Abstract

The compounds responsible for smoky and mouldy–musty off-flavours in fermented cocoa have recently been elucidated; however, their behaviour during further processing into chocolate was still unclear. The compounds 2-methoxyphenol, 3-methylphenol, 4-methylphenol, 3-ethylphenol, 4-ethylphenol, and 3-propylphenol known to contribute to smoky off-flavours showed a tendency towards a minor increase during roasting and processing into cocoa liquor. This increase amounted to 1.4-fold at the most, however, was clearly compensated by losses of 30–63% during further processing into chocolate mass and conching. Among the off-flavour compounds identified in mouldy–musty smelling cocoa, faecal, mothball-like 3-methyl-1H-indole showed a clear decrease during roasting and processing into cocoa liquor, at least at rather high roasting temperatures, and a further decrease during processing into chocolate mass and conching. In contrast, faecal, mothball-like 1H-indole substantially increased during roasting and processing into cocoa liquor, namely from concentrations below its odour threshold value to concentrations up to 8 times beyond its odour threshold value. During processing into chocolate mass and conching, 1H-indole remained virtually unchanged. The data suggested that the monitoring of off-flavour compounds at the incoming goods inspection in the chocolate industry should not be limited to the fermented beans as such but additionally include the analysis of a bean sample after test roasting to correctly assess the off-flavour potential of 3-methyl-1H-indole and 1H-indole.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

To make chocolate, the fermented seeds of the cocoa tree (Theobroma cacao L.) are roasted and then ground into cocoa liquor. After addition of further ingredients such as sugar, cocoa butter, and milk powder, the mixture is ground to yield chocolate mass. Further homogenisation and refining is achieved by conching, a process that lasts between hours and days, before the mass is finally moulded into chocolate [1, 2].

Fermented cocoa is occasionally tainted with off-flavours. Such batches must be sorted out during incoming goods inspection in the chocolate industry to avoid quality issues with the final product. In two recent studies, we identified the crucial odorants responsible for the smoky off-flavour and the crucial odorants responsible for the mouldy–musty off-flavour in fermented cocoa. We showed that the smoky off-note is caused by 2-methoxyphenol, 3-methylphenol, 4-methylphenol, 3-ethylphenol, 4-ethylphenol, and 3-propylphenol [3], whereas (−)-geosmin, 3-methyl-1H-indole, 1H-indole, and 4-methoxy-2,5-dimethylfuran-3(2H)-one (MDMF) are potential off-flavour compounds in mouldy–musty smelling cocoa samples [4]. Predominantly based on the odour threshold values in deodorized cocoa butter, maximum tolerable concentrations in fermented cocoa were suggested. These limits amounted to 1.1 µg/kg for 3-methyl-1H-indole, 1.6 µg/kg for (−)-geosmin, 2 µg/kg for 3-ethylphenol and 3-propylphenol, 20 µg/kg for 3-methylphenol, 4-methylphenol, and 4-ethylphenol, and 70 µg/kg for 2-methoxyphenol [3, 4]. The decision on acceptance or rejection can thus be made on a more objective basis than with sensory testing only. However, it was so far largely unclear, how further processing influences the concentrations of the off-flavour compounds. Given the elevated temperatures, a substantial impact could be expected from roasting and conching. Cocoa bean roasting is typically done at 120–140 °C for 20–30 min [2, 5, 6], whereas during conching, temperatures of ~ 50–80 °C are applied for up to 3 days [1, 2, 7].

Several studies have addressed the changes in odorant concentrations during cocoa processing [6, 8,9,10,11,12,13,14,15]. It was shown that the high temperatures during roasting converted thermolabile precursors formed during fermentation [16, 17] into important odour-active compounds such as Strecker aldehydes, pyrazines, and furanones [8,9,10, 18]. At the same time, the concentrations of some undesired odorants such as acetic acid were reduced [6, 11]. Conching not only improved the rheological properties of the chocolate but also affected chocolate flavour [14, 19]. Specifically, the concentrations of some undesired volatile acids decreased [14], whereas for example caramel-like smelling 4-hydroxy-2,5-dimethylfuran-3(2H)-one (HDMF; Furaneol®) increased during conching [14, 15]. So far, no study on the effect of cocoa processing focused on off-flavour compounds. Nonetheless, Frauendorfer et al. reported higher concentrations of 2-methoxyphenol and 4-methylphenol after roasting of Criollo and Forastero cocoa beans [9, 10]. Moreover, Counet et al. who quantitated 44 volatiles in dark chocolate before and after conching found that 2-methoxyphenol and 1H-indole increased [14]. In contrast, Beckett reported a reduction in the amount of phenols during conching; however, no data on individual compounds was provided [20].

To obtain a better view on the behaviour of the compounds contributing to smoky and mouldy–musty off-flavours during chocolate manufacturing, the aim of the current study was to determine their concentration changes induced by 1) cocoa roasting and processing into cocoa liquor and by 2) further processing into chocolate mass and conching. If substantial differences were to occur, the previously suggested maximum tolerable concentrations in fermented cocoa might need to be adjusted.

Materials and methods

Cocoa

The samples of fermented cocoa beans were obtained from German chocolate manufacturers. The samples SOF1 and SOF2 showed smoky off-flavours, the samples MOF1 and MOF2 were tainted with mouldy–musty off-flavours, and the reference sample REF exhibited a characteristic aroma without off-notes. All samples were stored at + 4 °C.

Chemicals

The reference odorants 2-methoxyphenol, 4-methylphenol, 3-methylphenol, 4-ethylphenol, 3-ethylphenol, 3-propylphenol, MDMF, 3-methyl-1H-indole, 1H-indole, and geosmin as well as 4-(2H3)methyl(2H4)phenol were purchased from Merck (Darmstadt, Germany). The following isotopically substituted odorants were synthesised as detailed in the literature: 2-[(2H3)methyloxy]phenol [21], 4-(1,1-2H2)ethylphenol [3], 4-(1,1-2H2)propylphenol [3], 2,5-dimethyl-4-[(2H3)methyloxy]furan-3(2H)-one [22], 3-(2H3)methyl(2,4,5,6,7-2H5)-1H-indole [23], and ((4S,4aS,8aR)-4,8a-dimethyl(3,3,4-2H3)octahydronaphthalen-4a(2H)-ol) [24]. (2,3,4,5,6,7-2H6)-1H-Indole was synthesised from the isotopically unmodified compound 1H-indole according to the approach published for the synthesis of 3-(2H3)methyl(2,4,5,6,7-2H5)-1H-indole [23]. Dichloromethane was freshly distilled through a column (120 cm × 5 cm) packed with Raschig rings before use. Ethanol (99.9%) was purchased from Honeywell (Seelze, Germany).

Roasting and processing into cocoa liquor

The fermented cocoa beans were roasted according to the protocol “Elements of harmonized international standards for cocoa quality and flavour assessment” of the Cocoa of Excellence (CoEx) Programme [25]. In brief, the fermented cocoa beans were placed in a single layer on a stainless steel mesh tray and put in a pre-heated convection oven FP53 (Binder, Tuttlingen, Germany) for 25 min. The roasting temperatures were 110, 125, and 140 °C. After roasting, the cocoa beans were allowed to cool down to room temperature before the shells were removed manually. The cocoa was processed into cocoa liquor using a preheated (45 °C) RM 200 mortar grinder (Retsch, Haan, Germany) equipped with a porcelain pestle and a porcelain mortar. The cocoa liquors were stored at + 4 °C until analysis.

Processing into chocolate mass and conching

Solutions of the off-flavour compounds (0.2–9 mg in 200 µl ethanol) were premixed with molten cocoa liquor (500 g). In the pilot plant of a German chocolate manufacturer, the spiked cocoa liquors were included into the recipes used for making a dark chocolate mass (10 kg; > 50% cocoa liquor; further ingredients: cocoa butter, sugar) and a milk chocolate mass (10 kg; < 10% cocoa liquor; further ingredients: cocoa butter, milk powder, sugar) and conched at a temperature of 80 °C. After 12 h, the mass was moulded into chocolate.

Odorant quantitation

Samples of the cocoa liquors and chocolates were immersed in liquid nitrogen, crushed using a GM 200 laboratory mill (Retsch) and further ground into a fine powder using a 6875 Freezer Mill (Spex SamplePrep, Stanmore, UK). To portions (1−50 g) of the powder, dichloromethane (25−100 mL) was added and the mixture was spiked with the isotopically substituted odorants (0.04–8 µg) in dichloromethane (40–400 µL) as internal standards. After magnetic stirring at room temperature for ~ 15 h, the mixture was filtered through a folded paper filter. The filtrate was dried over anhydrous sodium sulphate. Non-volatiles were removed by SAFE at 40 °C [26]. The distillate was concentrated using a Vigreux column (50 × 1 cm) and a Bemelmans microdistillation device [27] to a final volume of 200 µL. Portions of the concentrates (1–2 µL) were analysed by GC–MS. Quantitation of 2-methoxyphenol, 3- and 4-methylphenol, 3- and 4-ethylphenol, 3-methyl-1H-indole, 1H-indole, and MDMF was accomplished using a heart-cut GC–GC–MS system. For the quantitation of 3-propylphenol and (−)-geosmin, a heart-cut GC–GC–HRMS system was employed. Odorant concentrations were finally calculated from the peak area counts of the analyte peak and the internal standard peak in the extracted ion chromatograms of characteristic quantifier ions, the amount of sample used, and the amount of standard added, by employing a calibration line equation obtained by linear regression after the analysis of analyte/standard mixtures in at least five different concentration ratios, covering a range of at least 1:5 to 5:1. Details on the GC–MS systems, the quantifier ions, and the calibrations are provided in the Supplementary Information file.

Results and discussion

Impact of roasting and processing into cocoa liquor on cocoa off-flavour compounds

Two samples of fermented cocoa beans with a smoky off-flavour, two samples of fermented cocoa beans with a mouldy–musty off-flavour, and a reference sample with a characteristic aroma and no off-flavour were roasted and then processed into cocoa liquor. Each of the five cocoa samples was roasted at three different temperatures, namely 110, 125, and 140 °C. Although roasting temperatures as low as 90 °C and as high as 170 °C have also been reported in the literature [1, 13, 28, 29], the range of 110–140 °C is the one most relevant in the chocolate industry [2, 6].

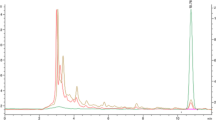

In the cocoa liquors obtained from the cocoa samples with a smoky off-flavour (SOF1, SOF2), the six phenols previously identified as causative for the off-note [3] were quantitated. In detail, the compounds and their odour qualities were 2-methoxyphenol (smoky, hammy), 3-methylphenol (smoky, phenolic), 4-methylphenol (horse stable-like, phenolic), 3-ethylphenol (smoky), 4-ethylphenol (smoky), and 3-propylphenol (smoky, phenolic). Quantitation was accomplished by GC–MS after solvent extraction and SAFE using stable isotopically substituted odorants as internal standards. The reference sample without off-flavour (REF) was analysed in parallel. The data obtained were compared to the concentrations before processing (Table 1). Moreover, the concentrations were divided by the odour threshold values of the compounds in deodorized cocoa butter to obtain odour activity values (OAVs) and thus to simultaneously assess the impact of processing and the odour relevance of the compounds (Fig. 1). The odour threshold values applied were 1.8 µg/kg for 2-methoxyphenol, 19 µg/kg for 3-methylphenol, 3.3 µg/kg for 4-methylphenol, 2.2 µg/kg for 3-ethylphenol, 23 µg/kg for 4-ethylphenol, and 2.0 µg/kg for 3-propylphenol [3].

Results indicated only minor changes of the compounds during roasting and processing into cocoa liquor. In particular, there was no general decrease of off-flavour compounds that could have been expected if—despite the rather high boiling points of the compounds of ~ 202−230 °C—evaporation during roasting had played a substantial role. In this case, an adjustment of the maximum tolerable concentrations in fermented cocoa during incoming goods inspection in the chocolate industry could have been considered. A clear decrease that reflected the roasting temperatures was only observed for a single compound in a single sample, namely 3-propylphenol in sample SOF2. The compound decreased during roasting and processing into cocoa liquor from 17.5 to 14.3 µg/kg at 110 °C, 6.93 µg/kg at 125 °C, and 5.56 µg/kg at 140 °C (Table 1) which corresponded to OAVs of 8.8 before roasting and 7.1, 3.5, and 2.8 after roasting and processing into cocoa liquor (Fig. 1). However, no such behaviour was observed for 3-propylphenol in sample SOF1. By contrast, some of the off-flavour compounds in the off-flavour samples rather showed a tendency towards a slight increase. This increase was clearly beyond the concentration effect associated with the loss of water during roasting. Given a typical water content of 4–8% in the unroasted cocoa and a final water content of ~ 2% in the roasted cocoa [1, 30, 31], such an increase would be clearly below the 1.1-fold. On the other hand, the increase was also never greater than 1.4-fold and, in particular, did not change the order of the off-flavour compounds in terms of OAVs: before and after roasting and processing into cocoa liquor, 2-methoxyphenol showed the highest OAVs among the six compounds in the two off-flavour samples followed by 4-methylphenol and 3-ethylphenol. In the reference sample without off-flavour, the levels of all off-flavour compounds were clearly lower, before roasting as well as after roasting and processing into cocoa liquor. 2-Methoxyphenol and 4-methylphenol were the only compounds exceeding their odour threshold levels before roasting. During roasting and processing into cocoa liquor, both did not show substantial changes; however, the concentrations of 3-ethylphenol and 4-ethylphenol increased up to 15-fold for 3-ethylphenol and up to 5.4-fold for 4-ethylphenol, resulting in concentrations slightly beyond their threshold values, whereas 3-methylphenol concentrations and 3-propylphenol concentrations stayed below the threshold value.

Different from our results, Frauendorfer and Schieberle reported a clear increase of 2-methoxyphenol and 4-methylphenol during roasting of cocoa beans without an off-flavour [9, 10], although conditions with 95 °C roasting temperature and 14 min roasting time were rather mild. For 2-methoxyphenol, they found an increase from 110 µg/kg (Criollo beans) and 61 µg/kg (Forastero beans) to 230 and 100 µg/kg, respectively, whereas in our reference sample, the concentration even slightly decreased from 71 to 57.7–67.5 µg/kg, depending on the roasting temperature. For 4-methylphenol, Frauendorfer and Schieberle observed an increase from 5.3 (Criollo) and 4.6 (Forastero) to 9.9 and 7.6 µg/kg, respectively. In our reference sample, the concentration before roasting was 19.1 µg/kg and after roasting and processing into cocoa liquor it ranged from 16.0 to 21.5 µg/kg.

In the cocoa liquors obtained from the cocoa samples with a mouldy–musty off-flavour (MOF1, MOF2), (−)-geosmin, 3-methyl-1H-indole, 1H-indole, and 4-methoxy-2,5-dimethylfuran-3(2H)-one (MDMF) were quantitated. This selection was based on our previous study [4]. Again, the reference sample without off-flavour (REF) was analysed in parallel. Results are depicted in Table 2 together with the concentrations before processing. Figure 2 shows the OAVs calculated from the concentrations and the odour threshold values of the compounds in deodorized cocoa butter. The odour threshold values used for these calculations were 1.6 µg/kg for (−)-geosmin, 1.1 µg/kg for 3-methyl-1H-indole, 51 µg/kg for 1H-indole, and 350 µg/kg for MDMF [4].

(−)-Geosmin, the compound with the most pronounced mouldy smell, was present in odour-active amounts only in sample MOF1. Its concentration in the samples roasted at 110 and 125 °C was almost twice the concentration in the unprocessed sample. This is hard to explain, given that the compound is a well-known product of microbiological metabolism but not known to be formed thermally [32,33,34]. Furthermore, (−)-geosmin has been found enriched in the cocoa seed shells [4]. The shells, however, had been removed during processing of the roasted cocoa samples to cocoa liquor. Thus, rather a lower concentration was to be expected in the roasted samples. This, however, was only the case for the sample roasted at 140 °C, in which not more than 2/3 of the initial (−)-geosmin was recovered.

Faecal, mothball-like smelling 3-methyl-1H-indole was the most odour-active compound in the unprocessed off-flavour sample MOF2 and the second most odour-active compound in the unprocessed off-flavour sample MOF1. In both off-flavour samples, its concentration clearly decreased during roasting and processing into cocoa liquor, at least when higher roasting temperatures were applied. After roasting at 125 and 140 °C and processing into cocoa liquor, its OAV in sample MOF1 had decreased from 1.8 to clearly below 1 and in sample MOF2, the decrease was from 60 to 1.5 and 2.2, respectively.

The most conclusive change during roasting and processing into cocoa liquor was observed for faecal, mothball-like smelling 1H-indole. In all three cocoa samples, the concentration in the unprocessed cocoa was below the odour threshold value of 51 µg/kg. In the processed samples, the amounts increased continuously with increasing roasting temperature leading to OAVs between 1.7 and 8.0 in the samples roasted at 140 °C. In the three 140 °C samples, 1H-indole was the most odour-active among the four off-flavour compounds. Moreover, in the reference sample 1H-indole was the only compound of the four that exceeded the odour threshold, namely in the samples roasted at 125 and 140 °C.

Caramel-like and musty smelling MDMF showed a heterogeneous behaviour during roasting. Whereas in sample MOF1 and in the reference sample its concentration increased with the roasting temperature, a decrease was observed in sample MOF2. However, in none of the samples any concentration ever exceeded the odour threshold value of the compound.

Impact of processing into chocolate mass and conching on cocoa off-flavour compounds

A cocoa liquor with a characteristic aroma and no off-flavour was spiked with the compounds previously identified as crucial for smoky and mouldy–musty off-flavours. The final concentrations resulting from the amounts naturally present in the cocoa liquor plus the spiked amounts were in the ranges previously determined in cocoa samples with the respective off-flavours [3, 4]. Portions of the spiked cocoa liquor were processed into a dark chocolate mass and into a milk chocolate mass, respectively. After conching at 80 °C for 12 h, the off-flavour compounds were quantitated and the concentrations obtained were compared to the concentrations in the cocoa liquor before processing.

The results (Table 3) revealed recoveries between 9 and 101%. For none of the compounds, a substantial difference between the dark chocolate mass and the milk chocolate mass was observed. The six phenolic compounds crucial for the smoky off-flavours showed recoveries of 37–70% in the dark chocolate mass and recoveries of 41–74% in the milk chocolate mass. The lowest recoveries were obtained for 2-methoxyphenol. Interestingly, Counet et al. [14] reported higher concentrations for 2-methoxyphenol after conching. In two different chocolate samples, the 2-methoxyphenol concentrations increased by 50 and 13%, respectively. However, these experiments had been performed at much lower concentration levels (66 and 75 µg/kg) than our experiments (926 and 897 µg/kg), which probably shifted the balance between losses and formation from precursors.

Among the four compounds potentially contributing to mouldy–musty off-flavours, (−)-geosmin and 3-methyl-1H-indole showed recoveries around 80%. The recoveries for 1H-indole were higher, namely 101% in the dark chocolate mass and 93% in the milk chocolate mass. Possibly, losses of 1H-indole during conching were in parts compensated by its formation from thermolabile precursors. The rather high recoveries of 1H-indole during conching were thus in line with its clear increase during roasting. MDMF behaved differently from all other compounds as its recovery with 9% and 11% was quite low.

Conclusions

Our data suggests that for the off-flavour compounds causing smoky off-flavours, namely 2-methoxyphenol, 3-methylphenol, 4-methylphenol, 3-ethylphenol, 4-ethylphenol, and 3-propylphenol, minor increases during roasting and processing into cocoa liquor are compensated by losses during processing into chocolate mass and conching. For these compounds, no adjustment of the previously suggested maximum tolerable concentrations on the level of the fermented cocoa is, therefore, necessary. The compounds potentially contributing to mouldy–musty off-flavours showed a less homogeneous behaviour. For (−)-geosmin, a clear statement is not possible, because only a single dataset was available to assess the changes during roasting and processing into cocoa liquor. Given the decomposition of 3-methyl-1H-indole during roasting and processing into cocoa liquor, its limit might be raised, at least when higher roasting temperatures are applied. By contrast, 1H-indole showed a clear increase during roasting and processing into cocoa liquor that was not compensated by processing into chocolate mass and conching. In the incoming goods inspection in the chocolate industry, monitoring of 1H-indole should therefore include roasting of the beans before analysis. MDMF needs not to be included in the monitoring. Its concentration in the fermented beans is typically below its relatively high odour threshold value and is further reduced during processing.

Abbreviations

- GC–MS:

-

Gas chromatography–mass spectrometry

- Geosmin:

-

(4S,4AS,8aR)-4,8a-Dimethyloctahydronaphthalen-4a(2H)-ol

- MDMF:

-

4-Methoxy-2,5-dimethylfuran-3(2H)-one

- OAV:

-

Odour activity value

- SAFE:

-

Solvent-assisted flavour evaporation

References

Afoakwa EO (2010) Chocolate science and technology, 1st edn. John Wiley & Sons, Chichester

Ziegleder G (2017) Flavour development in cocoa and chocolate. In: Beckett ST, Fowler MS, Ziegler GR (eds) Beckett’s industrial chocolate manufacture and use, 5th edn. John Wiley & Sons, Chichester

Füllemann D, Steinhaus M (2020) Characterization of odorants causing smoky off-flavors in cocoa. J Agric Food Chem 68:10833–10841

Porcelli C, Neiens SD, Steinhaus M (2021) Molecular background of a moldy-musty off-flavor in cocoa. J Agric Food Chem 69:4501–4508

Biehl B, Ziegleder G (2003) COCOA|Chemistry of processing. In: Caballero B (ed) Encyclopedia of food sciences and nutrition, 2nd edn. Academic Press, Oxford

Hashim L (2000) Flavor development of cocoa during roasting. In: Parliament et al (eds) Caffeinated beverages. American Chemical Society, Washington, DC

Bolenz S, Thiessenhusen T, Schäpe R (2003) Fast conching for milk chocolate. Eur Food Res Technol 218:62–67

Ziegleder G (1991) Composition of flavor extracts of raw and roasted cocoas. Z Lebensm Unters Forsch 192:521–525

Frauendorfer F, Schieberle P (2008) Changes in key aroma compounds of Criollo cocoa beans during roasting. J Agric Food Chem 56:10244–10251

Frauendorfer F, Schieberle P (2019) Key aroma compounds in fermented Forastero cocoa beans and changes induced by roasting. Eur Food Res Technol 245:1907–1915

Jinap S, Dimick PS (1991) Effect of roasting on acidic characteristics of cocoa beans. J Sci Food Agric 54:317–321

Owusu M, Petersen MA, Heimdal H (2012) Effect of fermentation method, roasting and conching conditions on the aroma volatiles of dark chocolate. J Food Process Preserv 36:446–456

Jinap S, Wan Rosli WI, Russly AR, Nordin LM (1998) Effect of roasting time and temperature on volatile component profile during nib roasting of cocoa beans (Theobroma cacao). J Sci Food Agric 77:441–448

Counet C, Callemien D, Ouwerx C, Collin S (2002) Use of gas chromatography−olfactometry to identify key odorant compounds in dark chocolate. Comparison of samples before and after conching. J Agric Food Chem 50:2385–2391

Schnermann P, Schieberle P (1997) Evaluation of key odorants in milk chocolate and cocoa mass by aroma extract dilution analyses. J Agric Food Chem 45:867–872

Voigt J, Heinrichs H, Voigt G, Biehl B (1994) Cocoa-specific aroma precursors are generated by proteolytic digestion of the vicilin-like globulin of cocoa seeds. Food Chem 50:177–184

Rohan TA (1964) The precursors of chocolate aroma: a comparative study of fermented and unfermented cocoa beans. J Food Sci 29:456–459

Granvogl M, Bugan S, Schieberle P (2006) Formation of amines and aldehydes from parent amino acids during thermal processing of cocoa and model systems: new insights into pathways of the strecker reaction. J Agric Food Chem 54:1730–1739

Afoakwa EO, Paterson A, Fowler M (2007) Factors influencing rheological and textural qualities in chocolate—a review. Trends Food Sci Technol 18:290–298

Beckett ST (2008) The science of chocolate, 2nd edn. The Royal Society of Chemistry, Cambridge

Cerny C, Grosch W (1993) Quantification of character-impact odour compounds of roasted beef. Z Lebensm Unters Forsch 196:417–422

Schieberle P, Hofmann T (1997) Evaluation of the character impact odorants in fresh strawberry juice by quantitative measurements and sensory studies on model mixtures. J Agric Food Chem 45:227–232

Steinhaus M, Schieberle P (2005) Role of the fermentation process in off-odorant formation in white pepper: on-site trial in Thailand. J Agric Food Chem 53:6056–6060

Porcelli C, Kreissl J, Steinhaus M (2020) Enantioselective synthesis of tri-deuterated (–)-geosmin to be used as internal standard in quantitation assays. J Label Compd Radiopharm 63:476–481

Elements of harmonized international standards for cocoa quality and flavour assessment (2017) International standards for the assessment of cocoa quality and flavour. Bioversity International, Rome. https://www.cocoaqualitystandards.org/initiative-background/documents-and-reports. Accessed 26 Jul 2021

Engel W, Bahr W, Schieberle P (1999) Solvent assisted flavour evaporation - a new and versatile technique for the careful and direct isolation of aroma compounds from complex food matrices. Eur Food Res Technol 209:237–241

Bemelmans JMH (1979) Review of isolation and concentration techniques. In: Land DG, Nursten HE (eds) Progress in flavour research. Applied Science Publishers, London

Ramli N, Hassan O, Said M, Samsudin W, Idris NA (2006) Influence of roasting conditions on volatile flavor of roasted Malaysian cocoa beans. J Food Process Preserv 30:280–298

Afoakwa EO, Paterson A, Fowler M, Ryan A (2008) Flavor formation and character in cocoa and chocolate: a critical review. Crit Rev Food Sci Nutr 48:840–857

Amoa-Awua WK (2014) Methods of cocoa fermentation and drying. In: Schwan RF, Fleet GH (eds) Cocoa and coffee fermentations, 1st edn. CRC Press, Boca Raton

Afoakwa EO (2014) Cocoa processing and chocolate technology. In: Schwan RF, Fleet GH (eds) Cocoa and coffee fermentations, 1st edn. CRC Press, Boca Raton

Gerber NN, Lechevalier HA (1965) Geosmin, an earthly-smelling substance isolated from actinomycetes. Appl Microbiol 13:935–938

Liato V, Aïder M (2017) Geosmin as a source of the earthy-musty smell in fruits, vegetables and water: origins, impact on foods and water, and review of the removing techniques. Chemosphere 181:9–18

Callejón RM, Ubeda C, Ríos-Reina R, Morales ML, Troncoso AM (2016) Recent developments in the analysis of musty odour compounds in water and wine: a review. J Chromatogr A 1428:72–85

Acknowledgements

The authors thank Monika Riedmaier for the excellent technical assistance.

Funding

Open Access funding enabled and organized by Projekt DEAL. This IGF Project of the FEI was supported via AiF within the programme for promoting the Industrial Collective Research (IGF) of the German Ministry of Economic Affairs and Energy (BMWi), based on a resolution of the German Parliament; project no. 19455 N.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Compliance with ethics requirements

This article does not contain any studies with human or animal subjects.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Füllemann, D., Neiens, S.D. & Steinhaus, M. Impact of processing on important cocoa off-flavour compounds. Eur Food Res Technol 248, 197–205 (2022). https://doi.org/10.1007/s00217-021-03873-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-021-03873-0