Abstract

Aiming at the mitigation of the toxicologically relevant styrene formed during wheat beer brewing, different malting parameters, such as steeping temperature, germination temperature, withering and kilning temperatures applied during kiln-drying, and aeration rate, were evaluated for their suitability to reduce the content of cinnamic acid, the precursor of styrene, in malts of barley and wheat, responsible for the input of the undesired precursor into the brewing process. According to the results of the present study, higher steeping temperatures, higher germination temperatures, lower aeration rates, and lower withering temperatures during malting are beneficial for the overall reduction of cinnamic acid in wort produced with barley and wheat malts. Thereby, the withering temperature showed the highest impact among the investigated parameters, able to reduce the soluble cinnamic acid content in wort by up to 72%, followed by the germination temperature in combination with the aeration rate and the steeping temperature with reduction capacities of 52 and 16%, respectively. Additionally, a kilning temperature of 200 °C led to the absence of enzyme activities in dark malts, which might also be the main reason for the low phenolic acid contents found in the corresponding wort, finally causing the low concentrations of styrene but also to a certain extent of desired vinyl aromatics in dark wheat beers.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Toxicologically relevant compounds in groceries are not always an issue of contamination, e.g., from environmental pollution, cultivation, or packaging, but they can also be present as natural occurring components or formed during food processing [1,2,3]. This is also the case for wheat beer, a special beer type originating from the southern part of Germany (Bavaria), which contains styrene in relevant amounts. The presence of styrene in wheat beer is known since the late 1970s [4, 5]; however, its toxicological relevance was not considered until 1996, when a tolerable daily intake (TDI) of 7.7 µg/kg body weight per day was published by the World Health Organization (WHO) [6]. This first toxicological assessment was then updated in 2002 by the International Agency for Research on Cancer (IARC), which classified styrene as possibly carcinogenic to humans (class 2B) [7], based on the results of studies on rats [8] and mice [9]. According to different studies [10,11,12], styrene concentrations can be expected within the range of 9.8–33 µg/L, not exceeding the established TDI by normal wheat beer consumption. Nevertheless, mitigation strategies should be applied also to wheat beer to increase consumer’s safety.

The difficulty of this objective is given by similar formation pathways of styrene and two key aroma compounds in wheat beer, namely 4-vinylphenol and 2-methoxy-4-vinylphenol, which are mainly responsible for the formation of the well-known and characteristic clove-like and slightly phenolic aroma of wheat beer [13]. These three compounds derive from the precursors cinnamic acid, p-coumaric acid, and ferulic acid, which belong to the same compound class of cinnamic acid derivatives, also known as phenolic acids. The major sources of phenolic acids in the brewing process are barley and wheat malts. By law, the content of wheat malt has to be at least 50%. In both barley and wheat, phenolic acids fulfill multiple tasks. Based on the phenylpropanoid metabolism, they are the major building blocks for the formation of flavonoids, stilbenoids, and lignin [14, 15]. Additionally, they are able to link the linear polysaccharide chains of arabinoxylan to a three-dimensional network [16,17,18], which build up the cell walls in grain of barley and wheat. This structure is seen as the main source of precursors of the desired and undesired vinyl aromatics in wheat beer [19,20,21].

Within the first steps (malting and mashing) of the brewing process, different enzymes lead to the degradation of the polysaccharide backbone of the arabinoxylan structure [22]. Simultaneously, the feruloyl esterase directly splits off the phenolic acids from arabinoxylan. As a consequence, three different phenolic acid forms are formed according to the size of the fragments, the insoluble ester-bound phenolic acids, the soluble ester-bound phenolic acids, and the free phenolic acids. However, only the soluble forms (the soluble ester-bound and free phenolic acids) can be transferred from malt into wort during mashing and are, therefore, later on accessible by yeasts. In the following fermentation step, the free phenolic acids are decarboxylated to the corresponding desired and undesired vinyl aromatics by yeasts. Their decarboxylation ability is related to an active POF1 gene. A study of Daly et al. [12] revealed that bottom-fermenting yeasts lack this ability without any exception, whereas top-fermenting yeasts have either no, a reduced, or a high Pof-activity. Typically, wheat beers are brewed with top-fermenting yeasts with high Pof-activities, leading to the formation of styrene in relevant amounts. Consequently, styrene does not play a significant role in beers brewed with a bottom-fermenting yeast, e.g., lager beers, or in wheat beers brewed with a top-fermenting yeast having no/strongly reduced Pof-activity [13].

Several studies on the reduction of styrene in wheat beer were examined by Langos and Granvogl [11], Langos et al. [23, 24], Schwarz and Methner [25], and Schwarz et al. [26,27,28,29], mainly focusing on the impact of brewing steps after malting, such as mashing, wort boiling, and fermentation. Thereby, found styrene mitigation strategies within these processing steps were mostly accompanied by a significant reduction of the desired vinyl aromatics and, therefore, with the risk to lose the characteristic wheat beer aroma. Thus, another mitigation approach of styrene aimed at the reduction of its precursor cinnamic acid by altering the malting parameters. In a first study performed by Langos et al. [24], “undermodified” malts (malting parameters: steeping degree, 42%; germination temperature, 12 °C; germination time, 5 days) showed a clear reduction of the undesired cinnamic acid (56% for barley, 30% for wheat) in comparison to “highly modified” malts (malting parameters: steeping degree, 48%; germination temperature, 18 °C; germination time, 7 days), proving that the malting process is a promising tool to lower the styrene content in wheat beer.

The aim of the present study was to get a better understanding of the impact of various malting parameters on the release of the different forms of phenolic acids and the enzymatic degradation of the arabinoxylan structure. Further, this knowledge should be a toolbox for brewers to establish beneficial malting conditions allowing a reduction of the styrene content in wheat beer. Therefore, barley and wheat malts were produced by either varying (1) the steeping temperature, (2) the germination temperature in combination with the aeration rate, or (3) the withering temperature and (4) the kilning temperature both applied during kiln-drying. Within these malts and congress wort produced thereof, the insoluble ester-bound, soluble ester-bound, and the free cinnamic, p-coumaric, and ferulic acid contents were determined, as well as the amount of water-extractable arabinoxylan and the feruloyl esterase activity.

Materials and methods

Malt samples and congress wort

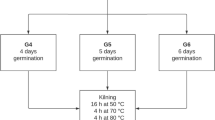

Malting and mashing experiments as well as the standard brewing analysis according to MEBAK® [30] and EBC [31] were performed by the Chair of Brewing Science and Beverage Technology (Technical University of Berlin, Berlin, Germany). The sample set included two industrially relevant barley varieties, namely, Solist (spring barley (sp), two-rowed (2r), Franconia, Germany) and Quench (sp, 2r, Denmark), both harvest year 2017, and one industrially relevant wheat variety, namely, Dacanto (winter wheat, Denmark), harvest year 2016. The standard malting conditions selected within this study were closely related to the parameters normally used by malthouses: a steeping degree of 45% was adjusted by steeping the grain in a physiological saline solution (0.9%) for 4 h at 16 °C, followed by an air rest for 20 h at a flow rate of 25 L/min and an air humidity of 80%. This cycle was repeated with an additional steeping for 3 h and an air rest for 21 h. Next, the grain was germinated for 5 days at 18 °C. The green malts were withered at a temperature of 50 °C for 16 h, followed by kilning at a temperature of 80 °C for 4 h to reach a water content < 5%. Subsequently, the kilned malts were deculmed. These standard malting conditions have been adapted to different experiments to study the impact of the malting parameters on the formation and release of the desired and undesired precursors of the vinyl aromatics during malt production. In experiment 1, the steeping temperature was varied between 10, 20, and 30 °C, covering a broad temperature range allowing the visualization of the impact of this malting parameter on the target analytes. For experiment 2, the response surface methodology (RSM) was employed to investigate the variation of the analytes of interest with respect to the temperature in combination with the aeration rate during germination. The composition of the two variables was designed by the central composite design approach, which is a 2k factorial design with 2k star points and central points. With α = ± 1 as the relative distance from the center of the design to a factorial point, the relative distance of a star point is α = 2k/4. The ranges of the variables were defined as follows: germination temperature, 10–26 °C; aeration rate, 15–35 L/min. For reference purposes, malts were balanced according to their malting degree. Therefore, the germination time was extended to 6 days for malts with a germination temperature of 10 and 12 °C. In total, 14 experimental settings consisting of 4 factorial, 4 star, and 6 central points were generated on the basis of the two variables of the experiment (Table 1). Within experiment 3, the withering temperature was varied between 30, 40, 50, and 60 °C and maintained for 16 h. For the production of pale malts, the kilning temperature was set to 80 °C for 4 h to reach a water content < 5%. Again, the kilned malts were directly deculmed. To study the impact of the kilning temperature within experiment 4, a set of dark malts was additionally produced to the pale malts with a withering temperature of 50 °C and a kilning temperature of 200 °C (2 min). Further, from all these malts, the corresponding wort was produced according to the standard mashing procedure of congress mash (50 g of malt, 400 mL of water) (MEBAK® 4.1.4.2 [30], EBC 4.5.1 [31]), since a former study [35] revealed that changes within the malts can differ from the impact that varying malting parameters have on the final state in wort.

Chemicals

The following compounds were commercially available: 2-morpholinoethanesulfonic acid (Mes) and polyethylene glycol mono(p-(1,1,3,3-tetramethylbutyl)phenyl) ether (Triton X-100) (AppliChem, Darmstadt, Germany); acetonitrile and methanol (Baker, Gliwice, Poland); 4-nitrophenyl trans-ferulate (Carbosynth, Compton, Berkshire, United Kingdom); 2-amino-2-(hydroxymethyl)propane-1,3-diol (Tris base) and p-nitrophenol (Carl Roth, Karlsruhe, Germany); hydrochloric acid, dimethyl sulfoxide (DMSO), formic acid (FA), and potassium dihydrogen phosphate (Merck, Darmstadt); and cinnamic acid, p-coumaric acid, ferulic acid, and sodium hydroxide (Sigma-Aldrich; Merck). All solvents were of HPLC gradient grade and ultrapure water was from an in-house source.

Stable isotopically labeled internal standards

The following stable isotopically labeled internal standards were commercially available: [2H7]-cinnamic acid (98 atom % 2H), [13C3]-p-coumaric acid (99 atom % 13C), and [13C3]-ferulic acid (99 atom % 13C) (Sigma-Aldrich; Merck).

Sample pre-treatment

Prior to use, malt samples (frozen at − 18 °C) were first ground by means of a centrifugal mill (12,000 rpm, sieve opening 0.5 mm; ZM 200; Retsch, Haan, Germany) and then stored in wide-necked brown glass bottles for light exclusion at room temperature (RT).

Total and water-extractable arabinoxylan contents in malt

Total and water-extractable arabinoxylan contents in malt were determined by the application of a d-xylose assay kit (K-XYLOSE 04/16; Megazyme, Wicklow, Ireland) as previously described [32].

Briefly, total arabinoxylan contents were determined from ground samples directly hydrolyzed with hydrochloric acid (1.3 mol/L; 1 h at 100 °C; 600 rpm; HCL HeizThermoMixer MHL23; Digital Biomedical Imaging Systems, Pforzheim, Germany). The hydrolysates were neutralized with sodium hydroxide (1.3 mol/L) and adjusted to 100 mL with distilled water. Subsequently, aliquots (15 mL) were centrifuged (4600 rpm, 10 min, RT; Heraeus Multifuge X3 FR; Thermo Fisher Scientific, Dreieich, Germany) and aliquots of the supernatants (500 µL) were used within the enzyme assay.

For the determination of the water-extractable arabinoxylan content, a modified sample preparation was used. Briefly, malt samples were mixed with hot water (85 °C) followed by an incubation for 15 min at 90 °C and additional 30 min at 60 °C (600 rpm; HCL HeizThermoMixer MHL23). Then, the extracts were cooled to RT, centrifuged (4600 rpm, 10 min, RT; Heraeus Multifuge X3 FR), and the supernatants were hydrolyzed by the addition of hydrochloric acid (32%; 1 h at 100 °C). The hydrolysates were neutralized with sodium hydroxide (1.3 mol/L) and adjusted to 20 mL with distilled water. Prior to the enzyme assay, the precipitates were removed by an additional centrifugation step (10,000 rpm, 5 min, RT; Himac 15RE; VWR, Ismaning, Germany). Aliquots of the supernatants (375 µL) were then transferred together with distilled water, a buffer solution (pH value of 7.5), an NAD+/ATP solution, and a hexokinase suspension into semi-micro cuvettes (poly(methyl methacrylate), PMMA); 1.6 mL, 1 cm light path; Ratiolab, Dreieich). After mixing and incubation for 5 min, the absorbance was measured via an UV/VIS-spectrophotometer (UV-2401 PC; Shimadzu, Duisburg, Germany) at 340 nm (A1). Further, to the same mixtures, a xylose mutarotase/β-xylose dehydrogenase solution was added, and after mixing and incubation for another 6 min, the absorbance was measured for a second time (A2). By treating a blank sample with distilled water in the same way (B1, B2), the d-xylose content was calculated from the difference of the sample absorption (A2 − A1) and the difference of the blank absorption (B2 − B1) via the Lambert-Beer law (ε = 6300 L/(mol*cm)). From the d-xylose content, the water-extractable arabinoxylan content was calculated considering the xylose to arabinose ratio in arabinoxylan (0.62 [33, 34]) and the condensation factor (0.88). For more details, see [32].

Feruloyl esterase activity in malt

For the determination of the feruloyl esterase activity in malts, the recently published enzyme assay was applied [32]. Briefly, feruloyl esterase was extracted from malt samples with Mes-buffer (50 mmol/L Mes, pH value of 6.0) for 30 min at RT (900 rpm; HLC HeizThermoMixer MHL23). After centrifugation (4700 rpm, 15 min, RT; Heraeus Multifuge X3 FR) and membrane filtration (0.45 µm, Minisart RC, hydrophilic, 15 mm; Sartorius, Göttingen, Germany) of the extracts, the supernatants were further used in the enzymatic assay. Therefore, aliquots of the supernatants (0.3 mL) together with Mes-buffer (0.9 mL) were pre-incubated for 5 min at 30 °C, before the 4-nitrophenyl trans-ferulate substrate solution (1 mmol/L in phosphate buffer (0.1 mol/L, 2.5% Triton X-100 (v/v), pH value of 6.0)) was added to start the enzymatic reaction. After exactly 2 h, the enzymatic reaction was stopped by the addition of a Tris base solution (1% Tris base (w/v), pH value of 8.5), and the absorption was measured at 400 nm (UV-2401 PC). According to the minor enzymatic activity left under these conditions, a blank of the same composition (aside from the sample extract) was included for each sample triplicate. By a precise simulation of the time between stopping of the enzymatic reaction and the measurement of the absorption, the increase in absorption due to the insufficient deactivation of the feruloyl esterase can be compensated. After subtraction of the blank absorbtion from the sample absorbtion, the feruloyl esterase activity was calculated using a calibration line of 4-nitrophenol. One unit of feruloyl esterase activity is defined as the amount of enzyme that is needed to release 1 nmol of 4-nitrophenol from 4-nitrophenyl trans-ferulate in 1 min under the defined assay conditions. For more details, see [32].

Phenolic acid extraction from malt and quantitation by stable isotope dilution analysis

Total, soluble, and free phenolic acids were isolated and their contents in malts were determined as previously described in detail [35].

Briefly, total phenolic acids (PAtot; = sum of free, soluble ester-bound, and insoluble ester-bound phenolic acids) in malts were determined after alkaline hydrolysis. Therefore, sodium hydroxide (2 mol/L) and the stable isotopically labeled internal standards [2H7]-cinnamic acid, [13C3]-p-coumaric acid, and [13C3]-ferulic acid (amounts depending on the concentrations of the analytes determined in preliminary experiments) were added to the malts, and after covering with argon, the samples were hydrolyzed for 2 h at RT (Multi-Tube Vortexer; VWR). Subsequently, the hydrolysates were neutralized with hydrochloric acid (2 mol/L), centrifuged (4700 rpm, 10 min, RT; Heraeus Multifuge X3 FR), and membrane filtered (0.45 µm) prior to the quantitation of the phenolic acids by means of high-performance liquid chromatography–tandem mass spectrometry (HPLC–MS/MS).

Soluble phenolic acids (PAsol; = sum of free and soluble ester-bound phenolic acids) in malts were quantitated after a hot water extraction in combination with an alkaline hydrolysis. Therefore, malts were suspended in hot water (95 °C), followed by an incubation for 1 h at 100 °C (600 rpm; HLC HeizThermoMixer MHL23). The extracts were then cooled to RT and the stable isotopically labeled internal standards [2H7]-cinnamic acid, [13C3]-p-coumaric acid, and [13C3]-ferulic acid (amounts depending on the concentrations of the analytes determined in preliminary experiments) were added. After equilibration by thorough mixing (GFL Orbital Shaker 3005; Gesellschaft für Labortechnik, Burgwedel, Germany), the extracts were centrifuged twice (4700 rpm, 10 min, RT; Heraeus Multifuge X3 FR; 15,000 rpm, 5 min, RT; Himac CT 15 RE), and aliquots of the supernatants (0.5 mL) were hydrolyzed with sodium hydroxide (4 mol/L) for 2 h at RT. Then, the hydrolysates were neutralized by adding hydrochloric acid (4 mol/L). After membrane filtration (0.45 µm), the contents of phenolic acids were determined by HPLC–MS/MS.

Free phenolic acids (PAfree) in malts were directly accessible after liquid extraction. Therefore, malts, the stable isotopically labeled internal standards [2H7]-cinnamic acid, [13C3]-p-coumaric acid, and [13C3]-ferulic acid (amounts depending on the concentrations of the analytes determined in preliminary experiments), and the extraction solvent (methanol/water (60/40, v/v)) were transferred into Precellys tubes (15 mL; CK28L; Bertin Technologies, Montigny-le-Bretonneux, France) and stored at − 18 °C for 12 h. In the next step, the samples were homogenized by means of a Precellys bead beater (6000 rpm, 3 × 45 s, break 25 s, nitrogen cooling; Precellys Evolution; Bertin Technologies), followed by a 1 h rest at RT for equilibration. Prior to analysis by HPLC–MS/MS, the extracts were centrifuged (4700 rpm, 10 min, RT; Heraeus Multifuge X3 FR) and the supernatants were membrane filtered (0.45 µm).

Quantitation of phenolic acids in wort by stable isotope dilution analysis

The determination of soluble and free phenolic acids in wort was performed as recently described [35].

Briefly, soluble phenolic acids were accessible after alkaline hydrolysis of wort. Therefore, the stable isotopically labeled internal standards [2H7]-cinnamic acid, [13C3]-p-coumaric acid, and [13C3]-ferulic acid (amounts depending on the concentrations of the analytes determined in preliminary experiments) were added to aliquots (0.5 mL) of the wort. Subsequently, sodium hydroxide (4 mol/L) was added for hydrolysis (600 rpm, 2 h, RT; HCL HeizThermoMixer MHL23). After incubation, the hydrolysates were neutralized with hydrochloric acid (4 mol/L), membrane filtered (0.45 µm), and analyzed by HPLC–MS/MS.

Free phenolic acids in wort were determined after inhibition of the enzyme activities by the addition of methanol in a ratio of 1 + 1 (v + v). Next, the stable isotopically labeled internal standards [2H7]-cinnamic acid, [13C3]-p-coumaric acid, and [13C3]-ferulic acid (amounts depending on the concentrations of the analytes determined in preliminary experiments) were added, and after equilibration by thorough mixing (GFL Orbital Shaker 3005) and membrane filtration (0.45 µm), the contents of free phenolic acids were analyzed by HPLC–MS/MS.

Quantitation of phenolic acids by high-performance liquid chromatography–tandem mass spectrometry (HPLC–MS/MS)

Phenolic acids from the different sample preparation procedures were analyzed by HPLC–MS/MS using an UltiMate 3000 HPLC system (Thermo Scientific; Dionex Softran, Germering, Germany) equipped with a Kinetex C18 column (100 × 2.1 mm, 2.6 µm, 100 Å; Phenomenex, Aschaffenburg, Germany; column temperature, 24 °C) and connected to a triple quadrupole mass spectrometer (TSQ Vantage; Thermo Fisher Scientific, Bremen, Germany). The injection volume was 10–20 µL and the mobile phases were 0.1% FA in water (v/v) (A) and 0.1% FA in acetonitrile (v/v) (B). The following linear gradient was applied: 0–2 min, 10% B; 2–15 min, from 10 to 90% B; 15–18 min, 90% B; 18–19 min, from 90 to 10% B; and 19–30 min, 10% B, with a flow gradient of 0.05 mL/min (0–1 min), from 0.05 to 0.2 mL/min (1–2 min), and 0.2 mL/min (2–30 min). Positive atmospheric pressure chemical ionization (APCI+) was applied using the following conditions: vaporizer temperature, 250 °C; discharge current, 4.0 µA; sheath gas pressure, 30 arbitrary units (au); auxiliary gas pressure, 10 au; declustering voltage, -10 V; and capillary temperature, 300 °C. The mass spectrometer was operated in the multiple reaction monitoring (MRM) mode, and the most intensive fragment ion was chosen as the quantifier ion, together with two qualifier ions [35].

Calibration lines were determined from mixtures of known contents of the unlabeled analyte and the corresponding stable isotopically labeled internal standard in seven different concentration ratios (10:1, 5:1, 3:1, 1:1, 1:3, 1:5, and 1:10) with good linearity (R2 > 0.99) for all analytes in the applied range [35].

Parameters describing the malt quality

Moisture content, extract, color, pH value, total protein content, Kolbach index, FAN, and soluble β-glucane content of the malt samples were determined according to MEBAK® [30] and EBC methods [31].

Statistical analysis

Means and standard deviations were calculated by Microsoft Office Excel (Microsoft Corporation, Seattle, WA). Statistical analyses were performed by the R statistical software (version 3.6.0) [36] using the interface R Studio (version 1.1.423) [37]. Significant differences across groups were calculated with either ANOVA (aov), Welch test (oneway.test), or the Kruskal-Wallis test (kruskal.test) from the stats package (version 3.6.0) [36]. To evaluate which groups differ from each other, the post hoc tests pairwise t-test (pairwise.t.test, p.adjustment = holm, pool.sd = TRUE(homogen variance)/FALSE(inhomogen variance)) and Dunn test (dunnTest, method = holm) were applied from the stats and FSA packages (version 0.28.27) [38]. Considering the α inflation with multiple testing, the p-values of the post hoc tests were adjusted according to the method of Holm. To decide in each case of the different dataset which of these tests fits best, normal distribution and homogeneity of variances were determined using the Shapiro-Wilk test (shapiro.test) and the Levene test (leveneTest, center = median) from the packages stats and car (version 3.0.6) [39]. Further, response surface models were assessed by applying the rsm function from the rsm package (version 2.10) [40], and three-dimensional plots were generated with the persp function from the package plot3D (version 1.3) [41].

Results and discussion

Impact of the steeping temperature on the release of phenolic acids during malting

Malts of the two barley varieties Solist and Quench and the wheat variety Dacanto were produced at three different steeping temperatures of 10, 20, and 30 °C to study the suitability of this malting parameter for styrene mitigation via a reduction of its precursor cinnamic acid in malts. Figure 1 (for detailed values and statistics, see Tables S1–S3 in the Online Resources) summarizes the total, soluble, and free phenolic acid contents in these malts and wort produced thereof. Malts of the two barley varieties revealed that cinnamic, but also p-coumaric and ferulic acid contents tended to decrease with increasing steeping temperatures. For example, free cinnamic, p-coumaric, and ferulic acid contents in malts of Solist decreased by 2% from 0.97 to 0.95 mg/kg dm, by 8% from 1.42 to 1.30 mg/kg dm, and by 6% from 4.27 to 4.03 mg/kg dm, with an increasing steeping temperature. For Quench, this decrease was even more pronounced with 31% from 0.72 to 0.50 mg/kg dm, 19% from 1.08 to 0.87 mg/kg dm, and 15% from 4.12 to 3.52 mg/kg dm for free cinnamic, p-coumaric, and ferulic acid. These results also indicated that the impact of the steeping temperature seems to be strongest for cinnamic acid and weaker for p-coumaric and ferulic acid (except for cinnamic acid in Solist). Additionally, the steeping temperature seems to have a slightly higher impact on the free form of the phenolic acids and to a lesser degree on the total and soluble form. After mashing, again both soluble and free cinnamic acid contents tended to decrease with an increasing steeping temperature in wort produced from the corresponding malts. For Solist, a reduction of soluble cinnamic acid in wort of 13% and for Quench of 16% was possible using a steeping temperature of 30 °C instead of 10 °C. Interestingly, this tendency was not found for p-coumaric and ferulic acid for which the soluble and free contents showed the highest amounts at 20 °C (Fig. 1). Thus, for the barley varieties, a higher steeping temperature seems to be recommendable to reduce styrene via its precursor during wheat beer brewing, despite the fact that only two varieties were used in the present study. Luckily, this would also have no severe impact onto the desired aroma of wheat beer, as p-coumaric and ferulic acid, precursors of the desired vinyl aromatics 4-vinylphenol and 2-methoxy-4-vinylphenol, were still present at sufficient amounts.

Total (= sum of free, soluble ester-bound, and insoluble ester-bound), soluble (= sum of free and soluble ester-bound), and free phenolic acid contents of cinnamic, p-coumaric, and ferulic acid in dependency of the steeping temperature (10, 20, and 30 °C) in malts of the barley varieties Solist and Quench and the wheat variety Dacanto as well as in the corresponding wort (50 g of malt, 400 mL of water) produced thereof

Different from the barley varieties, total, soluble, and free phenolic acids in malts of the wheat variety Dacanto showed a concentration optimum at 20 °C. For example, in the case of the free phenolic acid contents, cinnamic acid was found with 0.67 mg/kg dm at 20 °C compared to 0.54 and 0.61 mg/kg dm (20 and 10% lower contents) at 10 and 30 °C, p-coumaric acid with 1.33 mg/kg dm compared to 0.95 and 1.05 mg/kg dm (28 and 21% lower contents), and ferulic acid with 4.46 mg/kg dm compared to 3.86 and 4.05 mg/kg dm (13 and 9% lower contents) (Fig. 1). After mashing, still the highest amounts of soluble p-coumaric and ferulic acid were found in wort produced of malts steepened at 20 °C, which was different for cinnamic acid, showing the lowest contents at this temperature. In case of soluble cinnamic acid, the content was 6 and 14% lower compared to the contents found at 10 and 30 °C. Based on these results, a steeping temperature of 20 °C seems favorable for the production of wheat malts from the perspective of styrene mitigation. Further, with a parallel increase of the desired precursors, also the maintenance of the typical wheat beer aroma expected by the consumers would be guaranteed.

In accordance with a former study [32], feruloyl esterase activities (Fig. 2; for detailed values and statistics, see Tables S1–S3 in the Online Resources), enabling the direct release of phenolic acids from arabinoxylan chains, did not explain the pattern found for the free phenolic acid contents in these malts produced at different steeping temperatures. Instead of showing a decrease with increasing steeping temperatures in the barley varieties, the feruloyl esterase activity showed an optimum for Solist and a minimum for Quench at 20 °C. Also for the wheat variety Dacanto, a different pattern compared to the free phenolic acid contents was found with the lowest feruloyl esterase activity at 20 °C. In contrast, the same study [32] confirmed a link between the degradation degree of arabinoxylan and the content of soluble phenolic acids. Also in the present study, water-extractable arabinoxylan contents (Fig. 2; for detailed values and statistics, see Tables S1–S3 in the Online Resources) showed the same pattern in dependence of the steeping temperatures as found for the soluble and free phenolic acids in malts of the barley and wheat varieties (Fig. 1). Thus, also the water-extractable arabinoxylan contents decreased with increasing steeping temperatures in the barley malts from 0.61 to 0.56 g/100 g dm (8%; Solist) and from 0.68 to 0.58 g/100 g dm (15%; Quench). In case of the wheat variety Dacanto, also an optimum was formed, with the highest water-extractable arabinoxylan content at a steeping temperature of 20 °C, revealing a content of 1.56 g/100 g dm compared to 1.36 and 1.43 g/100 g dm (13 and 8% lower contents) at 10 and 30 °C (Fig. 2). Regarding the total arabinoxylan contents, no changes were found with respect to the different steeping temperatures applied (Fig. 2). This was in accordance with the results of a previous study performed by Kalb et al. [32], in which also no significant differences were found in the total arabinoxylan contents upon malting of four barley and three wheat varieties. As an explanation for the absence of increasing amounts, the authors quoted that cell walls have to be degraded during germination to make starch and proteins accessible for the seedling, rather than building up new cell walls.

According to the results of the present study, the potential of the steeping temperature to reduce the soluble cinnamic acid content in wort within the applied temperature range can reach up to 16%. Further, the data also demonstrated that under these beneficial conditions, still sufficient amounts of the desired precursors can be expected, allowing the formation of the typical wheat beer aroma. Although clear trends were found related to the steeping temperature, statistics (Tables S1–S3 in the Online Resources) and an expected reduction of soluble cinnamic acid in wort of < 16% proved the rather small impact of the steeping temperature. However, this finding is not surprising as the temperature dependency of the feruloyl esterase [42] and of enzymes responsible for the degradation of arabinoxylan, such as β-d-xylosidase, endo-1,4-β-xylanase, and α-l-arabinofuranosidase [22], show only tiny changes in their enzyme activities in the applied temperature range. Nevertheless, the steeping temperature is one parameter which can be modified to reduce the overall styrene content in wheat beer.

Impact of the germination temperature in combination with the aeration rate on the release of phenolic acids during malting

The response surface methodology (RSM) was applied to simultaneously study the impact of the germination temperature and the aeration rate on the release of phenolic acids during malting. Therefore, 14 different malts including 4 factorial, 4 star, and 6 central points were prepared at germination temperatures ranging from 10 to 26 °C and aeration rates ranging from 15 to 35 L/min. For models with a coefficient of multiple determination (MR2) ≥ 0.8 and a corresponding p-value < 0.05, the impact on the analytes of interest was considered as statistically relevant (Table 2; for each response surface plot, see Figures S1–S6 in the Online Resources). For the barley varieties Solist and Quench, it was proven that the germination temperature in combination with the aeration rate had an impact on the water-extractable arabinoxylan contents (Table 2). While increasing germination temperatures led to a decrease of the contents, increasing aeration rates had an increasing effect (Fig. 3). Thereby, the impact of the germination temperature was stronger than the influence of the aeration rate. According to the data of the present study, a reduction of the water-extractable arabinoxylan content of approximately 35% has to be expected, when using sets of parameters favorable for low water-extractable arabinoxylan contents compared to sets favorable for high contents (Fig. 3). In case of the wheat variety Dacanto, statistics showed that the water-extractable arabinoxylan content was not affected by the applied parameters. Additionally, the statistical data also showed no impact on the feruloyl esterase activity independent of the barley and wheat varieties (Table 2).

Similar to the steeping temperature, also in case of the germination temperature in combination with the aeration rate, the tendencies found for the water-extractable arabinoxylan contents could be linked to the dependency of the soluble and free phenolic acid contents on these parameters. For the barley varieties, also a decrease of the free phenolic acid contents with increasing germination temperatures was found, whereby the aeration rate played a secondary role (Figure S4 in the Online Resources). Exemplarily, comparing “favorable” (cinnamic acid reduction) and “unfavorable” (cinnamic acid increase) parameters, a reduction of free cinnamic, p-coumaric, and ferulic acid of roughly 70, 70, and 50% was found in malts of Solist within the present study (Fig. 4). Looking at the wheat variety Dacanto, free cinnamic and p-coumaric acid contents, again in accordance with the results of the water-extractable arabinoxylan contents, were unaffected by the varied parameters (Table 2). Ferulic acid was an exception to this rule and contrarily showed a decrease with increasing germination temperatures, which was similar to the barley varieties (Figure S4 in the Online Resources). In comparison to the free phenolic acid contents, the impact of the applied parameters on the total and soluble phenolic acid contents in the same malts was rather limited (Table 2).

Mashing of the malts produced at different germination temperatures in combination with the aeration rates led to wort with similar trends for the soluble and free phenolic acid contents as found for the respective malts (Figures S5 and S6 in the Online Resources). More precisely, this was the case for cinnamic and ferulic acid, whereas for p-coumaric acid no statistical correlation was found (Table 2). According to the results of the present study, sets of favorable (cinnamic acid decrease) parameters led to a reduction of soluble cinnamic acid in wort of approximately 52 and 40% in the varieties Solist and Dacanto compared to unfavorable (cinnamic acid increase) parameters. For soluble ferulic acid contents, a smaller reduction of 20 and 26% was found in the varieties Solist and Quench (Figure S5 in the Online Resources).

Thus, the results of the present study recommend higher germination temperatures for the preparation of barley and wheat malts for wheat beer brewing. Regarding the aeration rate, no final recommendation can be made, as no clear trends were found among the phenolic acids in malt and wort and, apart from that, the aeration rate seems to play only a secondary role in the reduction of the undesired styrene precursor cinnamic acid in wheat beer. In conclusion, germination parameters revealed a high potential for styrene mitigation, since a reduction of the undesired cinnamic acid in wort of up to 50% was possible within the present study.

Impact of the withering temperature during kiln-drying on the release of phenolic acids during malting

Four different withering temperatures (30, 40, 50, and 60 °C; applied isothermally to enable the comparability of the data related to specific temperatures) were applied during malting of the barley varieties Solist and Quench and the wheat variety Dacanto to evaluate the impact of kiln-drying on the release of the precursors of the desired and undesired vinyl aromatics during malt production. Based on the temperature optima (varying between 40 and 70 °C) of the arabinoxylan-degrading enzymes [22] and of the feruloyl esterase [42], responsible for the direct release of phenolic acids from this non-starch polysaccharide structure, the withering temperature was expected to have the most pronounced impact on the release of the phenolic acids during malting among the malting parameters evaluated in the present study, as the temperatures applied during kiln-drying represent the range showing the biggest differences in the respective enzyme activity. In fact, the results of the present study confirmed this expectation (Fig. 5; for detailed values and statistics, see Tables S4–S6 in the Online Resources). In malt, free phenolic acid contents were found to be highest at a withering temperature of 60 °C and lowest at 30 °C. For the barley varieties Solist and Quench, a moderate increase was found for the free cinnamic, p-coumaric, and ferulic acid contents from 30 to 50 °C, followed by a dominant increase from 50 to 60 °C. Interestingly, the impact was more pronounced for cinnamic and p-coumaric acid as for ferulic acid. Comparing the amounts of free phenolic acids at 30 (favorable) and 60 (unfavorable) °C, the withering temperature had the power to decrease the contents of cinnamic acid by 76 and 84%, of p-coumaric acid by 72 and 80%, and of ferulic acid by 29 and 33% in malts of Solist and Quench (Fig. 5). For the wheat variety Dacanto, the increase of the free phenolic acid contents was found to be less distinct than for the barley varieties, especially the pronounced increase from 50 to 60 °C was not present in the wheat variety. Still, with respect to the analyzed wheat variety, decreases in the free phenolic acid contents of 67, 21, and 24% for cinnamic, p-coumaric, and ferulic acid were possible comparing the contents at 30 (favorable) and 60 (unfavorable) °C (Fig. 5).

Total (= sum of free, soluble ester-bound, and insoluble ester-bound), soluble (= sum of free and soluble ester-bound), and free phenolic acid contents of cinnamic, p-coumaric, and ferulic acid in dependency of the withering temperature (30, 40, 50, and 60 °C) in malts of the barley varieties Solist and Quench and the wheat variety Dacanto as well as in the corresponding wort (50 g of malt, 400 mL of water) produced thereof

Looking at the total and soluble phenolic acid contents in malts (Fig. 5), the impact of the withering temperature was less pronounced, which was in accordance with the results of the steeping temperature as well as of the germination temperature in combination with the aeration rate. At a first glance, this statement seemed to be in conflict with the pattern found for cinnamic acid; however, it was the consequence of the occurrence of cinnamic acid mostly in its free form. Also in a former study [35], the free form of cinnamic acid was the most dominant form in malts, which was explained by the fact that cinnamic acid only plays the role of an intermediate in the phenyl propanoid metabolism leading to the formation of further phenolic acids, e.g., p-coumaric, ferulic, and sinapic acid [14, 15]. A comparison of the total, soluble, and free cinnamic acid contents in malts (Fig. 5) further revealed that enzymatic degradation processes, leading to soluble and free phenolic acids, are not solely able to explain all the concentration changes found in dependency of the varied withering temperatures. As most of the differences found in the total and soluble contents were caused by the free form in both grain types, which was not the result of the feruloyl esterase activity as already explained above, proven by the absence of considerable amounts of insoluble or soluble ester-bound cinnamic acid contents, a formation of cinnamic acid via the phenyl propanoid metabolism is very likely. Therefore, also the biosynthesis of phenolic acids has to be considered to explain changes in phenolic acid contents caused by the different malting parameters.

To estimate to which extent arabinoxylan-degrading enzymes contribute to the release of phenolic acids based on the varied parameter, the water-extractable arabinoxylan content can be used. For the barley variety Solist, an increase of the water-extractable arabinoxylan content by about 25% from 0.39 to 0.49 g/100 g dm (Fig. 6) was found with an increasing temperature from 30 to 60 °C. For Quench, the temperature with the highest water-extractable arabinoxylan content was 50 °C (0.68 g/100 g dm), while the contents were at maximum 24% lower at the other temperatures. For the wheat variety Dacanto, statistical data revealed that the water-extractable arabinoxylan content was unaffected by the withering temperature (Table S6 in the Online Resources). Therefore, arabinoxylan-degrading enzymes cannot be used to explain the differences in the contents of > 24%. With overall differences of up to 84%, this fact underlines that arabinoxylan-degrading enzymes are only one of the factors explaining the overall changes. For the feruloyl esterase, the withering temperature had no effect on its activity in malts of the barley variety Solist (Fig. 6 and Table S4 in the Online Resources). In contrast, for both the barley variety Quench and the wheat variety Dacanto, the highest feruloyl esterase activity was found in malts withered at 50 °C with 7.63 and 3.87 U/g dm, respectively. Comparing the activities at 30, 40, and 60 °C to the temperature optimum of the enzyme at 50 °C, activities were < 41% lower.

With respect to the withering temperature, mashing of all three varieties led to wort with a similar pattern of soluble and free cinnamic acid contents compared to the applied malts (Fig. 5). For the barley varieties, the highest contents of cinnamic acid were found at 60 °C and for the wheat variety at 50 and 60 °C. Comparing the contents at a withering temperature of 30 (favorable) and 60 (unfavorable) °C, this parameter had the power to reduce the soluble cinnamic acid content by 72, 69, and 46% in the respective wort of Solist, Quench, and Dacanto. For Solist, also the desired precursors had their highest contents in wort produced from malts withered at 60 °C. Again, in accordance with the malts, only tiny differences were found between the withering temperatures of 30, 40, and 50 °C, whereat the most distinctive increase was found between 50 and 60 °C (Fig. 5). Therefore, in case of Solist, a correlation was given for the soluble and free contents between wort and the corresponding malts. Comparing the contents at 30, 40, and 50 °C to the content at 60 °C, a reduction of soluble cinnamic acid was accompanied by a reduction of p-coumaric and ferulic acid of up to 51 and 31%. With regard to the soluble and free p-coumaric and ferulic acid contents in wort of the barley variety Quench and the wheat variety Dacanto, the highest contents were found at a withering temperature of 50 °C (negligible for ferulic acid in Dacanto) (Fig. 5 and Table S6 in the Online Resources). This was quite different to the pattern found for the corresponding malts and seemed to be a consequence of the feruloyl esterase activity, still active after kiln-drying, which had its temperature optimum in the malts of Quench and Dacanto at 50 °C (Fig. 6). Another evidence for this assumption was the absence of this effect in the case of Solist, where no significant impact was found on the feruloyl esterase activity in dependency of the withering temperature (Table S4 in the Online Resources). Comparing unfavorable with favorable conditions related to cinnammic acid reduction, also a reduction of the soluble desired p-coumaric and ferulic acid contents of up to 49 and 14% for Quench and 34 and 8% for Dacanto has to be considered.

From the perspective of styrene mitigation in wheat beer via its precursor cinnamic acid, low withering temperatures are recommended during malt production according to the results of the present study. Concerning the desired precursors, sufficient amounts allowing the formation of the distinct aroma in wheat beer brewed from these malts can still be expected, although favorable conditions could reduce the p-coumaric acid content by up to 51% and the ferulic acid content by up to 31%. With the power to reduce the soluble cinnamic acid content in wort by up to 72%, the withering temperature was proven to have the strongest impact on the formation and release of the desired and undesired precursors of the vinyl aromatics during malt production among the parameters analyzed within this study, underlining its importance as a tool for styrene mitigation.

Impact of the kilning temperature on the release of phenolic acids during malting

In a former study comparing dark and pale wheat beers [10], significantly lower concentrations of the desired and undesired vinyl aromatics were analyzed in dark wheat beers. Further, a nearly complete decarboxylation of the free precursors was found in both types. With these analyte pattern at hand and considering that both types were brewed with the same original gravity, it was assumed that phenolic acid contents in dark malts were significantly reduced via thermal decarboxylation as a consequence of the high temperature applied during kiln-drying. This assumption was based on the results of the study of Samaras et al. [43], who showed that high kilning temperatures, used for the production of dark malts, led to a massive decrease of the free phenolic acid contents in the respective malts. However, according to the results of the present study, thermal decarboxylation is only one of the factors responsible for the lower vinyl aromatic contents in dark wheat beers. Malts of the barley varieties Solist and Quench and the wheat variety Dacanto kilned at 80 (pale) and 200 (dark) °C revealed that the total, soluble, and free phenolic acid contents were only slightly affected by the higher kilning temperature of 200 °C compared to 80 °C (Fig. 7; for detailed values and statistics, see Tables S4–S6 in the Online Resources).

Recovered total (= sum of free, soluble ester-bound, and insoluble ester-bound), soluble (= sum of free and soluble ester-bound), and free phenolic acid contents as well as total (AXtot) and water-extractable arabinoxylan (WEAX) contents and feruloyl esterase activity in dark malts (withering temperature, 50 °C; kilning temperature, 200 °C) in comparison to pale malts (withering temperature, 50 °C, kilning temperature, 80 °C) of the barley varieties Solist and Quench and the wheat variety Dacanto. The red line represents a recovery of 100%

Different to the malts, soluble and free phenolic acid contents were highly affected in wort. However, the slightly lower contents in the malts were not enough to explain the significant reductions in the corresponding wort (Tables S4–S6 in the Online Resources). In contrast, the absence of additional biosynthesis that is normally found for cinnamic acid, unusual low transfer rates of already soluble phenolic acids, and the lack of an additional release of p-coumaric and ferulic acid by the feruloyl esterase during mashing were found to cause the low phenolic acid contents in wort. A hint for the explanation of this observation might be given by the missing feruloyl esterase activity in malts produced at 200 °C, suggesting that also other enzymes involved in the biosynthesis and the degradation of non-starch polysaccharides were affected by the high kilning temperatures applied. This finding fits also to the bad filtration behavior found during mashing of dark malts in the present study.

Specifications of applied malts

To determine to what extent these possible new styrene mitigation strategies can be applied to wheat beer brewing, malts were tested if they fulfill certain specifications. Addressing this challenge, malt samples prepared within this study were analyzed for the quality determining parameters moisture content, extract, color, pH value, total protein content, Kolbach index, FAN (free amino nitrogen), and soluble β-glucan content using the standard brewing methods described by MEBAK® [30] (Table 3). Malts prepared from the barley variety Solist matched the standard values defined by MEBAK® [30] and Krüger and Anger [44] in each case of the 16 different experimental settings. Only at a steeping temperature of 30 °C or a withering temperature of 30 °C, the FAN content was slightly too low (105 and 115 mg/100 g, respectively). For the barley variety Quench, again most of the parameters indicated that the respective malts had a high brewing potential. Indeed, the FAN values were too low to guarantee the sufficient sustenance of yeast with essential nutrients during fermentation. This seemed to be a characteristic of this variety and can also be explained by the lower total protein content. However, this should not limit the applicability of these malts at first instance, and thus, the significance of the gained knowledge for styrene mitigation, as it is a common practice in the malting industry to blend malts with different specifications to match the requirements of a distinct beer type.

Based on the fact that the standard malt quality values are defined for Pilsner malts, malts prepared from the wheat variety Dacanto were compared to a commercial wheat malt used for beer brewing, again showing high accordance of the values. Thus, also for the wheat malts prepared within this study, their potential for wheat beer brewing could be shown. In conclusion, malts prepared within this study showed a high conformance with standard malt quality values and values from commercial malts, highlighting their applicability for wheat beer brewing, and therefore, underlining malting as an important tool within a strategy for styrene mitigation.

Studies how malting parameters affect the content of phenolic acids in malts of barley and wheat are scarcely available. A study by Szwajgier et al. [45], addressing the impact of the pH value of the steeping water and the temperature applied during steeping and germination on the release of the free desired phenolic acids during malting, showed that a reduced pH value of the steeping water of pH 5.2 compared to 7.4 during malting of barley (varieties: Rudzik and Krona) resulted in an increase of the content of free p-coumaric and ferulic acid by approximately 200–300%. Further, they attested an increase of these phenolic acids by 160–210% when increasing the temperature during steeping and germination from 14 to 22 °C. However, these results were in conflict with a study of Langos et al. [24], who varied the germination temperature between 12 and 18 °C, with nearly no effect on the free phenolic acid contents in barley malts (variety: Marthe) (cinnamic, p-coumaric, and ferulic acid: 1.17, 1.17, and 3.24 mg/kg dm at 12 °C; 1.04, 1.15, and 3.29 mg/kg dm at 18 °C), and, in line with the results of the present study, with slightly decreasing contents with an increase of the germination temperature for wheat malts (variety: Hermann) (cinnamic, p-coumaric, and ferulic acid: 0.61, 0.84, and 2.54 mg/kg dm at 12 °C; 0.54, 0.69, and 2.41 mg/kg dm at 18 °C). Additionally, Langos et al. [24] showed that an prolongation of the germination time from 5 to 7 days led to an increase of the free phenolic acid contents in barley malts (cinnamic, p-coumaric, and ferulic acid: 0.85, 0.84, and 2.94 mg/kg dm at 5 days; 1.19, 1.07, and 3.50 mg/kg dm at 7 days), whereas no clear trend was found in wheat malts (cinnamic, p-coumaric, and ferulic acid: 0.45, 0.83, and 2.35 mg/kg dm at 5 days; 0.48, 0.65, and 2.68 mg/kg dm at 7 days).

In summary, the results of the present study proved the ability of the malting parameters steeping temperature, germination temperature in combination with the aeration rate, withering temperature, and kilning temperature to lower the input of the styrene precursor cinnamic acid into the brewing process. The lab-scale experiments also revealed promising perspectives regarding the malts prepared in this study fulfilled most of the malt quality specifications for brewing. With the capacity to lower the soluble cinnamic acid content in wort by up to 72%, the withering temperature during kiln-drying had the strongest impact among the malting parameters evaluated in the present study, followed by the germination temperature together with the aeration rate, showing a reduction capacity of up to 52%, and the steeping temperature having the lowest impact with a maximum reduction capacity of 16%. In dark wheat beers, the kilning temperature proved to be another important factor, with the capacity to reduce styrene also by up to 72%. Conditions, favorable for lower cinnamic acid contents, also had a reducing effect on the contents of the desired precursors. While p-coumaric acid derives mainly from barley malts, the potential regarding ferulic and cinnamic acid is quite equal to malts from barley and wheat [35]. However, the corresponding wort was found to have still sufficient amounts of p-coumaric and ferulic acid to allow the formation of the distinct aroma of wheat beer expected by the consumers.

References

Shimada K, Kimura D, Yasui Y, Tanaka H, Matsushita S, Hagihara H, Nagakura M, Kawahisa M (1992) Styrene formation by the decomposition by Pichia carsonii of trans-cinnamic acid added to a ground fish product. Appl Environ Microbiol 5:1577–1582

Steele DH, Thornburg MJ, Stanley JS, Miller RR, Brooke R, Cushman JR, Cruzan G (1994) Determination of styrene in selected foods. J Agric Food Chem 42:1661–1665

Fragnière C, Aebischer J-N, Dudler V, Sager F (2003) A short study on the formation of styrene in cinnamon. Mitt Lebensm Hyg 94:609–620

Renner R, Bartels H, Tressl R (1976) Enrichment and quantitative determination of beer aroma substances by gas extraction (in German). Monatsschr Brau 29:478–480

Tressl R, Friese L, Fendesack F, Koeppler H (1978) Gas chromatographic-mass spectrometric investigation of hop aroma constituents in beer. J Agric Food Chem 6:1422–1426

WHO (1996) Guidelines for drinking-water quality. World Health Organization, Geneva

IARC (2002) IARC monographs of the evaluation of carcinogenic risks to humans. International Agency for Research on Cancer, Lyon

Cruzan G, Cushman JR, Andrews LS, Granville GC, Johnson KA, Hardy CJ, Coombs DW, Mullins PA, Brown WR (1998) Chronic toxicity/oncogenicity study of styrene in CD rats by inhalation exposure for 104 weeks. Toxicol Sci 46:266–281

Cruzan G, Cushman JR, Andrews LS, Granville GC, Johnson KA, Bevan C, Hardy CJ, Coombs DW, Mullins PA, Brown WR (2001) Chronic toxicity/oncogenicity study of styrene in CD-1 mice by inhalation exposure for 104 weeks. J Appl Toxicol 21:185–198

Kalb V, Granvogl M (2019) Formation of desired smoky key odorants in wheat beer: a comparison with the undesired toxicologically relevant styrene. In: Guthrie B, Beauchamp JD, Buettner A, Toth S, Qian MC (eds) Sex, smoke, and spirits: the role of chemistry; ACS Symposium Series 1321. American Chemical Society, Washington, DC

Langos D, Granvogl M (2016) Studies on the simultaneous formation of aroma-active and toxicologically relevant vinyl aromatics from free phenolic acids during wheat beer brewing. J Agric Food Chem 11:2325–2332

Daly B, Collins F, Madigan D, Donelly D, Coakley M, Ross P (1997) An investigation into styrene in beer. Proc Congr Eur Brew Conv 26:623–630

Langos D, Granvogl M, Schieberle P (2013) Characterization of the key aroma compounds in two Bavarian wheat beers by means of the sensomics approach. J Agric Food Chem 47:11303–11311

Hahlbrock K, Scheel D (1989) Physiology and molecular biology of phenylpropanoid metabolism. Annu Rev Plant Physiol Plant Mol Biol 40:347–369

Ververidis F, Trantas E, Douglas C, Vollmer G, Kretzschmar G, Panopoulos N (2007) Biotechnology of flavonoids and other phenylpropanoid-derived natural products. Part I: Chemical diversity, impacts on plant biology and human health. Biotechnol J 10:1214–1234

Finche GB (1989) Molecular and cellular biology associated with endosperm mobilization in germinating cereal grains. Annu Rev Plant Physiol Plant Mol Biol 40:305–346

Fincher GB (2009) Revolutionary times in our understanding of cell wall biosynthesis and remodeling in the grasses. Plant Physiol 1:27–37

Gubler F, Ashford AE (1985) Release of ferulic acid esters from barley aleurone. I. Time course of gibberellic-acid-induced release from isolated layers. Aust J Plant Physiol 3:297–305

Dvořáková M, Guido LF, Dostálek P, Skulilová Z, Moreira MM, Barros AA (2008) Antioxidant properties of free, soluble ester and insoluble-bound phenolic compounds in different barley varieties and corresponding malts. J Inst Brew 1:27–33

Maillard M-N, Berset C (1995) Evolution of antioxidant activity during kilning: role of insoluble bound phenolic acids of barley and malt. J Agric Food Chem 7:1789–1793

Nordkvist E, Salomonsson A-C, Åman P (1984) Distribution of insoluble bound phenolic acids in barley grain. J Sci Food Agric 35:657–661

Rasmussen CV, Hansen HB, Hansen Å, Larsen LM (2001) pH-, temperature- and time-dependent activities of endogenous endo-β-d-xylanase, β-d-xylosidase and α-l-arabinofuranosidase in extracts from ungerminated rye (Secale cereale L.) grain. J Cereal Sci 1:49–60

Langos D, Gastl M, Granvogl M (2017) Reduction of toxicologically relevant styrene in wheat beer using specially produced wheat and barley malts. Eur Food Res Technol 193:558–568

Langos D, Granvogl M, Gastl M, Schieberle P (2015) Influence of malt modifications on the concentrations of free phenolic acids in wheat and barley malts. Brew Sci 68:93–101

Schwarz KJ, Methner F-J (2011) Styrene concentrations during wheat beer production. Brew Sci 64:156–158

Schwarz KJ, Boitz LI, Methner F-J (2012) Enzymatic formation of styrene during wheat beer fermentation is dependent on pitching rate and cinnamic acid content. J Inst Brew 3:280–284

Schwarz KJ, Boltz LI, Methner F-J (2012) Release of phenolic acids and amino acids during mashing dependent on temperature, pH, time and raw materials. J Am Soc Brew Chem 70:290–295

Schwarz KJ, Stübner R, Methner F-J (2012) Formation of styrene dependent on fermentation management during wheat beer production. Food Chem 4:2121–2125

Schwarz KJ, Boltz LI, Methner F-J (2013) Influence of mashing conditions on the release of precursors of phenolic wheat beer aroma (in German). Brauwelt 153:274–279

Pfenninger H (1997) Methodensammlung der Mitteleuropäischen Brautechnischen Analysenkommission (MEBAK). Selbstverlag der MEBAK, Freising

European Brewery Convention (2010) Analytica-EBC. Fachverlag Hans Carl, Nuremberg

Kalb V, Seewald T, Hofmann T, Granvogl M (2020) The role of endogeneous enzymes during malting of barley and wheat varieties in the mitigation of styrene in wheat beer. J Agric Food Chem 68:13888–13896

Andersson AAM, Lampi A-M, Nyström L, Piironen V, Li L, Ward JL, Gebruers K, Courtin CM, Delcour JA, Boros D, Fraś A, Dynkowska W, Rakszegi M, Bedo Z, Shewry PR, Åman P (2008) Phytochemical and dietary fiber components in barley varieties in the HEALTHGRAIN diversity screen. J Agric Food Chem 21:9767–9776

Gebruers K, Dornez E, Boros D, Fraś A, Dynkowska W, Bedo Z, Rakszegi M, Delcour JA, Courtin CM (2008) Variation in the content of dietary fiber and components thereof in wheats in the HEALTHGRAIN diversity screen. J Agric Food Chem 21:9740–9749

Kalb V, Seewald T, Hofmann T, Granvogl M (2020) Studies on the impact of malting and mashing on the free, soluble ester-bound, and insolbule ester-bound forms of desired and undesired phenolic acids aiming at styrene mitigation during wheat beer brewing. J Agric Food Chem 68:12421–12432

R Development Core Team (2019) A language and environment for statistical computing. R Foundation for Statistical Computing, Vienna. https://www.r-project.org. Accessed 14 Apr 2020

RStudio Team (2019) RStudio: integrated development for R. RStudio, Boston, MA. https://www.rstudio.com/. Accessed 14 Apr 2020

Ogle D, Wheeler P, Dinno A (2020) R FSA: simple fisheries stock assessment methods. https://cran.r-project.org/package=FSA. Accessed 14 Apr 2020

Fox J, Weisberg S (2019) R car: companion to applied regression. https://cran.r-project.org/package=car. Accessed 14 Apr 2020

Lenth R (2018) R rsm: response-surface analysis. https://cran.r-project.org/package=rsm. Accessed 14 Apr 2020

Soetaert K (2019) R plot3D: plotting multi-dimensional data. https://cran.r-project.org/package=plot3D. Accessed 14 Apr 2020

Wang D, Meng-Meng G, Jin-Hua D (2011) Determination and characterisation of feruloyl esterase in wheats and malts. Food Ferment Ind 37:181–185

Samaras TS, Camburn PA, Chandra SX, Gordon MH, Ames JM (2005) Antioxidant properties of kilned and roasted malts. J Agric Food Chem 20:8068–8074

Krüger E, Anger H-M (1990) Kennzahlen zur Betriebskontrolle und Qualitätsbeschreibung in der Brauwirtschaft: Daten über Roh- und Hilfsstoffe, Halbfertig- und Fertigprodukte bei der Bierbereitung. Behr, Hamburg

Szwajgier D, Pielecki J, Targoński Z (2005) Changes of free ferulic and coumaric acid contents during malting of balrey grain. Pol J Food Nutr Sci 4:423–429

Acknowledgements

The authors thank Miss Anneliese Köhler for technical assistance, and Mr. Sami Kaviani-Nejad for performing the LC/MS–MS measurements.

Funding

Open Access funding enabled and organized by Projekt DEAL. The IGF Project (AiF 19593 N) of the Association for the Promotion of Science of the German Brewing Industry (Wifö) was supported via AiF within the program for promoting the Industrial Collective Research (IGF) of the German Ministry of Economic Affairs and Energy (BMWi), based on a decision by the German Bundestag.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

None.

Compliance with ethics requirements

The authors Valerian Kalb, Michael Granvogl, Torsten Seewald, and Thomas Hofmann hereby confirm that this manuscript is performed according and follows the COPE guidelines and has not already been published nor is it under consideration for publication elsewhere. This article does not contain any studies with human or animal subjects.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kalb, V., Seewald, T., Hofmann, T. et al. The malting parameters: steeping, germination, withering, and kilning temperature and aeration rate as possibilities for styrene mitigation in wheat beer. Eur Food Res Technol 248, 69–84 (2022). https://doi.org/10.1007/s00217-021-03852-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-021-03852-5