology of the University of Agriculture in Kraków were used in the study. To make wort the malts Pale Ale Malt (Weyermann, Germany), Munich Malt (Weyermann, Germany) and Crystal (Fawcett, Great Britain), as well as the hop pellets Marynka were used. The red grape variety Merechal Foch from the Goja vineyard in Burów was used in the study.

Preparation of wort and grape must

Wort was prepared by heating 20 L of water to the temperature of 67 °C and subsequently adding 5 kg of the Pale Ale Malt (Weyermann, Germany), 0.7 kg of the Munich Malt (Weyermann, Germany), and 0.3 kg of Crystal (Fawcett, Great Britain). Mash was kept at the temperature of 65 °C for 60 min. The temperature was then raised to 75 °C and the mash continued to be kept at such temperature for 1 min. An iodine test was performed to determine if all starch had been saccharified. To complete the mashing process, the wort was heated to the temperature of 78 °C and kept at it for 10 min. The mash was then transferred to a filter tank and left to develop a layer of spent grain. Subsequently, the mash was filtered with liquor of 68 °C, yielding 40.5 L of wort. Then, the wort was boiled for an hour. 79.77 g of the Marynka hop pellets were added in the beginning of boiling, to obtain an appropriate degree of hopping (approximately 91 IBU—International Bitterness Unit). After boiling, the wort was left to cool down (extract 16.3°P). Grape must was obtained by pressing grapes and it was subsequently pasteurized (100 °C, 15 min).

Inoculation and fermentation

Pure yeast cultures were passaged in triplicate. In the first stage, the strains were grown on the Sabouraud agar (Biocorp, Poland) slants for 24 h. Then, the strains were transferred to 10 mL of Sabouraud Broth (Biocorp, Poland). After another 24 h, dynamic propagation of the strains was conducted in 200 mL of Sabouraud Broth (Biocorp, Poland) on a water bath shaker (120 rpm, 20 °C) for 48 h. After the growth process, the dry yeast mass was determined on a moisture analyzer and an appropriate amount of yeast slurry was centrifuged (10 min, 4989×g/min). Sediment obtained from centrifugation of the yeast slurry was washed with sterile water, centrifuged again under the same conditions, and introduced to wort and wort with an addition of grape must.

The basic raw material for fermentation was wort (extract 16.3°P, 91 IBU) and wort with an addition of grape must. The samples of 0.3 L were fermented in 0.5 L glass flasks. The wort and appropriate volumes of grape must were introduced into them (according to the variants below). The yeast slurry was introduced in an amount of 0.5 g d.w./L. The S. cerevisiae Safale US-05 yeast was used as a control. After carefully closing the flasks and attaching fermentation tubes filled with glycerin, the system was additionally sealed with parafilm. The fermentation process was conducted for 13 days at the temperature of 20 °C.

The fermentation was conducted using the yeast strains Saccharomyces cerevisiae Safale US-05, Dekkera bruxellensis 3429, Wickerhamomyces anomalus MG971261, and Kluyveromyces lactis MG971263 in the following variants (each sample in triplicate): wort; wort + 20% addition of grape must; wort + 40% addition of grape must.

Methods

Determination of fermentation dynamics

The fermentation rate was determined based on a weight loss of samples weighted every 24 h with 0.01 g accuracy. Results from three independent repetitions were presented as a percentage loss of the fermentation media mass.

Determination of real extract and alcohol content

Alcohol concentration in final beer was determined using the pycnometric method. For this purpose, the sample after fermentation was distilled. The obtained distillate was filled up to 100 g with distilled water, its density was determined, and the concentration of ethanol was read from the adequate tables (Analytica EBC Methods 9.2.1, Analytica EBC Methods 9.4), (Analytica EBC, European Brewery Convention, 1998).

Determination of titratable acidity

The potentiometric method was applied to determine titratable acidity, titrating a sample with 0.1 M NaOH solution to obtain pH = 8.

Determination of FAN content

Free amino nitrogen (FAN) was measured using ninhydrin-based methods with the use of the absorbance measurement at 570 nm (Beckman DU-650 UV–Vis) according to the method: 8.10 Free Amino Nitrogen in wort by Spectrophotometry (IM) (Analytica EBC, European Brewery Convention, 1998).

Determination of color

The color of filtered samples was determined spectrophotometrically (Beckman DU-650 UV–Vis) at a wavelength of 430 nm (according to Analytica EBC Methods 8.5 and Analytica EBC Methods 9.6).

Determination of sugars’ content (HPLC)

Analyses were performed using a Shimadzu (Japan) NEXERA XR with an RF-20A refractometric detector. The separation was performed on an Asahipak NH2P-50 250 × 4.6 mm Shodex column (Showa Denko Europe, Germany), thermostated at 30 °C. The mobile phase was an aqueous solution of acetonitrile (70%), while the isocratic elution profile (0.8 mL/min) lasted for 20 min. For quantitative determination, standard curves were prepared for the respective sugars: fructose, glucose, sucrose, and maltose.

Statistical analysis

The results have been presented as an arithmetic mean of three repetitions, standard deviation included. Moreover, a repeated-measures ANOVA and a Tukey’s (HSD) multiple range test at the significance level of α = 0.05 have been performed.

Results and discussion

Characteristics of wort and wort with an addition of grape must

The right amount of free amino acids in wort is needed to build yeast cells and has a positive effect on the fermentation process and, consequently, on the final character of produced beverages. It is assumed that yeast consumes 10–14 mg of nitrogen per 100 ml of wort. The correlation between amino acids, peptides, and polyphenols also affects beer stability and its sensory properties. Free amino nitrogen (FAN) is used for yeast metabolism, including the synthesis of new amino acids. FAN deficiency causes disturbances in the fermentation process [8]. The content of free amino nitrogen in the tested wort was 86.2 mg/L (Table 1). The results obtained for the wort with the addition of grape must did not differ significantly from the sample without the addition of must. It is assumed in the literature that the average FAN value in wort equals to 100–140 mg/L [8]. The obtained result may have been caused by relatively low-quality malt.

The visual quality of beer is highly dependent on color, clarity, and foam. Color is mainly a product of the Maillard reaction, but may also be the result of the oxidation of polyphenols derived from malt or hops. Barley malt has the greatest influence on color. Yeast can adsorb various color compounds on the cell wall [9]. Table 1 shows quite uniform color measurement results. The color measurement of the tested wort was 20.1 EBC. The color of the samples with the addition of grape must was similar to the wort, ranging from 20.3 to 21.8 EBC (Table 1).

The wort was characterized by a low acidity of only 1.16 mL of 1 M NaOH/100 mL of wort, which could have been caused by the parameters of the malt used (Table 1). The addition of grape must to the wort increased the titratable acidity of the samples (Table 1).

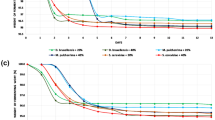

Fermentation dynamics

Figure 1 shows different courses of the fermentation process for the wort without the addition of grape must, fermented with monocultures of the tested yeasts. The yeast D. bruxellensis 3429 began fermentation on the first day of the process. There was a sharp decrease in the mass of the samples which slowed down on the third day of fermentation. The obtained results differ from the data presented in the work of Nardi et al. [11]. They proved that B. bruxellensis ferments slower than S. cerevisiae, which cannot be observed in graph 1 shown. For the wort fermented with yeasts S. cerevisiae Safale US-05 and W. anomalus MG971261, turbulent fermentation occurred after the first and second day, respectively, and lasted about 3 days. The wort inoculated with the yeast strain K. lactis MG971263 showed a different nature of the process. The tested yeast performed the fermentation process slowly. No rapid mass loss was observed, as in the case of the other samples. Most sugars had been fermented by the tenth day. The greatest mass loss among all the samples was found for the wort inoculated with the yeast W. anomalus MG971261, while the smallest for K. lactis MG971263 (Fig. 1).

Figure 2 shows different courses of the fermentation process for the wort with the addition of grape must. The yeast D. bruxellensis 3429 showed the fastest adaptation to the environment. Already on the first day after inoculation, significant mass loss indicating fermentation was noted. W. anomalus MG971261 and S. cerevisiae Safale US-05 started fermentation on the first day of the process, mass loss in the samples with 20% grape must addition was slightly lower than in the samples with 40% grape must addition (Fig. 2). According to studies by Blomqvist et al. [12], the strain D. bruxellensis, compared to S. cerevisiae, is characterized by a slower rate of growth and consumption of sugars, as well as greater or equal mass loss. The aforementioned authors also noted in their research that in the case of using glucose as the carbon source, the growth of yeast and alcohol production were faster than when using maltose. The addition of grape must introduce naturally occurring simple sugars to the samples. The increased amount of these compounds could have contributed to a greater loss of sample mass during fermentation process for D. bruxellensis 3429 (Figs. 1, 2). A quite different type of fermentation was observed for K. lactis MG971263. These yeasts fermented slowly, and the mass loss of the samples took place until the seventh day of the process. The greatest mass loss was observed for the samples with 40% addition of grape must. The yeasts D. bruxellensis 3429 and W. anomalus MG971261, compared to S. cerevisiae Safale US-05, are equally able to use the ingredients contained in the wort. The samples with the addition of grape must showed similar mass loss and course of the fermentation process, which may mean that these yeasts are able to adapt to the fermentation conditions similarly to S. cerevisiae Safale US-05 and can be used to produce the hybrid type of alcoholic beverages.

Alcohol and real extract content

Yeast uses fermentable ingredients contained in wort, and, as a result of biochemical reactions, they produce ethanol, carbon dioxide, and other metabolites. Ethyl alcohol, in addition to providing organoleptic properties, also contributes to the proper viscosity, stability, and foaming of beers. In addition to ethanol, also higher alcohols are produced as a result of the microorganisms’ activity, which can have a positive and negative effect on the final product. A large amount of these compounds results in a very bitter taste of the drink, while a moderate amount is desirable as it gives beer fullness of flavor [13]. Blomqvist [14] and Gobbi et al. [15] proved that samples inoculated with D. bruxellensis showed a similar or higher amount of ethanol produced compared to S. cerevisiae. Our study found a comparable amount of alcohol in beers produced by the yeasts D. bruxellensis 3429 and S. cerevisiae Safale US-05 (Table 2). Saccharomyces and K. lactis belong to the family Saccharomycetaceae. Both yeasts belong to the facultative aerobic group that displays the ability to metabolize glucose by oxidative and oxidoreductive pathways. The difference lies in the relative importance of these routes in aerobic conditions, S. cerevisiae is an aerobic fermentative yeast, and K. lactis is an aerobic respiratory yeast. For S. cerevisiae, the respiration process accounts for only 10% of oxygen metabolism, while for K. lactis, respiration constitutes a much higher percentage in oxygen metabolism. Conducted studies showed the ability of the latter yeast to produce high levels of ethanol under anaerobic conditions [16]. Also, in our study, a higher amount of alcohol was found in beers fermented by K. lactis MG971263 (Table 2).

Beer extract contains 75–80% carbohydrates, mainly dextrins, 6–9% protein, 4–5% glycerol, β-glucans, minerals, tannins, organic acids, and other components that have a great impact on the quality of final product, despite their smaller quantities [17,18,19]. The quality of wort largely depends on malt extract. The standard residual extract content in beers ranges from less than 1%, in heavily attenuated styles such as lambic, to almost 10% in sweet Barley wine. A high content of residual sugars adds fullness and often a sweet taste to beverages, and a low content gives the impression of a lighter beer in the mouth [20]. The extract of the tested samples ranged from 3.76 to 5.39 ºP (Table 2). Due to the presence of ß-D-glucosidase, D. bruxellensis has the ability to metabolize complex sugars [21]. However, the results obtained for D. bruxellensis 3429 do not give extract values low enough for proving high enzymatic activity and increased assimilation of carbohydrates (Table 2). Among the tested variants, the highest extract was found in beers containing 40% of the addition of grape must. The introduction of grape must into the wort resulted in an increase in the extract in these samples. The least significant differences of real extract content were observed in beers attenuated with S. cerevisiae Safale US-05 (Table 2). Compared to beers attenuated using S. cerevisiae Safale US-05, the ones obtained with K. lactis MG971263, were characterized by lower extract, what was connected with higher alcohol concentration (Table 2).

Titratable acidity

Beer contains various types of organic acids, such as malic, citric, lactic, fumaric, and many others, and their amount varies depending on the type of beer. They come from raw materials, wort boiling, and yeast metabolism. Such compounds are responsible for the quality and stability of final product and give beer sour, but also bitter or salty taste. The formation of acids during the fermentation process contributes to the decrease in pH [22]. B. bruxellensis is able to produce acetic acid as a by-product of metabolism, and the presence of glucose enhances this process. When glucose is low, yeast assimilates ethanol, transforming it into acetic acid, leading to an increase in its level in beer [23]. In our study, the samples with the addition of 40% grape must inoculated with the yeast D. bruxellensis 3429 were characterized by the highest acidity (Table 2). Osburn et al. [24] proved in their research that W. anomalus can be a good alternative to yeast used in the production of sour beers. This is due to the production of larger amounts of lactic acid. Titratable acidity of beers without the addition of grape must made with the yeast W. anomalus MG971261 was not high (Table 2). The highest acidity was found in samples with 40% addition of grape must. This was probably due to acids naturally occurring in grapes.

Free amino nitrogen (FAN)

Beer wort, in addition to fermentable and non-fermentable sugars, also contains nitrogen compounds which constitute about 5% of the extract. They contain polypeptides and amino acids necessary for the proper course of the fermentation process and cell building. Nitrogen in beer comes mainly from malt. The use of unmalted raw materials to produce beer causes the amount of this element to be insufficient and there is a need for supplementation using protease which increases the amount of free amino acids. After the fermentation has taken place, the nitrogen level should be kept as low as possible. Its low content has a positive effect on slowing down the aging of beer and the colloidal stability and sensory properties of the drink. The final content of nitrogen compounds is influenced by raw materials used to produce wort [25].

All beers were characterized by relatively low FAN values. It should be noted that the initial amount of FAN in the wort and worts with must was also small (Tables 1, 2). Both non-Saccharomyces species and S. cerevisiae Safale US-05 assimilated nitrogen compounds well in the samples. According to Tiukova [26], D. bruxellensis is able to assimilate alternative sources of nitrogen, thanks to the ability to use nitrates, while other resources of this element are depleted. According to Colomer et al. [27], the yeast D. bruxellensis 3429 uses a wide range of compounds as a source of nitrogen. In addition, these strains show the ability to assimilate nitrates, which to a large extent pass into the hop wort.

Color

Color, aroma, bitterness, taste, palatability, clarity, and foaming are the main features that determine the sensory quality of beer. Color is one of the first properties that the consumer perceives. The shade of beer depends on the raw materials used and the processes grain has undergone (drying, roasting). Another factor influencing the degree of color saturation is the oxidation of phenolic components [29]. The beers obtained with S. cerevisiae Safale US-05 showed the lightest color (13.3–14.5 EBC). No significant differences were found for the beers inoculated with yeast not belonging to the genus Saccharomyces (Table 2). The relatively dark color of beers could have also been caused by the FAN content, and more specifically low-molecular-weight nitrogen compounds.

Sugars content

Among sugars in typical wort, maltose is present in the highest amount [10]. Its level ranges from 33 to 54 g/L [10]. A significant amount of maltose and a small content of other sugars were found in the tested wort (Table 3). This is appropriate for typical beer wort [10]. The content of fructose in wort [10] ranges from 1.0 to 1.5 g/L. No fructose was found in the analyzed wort, while the presence of this sugar was noted in variants with the addition of grape must (Table 3). Glucose was present in the wort at the level of 7.50 g/L (Table 3). The obtained value is similar to the content of this sugar in wort given in the literature (8–10 g/L) [10].

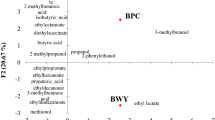

A very important stage in the production of beer is the fermentation of sugars contained in wort to alcohol and carbon dioxide. For this to happen, insoluble compounds must be transformed into soluble and, above all, into fermentable sugars. This is the purpose of wort production and, at the same time, the basis of the fermentation process. Beer wort contains sugars that can be divided into fermentable and non-fermentable. The former include fructose, sucrose, maltose, maltotriose, and the latter include dextrins [28]. About 98% sugars are fermented, while the rest is intended for respiration. A small proportion of maltose is converted into storage carbohydrates, such as glycogen. Table 4 shows a large variation in the amounts of sugars. No sucrose was found in the analyzed beers. The greatest amount of glycerol was found in the beers obtained with D. bruxellensis 3429 (7.45 g/L) and K. lactis MG971263 (8.34 g/L), with 40% grape must added. The lowest amount of glycerol was found in variants without the addition of grape must, which proves that the addition of must increases the amount of glycerol in beer. Literature data indicate a higher content of glycerol in beers fermented with non-Saccharomyces yeast, compared to traditional brewer’s yeast [30]. Galaffasi et al. [31] state that B. bruxellensis produces glycerol and accumulates it inside cells to prevent increased environmental osmolarity. In the beers obtained with S. cerevisiae Safale US-05, no glucose was found, which proves the complete utilization of this sugar by the tested yeast (Table 4). The results obtained from the analysis of the obtained samples are within the range given by the literature data for glucose (0–8 g/L) in beers after fermentation [1]. The highest amount of fructose was found in the beer obtained with W. anomalus MG971261. On the other hand, the lowest amount of fructose was found in the samples fermented with S. cerevisiae Safale US-05 (Table 4). All analyzed variants were within the range of fructose content in beers (0–5.5 g/L) [1]. The highest content of maltose was found in beers with 40% addition of grape must. In such cases, simple sugars were probably used first during the fermentation process (Table 4). The content of maltose in all tested beers was within the range reported in the literature, i.e., 0–2 g/L [1].

Comparing the course of the dynamics of fermentation with the use of sugars by the tested yeasts, it was found that all the tested yeasts carried out the fermentation satisfactorily. The non-Saccharomyces showed a similar ability to attenuate and utilize the ingredients contained in the wort as S. cerevisiae. Therefore, both S. cerevisiae Safale US-05 and the non-Saccharomyces strains are suitable for the fermentation of beer. Despite the longer fermentation time by K. lactis MG971263 strain and lower mass loss compared to the other trials, this yeast used most of the available sugars in the fermenting media (Figs. 1, 2, Table 4).

Conclusion

The obtained results have proven that the yeasts D. bruxellensis 3429 and W. anomalus MG971261 can utilize the ingredients contained in the wort as well as the yeast S. cerevisiae Safale US-05. The yeast K. lactis MG971263 produced a greater amount of alcohol in beers compared to other yeast strains. There were no significant differences in the color of the obtained beers and in the degree of FAN utilization during the fermentation process. The obtained results have proven that the unconventional yeasts used are capable of producing beers without and with the addition of grape must with parameters similar to beers obtained using S. cerevisiae Safale US-05.

Data availability

The authors confirm that the data supporting the findings of this study are available within the article.

References

Bamforth CW (2005) Beer, carbohydrates and diet. J Inst Brew 111:259–264. https://doi.org/10.1002/j.2050-0416.2005.tb00681.x

Bamforth CW (2002) Nutritional aspects of beer—a review. Nutr Res 22:227–237. https://doi.org/10.1016/S0271-5317(01)00360-8

Patrașcu L, Banu I, Bejan M, Aprodu I (2018) Quality parameters of fruit beers available on Romanian market. Sci Study Res 19:323–335

Escalante WDE (2019) Perspectives and uses of non-Saccharomyces yeasts in fermented beverages. Front New Trends Sci Fermented Food Beverages. https://doi.org/10.5772/intechopen.81868

Callejo MJ, González C, Morata A (2017) Use of non-Saccharomyces yeasts in bottle fermentation of aged beers. In: Kanauchi M (ed) Brewing Technology. Intech, London, pp 101–119

Bagheri B, Zambelli P, Vigentini I et al (2018) Investigating the effect of selected non-Saccharomyces species on wine ecosystem function and major volatiles. Front Bioeng Biotechnol 13:169. https://doi.org/10.3389/fbioe.2018.00169

De Francesco G, Turchetti B, Sileoni V et al (2015) Screening of new strains of Saccharomycodes ludwigii and Zygosaccharomyces rouxii to produce low-alcohol beer. J Inst Brew 121:113–121. https://doi.org/10.1002/jib.185

Hill AE, Stewart GG (2019) Free amino nitrogen in brewing. Fermentation 5:22. https://doi.org/10.3390/fermentation5010022

Shellhammer TH (2009) Beer color. In: Bamforth CW (ed) Beer: A quality perspective. Academic Press, San Diego, pp 213–227

Hough JS, Hough JS (1991) The biotechnology of malting and brewing. Cambridge University Press, Cambridge

Nardi T, Remize F, Alexandre H (2010) Adaptation of yeasts Saccharomyces cerevisiae and Brettanomyces bruxellensis to winemaking conditions: a comparative study of stress genes expression. Appl Microbiol Biotechnol 88:925–937. https://doi.org/10.1007/s00253-010-2786-x

Blomqvist J, Eberhard T, Schnürer J, Passoth V (2010) Fermentation characteristics of Dekkera bruxellensis strains. Appl Microbiol Biotechnol 87:1487–1497. https://doi.org/10.1007/s00253-010-2619-y

Tang K, Li Q (2017) Biochemistry of wine and beer fermentation. In: Pandey A, Sanroman MA, Du G, Soccol CR, Dussap CG (eds) Current Developments in Biotechnology and Bioengineering. Elsevier, pp 281–304

Blomqvist J (2011) Dekkera bruxellensis-a competitive yeast for ethanol production from conventional and non-conventional substrates. Swedish University of Agricultural Sciences

Gobbi M, De Vero L, Solieri L et al (2014) Fermentative aptitude of non-Saccharomyces wine yeast for reduction in the ethanol content in wine. Eur Food Res Technol 239:41–48. https://doi.org/10.1007/s00217-014-2187-y

Siso MIG, Ramil E, Cerdán ME, Freire-Picos MA (1996) Respirofermentative metabolism in Kluyveromyces lactis: ethanol production and the Crabtree effect. Enzyme Microb Technol 18:585–591. https://doi.org/10.1016/0141-0229(95)00151-4

Esslinger HM (2009) Handbook of brewing: processes, technology, markets. Wiley-VCH, Weinheim

Olšovská J, Šterba K, Vrzal T (2019) Nutritional composition and energy value of different types of beer and cider. Kvas Prum 65:32–37. https://doi.org/10.18832/kp2019.65.32

Salamon A (2016) Ocena wartości energetycznej piwa i napojów piwnych. Zesz Probl Postępów Nauk Rol 585:141–148

Garrett O (2012) The Oxford companion to beer. Oxford University Press, New York, New York

Steensels J, Daenen L, Malcorps P et al (2015) Brettanomyces yeasts—from spoilage organisms to valuable contributors to industrial fermentations. Int J Food Microbiol 206:24–38. https://doi.org/10.1016/j.ijfoodmicro.2015.04.005

Liu F (2015) Changes in organic acids during beer fermentation. J Am Soc Brew Chem 73:275–279. https://doi.org/10.1094/ASBCJ-2015-0509-01

Moktaduzzaman M, Galafassi S, Capusoni C et al (2015) Galactose utilization sheds new light on sugar metabolism in the sequenced strain Dekkera bruxellensis CBS 2499. FEMS Yeast Res 15:1–9. https://doi.org/10.1093/femsyr/fou009

Osburn K, Amaral J, Metcalf SR et al (2018) Primary souring: a novel bacteria-free method for sour beer production. Food Microbiol 70:76–84. https://doi.org/10.1016/j.fm.2017.09.007

Stewart GG (2016) Saccharomyces species in the production of beer. Beverages 2:34. https://doi.org/10.3390/beverages2040034

Tiukova I (2014) Dekkera bruxellensis, a non-conventional ethanol production yeast. Doctoral Thesis, Uppsala

Serra Colomer M, Funch B, Forster J (2019) The raise of Brettanomyces yeast species for beer production. Curr Opin Biotechnol 56:30–35. https://doi.org/10.1016/j.copbio.2018.07.009

Ferreira IM, Guido LF (2018) Impact of wort amino acids on beer flavour: A review. Fermentation 4:23. https://doi.org/10.3390/fermentation4020023

Koren D, Vecseri BH, Kun-Farkas G et al (2020) How to objectively determine the color of beer? J Food Sci Technol 57:1183–1189. https://doi.org/10.1007/s13197-020-04237-4

Contreras A, Hidalgo C, Henschke PA et al (2014) Evaluation of non-Saccharomyces yeasts for the reduction of alcohol content in wine. Appl Environ Microbiol 80:1670–1678. https://doi.org/10.1128/AEM.03780-13

Galafassi S, Toscano M, Vigentini I et al (2013) Osmotic stress response in the wine yeast Dekkera bruxellensis. Food Microbiol 36:316–319. https://doi.org/10.1016/j.fm.2013.06.011

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

MC-S: conceptualization, methodology, and validation; SS: software; MC-S and NC: formal analysis and investigation; MC-S: original draft preparation; MC-S, SS, and PS: review and editing; MC-S and SS: visualization. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Compliance with Ethics requirements

All authors were compliant and followed the ethical guidelines, according to the requirements of European Food Research and Technology.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Cioch-Skoneczny, M., Cichoń, N., Satora, P. et al. Physicochemical characteristics of beer with grape must addition produced using non-Saccharomyces yeasts. Eur Food Res Technol 249, 903–912 (2023). https://doi.org/10.1007/s00217-022-04182-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-022-04182-w