Abstract

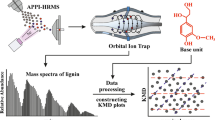

Sample preparation of complex, natural mixtures such as lignin prior to mass spectrometry analysis, however minimal, is a critical step in ensuring accurate and interference-free results. Modern shotgun-MS techniques, where samples are directly injected into a high-resolution mass spectrometer (HRMS) with no prior separation, usually still require basic sample pretreatment such as filtration and appropriate solvents for full dissolution and compatibility with atmospheric pressure ionization interfaces. In this study, sample preparation protocols have been established for a unique sample set consisting of a wide variety of degraded lignin samples from numerous sources and treatment processes. The samples were analyzed via electrospray (ESI)-HRMS in negative and positive ionization modes. The resulting information-rich HRMS datasets were then transformed into the mass defect space with custom R scripts as well as the open-source Constellation software as an effective way to visualize changes between the samples due to the sample preparation and ionization conditions as well as a starting point for comprehensive characterization of these varied sample sets. Optimized conditions for the four investigated lignins are proposed for ESI-HRMS analysis for the first time, giving an excellent starting point for future studies seeking to better characterize and understand these complex mixtures.

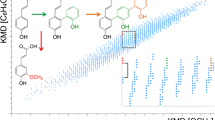

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Lignin is the most abundant natural aromatic polymer and an exciting renewable resource with a diverse range of applications [1], including fossil fuel replacement in bioethanol production [2] and use in the sustainable production of bulk chemicals [3]. However, its innately complex structure, consisting of a number of common monomers and other substructures [4], which can cross-link in a variety of ways, presents a considerable analytical challenge [5]. In the last few decades, developments in mass spectrometry have vastly expanded the capabilities of the technique for characterizing complex samples (such as NOM [6], crude oil [7], or lignin [8]) without the need for extensive sample preparation or chromatography. However, there are still many factors to consider before a complex natural sample can be introduced to an MS instrument, even when minimal sample preparation is performed. When attempting to retain as many components of the sample as possible in an intact, non-fragmented state, including very high MW components, there needs to be a careful consideration of which solvents, additives, and filtration techniques are employed in the preparation stages.

Lignin can be categorized in various ways — by the source of the lignin, the industrial process from which particular types of lignin are derived, and the pretreatments applied to the lignin for various purposes [9]. Sources of lignin include hardwoods, softwoods, and grasses, which have often undergone industrial pulping processes — including alkaline (Kraft and soda) or organosolv [10] — which can affect the structure and composition of the lignin. Pretreatments can also play a significant role in determining the character of the lignin being studied, including high-pressure steaming (with or without explosion), acid hydrolysis, milling, microwave irradiation, enzymatic and chemical degradation, or biological pretreatment [11]. Many of these pretreatments can induce depolymerization/fragmentation of the lignin. Lignin can also be broadly categorized as sulfur or sulfur-free. Examples of sulfur lignins are lignosulfonates or lignins from the Kraft process [12]. Sulfur-free lignins include soda, alkaline, or organosolv lignins [13]. The source and characteristics of each particular sample can mean that there may be a different ideal combination of sample preparation steps and/or different ionization techniques prior to MS analysis [14]. A small selection of the literature on sample preparation for API-MS of lignin will be presented in this introduction; however, a more comprehensive review is available in the Supporting Information in Table S1.

While some direct injection techniques such as pyrolysis combined with API-HRMS [15] do not require a prior solvent extraction, many others do, and selecting a solvent for dissolution of a polymer can be challenging. Unlike non-polymeric materials, polymers do not dissolve instantaneously and the dissolution is controlled by either the disentanglement of the polymer chains or by the diffusion of the chains through a boundary layer adjacent to the polymer–solvent interface [16]. Lignin is no exception. Although lignin is known to exhibit high solubility in pyridine and DMSO [17, 18], a variety of industrial solvents [19], and various ionic liquids [20, 21], these solvents are not amenable to atmospheric pressure ionization (API) for liquid chromatography-mass spectrometry (LC–MS) and can also be quite harsh, resulting in unwanted reactions or corrosion [14]. In addition, lignins from various sources may be better suited to certain solvent mixtures — for example, organosolv lignin can be dissolved in various organic solvents, with the highest solubility observed in methanol and dioxane [22], whereas LignoBoost and Kraft lignins are better matched with ethanol, acetic acid, or methanol [23]. In general, pure organic solvents (acetonitrile, THF) or water is not usually able to completely dissolve lignin to give a true solution [24]. Molecular dynamics solvation simulations have showed that different water/co-solvent mixtures (e.g., water/acetone, dioxane/water, or THF/water) that exhibit an intermediate polarity can be ideal for the lignin polymer [25], with the optimal ratio depending on the lignin source. Table 1 highlights several solvents used for API-MS analysis of various lignins.

After dissolving lignin in a suitable solvent, it is still often necessary to perform a filtration step prior to MS analysis to ensure any particulate impurities and/or bacteria [29] are removed. Microfiltration (0.1–0.45 μm) is usually performed for this purpose, although filters of smaller pore sizes can also be used as a way to fractionate lignin into different molecular weights [30]. The membrane material for filtration is an important consideration. Cellulose offers low protein binding characteristics [31] and has been used in filtering “dirty” water samples [32]; however, others have used polytetrafluoroethylene (PTFE) [33, 34] and polyethersulfone (PES) [35, 36] filters for the same reason. Membrane sizes are usually 0.2–0.45 μm.

High-resolution mass spectrometry has long been established as a powerful tool for characterizing lignin [8]. A great variety of MS-based techniques have been utilized for this purpose, including hybrid methods involving chromatography as well as “shotgun” techniques, where a complex mixture is directly injected, often via an API interface, without prior separation. Other studies [14, 37] have extensively compared different API methods for effective ionization of lignin, either degraded or intact. Briefly, APPI has been successfully used to characterize a variety of lignins [38,39,40,41,42], with some noting improved signal intensities and a lower sensitivity to contaminants when compared to APCI and ESI [37]. APCI has been noted for its abilities to more successfully ionize weakly polar lignin molecules, and reduce matrix effects [37]. However, others have observed that APCI and APPI are often limited to a low MW range (< 1800 Da) and singly charged ions, and APCI can result in unwanted fragmentation of lignin in the ion source [24]. Therefore, out of the available API techniques, ESI tends to be the most common choice for lignin analysis. One study found that out of all API techniques surveyed, ESI performed the best for lignin-like species (O/C 0.2–0.6 and H/C 0.7–1.5), and ionized some sulfur-containing lignin species not observed in APCI or APPI [43]. The same study observed that a greater number of elemental formulae were found when using ESI − mode when compared to ESI + or APCI/APPI in either mode [43]. ESI does come with limitations, and given that it performs best in the analysis of polar compounds, it will be best suited for studying high- and medium-polarity lignin components [44]. However, the ubiquity of this technique in the literature makes it easy to compare results to other published research, and it is therefore an obvious choice when selecting a single ionization technique to compare the various sample preparation conditions that are the focus of this study.

Once HRMS spectra have been collected, there are numerous techniques to untangle and interpret the highly complex data [39, 45, 46]. Among the most popular are Kendrick mass defect plots, which exploit high-accuracy mass information to transform MS data into the so-called mass defect space, revealing patterns due to repeating structural motifs [47]. Several recent studies have employed this technique to remove undesired mass spectral features [48], process congested spectra of polymers with multiple charges [49], and screen for poly- and perfluroalkyl substances in contaminated soil [50], among many other studies including numerous analyses of lignin [39]. Custom algorithms and software tools have also played a major role in many recent publications when processing the data resulting from HRMS analyses of complex samples such as lignin [51,52,53,54,55,56]. Among these are various open-source software solutions, including the web-based software Constellation (previously developed in-house), which allows expansion and manipulation of HRMS data into the mass defect space, as well as algorithms which are able to automatically find repeating patterns (potentially corresponding to repeating units in polymers or molecules with moieties of changing mass) or assign molecular formulae to masses in the HRMS dataset [57, 58].

In this work, we present the optimized sample preparation of a unique sample set of lignins from various sources and treatment processes, followed by characterization via ESI-HRMS and subsequent data analysis with custom mass defect analysis software tools developed in-house. Although a number of reviews have been conducted of various mass spectrometry-based analytical techniques for lignin (MALDI-MS [59], API-MS [37], ESI–MS [24]), to our knowledge, this is the first study attempting to systematically optimize conditions for ESI-HRMS analysis of a highly varied set of lignin samples. After deciding on sample preparation protocols and selecting a set of solvent mixtures to test, we performed HRMS experiments and used custom mass defect analysis software to transform and visualize the spectra in the mass defect space, as well as to assign molecular formulae based on the exact masses. From this analysis, we were able to characterize several groupings visible in the mass defect space based on their mass and mass defect ranges, as well as DBE, H/C and O/C ratios, and any heteroatom classes present. Of particular interest are the noted differences in these groupings between lignin samples from various sources and pretreatments, and between the different solvents used for extraction and ionization. In general, we observed that the choice of solvent mixture is of critical importance when optimizing sample preparation for degraded versus non-degraded lignins, and for lignins from different sources. We found that depending on the lignin source or treatment, use of a particular solvent mixture versus another may result in some components of the lignin (visible as groupings of peaks in the mass defect space) not being fully extracted or ionized in an API source. Solvent choice and preparation conditions are therefore important considerations before ionization and HRMS analysis when attempting to acquire a complete picture of any given lignin sample being studied.

Materials and methods

Chemicals and materials

HPLC–MS grade acetonitrile (AcN) was obtained from Chemsolute (Th. Geyer GmbH & Co. KG, Renningen, Germany); methanol (MeOH) from VWR Chemicals (Darmstadt, Germany); and acetone (AC) and ethanol (EtOH) from Carl Roth GmbH & Co. KG (Karlsruhe, Germany). Organic-free water (H2O) was generated by a Millipore (Bedford, MA, USA) Direct-Q8 purification system.

Lignin samples

A large variety of powdered lignin samples from various sources and process types were kindly provided by LignoPure GmbH [60]. From these samples, we chose four (LP3, LP5, LP7, LP9) to represent lignin originating from different sources (i.e., hardwood, softwood), having undergone various treatments (i.e., organosolv, steam treatment) and in different states of degradation (i.e., having undergone enzymatic hydrolysis or not). Table 2 lists the investigated samples along with their associated process type and Klason lignin content.

Solvent mixtures

Ten different solvent mixtures were evaluated in terms of dissolution for lignin and minimum background noise and enhanced ionization during MS analysis: acetone:H2O (1:1, v/v), MeOH:H2O (1:1, v/v), EtOH:H2O (1:1, v/v), AcN:H2O (1:1, v/v), MeOH:H2O (3:1, v/v), AcN:H2O (3:1, v/v), MeOH:H2O (1:3, v/v), AcN:H2O (1:3, v/v), acetone:AcN:H2O (1:1:2, v/v/v), acetone:MeOH:H2O (1:1:2, v/v/v). The selection of these solvents was based on an extensive review of the literature regarding known preparations of lignin and lignin model compounds prior to direct analysis by API-MS, available in Table S1 in the Supporting Information. The solvent mixtures along with their associated organic/aqueous ratios are listed in Table 3.

Sample preparation of lignin

Ten milligrams of each lignin sample was dissolved in 4 mL of each solvent mixture at room temperature and then vortexed for 1 min. Subsequently, centrifugation at 9000 rpm took place for 7 min, after which 0.2 mL of the supernatant was transferred to 10 mL of the same solvent mixture. Finally, the diluted sample was filtered through a Millex syringe filter (0.45 µm pore size, 25 mm diameter, Millex-HA mixed cellulose esters membrane, hydrophilic, Merck Millipore Ltd., Tullagreen, Carrigtwohill, Co Cork, Ireland) prior to storage in the final sample container to ensure that there were no remaining particles. In addition, solvent blanks were included in this sample preparation process, undergoing the exact same treatment as the lignin samples. The resulting sample blank spectra were subsequently subtracted from the spectra of the lignin-containing samples to try and mitigate any potential contamination from polar components at this stage.

It should be noted that although all samples underwent a full solvent extraction, as is standard for most studies in the literature analyzing lignin via API-MS, not every sample fully dissolved in each solvent mixture, and it is therefore possible that there were a variety of lignin components not extracted during sample preparation due to their high MW and low solubility. This would render these lignin components invisible in our analyses, and this is considered when discussing results and comparing samples.

Mass spectrometry

Prior to MS analysis, samples were diluted tenfold in their respective solvents. To some samples, 0.1% formic acid was added to the diluted solutions to enhance protonation. All samples including solvent blanks were analyzed on a 15-T Bruker Solarix XR FT-ICR (Bruker, Bremen, Germany) using a dynamically harmonized cell in 1-omega mode acquired with a 4-megaword (32-bit integer) transient. Two hundred average scans were acquired for all data files with an accumulation time of 0.2 s in broadband mode. No phasing was performed on the data. Data was acquired in both positive and negative ion modes. Samples were ionized using a home-built nESI source with a nichrome wire placed into the sample for the ground electrical connection. All samples were directly infused into the mass spectrometer.

All data files (samples and solvent blanks) were calibrated externally using Hpmix (Agilent Technologies, Santa Clara, USA), selecting reference peaks that covered the entire m/z range of the samples. Once calibrated, solvent blanks were subtracted from the samples to minimize peaks not related to the sample itself. The solvent subtracted data files were then exported as “.xy” (ASCII text files) for analysis, summarized as two columns of data, “m/z” (mass-to-charge ratio) and “I” (intensity). Data calibration, subtraction, and extraction were performed in Bruker DataAnalysis 5.0 software.

Data processing

All data files were loaded into RStudio 2022.07.2 Build 576 via custom R scripts, where data processing and analysis were then carried out with the help of various R packages including tidyverse, dplyr, and gatepoints [61] as well as default built-in R functions. All peaks with less than 1% normalized intensity were filtered out of all mass spectra unless otherwise noted. Figures were first generated using ggplot2 [62] in R and then exported as “.png” files and in some cases, further customized in Adobe Illustrator 2022.

Molecular formula finding was performed using the open-source CoreMS SearchMolecularFormulas function [63] built into the Constellation mass defect analysis web application [57] previously developed by our group. This application allows users to upload their raw MS data, transform it into the mass defect space, and perform various data analysis and visualization functions, including molecular formula finding. Settings for molecular formula finding are fully user-selectable, and for this study, the parameters were as follows: minimum error − 0.5 ppm, maximum error 0.5 ppm; minimum DBE 0, maximum DBE 50; MS noise threshold 3; elemental limits: C 1–90, H 4–200, O 1–23, N 0–5, S 0–1. All other settings were left to their defaults in Constellation. These defaults include a search for all isotopes including automatic fine isotopic structure calculation [63], and exclusion of adducts from elemental composition determination. In the case that multiple molecular formulae matched a particular HRMS peak, the formula with the lowest m/z error (highest mass accuracy) was chosen. However, as with any complex mixture, the assignment of molecular formulae using only high-resolution mass information is decidedly tentative, and caution should be used in interpreting results. The resulting “.csv” files of formula information (including molecular formulae, heteroatom classes, DBE, and H/C and O/C ratios) were then loaded into R, and the information was matched with corresponding peaks in the HRMS spectra via the index of each point from the raw MS data files.

Results and discussion

A diverse set of lignin samples were prepared in various solvents, ionized via ESI in both positive and negative modes, and analyzed via HRMS and custom mass defect analysis software. The results from all stages of the study indicated a high level of variation in spectral composition among both samples from various sources and treatment processes, and different solvent mixtures used in extraction and ionization. A summary of the experiments conducted is presented in Table 4, which are described in detail individually in the following sections.

General qualitative observations during sample preparation

During sample preparation, qualitative observations were noted regarding how each powdered lignin sample interacted with each solvent mixture upon contact and mixing (after vortexing, but prior to the centrifugation and filtering steps). A “variation score” from 1–3 was established, where samples were ranked according to how much variation they exhibited after their initial mixing with the 8 different solvent mixtures: 1 = very little variation, 2 = some variation, 3 = dramatic variation between solvent mixtures. Variation was observed for 3 categories: color, residue, and “milkiness.” We then summed these variation scores to give a total score out of 9, and then ranked the samples according to this total score, in order to select a lignin exhibiting high variation among solvents for an initial set of HRMS experiments. The full results are summarized in the Supporting Information (Table S2).

The hardwood lignin LP3 from the organosolv process, with no prior enzymatic degradation, exhibited the highest qualitative variation score (8) during this sample preparation stage and was thus chosen for an initial run of experiments comparing all solvent mixtures under 3 different ionization conditions, with the expectation that these qualitative observations of variation would translate into distinct spectral differences after HRMS and data analysis.

Characterization of a non-degraded hardwood lignin sample

Full-scan mass spectra were measured from m/z 100–2000 for the LP3 sample in all solvent mixtures in both ESI − and ESI + modes (ESI + mode, with and without formic acid). From each spectrum, we subtracted the solvent blank spectrum, and exported a mass list to a text file. We then calculated molecular formula information for each peak using the molecular formula finding algorithm from CoreMS [63], running in the Constellation software environment [57], as described in the “Materials and methods” section. The resulting spectra were highly complex, containing hundreds to thousands of peaks, many with an associated molecular formula. Figure 1 shows an example of one of these spectra for the LP3 sample in 1:1 AcN:H2O, ionized in ESI − mode, and partially annotated (for clarity’s sake) with molecular formula information. As in the analysis of many complex mixtures via HRMS, these are tentative molecular formulae assignments, and should be interpreted with caution.

The total number of peaks in each spectrum (corresponding to the total number of non-background ions observed) was used as an initial step to ascertain how much ionizable lignin material each solvent mixture had extracted during sample preparation. For each sample set (ESI − , ESI + , ESI + with formic acid), the data was sorted according to the number of peaks observed in each spectrum. The full results are summarized in the Supporting Information (Table S3).

Results showed that for this hardwood, non-degraded lignin, the best solvent mixture for both positive and negative ionization modes was 1:1 AcN:H2O, and the best for positive mode with formic acid addition was 1:1 MeOH:H2O. On average, there were slightly more ions observed in ESI + mode without formic acid added than with (~ 10% increase), and a wealth of additional ions observed in negative over positive ion mode (~ 200% increase). Overall rankings suggest that solvents with an organic/aqueous ratio of 0.5 or greater are ideal for this lignin sample and that 1:1 AcN:H2O is likely the best choice over all ionization modes. However, this only represents one strategy for ranking the effectiveness of these solvent mixtures and does not consider more subtle variances in spectrum composition which may be worth considering and are therefore discussed next.

Characterization in ESI − mode across all solvent mixtures

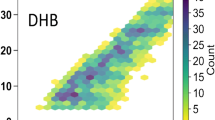

As previously observed [39, 45, 49, 57, 64], transforming a high-resolution mass spectrum into the mass defect space can allow for the insightful observation of patterns and/or groupings of peaks in the spectra. Here, we wanted to use this transformation to better characterize the effectiveness of each solvent mixture used in sample preparation in extracting and ionizing various components of our lignin mixtures. The same set of spectra collected for the hardwood, non-degraded lignin (LP3) in the previous step were transformed into the mass defect space via the CH2 base (nominal mass 14, exact mass 14.01565). In the resulting graphs of Kendrick mass versus Kendrick mass defect, we observed four distinct groupings of peaks, as shown in Fig. 2. An area with < 5 peaks was not considered to be a group. Each grouping was then selected directly on the graphs (generated using ggplot2 [62] in R) using the gatepoints [61] package. This gave a list of indices for each point in the grouping, allowing us to match each point with any corresponding molecular formula information.

As previously mentioned, for each spectrum, we ran the molecular formula finding algorithm from CoreMS [63], running on a server at HU Berlin and accessible via an interface built into the Constellation mass defect analysis software developed by our group [58]. This molecular formula data allowed us to better characterize these groupings of peaks and make distinctions not only based on their positioning in the mass defect space (KM and KMD), but also based on their DBE, H/C and O/C ratios, and heteroatom classes present. These data are summarized in Table 5.

Based on these results for the hardwood, non-degraded lignin LP3 in all solvent mixtures in ESI − mode, we can summarize our observations as follows:

-

Groupings 3 and 4 contain compounds with higher H/C ratios, lower O/C ratios, and lower DBE than groupings 1 and 2

-

Solvent mixtures with an organic/aqueous ratio ≥ 0.5 provide improved extraction and ionization of compounds in groupings 1 and 4

-

Solvent mixtures with an organic/aqueous ratio ≤ 0.5 exhibit better extraction and ionization of compounds in groupings 2 and 3

-

The solvent mixtures which extracted and ionized the largest number of components for all groups were 1:1 EtOH:H2O and 1:1 AcN:H2O

-

3:1 AcN:H2O and 1:1:2 acetone:AcN:H2O did not extract or ionize any material from any of the 4 groupings and were therefore the worst solvent mixture choices for this lignin sample in ESI − mode

Characterization in ESI + mode across all solvent mixtures

An identical process of identifying and characterizing groups of peaks was conducted for mass defect-transformed HRMS spectra of the same non-degraded hardwood lignin (LP3) for all solvent mixtures in ESI + mode. Figure 3 displays these spectra in the base CH2 (14/14.01565) mass defect space, where we observed three distinct groupings of peaks. As before, an area with < 5 peaks was not considered to be a group.

As before, this was followed by further characterization of these groupings via DBE, H/C and O/C ratios, and heteroatom classes obtained from the molecular formula calculations. These data are summarized in Table 6.

Based on these results for the hardwood, non-degraded lignin LP3 in all solvent mixtures in ESI + mode, we can summarize our observations as follows:

-

Groupings 2 and 3 share the same optimum solvents and contain compounds with similar H/C and O/C ratios

-

Grouping 3 contains compounds with higher DBE than groupings 1 and 2

-

Solvent mixtures with an organic/aqueous ratio ≥ 0.5 performed better at extracting and ionizing compounds in groupings 2 and 3

-

The solvent mixtures which extracted and ionized the largest number of components for all groups were 1:1 acetone:H2O, 1:1 AcN:H2O, and 3:1 MeOH:H2O

-

1:3 MeOH:H2O did not extract or ionize any material from any of the 3 groupings and was therefore the worst choice for this lignin sample in ESI + mode

Comparison of lignin samples across all solvent mixtures and ionization modes

From our inventory of samples, we selected another three lignins in addition to the hardwood, non-degraded lignin (LP3) to analyze with all of our solvent mixtures in both ionization modes: degraded lignins from grasses (LP5), degraded lignins from softwood (LP7), and degraded lignins from hardwood (LP9). This selection allowed us to compare lignins from three different sources (hardwood, softwood, grasses) and those which have been degraded via enzymatic hydrolysis versus those which have not. An identical data analysis process from the previous sections was conducted for these samples, where groupings of peaks were categorized for each ionization mode and characterized via information gathered from molecular formula data.

Characterizing degraded versus non-degraded lignins

Comparing two hardwood lignins, one degraded via enzymatic hydrolysis (LP9) and one left intact (LP3), it was clear that there were significant differences in both the amount of extracted/ionized material and the groupings of peaks observed in the mass defect-transformed HRMS spectra. In ESI + mode, the differences in number of peaks and variety of groupings extracted and ionized were significantly impacted by the choice of solvent mixture. More components of the degraded lignin (LP9) were extracted/ionized with a low organic/aqueous ratio (< 0.5) solvent mixture, whereas more components of the non-degraded lignin (LP3) were extracted/ionized with solvents with an organic/aqueous ratio of 0.5. The degraded lignin also exhibited several groupings of peaks (groupings 4 and 5) not observed in the non-degraded lignin. The characteristics of these unique groupings are presented in Table 7.

In ESI − mode, differences between solvent mixtures were less pronounced and groupings of peaks looked similar between samples. For both hardwood lignin samples, solvent mixtures with a higher organic/aqueous ratio (0.75, e.g., 3:1 AcN:H2O) performed poorly in this mode. The same poor performance was observed for tri-solvent mixtures (e.g., 1:1:2 acetone:MeOH:H2O, 1:1:2 acetone:AcN:H2O) for both the degraded and non-degraded samples in this mode. Table 8 summarizes the observations and suggests optimized solvent mixtures for each lignin and each ionization mode.

Characterizing lignin from softwood, hardwood, and grasses

We also compared lignins across various sources that had otherwise experienced a similar treatment process (i.e., all had undergone degradation via enzymatic hydrolysis). We chose three degraded lignins from softwood (LP7), hardwood (LP9), and grass (Miscanthus, LP5) sources. In ESI + mode, differences in the spectra between the three samples were quite pronounced across the various solvent mixtures. For both the softwood lignin (LP7) and the lignin from grasses (LP5), the solvent mixture of 1:1:2 acetone:AcN:H2O extracted a grouping of peaks (grouping 5) not seen to this degree or at all in other solvents or in the hardwood lignin (LP9) in this mode. 1:1:2 acetone:AcN:H2O also ranked as the best solvent in positive ion mode for LP5 and 7, whereas it performed the worst for LP9. For all 3 samples in this mode, the solvent mixture of 3:1 AcN:H2O was the best at extracting/ionizing a grouping of peaks (grouping 4) common to all samples.

In ESI − mode, differences in spectra were less obvious between solvents and groupings of peaks looked similar between samples. However, the similarities between the softwood and grass lignins (LP5 and LP7) and their shared differences in comparison with the hardwood lignin (LP9), which were observed in ESI + mode, were also observed in ESI − mode. Specifically, the mixtures of 1:1 AcN:H2O and 1:1:2 acetone:AcN:H2O ranked highly for LP5 and 7, but not for LP9, and the mixture of 1:3 MeOH:H2O ranked highly for LP9 but not for LP5 and 7. In general, across both ionization modes, it seems that the hardwood lignin sample (LP9) seemed better suited to solvent mixtures with lower organic/aqueous ratios than the grass and softwood lignins (LP5 and 7). Table 9 summarizes these results.

Conclusions

In this work, we have demonstrated how the choice of solvent mixture during sample preparation, extraction, and ionization steps can drastically affect the results of ESI-HRMS analyses of powdered lignin samples. We have presented a sample preparation method involving a number of different solvent mixtures for a variety of lignins from various sources and treatment processes, followed by analysis via ESI-HRMS in both positive and negative ionization modes. We then characterized these lignins using different procedures, including assigning tentative molecular formulae and identifying groupings of peaks within the detailed HRMS spectra after transformation into the mass defect space and analysis with custom software routines. Significant differences were noted in these groupings, which varied with solvent mixture, lignin source, and the degree of lignin degradation. Through this, we have suggested optimized solvent choices for sample preparation of various lignins depending on lignin origin and treatment process.

Our results indicate that differences between lignin samples from various sources are much more pronounced in positive ion mode, and lignins from grasses and softwood (LP5 and 7) have more groupings of peaks in common with each other than they do with hardwood lignin (LP9) after enzymatic hydrolysis (degradation). However, if degradation has not occurred for all samples, the differences when comparing between various sources are less pronounced (as would be expected, as here the results are not truly comparable). In general, we observe that the choice of solvent mixture is very important when optimizing sample preparation for degraded versus non-degraded lignins, and for lignins from different sources.

References

Saito T, Brown RH, Hunt MA, Pickel DL, Pickel JM, Messman JM, Baker FS, Keller M, Naskar AK. Turning renewable resources into value-added polymer: development of lignin-based thermoplastic. Green Chem. 2012;14:3295–303. https://doi.org/10.1039/C2GC35933B.

Yuan Y, Jiang B, Chen H, Wu W, Wu S, Jin Y, Xiao H. Recent advances in understanding the effects of lignin structural characteristics on enzymatic hydrolysis. Biotechnol Biofuels. 2021;14:205. https://doi.org/10.1186/s13068-021-02054-1.

Zakzeski J, Bruijnincx PCA, Jongerius AL, Weckhuysen BM. The Catalytic Valorization of Lignin for the Production of Renewable Chemicals. Chem Rev. 2010;110:3552–99. https://doi.org/10.1021/cr900354u.

del Río JC, Rencoret J, Gutiérrez A, Elder T, Kim H, Ralph J. Lignin Monomers from beyond the Canonical Monolignol Biosynthetic Pathway: Another Brick in the Wall. ACS Sustainable Chem Eng. 2020;8:4997–5012. https://doi.org/10.1021/acssuschemeng.0c01109.

Ralph J, Lapierre C, Boerjan W. Lignin structure and its engineering. Curr Opin Biotechnol. 2019;56:240–9. https://doi.org/10.1016/j.copbio.2019.02.019.

Qi Y, Fu P, Volmer DA. Analysis of natural organic matter via fourier transform ion cyclotron resonance mass spectrometry: an overview of recent non-petroleum applications. Mass Spectrom Rev. 2022;41:647–61. https://doi.org/10.1002/mas.21634.

Cho Y, Ahmed A, Islam A, Kim S. Developments in FT-ICR MS Instrumentation, Ionization Techniques, and Data Interpretation Methods for Petroleomics. Mass Spectrom Rev. 2015;34:248–63. https://doi.org/10.1002/mas.21438.

Letourneau DR, Volmer DA. Mass spectrometry-based methods for the advanced characterization and structural analysis of lignin: A review. Mass Spectrom Rev. 2021;42:144–88. https://doi.org/10.1002/mas.21716.

Nasrullah A, Bhat AH, Khan AS, Ajab H. 9 - Comprehensive approach on the structure, production, processing, and application of lignin. In: Jawaid M, Tahir PM, Saba N, editors. Lignocellulosic Fibre and Biomass-Based Composite Materials. Woodhead Publishing; 2017. p. 165–78.

Latif NHA, Brosse N, Ziegler-Devin I, Chrusiel L, Hashim R, Hussin MH. A comparison of alkaline and organosolv lignin extraction methods from coconut husks as an alternative material for green applications. BioResources. 2022;17:469–91.

Pereira Ramos L. The Chemistry Involved in the Steam Treatment of Lignocellulosic Materials. Química Nova. 2003;26. https://doi.org/10.1590/S0100-40422003000600015.

Aro T, Fatehi P. Production and Application of Lignosulfonates and Sulfonated Lignin. Chemsuschem. 2017;10:1861–77. https://doi.org/10.1002/cssc.201700082.

Nadif A, Hunkeler D, Käuper P. Sulfur-free lignins from alkaline pulping tested in mortar for use as mortar additives. Biores Technol. 2002;84:49–55. https://doi.org/10.1016/S0960-8524(02)00020-2.

Kubátová A, Andrianova AA, Hatton J, Kozliak EI. Atmospheric pressure ionization mass spectrometry as a tool for structural characterization of lignin. Rapid Commun Mass Spectrom. 2020;34. https://doi.org/10.1002/rcm.8813.

Zhou Z, Zhu L, Cui C, Liu H, Shen Y, Yuan W, Qi F. Pyrolysis of lignocellulosic biomass: Molecular-level insights with online ultrahigh-resolution mass spectrometry. Fuel Process Techn. 2022;236:107439. https://doi.org/10.1016/j.fuproc.2022.107439.

Miller-Chou BA, Koenig JL. A review of polymer dissolution. Prog Polym Sci. 2003;28:1223–70. https://doi.org/10.1016/S0079-6700(03)00045-5.

Shukry N, Fadel SM, Agblevor FA, El-Kalyoubi SF. Some physical properties of acetosolv lignins from bagasse. J Appl Polym Sci. 2008;109:434–44. https://doi.org/10.1002/app.28059.

Sameni J, Krigstin S, Sain M. Solubility of Lignin and Acetylated Lignin in Organic Solvents. BioResources. 2017;12:1548–65.

Dastpak A, Lourenҫon TV, Balakshin M, Hashmi SF, Lundström M, Wilson BP. Solubility study of lignin in industrial organic solvents and investigation of electrochemical properties of spray-coated solutions. Ind Crops Prod. 2020;148:112310. https://doi.org/10.1016/j.indcrop.2020.112310.

Xue Z, Zhao X, Sun R, Mu T. Biomass-Derived γ-Valerolactone-Based Solvent Systems for Highly Efficient Dissolution of Various Lignins: Dissolution Behavior and Mechanism Study. ACS Sustainable Chem Eng. 2016;4:3864–70. https://doi.org/10.1021/acssuschemeng.6b00639.

Melro E, Alves L, Antunes FE, Medronho B. A brief overview on lignin dissolution. J Mol Liq. 2018;265:578–84. https://doi.org/10.1016/j.molliq.2018.06.021.

Cybulska I, Brudecki G, Rosentrater K, Julson JL, Lei H. Comparative study of organosolv lignin extracted from prairie cordgrass, switchgrass and corn stover. Biores Technol. 2012;118:30–6. https://doi.org/10.1016/j.biortech.2012.05.073.

Giummarella N, Lindgren C, Lindström M, Henriksson G. Lignin Prepared by Ultrafiltration of Black Liquor: Investigation of Solubility, Viscosity, and Ash Content. Bioresources. 2016;11:3494. https://doi.org/10.15376/biores.11.2.3494-3510.

Andrianova AA, DiProspero T, Geib C, Smoliakova IP, Kozliak EI, Kubátová A. Electrospray Ionization with High-Resolution Mass Spectrometry as a Tool for Lignomics: Lignin Mass Spectrum Deconvolution. J Am Soc Mass Spectrom. 2018;29:1044–59. https://doi.org/10.1007/s13361-018-1916-z.

Vermaas JV, Crowley MF, Beckham GT. Molecular Lignin Solubility and Structure in Organic Solvents. ACS Sustainable Chem Eng. 2020;8:17839–50. https://doi.org/10.1021/acssuschemeng.0c07156.

Wang G, Chen H. Fractionation and characterization of lignin from steam-exploded corn stalk by sequential dissolution in ethanol–water solvent. Sep Purif Technol. 2013;120:402–9. https://doi.org/10.1016/j.seppur.2013.10.029.

Lin Y, Pang Y, Li Z, Zhou M, Lou H, Qiu X. Thermo-Responsive Behavior of Enzymatic Hydrolysis Lignin in the Ethanol/Water Mixed Solvent and Its Application in the Controlled Release of Pesticides. ACS Sustainable Chem Eng. 2021;9:15634–40. https://doi.org/10.1021/acssuschemeng.1c06061.

Domínguez-Robles J, Tamminen T, Liitiä T, Peresin MS, Rodríguez A, Jääskeläinen A-S. Aqueous acetone fractionation of kraft, organosolv and soda lignins. Int J Biol Macromol. 2018;106:979–87. https://doi.org/10.1016/j.ijbiomac.2017.08.102.

Sleighter RL, Hatcher PG. Fourier transform mass spectrometry for the molecular level characterization of natural organic matter: instrument capabilities, applications, and limitations. InTech Open; 2011:295–320. https://doi.org/10.5772/15959.

Aminzadeh S, Lauberts M, Dobele G, Ponomarenko J, Mattsson T, Lindström ME, Sevastyanova O. Membrane filtration of kraft lignin: Structural charactristics and antioxidant activity of the low-molecular-weight fraction. Ind Crops Prod. 2018;112:200–9. https://doi.org/10.1016/j.indcrop.2017.11.042.

Joshi V, Chernokalskaya E. Filtration as a Sample Preparation Technique Prior to Mass Spectrometry: Selecting the Right Filtration Device; 2011. pp. 61–75.

Kern S, Fenner K, Singer HP, Schwarzenbach RP, Hollender J. Identification of Transformation Products of Organic Contaminants in Natural Waters by Computer-Aided Prediction and High-Resolution Mass Spectrometry. Environ Sci Technol. 2009;43:7039–46. https://doi.org/10.1021/es901979h.

Reymond C, Dubuis A, Le Masle A, Colas C, Chahen L, Destandau E, Charon N. Characterization of liquid–liquid extraction fractions from lignocellulosic biomass by high performance liquid chromatography hyphenated to tandem high-resolution mass spectrometry. J Chromatogr A. 2020;1610. https://doi.org/10.1016/j.chroma.2019.460569.

Kaserzon SL, Heffernan AL, Thompson K, Mueller JF, Ramos MJG. Rapid screening and identification of chemical hazards in surface and drinking water using high resolution mass spectrometry and a case-control filter. Chemosphere. 2017;182:656–64. https://doi.org/10.1016/j.chemosphere.2017.05.071.

Zhang H, Zhang Y, Shi Q, Ren S, Yu J, Ji F, Luo W, Yang M. Characterization of low molecular weight dissolved natural organic matter along the treatment trait of a waterworks using Fourier transform ion cyclotron resonance mass spectrometry. Water Res. 2012;46:5197–204. https://doi.org/10.1016/j.watres.2012.07.004.

Fox PM, Nico PS, Tfaily MM, Heckman K, Davis JA. Characterization of natural organic matter in low-carbon sediments: Extraction and analytical approaches. Org Geochem. 2017;114:12–22. https://doi.org/10.1016/j.orggeochem.2017.08.009.

Kosyakov DS, Ul’yanovskii NV, Anikeenko EA, Gorbova NS. Negative ion mode atmospheric pressure ionization methods in lignin mass spectrometry: A comparative study. Rapid Commun Mass Spectrom. 2016;30:2099–2108. https://doi.org/10.1002/rcm.7686.

Banoub JH, Benjelloun-Mlayah B, Ziarelli F, Joly N, Delmas M. Elucidation of the complex molecular structure of wheat straw lignin polymer by atmospheric pressure photoionization quadrupole time-of-flight tandem mass spectrometry. Rapid Commun Mass Spectrom. 2007;21:2867–88. https://doi.org/10.1002/rcm.3159.

Dier TKF, Egele K, Fossog V, Hempelmann R, Volmer DA. Enhanced Mass Defect Filtering to Simplify and Classify Complex Mixtures of Lignin Degradation Products. Anal Chem. 2016;88:1328–35. https://doi.org/10.1021/acs.analchem.5b03790.

Kosyakov DS, Ipatova EV, Krutov SM, Ul’yanovskii NV, Pikovskoi II. Study of Products of the Alkaline Decomposition of Hydrolysis Lignin by Atmospheric Pressure Photoionization High-Resolution Mass Spectrometry. J Anal Chem. 2017;72:1396–1403. https://doi.org/10.1134/S1061934817140064.

Mikhael A, Fridgen TD, Delmas M, Banoub J. Top-down lignomics analysis of the French pine lignin by atmospheric pressure photoionization quadrupole time-of-flight tandem mass spectrometry: Identification of a novel series of lignin–carbohydrate complexes. Rapid Communications in Mass Spectrometry 2020;34:e8910. https://doi.org/10.1002/rcm.8910.

Kosyakov DS, Pikovskoi II, Ul’yanovskii NV. Dopant-assisted atmospheric pressure photoionization Orbitrap mass spectrometry – An approach to molecular characterization of lignin oligomers. Anal Chim Acta. 2021;1179:338836. https://doi.org/10.1016/j.aca.2021.338836.

Qi Y, Fu P, Li S, Ma C, Liu C, Volmer DA. Assessment of molecular diversity of lignin products by various ionization techniques and high-resolution mass spectrometry. Sci Total Environ. 2020;713:136573. https://doi.org/10.1016/j.scitotenv.2020.136573.

Banoub J, Delmas GH, Joly N, Mackenzie G, Cachet N, Benjelloun-Mlayah B, Delmas M. A critique on the structural analysis of lignins and application of novel tandem mass spectrometric strategies to determine lignin sequencing. J Mass Spectrom. 2015;50:5–48. https://doi.org/10.1002/jms.3541.

Fouquet TNJ. The Kendrick analysis for polymer mass spectrometry. J Mass Spectrom. 2019;54:933–47. https://doi.org/10.1002/jms.4480.

Kew W, Blackburn JWT, Clarke DJ, Uhrín D. Interactive van Krevelen diagrams – Advanced visualisation of mass spectrometry data of complex mixtures. Rapid Commun Mass Spectrom. 2017;31:658–62. https://doi.org/10.1002/rcm.7823.

Edward K. A Mass Scale Based on CH2 = 14.0000 for High Resolution Mass Spectrometry of Organic Compounds. Anal Chem. 1963;35:2146–54. https://doi.org/10.1021/ac60206a048.

da Silva RR, Vargas F, Ernst M, Nguyen NH, Bolleddu S, del Rosario KK, Tsunoda SM, Dorrestein PC, Jarmusch AK. Computational Removal of Undesired Mass Spectral Features Possessing Repeat Units via a Kendrick Mass Filter. J Am Soc Mass Spectrom. 2019;30:268–77. https://doi.org/10.1007/s13361-018-2069-9.

Ishitsuka K, Kakiuchi T, Sato H, Fouquet TNJ. An arsenal of tools based on Kendrick mass defects to process congested electrospray ionization high-resolution mass spectra of polymers with multiple charging. Rapid Communications in Mass Spectrometry. 2020;34. https://doi.org/10.1002/rcm.8584.

Bugsel B, Zwiener C. LC-MS screening of poly- and perfluoroalkyl substances in contaminated soil by Kendrick mass analysis. Anal Bioanal Chem. 2020;412:4797–805. https://doi.org/10.1007/s00216-019-02358-0.

Sueur M, Maillard JF, Lacroix-Andrivet O, Rüger CP, Giusti P, Lavanant H, Afonso C. PyC2MC: an open-source software solution for visualization and treatment of high-resolution mass spectrometry data. 2022. https://doi.org/10.26434/chemrxiv-2022-cmnk3.

Boiko DA, Kozlov KS, Burykina JV, Ilyushenkova VV, Ananikov VP. Fully Automated Unconstrained Analysis of High-Resolution Mass Spectrometry Data with Machine Learning. J Am Chem Soc. 2022;144:14590–606.

Streun GL, Steuer AE, Ebert LC, Dobay A, Kraemer T. Interpretable machine learning model to detect chemically adulterated urine samples analyzed by high resolution mass spectrometry. Clin Chem Lab Med. 2021;59:1392–9. https://doi.org/10.1515/cclm-2021-0010.

Klingberg J, Cawley A, Shimmon R, Fu S. Towards compound identification of synthetic opioids in nontargeted screening using machine learning techniques. Drug Test Anal. 2021;13:990–1000. https://doi.org/10.1002/dta.2976.

Kitson E, Kew W, Ding W, Bell NGA. PyKrev: A Python Library for the Analysis of Complex Mixture FT-MS Data. J Am Soc Mass Spectrom. 2021;32:1263–7. https://doi.org/10.1021/jasms.1c00064.

Terrell E, Carré V, Dufour A, Aubriet F, Le Brech Y, Garcia-Pérez M. Contributions to Lignomics: Stochastic Generation of Oligomeric Lignin Structures for Interpretation of MALDI–FT-ICR-MS Results. Chemsuschem. 2020;13:4428–45. https://doi.org/10.1002/cssc.202000239.

Letourneau DR, Volmer DA. Constellation: An Open-Source Web Application for Unsupervised Systematic Trend Detection in High-Resolution Mass Spectrometry Data. J Am Soc Mass Spectrom. 2022;33:382–9. https://doi.org/10.1021/jasms.1c00371.

Letourneau DR, August DD, Volmer DA. New algorithms demonstrate untargeted detection of chemically meaningful changing units and formula assignment for HRMS data of polymeric mixtures in the open-source constellation web application. Journal of Cheminformatics. 2023;15:7. https://doi.org/10.1186/s13321-023-00680-5.

Kosyakov DS, Ul’yanovskii NV, Sorokina EA, Gorbova NS,. Optimization of sample preparation conditions in the study of lignin by MALDI mass spectrometry. J Anal Chem. 2014;69:1344–50. https://doi.org/10.1134/S1061934814140056.

LignoPure. LignoPure – Quality Lignin for High Value Products. 2022. https://lignopure.de/. Accessed 13 Oct 2022.

Jawaid W. gatepoints. 2021. https://github.com/wjawaid/gatepoints. Accessed 13 Dec 2022.

Wickham H, Chang W, Henry L, Pedersen TL, Takahashi K, Wilke C, Woo K, Yutani H, Dunnington D. ggplot2. In: Create Elegant Data Visualisations Using the Grammar of Graphics. 2022. https://ggplot2.tidyverse.org/. Accessed 13 Dec 2022.

Corilo YE, Kew WR, McCue LA. EMSL-Computing/CoreMS: CoreMS 1.0.0. 2021.

Alvarez-Martin A, Newsome GA, Janssens K. High-Resolution Mass Spectrometry and Nontraditional Mass Defect Analysis of Brominated Historical Pigments. Anal Chem. 2021. https://doi.org/10.1021/acs.analchem.1c03815.

Funding

Open Access funding enabled and organized by Projekt DEAL. DRL received supplementary fellowship and funding for computer hardware from SALSA (School of Analytical Sciences Adlershof, Berlin). DAV received financial support from the German Research Foundation (DFG VO 1355/4–3) and the Berlin University Alliance (BUA 501_LinkLab).

Author information

Authors and Affiliations

Contributions

DRL conceived of the study, collected and prepared the lignin samples, provided guidance with mass spectrometry experiments, developed the Constellation mass defect analysis software and custom R scripts for data analysis, and was the primary author of the manuscript. BPM analyzed the samples via FT-ICR-MS and wrote about the MS experimental parameters. AA helped to design the sample preparation protocols and prepare the samples, and co-authored the Experimental section. PBO and MPB supported the study and provided analytical instrumentation. DAV laid the groundwork for the ideas considered in this study provided the resources and co-authored the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Letourneau, D.R., Marzullo, B.P., Alexandridou, A. et al. Characterizing lignins from various sources and treatment processes after optimized sample preparation techniques and analysis via ESI-HRMS and custom mass defect software tools. Anal Bioanal Chem 415, 6663–6675 (2023). https://doi.org/10.1007/s00216-023-04942-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-023-04942-x