Abstract

The aim of this study was to evaluate the effect of Moringa oleifera leaf powder addition on physical, sensorial, and antioxidant properties of gluten-free bread. Moringa leaf powder (MLP) was incorporated at different levels (2.5, 5.0, 7.5, and 10% in basic replacement) in gluten-free bread. The results revealed that addition more than 2.5% decreased the specific volume of bread. The hardness and chewiness of bread slightly decreased with 2.5 and 10% MLP addition, whereas springiness was not affected by MLP. For sensory evaluation, the most acceptable gluten-free bread was obtained for control bread and bread with 2.5% MLP. The lightness of crumb and crust decreased with increasing of MLP from 63.37 to 27.59 and from 52.40 to 33.49, respectively. The total phenolics content (TPC) and antioxidant activity of extracts increased with the addition of MLP. The addition of MLP already for 2.5% resulted in large increase in the content of TPC (from 0.88 to 2.12 GAE/g dw). The high activity for DPPH scavenging was found for 7.5% and for 10% of MLP addition. For ABTS scavenging capacity, the high activity was for 5.0, 7.5, and 10%. Regarding RED and OH scavenging capacity, gluten-free breads with MLP from 2.5 to 10% presented significantly higher activity (RED from 32.92 to 21.56 and OH scavenging from 54.38 to 47.31 EC50 mg dw comparing to control bread (40.02; 90.81 EC50 mg dw/ml, respectively). Taking into account both the sensory evaluation and antioxidant activity, the addition of MFP should not exceed 5%.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Moringa oleifera commonly known as the miracle plant or the ‘tree of life’ is a plant native to India, but is cultivated throughout the world; it is a nutritious tree with a variety of potential uses [1,2,3]. Its leaves are an exceptional source of vitamin A, B group and C. Leaves are considered one of the best vegetable sources of minerals, their content of calcium, iron, and potassium are very high [4]. They are excellent sources of protein and contain very little fat and carbohydrates. They are an incomparable source of essential amino acids such as lysine, methionine, and cysteine often deficient in diets. Thus, making these leaves one of the best plant foods [2, 5, 6].

Moringa oleifera leaves are rich in phytonutrients source such as carotenoids [3, 7], tocopherols, and ascorbic acid, it has also been found to contain appreciable amounts of total phenols and flavonoids which can be used as antioxidant [3, 8, 9].

In many parts of the world including Africa, the use of M. oleifera as a food fortificant is on the increase. Some studies have been conducted for the use of Moringa leaf powder as nutrient supplement of wheat bread, but there is no study concerning gluten-free bread with the addition of Moringa leaf [4, 9, 10].

Gluten-free bread is often low in protein, minerals, and other nutrients in comparison with the traditional wheat bread [11, 12]. Supplementation of gluten-free bread by Moringa leaf seems to be a good way to provide appropriate levels of minerals, protein, phenols, and other nutrients.

Over the world, the only proven treatment for coeliac disease is a strict and lifelong adherence to a gluten-free diet, which leads to the deficiency in nutrients components resulting none only from the intestinal abnormalities, but also from an insufficient supply of nutrients in gluten-free diet [13,14,15,16]. Patients showing nutritional deficiencies could require supplementation of their diets with vitamins, antioxidants, minerals, and proteins to correct deficiencies and restore nutrient reserves [17, 18]. Bourekoua et al. [ 19] reported that celiac disease suffers from the lack of gluten-free products with the subsequent negative effects on nutritional and health status of patients.

In the absence of study about gluten-free bread with additional Moringa leaf, its seems interesting to conduct this work to determine the effect of Moringa leaf powder addition on the physical, sensorial, and antioxidant properties of gluten-free bread.

Materials and methods

Chemicals

ABTS (2,2′-azino-bis (3-ethylbenzothiazoline-6-sulphonic acid), DPPH (2,2–diphenyl-1-picrylhydrazyl), Folin–Ciocalteau reagent, ammonium thiocyanate, Fe SO4, and sodium thiocyanate were purchased from Sigma-Aldrich company (Poznan, Poland). All others chemicals were of analytical grade.

Raw materials

Moringa Oleifera leaves powder (MLP) derived from India was purchased from Targroch (Filipowice, Poland) (5.62% moisture, 27.85% fiber, 5.41% lipid, 23.29% protein, and 37.83% carbohydrates). Rice was obtained from MAKRO K & K Sp. Z.o.o, Cmolas, Poland, rice semolina (particle size from 200 to 500 µm) was obtained by grinding rice (10.33% moisture, 0.22% ash, 0.50% lipid, and 7.80% protein content) and sieved (laboratory sifter Retsh, AS200, Germany). Field bean (Vicia faba) (10.46% moisture, 0.50% ash, 1.03% lipid, and 30.86% protein) was purchased from Al-Amir Company (Albehera, Egypt). Field bean semolina (size from 200 to 500 µm) was obtained after grinding the hulled bean seeds. The grinding of rice and field bean was made using laboratory mill (LMN-100 TESTCHEM, Radlin, Poland). Instant dry yeast (Saf-Instant, France), salt, commercial sunflower oil, and fresh eggs were purchased from a local market.

Preparation of gluten-free breads with MLP

The gluten-free formula according to [20] included rice with supplemented field bean in a ratio of 2/1 (w/w) was used in this study. Gluten-free breads ingredients consisted on 200 g of rice/field bean semolina, 4 g dry yeast, 4 g salt, 20 g fresh egg, 40 g sunflower oil, and 150 g of water determined according to preliminary trials of baking tests.

Four formulas were prepared with different levels of MLP: 2.5, 5, 7.5, and 10% on rice/field bean semolina replacement basis, and a control bread was prepared with 0% levels of MLP. All ingredients were mechanically mixed with exception of fresh egg and MLP for 1 min. After a resting time of 10 min, the fresh egg and MLP were added and the mixture was kneaded (Kitchen Aid, Model 5KPM5-220–240 V 50/60 H-USA, St-Joseph, MI) for 15 min at 25 °C.

After kneading, the dough was divided into four portions (80 g), placed in molds and fermented in a climatic chamber (Sadkiewicz Instruments, Bydgoszcz, Poland) for 45 min at 37 °C (75–80% of relative humidity). The baking test of fermented dough was carried out for 20 min at 230 °C in an electric oven (Sadkiewicz Instruments, Bydgoszcz, Poland). The loaves were left 1 h at room temperature for cooling before evaluation of their characteristics. For each levels, one batch of dough was prepared and four loaves of bread were baked for physical and biochemical characteristics For sensory evaluation, additional four batches (16 loaves) were prepared. Control gluten-free bread and gluten-free bread with different levels of MLP are shown in Fig. 1.

Evaluation of physical properties of gluten-free breads

Four loaves were used. Bread volume was measured by the millet seed displacement method [21]. The specific volume was calculated by dividing the bread volume by its weight.

Textural properties of bread crumb (30 × 30 × 20 mm) were measured using a texture analyzer (ZWICK Z020/TN2S strength tester), and the samples were compressed twice using a capital equipped with a 30 mm plug until a 50% depth at a crosshead speed of 1 mm s−1 was achieved [22,23,24,25]. The parameters recorded were obtained from the TPA curves 1 and 2: hardness (peak force 1), springiness (length of the base of the area 2/length of the base of the area 1), and chewiness (hardness × cohesiveness × springiness). Data from four replicate were averaged.

Color of bread crumb and crust was measured using a colorimeter (4Wave CR30-16) (Planeta, Tychy, Poland) under conditions (Light: D65; observer angle: 10°; space: LAB; diam: 16 mm; style: 8/day). The color was determined in CIE-L*a*b* system, where L* indicates lightness. The redness +/greenness − and the yellowness +/blueness − are denoted by a* and b* values, respectively. The total color difference (∆E) was also determined as follows:

Data from three slices per sample were averaged.

Total phenolics content and antioxidant properties

Extract preparation

Dry samples of breads were ground to obtain powder. One gram of bread powder was extracted for 30 min with 5 ml of methanol:water mixture (1:1, v/v).

The extracts were separated by decantation in centrifuge for 15 min. The residues were extracted again with 5 ml of methanol and the extracts were combined and stored in darkness at −20 °C.

Total phenolics content

Total phenols were determined according to the Folin–Ciocalteu method [26]. For each sample, 0.1 ml of extract was mixed with 0.1 ml of distilled water, 0.4 ml of Folin reagent (1:5 H2O), and after 2 ml of 10%, Na2CO3 was added. The mixtures were kept at room temperature for 30 min before measuring the absorbance in spectrophotometer at a wavelength of 720 nm. The total phenols were expressed in mg as gallic acid equivalents (GAE).

Antioxidant activity

Antioxidant activity (AA) of MLP and gluten-free breads was evaluated by four different methods: the DPPH radicals scavenging activity [27]. ABTS radical scavenging activity [28], reducing antioxidant power (RED) [29], and OH· scavenging assay [30] were performed. All activities were expressed as EC50-extract concentrate ion that provided 50% of activity based on a dose-dependent mode of action. EC50 value (mg/ml) is the effective concentration at which the absorbance was 0.5 for RED and was obtained by interpolation from linear regression analysis. The lower EC50 value indicates a higher antioxidant activity.

Sensory evaluation

For sensory evaluation, the whole bread was divided into eight parts (slices) and the two slices for a each consumer were taken [31]. The panel for sensory evaluation consisted of 52 untrained consumers (23–48 years, 28 females and 24 males) who were habitual consumers of bread. According to a nine-point hedonic scale (1: dislike extremely, 5: neither like nor dislike, and 9: like extremely), the taste, aroma, texture, and the overall acceptability of breads were evaluated [32].

Statistical analysis

Four loaves of bread were used. All the experiments were replicated in triplicate unless otherwise stated.

Data were averaged and means were compared and evaluated using one-way analysis of variance (ANOVA) followed by the Tukey’s Significant Differences post hoc test, performed using the STATISTICA 7.0 software (StatSoft, Inc., Tulsa, OK, USA). A statistical difference at p < 0.05 was considered significant.

Results and discussion

Physical properties of gluten-free breads fortified with MLP

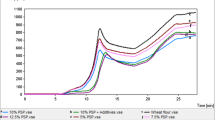

Results of specific volume, textural parameters, and crumb and crust color of obtained breads are shown in Fig. 2 and Tables 1, 2.

Specific volume The mean values of specific volume of loaves shown in Fig. 1 indicated no difference between sample containing 2.5% of MLP (2.48 cm3/g) and control bread (2.50 cm3/g); a significant decrease of specific volume was observed when higher amount of MLP was added. These results are consistent with those previously published for wheat bread enriched with MLP [4, 9].

Textural parameters

As shown in Table 1, hardness of gluten-free breads was decreased significantly with increasing MLP from 0 to 5% comparing to control bread (25.30 N). However, no significant effect was shown for bread with 7.5 and 10% of MLP on hardness of gluten-free breads in comparison with control bread. Comparing to control bread significant decrease was observed in chewiness of breads with addition MLP from 0 to 7.5%. The addition of MLP had no significant influence on springiness of obtained breads.

Color of bread

Considering color, lightness (L*) of crumb and crust decreased significantly with increasing MLP addition (Table 2). The redness (a*) of crumb was increased with the addition of MLP from 2.36 to 4.14. The highest redness was marked for bread crumb with 7.5% of MLP, and there were no significant differences between a* value for 7.5 and 10%. It could be caused by increasing the intensity of another color parameter with higher addition of MLP. Conversely, as shown in crust color, the addition of MLP from 0 to 10% decreased significantly this parameter from 13.99 to 6.37. The yellowness (b*) of crumb increased significantly with the addition of MLP (from 22.62 to 27.28). However, the yellowness (b*) of crust decreased significantly with increasing MLP addition (from 35.20 to 23.06). The total color difference of crumb and crust (ΔE) significantly increased with MLP addition from 18.84 to 37.46 for crumb and from 14.44 to 25.14 for crust. The differences in color parameters of breads are caused by pigments in MLP. As reported by [33], MLP had a deep green color related to high chlorophyll content, and this green color of MLP changes the color of bread.

Antioxidant properties

The total phenolics content (TPC) and antioxidant activity (AA) of MLP and obtained breads are shown in Table 3. Showing results of phenolic compounds, MLP present the highest value of TPC with 33.13 mg GAE/g dw. As reported by [34] analysis of hydro-methanolic extracts of Moringa, leaves revealed a wide range of phenolic compounds. Many authors also reported that the leaves of M. oleifera fresh or dried are known to be excellent source of antioxidants and they have significantly higher antioxidant content comparing to fruits such as strawberries known for high antioxidant contents [7, 35,36,37].

In general, all breads contain phenolics components. The addition of MFP significantly enriched gluten-free products with TPC from 0.88 mg GAE/g dw for control bread to 2.39 mg GAE/g dw for bread with 10% MFP. The addition of MFP already in the amount of 2.5% resulted in very large changes in the TPC from 0.88 to 2.12 GAE/g dw. Many authors reported that phenolics can form complexion with protein in matrix, and heating process also may alter phenolic antioxidants in bread during baking in different extents [38, 39].

In DPPH and ABTS radicals scavenging activity and for RED, the values were varied significantly for bread with different levels of MLP. The highest activities were found for bread with 7.5 and 10% of MLP. Instead of RED, there were no significant differences between AA of breads with 5.0 and 7.5% MLP. In general, breads with MFP had higher antioxidant activity compared to control bread. Breads with 2.5, 5.0, 7.5, and 10.0% of MLP presented a significantly higher ABTS scavenging activity (EC50 = 7.51, 6.15, 5.89, and 4.72 mg dw/ml) comparing to control bread with (EC50 = 9.95 mg dw/ml).

Scavenging of hydroxyl radicals is an important antioxidant activity because of very high reactivity of the OH· radicals, enabling it to react with a wide range of molecules found in living cells, such as sugars, amino acids, lipids, and nucleotides [40]. Thus, removing this radicals is very important for the protection of living systems. The hydroxyl radicals scavenging potential of various extracts is shown in Table 3. The lowest activity was observed for control bread. OH· radicals scavenging activity increased with increasing of MLP in bread recipe.

The highest activity was found for 7.5 and 10% of MLP addition, and these results were similar for the DPPH, ABTS, and RED. Higher antioxidant activities were found to be corresponded to higher TPC. Sowndhararajan and Kang [41] reported that the high phenolics component has more ability to quench free radicals. It must be mentioned that with low addition of MLP, there were no dose relationships for TPC, DPPH, and OH· radicals, as shown in Table 3, and according to Gawlik-Dziki et al. [42], this fact could be explained by the interactions between active compounds (mainly phenolics) and food matrix components and especially proteins and carbohydrates.

Regarding the results of the DPPH, ABTS, RED, and OH· scavenging assay, it can be concluded that the addition of MLP significantly enriched the gluten-free bread with compounds that have high antioxidant activity.

Results of sensory evaluation

Sensory evaluation showed that control bread was classified significantly with the highest scores for taste, aroma, and appearance (Table 4). These evaluation attributes decreased with the addition of MLP. The lowest evaluation of taste, aroma, and appearance was obtained for bread with 10% of MLP. The enrichment of bread with 2.5 and 5% of MLP had little influence of bread taste.

Regarding texture, there is no statistical difference with control gluten-free bread and bread with 2.5 and 5.0% of MLP. Results of overall acceptability showed that the highest value was found for control bread and bread with 2.5% of MLP against the lowest value for bread with 10% of MLP.

The lowest score for sensory attributes were obtained for bread with 10% of MLP. These can be related to the green color of the bread imparted by chlorophyll content of the MLP that affect negatively the acceptability of consumers.

Conclusion

In this study, different levels of MLP were chosen for partial replacement of formula based on rice/field bean semolina for gluten-free bread making process. The experiment results showed that gluten-free breads with higher level of MLP than 2.5% had poor physicals characteristics (low specific volume, compact texture) comparing to control gluten-free bread (p < 0.05). Sensory evaluation showed that the addition of MLP at high level affects overall acceptability of bread, and an acceptable gluten-free bread was obtained with 2.5% of MLP addition. The addition of MLP to gluten-free bread results in decrease in yellowness of color of bread which appears greenish and dark and became more pronounced with increase in MLP addition. Most importantly, the addition of MLP significantly increased TPC and AA of obtained bread. Obtained results indicated that the addition of MLP to gluten-free bread improves its nutritional quality and presents, therefore, a good material for enriching gluten-free bread with bioactive components for coeliac patients.

Abbreviations

- MLP:

-

Moringa leaf powder

- TPC:

-

Total phenolics content

- RED:

-

Reducing power

References

Morton J (1991) The horseradish tree, Moringa ptergosperma (Moringaceae)—a boon to Arid Lands? Econ Bot 45(3):318–333

Mohammed Nour AA, Mohamed AR, Adiamo OQ, Babiker EE (2016) Changes in protein nutritional quality as affected by processing of millet supplemented with Moringa seed flour Moringa. J Saudi Soc Agric Sci. doi:10.1016/j.jssas.2016.05.006

Wang Y, Gao Y, Ding H, Liu S, Han X, Gui J, Liu D (2017) Subcritical ethanol extraction of flavonoids from Moringa oleifera leaf and evaluation of antioxidant activity. Food Chem 218:152–158

Sengev AI, Abu JO, Gernah DI (2013) Effect of Moringa oleifera leaf powder supplementation on some quality characteristics of wheat bread. Food Nutr Sci 4:270–275

Teye GA, Baffoe F, Teye M (2013) Effects of Moringa (Moringa oleifera) leaf powder and dawadawa (Parkia biglobosa), on sensory characteristics and nutritional quality of frankfurter-type sausages—a preliminary study. Global Adv Res J Agri Sci 2:029–033

Hekmat S, Morgan K, Soltani M, Gough R (2015) Sensory evaluation of locally-grown fruit purees and inulin fibre on probiotic yogurt in Mwanza, Tanzania and the microbial analysis of probiotic yogurt fortified with Moringa oleifera. J Health Popul Nutr 33:60–67

Saini RK, Shetty NP, Giridhar P (2014) Carotenoid content in vegetative and reproductive parts of commercially grown Moringa oleifera Lam. cultivars from India by LC–APCI–MS. Eur Food Res Technol 238:971–978

Vázquez-León LA, Páramo-Calderón DE, Robles-Olvera VJ et al (2017) Variation in bioactive compounds and antiradical activity of Moringa oleifera leaves: influence of climatic factors, tree age, and soil parameters. Eur Food Res Technol. doi:10.1007/s00217-017-2868-4

Oyeyinka AT, Oyeyinka SA (2016) Moringa oleifera as a food fortificant: recent trends and prospects. J Saudi Soc Agric Sci. doi:10.1016/j.jssas.2016.02.002

Olaitan NI, Eke MO, Uja EM (2014) Quality evaluation of complementary food formulated from Moringa oleifera leaf powder and pearl millet (Pennisetum Glaucum) flou. Int J Eng Sci 3:59–63

Litwinek D, Ziobro R, Gambuś H, Sikora M (2014) Gluten free bread in a diet of celiacs. Int J Celiac Dis 2:11–16

Sabanis D, Tzia C, Papadakis S (2008) Effect of different raisin juice preparations on selected properties of gluten-free bread. Food Bioprocess Tech 1:374–383

Kiskini A, Kapsokefalou M, Yanniotis S, Mandala I (2012) Effect of iron fortification on physical and sensory quality of gluten-free bread. Food Bioprocess Tech 5:385–390

Krupa-Kozak U, Drabinska N (2016) Calcium in gluten-free life: health-related and nutritional implications. Rev. Foods 15:5. doi:10.3390/foods5030051

Vici G, Belli L, Biondi M, Polzonetti V (2016) Gluten free diet and nutrient deficiencies: a review. Clin Nutr 35:1236–1241

Wronkowska M, Haros M, Soral-Śmietana M (2013) Effect of starch substitution by buckwheat flour on gluten-free bread quality. Food Bioprocess Tech 6:1820–1827

Osella C, La Torre M, Sánchez H (2014) Safe foods for celiac people. Food Nutri Sci 5:787–800

Bascuñán KA, Vespa MC, Araya M (2016) Celiac disease: understanding the gluten-free diet. Rev Eur J Nutr. doi:10.1007/s00394-016-1238-5

Bourekoua H, Benatallah L, Zidoune MN, Rosell CM (2016) Developing gluten free bakery improvers by hydrothermal treatment of rice and corn flours. LWT Food Sci Technol 73:342–350

Benatallah L, Zidoune MN, Michon C (2012) Optimization of HPMC and water addition for a gluten-free formula with rice and field bean based on rheological properties of doughs. Int Rev Chem Eng 4:474–481

AACC (2000) American Association of Cereal Chemists. Approved methods of the AACC (10th ed). American Association of Cereal Chemists, St Paul, USA

Różyło R (2014) Effect of process modifications in two cycles of dough mixing on physical properties of wheat bread baked from weak flour. Food Bioprocess Tech 7:774–783

Różyło R, Dziki D, Laskowski J, Skonecki S, Łysiak G, Kulig R, Różyło K (2014) Texture and sensory evaluation of composite wheat-oat bread prepared with novel two-phase method using oat yeast fermented leaven. J Texture Stud 45:235–245

Różyło R, Rudy S, Krzykowski A, Dziki D (2015) Novel application of freeze–dried amaranth sourdough in gluten-free bread production. J Food Process Eng 38:135–143

Różyło R, Dziki D, Gawlik-Dziki U, Cacak-Pietrzak G, Miś A, Rudy S (2015) Physical properties of gluten-free bread caused by water addition. Int Agrophysics 29:353–364

Singleton VL, Rossi JA (1965) Colorimetry of total phenolics witch phosphomolybdic-phodphotungstics acid reagents. Am J Enol Vitic 16:144–158

Brand-William W, Cuvelier E, Berset CM (1995) Use of free radical method to evaluate antioxidant activity. LWT-Food Sci Technol 28:25–30

Re R, Pellegrini N, Proteggente A, Pannala A, Yang M, Rice-Evans C (1999) Antioxidant activity applying an improved ABTS radical cation decolorization assay. Free Radic Biol Med 6:1231–1237

Oyaizu M (1986) Studies on products of browning reaction—antioxidative activities of products of browning reaction prepared from glucosamine. Jpn J Nutr 44:307–315

Su XY, Wanga ZY, Liu JR (2009) In vitro and in vivo antioxidant activity of Pinus koraiensis seed extract containing phenolic compound. Food Chem 117:681–686

Matos ME, Rosell CM (2012) Relationship between instrumental parameters and sensory characteristics in gluten-free breads. Eur Food Res Technol 235(1):107–117

Lim HS, Park SH, Ghafoor K, Hwang SY, Park J (2011) Quality and antioxidant properties of bread containing turmeric (Curcuma longa L.) cultivated in South Korea. Food Chem 124:1577–1582

Karim O, Kayode R, Oyeyinka S, Oyeyinka A (2015) Physicochemical properties of stiff dough ‘amala’ prepared from plantain (Musa Paradisca) flour and Moringa (Moringa oleifera) leaf powder. Food Health Dis 4:48–58

Nouman W, Anwar F, Gull T, Newton A, Rosa E, Domínguez-Perles R (2016) Profiling of polyphenolics, nutrients and antioxidant potential of germplasm’s leaves from seven cultivars of Moringa oleifera Lam. Ind Crops Prod 83:166–176

Moyo B, Oyedemib S, Masika PJ, Muchenje V (2012) Polyphenolic content and antioxidant properties of Moringa oleifera leaf extracts and enzymatic activity of liver from goats supplemented with Moringa oleifera leaves/sunflower seed cake. Meat Sci 91:441–447

Vongsak B, Sithisarn P, Mangmool S, Thongpraditchote S, Wongkrajang Y, Gritsanapan W (2013) Maximizing total phenolics, total flavonoids contents and antioxidant activity of Moringa oleifera leaf extract by the appropriate extraction method. Ind Crops Prod 44:566–571

Gopalakrishnan L, Doriya K, Kumar DS (2016) Moringa oleifera: a review on nutritive importance and its medicinal application. Food Sci Human Wellness 5:49–56

Sivam AS, Sun-Waterhouse D, Quek SY, Perera CO (2010) Properties of bread dough with added fiber polysaccharides and phenolic antioxidants: a review. J Food Sci 75:163–174

Gawlik-Dziki U, Świeca M, Dziki D, Sęczyk L, Zlotek U, Różyło R, Kaszuba K, Ryszawy D, Czyż J (2014) Anticancer and antioxidant activity of bread enriched with broccoli sprouts. Bio Med Res Int. doi:10.1155/2014/608053

Wang H, Gao XD, Zhou GC, Cai L, Yao WB (2008) In vitro and in vivo antioxidant activity of aqueous extract from Choerospondias axillaris fruit. Food Chem 106:888–895

Sowndhararajan K, Kang SC (2013) Free radical scavenging activity from different extracts of leaves of Bauhinia vahlii Wight and Arn. Saudi J Biol Sci 20:319–325

Gawlik-Dziki U, Świeca M, Dziki D, Baraniak B, Tomiło J, Czyż J (2013) Quality and antioxidant properties of breads enriched with dry onion (allium cepa L.) skin. Food Chem 138(2–3):1621–1628

Acknowledgements

This research was funded by the exceptional National Program (PNE) from Algeria. H. Bourekoua acknowledges the financial support of Institut de la Nutrition, de l’Alimentation et des Technologies Agro-Alimentaires (INATAA). Experiments were also supported by the statutory funds of University of Life Science in Lublin, Poland.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There are no conflicts of interest to declare.

Compliance with ethics requirements

This article does not contain any studies with human participants or animals performed by any of the authors.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Bourekoua, H., Różyło, R., Gawlik-Dziki, U. et al. Evaluation of physical, sensorial, and antioxidant properties of gluten-free bread enriched with Moringa Oleifera leaf powder. Eur Food Res Technol 244, 189–195 (2018). https://doi.org/10.1007/s00217-017-2942-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-017-2942-y