Abstract

This study sheds light on how recombination of different kinds of knowledge changes along the technology life cycle. From a theoretical point of view, the cyclical technology life cycle model is extended to account for the influence of recombination of different kinds of knowledge in the different life cycle phases. This model is empirically tested for the technological life cycle of wind power and photovoltaics in Germany for the period from 1970 until 2006. Patent forward citations are considered as recombinatorial success and inventors’ patenting experience proxy different kinds of knowledge. Negative binomial regressions as well as rolling-window regressions are used to estimate the relevance of different kinds of knowledge along the technology life cycle. Results reveal that different kinds of knowledge matter along the technology life cycle. In the era of ferment, knowledge from domains external to the technology is relevant, but for the dominant design and the era of incremental change, new and specialized knowledge is most important. However, there are technological differences and deviations from the model. Rolling-window regressions reveal nuanced changes in the life cycle phases. The results have several policy and management implications, especially for the timing of whom to fund or hire for inventive activity.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Technologies develop by the inducement of new knowledge into the knowledge base, which is the result of the recombination of already existing knowledge and artifacts (Schumpeter 1912; Nelson and Winter 1982; Dosi and Nelson 2010, 2013). While there is an extensive stream of literature exploring the factors of recombinatorial success at the firm level (Kogut and Zander 1992; Savino et al. 2017), the influence of knowledge recombination on the technology knowledge base and its evolution over time is so far not well understood. It is well known that technologies evolve along their knowledge base, which itself shows certain dynamics and evolves over time (Malerba and Orsenigo 1996, 2000). Besides internal knowledge accumulation, the in-flow of knowledge from sources external to a technology is crucial for its evolution in terms of initiating, redirecting and refreshing the knowledge accumulation processes (Dosi and Nelson 2013). The way external knowledge diffuses into a technology, the source from which it comes, and the type of actors involved appear to be core determinants of that technology’s further development (Grant 1996; Dosi and Nelson 2013).

The evolution of a technology can be stylized along a life cycle. Anderson and Tushman (1990) propose a cyclical model of a technological life cycle (TLC). The model distinguishes four phases, an era of ferment, the emergence of a dominant design, an era of incremental change and a discontinuity, which restarts the cycle. This TLC model has been widely used to analyze technological development and is extended into various dimensions, for example covering the influence of cognitive factors (Kaplan and Tripsas 2008), specific phases (Murmann and Frenken 2006) or the level of granularity (Taylor and Taylor 2012). However, knowledge, the technology’s knowledge base and the influence of different types of knowledge along the TLC have been neglected from a theoretical and empirical perspective. While there is first empirical evidence that different kinds of knowledge matter along the technological development (Krafft et al.2011, 2014a), no theoretical foundation has been provided explaining the underlying factors and processes. The aim of the paper is to close this gap by extending the Anderson and Tushman (1990) model proposing how recombination of different kinds of knowledge shapes a technology over its life cycle. The extension states that in each TLC phase different sources of knowledge are required for successful recombination and technological evolution.

The proposed extension of the Anderson and Tushman (1990) model is empirically tested for two technologies, namely, wind power (WP) and photovoltaics (PV). In particular the development in Germany for the period from 1970 until 2006 is analyzed. After the oil crisis in the 1970s both technologies were considered as means to reduce the dependency on fossil fuels and to mitigate climate change (Jacobsson and Johnson 2000). Since then, severe effort has been put forward to enhance the technologies and both are nowadays competitive with incumbent technologies (REN21 2015). These makes WP and PV ideal cases to analyze how technologies evolve and mature over their life cycle. The period covers several TLC phases and allows us to draw conclusions how knowledge recombination patterns change over time. Patent data is used to proxy the technological knowledge base, while inventors and their inventive experience are used to characterize different sources of knowledge. Patent forward citations are taken as recombinatorial success and proxy the contribution to the knowledge base (Carpenter et al.1981; Harhoff et al. 1999, 2003, Jaffe and de Rassenfosse 2017). Negative binomial regressions are used to estimate the effect of different kinds of knowledge embedded in the inventors on the patents contribution to the knowledge base. Regressions are estimated for the overall period as well as for the different TLC phases. Furthermore, rolling-window regressions are used as a novel approach to capture dynamics on a fine grained level over time.

Results show that different sources of knowledge matter for technological evolution in general but differently in the phases of the TLC, by and large in line with the proposed theoretical model. For the overall technological development, inventors who possess specialized knowledge are most influential. In WP also, de-novo inventors matter, those who induce knowledge that has not been used before, as well as inventors who were previously active in unrelated technologies. Along the phases of the TLC, the era of ferment in WP is mainly shaped by inventors with unrelated knowledge but relevance shifts over time towards specialized and de-novo inventors. In PV, the era of ferment is shaped by several types of inventors, but here also a shift towards specialized inventors takes place over time. The rolling window regressions provide a more detailed picture and show how different kinds of inventors and their knowledge is also changing inside the phases.

These results contribute to a deeper understanding of the evolution of a technology’s knowledge base and the knowledge dynamics that take place along the TLC. The understanding how knowledge matter in different stages of a technology is crucial for policy maker to implement relevant policies and support the relevant actors, as well as for management to pursue an appropriate R&D strategy. Furthermore, the theoretical contribution by the extension of the Anderson and Tushman (1990) model provides a general framework to understand technological evolution and the respective knowledge dynamics, as well as the influence of knowledge from different origins and its integration success into the knowledge base. This complements previous work and allows a detailed approach to understand recombination and technological development along the TLC. From an methodological point of view, the utilization of previous patents of inventors to distinguish different sources of knowledge allows us to analyze long term developments, which cannot be captured, for example, by surveys (Conti et al. 2014). Additionally, rolling-window regressions prove to be a useful approach to shed light on dynamics in technology evolution.

In the following, Section 2 reviews the literature about knowledge base, knowledge recombination and their relevance for technological evolution and integrates these concepts into the TLC model, providing the theoretical framework for the empirical analysis. Section 3 introduces WP and PV as the technologies under consideration and discusses how they develop over time. Section 4 presents the data, econometric approach and the results. The last Section discusses findings and concludes.

2 A model for knowledge recombination along the technology life cycle

2.1 Knowledge recombination and the technology’s knowledge base

The notion of a knowledge base describes a set of knowledge, practices and routines attributed to an object of observation, such as a firm, a technology or a country. The relevance of the knowledge base has been studied extensively at the micro (firm) level (e.g. Nesta and Saviotti 2005; Krafft et al. 2014a; Roper and Hewitt-Dundas 2015), but also on more macro dimensions such as the regional (e.g. Leydesdorff and Fritsch 2006b; Cantner et al. 2010) and the country level (e.g. King 2004; Leydesdorff et al. 2006a). The knowledge base is of central importance for innovative activity at the firm level (Nesta and Saviotti 2005; Antonelli and Colombelli 2013) and for firm survival (Colombelli et al. 2013). Concerning the knowledge base of a technology, the understanding how the knowledge base shapes technological development is scarce. While some studies focus on the structure of the knowledge inside an industry and show that there are certain dynamics in the knowledge base evolution (Yayavaram and Ahuja 2008; Krafft et al. 2011, 2014a) and shifts between different Schumpeterian regimes (Maleki et al. 2018), a general understanding how the knowledge base evolves and how the respective technologies are shaped is scarce.

The evolution of the knowledge base is driven by knowledge accumulation and introducing new knowledge into it (Malerba and Orsenigo 1996). This new knowledge stems from the recombination of previously existing knowledge, either from within the knowledge base, or from outside. The idea of knowledge recombination was already proposed by Schumpeter (1912) using the phrase “Neue Kombinationen”. This recombination basically leads to a never ending cycle, as Arthur and Polak (2006, p. 23) put it: “New technologies are never created from nothing. They are constructed—put together—from components that previously exist; and in turn these new technologies offer themselves as possible components—building blocks—for the construction of further new technologies.” This continuous knowledge recombination extends and refreshes the knowledge base with new contributions of previously existing knowledge, which can be utilized to create new products, improve processes and foster economic growth (Weitzman1996, 1998).

The knowledge recombination process is an increasingly complex (Jones 2009) and uncertain task (Fleming 2001). Several determining factors for success have been identified at the firm level (e.g. Kogut and Zander 1992; Savino et al. 2017). For example, the previous or stock of knowledge that the firm possess is of importance (Liyanage and Barnard 2003) as well as its characteristics in terms of structure and complementarity (Dibiaggio et al. 2014). The recombination of knowledge present in the firm is relevant, as well as the reconfiguration of existing combinations (Carnabuci and Operti 2013). Also, the combination of new and old knowledge is important for technological advancement (Nerkar 2003). Especially, the ability to tap on new or external sources of knowledge that can be integrated in the knowledge base is relevant (e.g. labor mobility, hiring specific labor, acquisitions, collaboration, suppliers, customers, ...; see Savino et al. (2017) for an overview). These underlying processes partly apply to the level of the technology.

The determinants of knowledge recombination on the technological level are not as well understood as on the firm level.Footnote 1 However, generic determinants such as uncertainty and the increasing complexity apply in a similar vein. Similar to the relevance of integrating external knowledge into the knowledge base of the firm, Nemet (2012) shows for energy technologies that tapping on knowledge from outside the technological domain results in a higher recombinatorial success than knowledge from within the technological domain. Also, Schoenmakers and Duysters (2010) show that radical inventions rely more likely on existing knowledge and combine knowledge across multiple domains compared to non-radical inventions. With respect to the accumulation of knowledge in a technology, Popp (2002) shows that the quality adjusted accumulation of knowledge in a technology has a positive effect on recombinatorial success.

Knowledge recombination takes place across the knowledge space. A technology can be viewed as a specific area of the knowledge space that constitutes its knowledge base. If knowledge is recombined within such a knowledge base, it can be considered specialized, since it combines parts of knowledge that are familiar already. The relation between a technology and knowledge that is outside its knowledge base can be characterized by the distance or proximity in the knowledge space. The distance is relevant for example in collaborations, where the decision to collaborate is influenced by the distance between partners in knowledge space (e.g. Cowan et al. 2007; Baum et al. 2010) or the overlap of firms’ knowledge bases (Rosenkopf and Almeida 2003). The knowledge distance for recombination can be constructed either in a continuous way using patent classifications to calculate Euclidean distances or classification overlaps (e.g. Breschi et al. 2003; Benner and Waldfogel 2008; Bar and Leiponen 2012; vom Stein et al. 2015) or using binary categories such as related and unrelated knowledge. Applying this binary categorization to different technologies, Nemet and Johnson (2012) show that the use of related knowledge (they use the term “near”) leads to more valuable inventions, in terms of forward citations. Youn et al. (2015) distinguish knowledge in “broad” and “narrow” to analyze general recombinatorial patterns for US patents and show that there is an increase of “narrow” recombinations over time.

2.2 Knowledge and the technology life cycle

The knowledge base of a technology is central to a technology’s development. Malerba and Orsenigo (1996, p. 470) propose that the knowledge base itself is dynamic and “changes in Schumpeterian patterns occurring during a technology and an industry life cycle”. These changes in the knowledge base occur because different kinds of knowledge enter the knowledge base and their contribution to technological development might be conditioned on the stage of the technology. The process of technological evolution can be modeled by a TLC similar to the product or industry life cycle. In the TLC, neither the actual product is of importance nor the structure of the firms in the industry, but rather the application of the technology (see Taylor and Taylor 2012, for a discussion of the differences). With the technology as the unit of observation, the TLC allows us to understand how different kinds of knowledge alter the knowledge base over time.

There are several approaches to model a TLC. According to Taylor and Taylor (2012), these approaches can be generally distinguished into S-shaped and cyclical models. S-curve models depict technical progress usually in terms of cumulative diffusion or technical improvements over time. The S-curve models are closely related to the product life cycle covering a embryonic, growth, maturity and aging stage (Taylor and Taylor 2012). These stages are frequently applied to patent data to elaborate the state of a specific technology (Haupt et al. 2007). Cyclical models, especially the one by Anderson and Tushman (1990), present a macro view on the technology. In this model, a new discovery or breakthrough opens up new technological opportunities or trajectories and starts an era of ferment. This phase is followed by a phase in which a dominant design emerges and a main trajectory is established.Footnote 2 After the emergence of a dominant design, an era of incremental change follows in which the technology incrementally evolves along the trajectory until a new technological discontinuity disrupts the technology and the cycle begins again with a new or dramatically altered technology, replacing the current one.

While the TLC has been studied frequently in general, so far the underlying knowledge dimension that shapes the technological development has been neglected. However, with a focus on the knowledge base that constitutes a technology, there might be differences in the kind of knowledge necessary to alter and extend the knowledge base in different phases of the TLC. While it is widely accepted that a discontinuity in the knowledge base creates a new trajectory leading to a new technology (Dosi 1982), there is no general model of how different kinds of knowledge influence technological development over the TLC. There is the general concept of exploration and exploitation (March 1991) and the tendency to move from the former to the latter over time (Utterback and Abernathy 1975; Klepper 1996), along with the emergence of a dominant design (Utterback and Abernathy 1975; Murmann and Frenken 2006). However, a theoretical framework to integrate knowledge into the different phases of the TLC is missing.

Some empirical analyses try to understand how knowledge matters along the TLC and shape the evolution of a technology. Antonelli et al. (2010) use the co-occurrence of technological classes within patent applications to shed light on the dynamics of knowledge recombination for information and communication technologies, but do not consider a life cycle. Krafft et al. (2011) use social network analysis to elaborate on the relationship in co-occurrence of technological classes and show that, in biotechnology, the search process changes from exploration to exploitation in the recombination process. Krafft et al. (2014a) use the properties of the biotechnology and telecommunication knowledge base to elaborate on the phases of exploration and exploitation. They show that sectoral differences can be attributed to the phases of the knowledge base. Furthermore, Krafft et al. (2014b) explore the relationship between the structure of the biotechnology knowledge base and technological alliances along the TLC. They find that during the evolution of the biotechnology, the search pattern become less random and more organized and knowledge becomes more related. However, they point out that, along a trajectory, this sequence is not always the case.

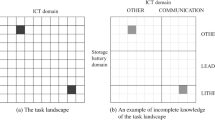

In the following, the missing link between the evolution of a technology’s knowledge base and the phases of the TLC is proposed by extending the Anderson and Tushman (1990) TLC model. In each phase of the TLC the relevance of different sources of knowledge is derived and how these knowledge can alter and extend the knowledge base.Footnote 3 The result is summarized in Fig. 1, which expands the initial graphical representation presented in Tushman and Rosenkopf (1992) with the relevant knowledge in each phase.

-

1.

Era of ferment: The era of ferment starts the development of a new technology, following the discovery of a new technological principle, technological disruption or scientific discovery (Anderson and Tushman 1990; Tushman and Rosenkopf 1992). The new technology is not well understood and uncertainty prevails about the technology’s characteristics and application (Kaplan and Tripsas 2008). The knowledge base is rather small and unstructured (Krafft et al. 2011). Here, experimentation and exploration are the main inventive activities (March 1991). First applications are derived and (product) variation is high (Van de Ven and Garud 1993). Niche markets emerge or are created, in which experimentation can take place to gain further understanding of the technology and required characteristics (Kemp et al. 1998).

Since in the era of ferment the knowledge base itself is rather small and unstructured, related and unrelated knowledge from other technological fields is important. This external knowledge is induced into the knowledge base and supports the development of the technology by recombination with existing knowledge already present in the knowledge base. This related and unrelated knowledge is able to provide new combinatorial possibilities from different fields and experiment with new ways of applications and characteristics. However, due to the high technological uncertainty, failure is very likely (Fleming 2001).

-

2.

Dominant design: The emergence of a dominant design is characterized by increasing economies of scale and scope, network externalities and standardization (Utterback and Abernathy 1975; Arthur 1989; Anderson and Tushman 1990; Klepper 1996; Murmann and Frenken 2006). The knowledge base becomes broader and structured, which supports the emergence of the dominant design (Krafft et al. 2011). There are several factors on the firm and environmental level that are influential as well (Suarez 2004), such as the emergence of institutions that facilitate knowledge exchange among actors (Kaplan and Tripsas 2008). The dynamics in the knowledge base play also a role, since the structure of the knowledge base changes and becomes denser (Krafft et al. 2011).

The knowledge base is enhanced with knowledge from related fields that share the same principles and allow useful recombinations to establish wider levels of application for the dominant design (Murmann and Frenken 2006). At the same time, the number of variation is reduced and a single trajectory emerges and development focuses along this trajectory (Metcalfe 1995). Here, specialized and detailed knowledge about the core principles of the technology is relevant to increase performance and application opportunities to expand the number of possible adopters.

-

3.

Era of incremental change: After the emergence of a dominant design, incremental change by solving rather small problems or improving performance along the technological trajectory takes place (Dosi 1982; Sahal 1985; Anderson and Tushman 1990). In this phase, the knowledge base is large and detailed, the technological principles are well understood and the dominant design is working. This era is characterized by exploitation of the knowledge base by localized search along the trajectory (Nelson and Winter 1982; Levitt and March 1988). Incremental improvements occur in a routinized way (Henderson and Clark 1990) and inertia exists towards switching the direction of search (Kaplan and Tripsas 2008). Social, political and organizational routines are established as well (Tushman and Rosenkopf 1992). Nevertheless, certain dynamics still exist along the trajectory (Funk 2009; Dokko et al. 2012; Lee and Berente 2013).

In the era of incremental change, specialized knowledge is necessary to solve the incremental problems, which allows further progress. Very detailed knowledge and experience is necessary for the incremental improvements. But also new knowledge might be relevant for further progress. New knowledge might come from a new generation of scientists and engineers, who are not primed towards a specific concept or way of thinking and can integrate their new ideas. Since over time specific educational facilities are established that provide detailed training in the field, this new knowledge can become particularly relevant in the era of incremental change (Baumol 2004; Vona and Consoli 2015).

-

4.

Technological discontinuity: The emergence of a technological discontinuity disrupts the technology and might establish a new trajectory. In this phase, the knowledge base is exhausted and technical opportunities are scarce. The disruption is usually assumed to be exogenous to the technology (Dosi 1982; Tushman and Anderson 1986). It can occur if the technology reaches its natural limits (Sahal 1985), the opportunity space for further improvement is exhausted (Fleming 2001; Adner 2004) or customers radically shift their preferences (Tripsas 2008). However, recently the idea that the discontinuity can emerge out of the incremental improvements, which become radical by accumulation (Funk 2009) or social interaction (Dokko et al. 2012), is discussed.

In this stage, the exhausted knowledge base can be rejuvenated by a disruption that can open up new recombinatorial possibilities. For the further evolution of the knowledge base, unrelated knowledge is most likely to refresh the technology in a disruptive way. Radical new ways of recombination can emerge out of these new opportunities. Furthermore, new unexploited ideas and knowledge can induce the discontinuity, especially if accumulated over time. If the unrelated or new knowledge gets successfully recombined with the knowledge base, a rejuvenation of the technology takes place and the life cycle starts again with a drastically altered or completely new technology.

2.3 Inventors and knowledge recombination

To understand the development of a technology, it is crucial to determine which factors influence the evolution of the underlying knowledge base. Since knowledge is embodied in people, the inventor who is able to create new and recombine existing knowledge is the core determinant for the evolution of the knowledge base. The individual person possess knowledge and competences, especially tacit ones, which are relevant for recombination and technological advancement (Grant 1996; Mascitelli 2000). The inventor can gain and use his knowledge from learning-by-doing, experimentation and application (Arrow 1962). This extends the inventor’s stock of knowledge and makes the inventor more effective in future inventive activity in recombination (Conti et al. 2014), but with diminishing returns to novelty (Audia and Goncalo 2007; Conti et al. 2014). However, the process of recombination is influenced by uncertainty about the usefulness of the outcome of the recombination process (Fleming 2001), and specific characteristics of the inventor play an important role for recombinatorial success.

Several findings reveal which inventor characteristics lead to successful recombinations and inventions. Gruber et al. (2013) show that the kind of education an inventor received influences the ability to combine knowledge from different fields. They show that scientists are better in integrating distant knowledge than engineers. Besides the kind of training the inventor receives, the breadth and depth of the knowledge the inventor possesses also has an influence, as shown by Boh et al. (2014). Conti et al. (2014) find that the previous inventive activity positively influences new inventions. In addition, Mohammadi and Franzoni (2014) show that for scientists’ knowledge relatedness influences the technological value of inventions. Meyer (2006) demonstrates that scientists in nanotechnology who invent at the same time are more effective than non-inventing scientists. Scandura (2019) shows that the success of inventors is influenced by the type of knowledge they use. Based on survey data, she reveals that combining scientific and market knowledge enhances inventive output.

While the characteristics of inventors are of importance, their origin in the knowledge space also play a role. Mobile inventors, which enter a technology from outside the technology’s knowledge domain, may alter a technology’s knowledge base and enhance recombination possibilities. Those inventors can transport or spill over their knowledge about a specific technology to a new one by moving between technologies and industries and carrying their knowledge and experience with them (Song et al. 2003; Hoisl 2007). By entering a technology, in terms of creating an invention in this field, the knowledge these people possess may increase the knowledge base of the technology into which they move. It can be assumed that, during the process of invention, the knowledge an inventor holds is recombined with knowledge present in the technology to which the inventor moves and increases the knowledge base, especially if the invention is followed up by other inventors. This transfer of knowledge is important for the technology’s progress and shapes the direction into which a technology develop (Schoenmakers and Duysters 2010). Here, the distance in the knowledge space plays a role again, since these inventors can originate from related technologies that are near or familiar with the technology or from unrelated technologies, which do not share common principles. Their movement from one technological field to another allows them to combine their previous knowledge with the one present in the technology’s knowledge base into which they move.

Based on the different characteristics and technological origin of inventors, inventors can be distinguished into four different groups based on their inventive experience. The characteristics these inventors have may influence their success of recombination, especially in different phases of the TLC. The distinction between different kinds of inventors can be drawn from the inventor’s personal knowledge and the knowledge base of a technology.

-

1.

New Inventors: Inventors have no inventive experience, which implies that their first invention contributes to the technology’s knowledge base. They may have gotten educational training in this field (Vona and Consoli 2015) but show no experience with inventive activities yet. They can also be customers who want specific features or characteristics of a technology and introduce them on their own (von Hippel 1976, von Hippel 1988, 2010) or the classical tinkerer (Bettiol et al. 2014). They have the advantage that they are not primed by any previous inventive activity and can bring novel and unexploited ideas with them. However, they lack experience and tacit knowledge in inventive activity and may not fully understand the technology.

-

2.

Specialized Inventors: Specialized inventors have contributed to the technology’s knowledge base by previous inventive activity. Due to their repetitive inventive activity, they benefit from learning-by-doing (Arrow 1962) and have accumulated knowledge in the technology that gives them a deep understanding of it (Conti et al. 2014). They are able to see opportunities for further improvement of the technology or their previous inventions. However, it can be assumed that they face diminishing returns of success, since they might follow an exploitative path, as suggested by Audia and Goncalo (2007).

-

3.

Related Inventors: Related inventors have contributed to technological fields that are related to the technology into which they move. These inventors are familiar with the technological field or underlying technological principles and can transfer related knowledge from other technologies or technical applications to the knowledge base under consideration. These inventors are able to recombine their previous knowledge with the knowledge already present in the knowledge base. Uncertainty about the recombinatorial success should be low, but radical contributions are not that likely.

-

4.

Unrelated Inventors: Unrelated inventors show no inventive background related to the technology’s knowledge base into which they move. These inventors generated inventive output in unrelated technologies and changed their field of inventive activity. By the shift from one technology to another, they carry with them specific knowledge from the former field of activity that may not be present in the technology’s knowledge base and they may combine this knowledge with the knowledge present already in the knowledge base. However, the knowledge they possess for recombination might be difficult to integrate into knowledge present in the technology and unsuccessful recombinations are likely (Fleming 2001).

These different types of inventors are the carriers of specific knowledge and can by their inventive activity recombine their knowledge with the knowledge present in a technology. In line with the extension of the Anderson and Tushman (1990) model, they provide the necessary different kinds of knowledge that influences the technological progress along the TLC. In the following the extended model and the influence of different kinds of inventors along the technology life cycle is tested with renewable energy technologies in Germany.

3 Renewable energies and their technology life cycle

3.1 Wind power and photovoltaics in Germany

To test the proposed extension and the effect of different sources of knowledge along the TLC, wind power (WP) and photovoltaics (PV) are chosen from the field of renewable energies. In the light of emerging environmental problems such as climate change, but also resource scarcity and rising energy consumption, alternative energy technologies are demanded. Since the oil crisis in the 1970s, renewable energy technologies, especially WP and PV, emerged and diffused in the electricity market (Jacobsson and Johnson 2000). During the last 40 years, these technologies underwent a remarkable development to catch up with incumbent technologies in terms of efficiency and cost competitiveness. The evolution of these technologies is driven by inventions and knowledge accumulation extending the knowledge bases of the technologies. Nowadays, WP and PV are cost competitive and contribute a substantial share of electricity in several countries (REN21 2015).

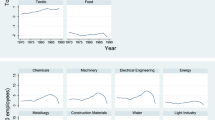

The technologies developed globally but, in the following, only the situation in Germany from 1970 until 2012 is considered. Germany can be seen as a forerunner for both technologies due to high inventive activity, installed capacity and policy support. The German government implemented various policy instruments to support the development and served in some period as the largest market (Lauber and Mez 2004). Figure 2 shows the R&D expenditures as well as the diffusion (by annual installed capacity) of both technologies over the last 40 years as well as the main demand pull policies. Over time, there was a shift from direct R&D subsidies to demand inducing policies that created a niche market for the technologies and supported their diffusion. This favorable environment helped the technologies to develop and the different instruments had vast effect on inventive activity (Johnstone et al. 2010; Wangler 2013; Cantner et al. 2016).

Wind power and photovoltaics policy instruments in Germany. Data source: Cantner et al. (2016)

3.2 Technology life cycle phases

Several attempts to distinguish technological phases for WP and PV are proposed in the literature, which mimic the TLC but also to some extend an industry life cycle. For example, Bergek and Jacobsson (2003) distinguish two phases in the worldwide WP development, a phase of experimentation from about 1975 until 1989 and a phase of turbulence and growth from 1990 until 1999. Wilson (2012) derives similar phases for the development in Denmark. Harborne and Hendry (2009) argue that, even though a dominant design seemed to emerge at the end of the 1980s, variation and experimentation was still high at the end of the 1990s. According to Huenteler et al. (2016b), WP follows a complex-products and systems life cycle (Davies 1997) and a dominant design emerged already in the late 1980s. Since then, WP has been in the era of incremental change. Hemmelskamp (1998) does not analyze a TLC in particular, but points out that even two dominant designs emerge for small and large wind turbines in the middle of 1990s. For Germany, the development for WP can, according to Bruns et al. (2009) and Bruns and Ohlhorst (2011), be distinguished in a pioneering phase from 1975 to 1985 followed by a rethinking/adopting framework period until 1990 succeeded by a breakthrough period until 1995. Then a three year transitory setback period was proposed followed by a second boom period until 2002. After 2002, consolidation in the industry took place and, according to them, a divergence of the trajectory took place.

PV can, according to Peters et al. (2012), be distinguished in three phases on the global level. The period 1974-1985 is a first boom phase, followed by a stagnation phase until 1994 and from 1995 onwards a second boom phase. Huenteler et al. (2016b) analyze the technology in detail and conclude that PV followed a mass-produced goods life cycle (Abernathy and Utterback 1988) and a dominant design emerged in the early 1990s. Since then, PV has been in the era of incremental change. For the development specifically in Germany, Jacobsson et al. (2004) distinguish the development of PV in two phases, a first until 1989, which they consider a science-based experimentation phase, and a growth phase from 1990 until 2001. Bruns et al. (2009) distinguish the development of PV in five phases. They attribute the period 1970-1985 as a pioneering phase, followed by a phase with reduced private and public R&D until 1991, when a demand inducing policy instrument was implemented that allowed first larger scale tests. From 1994 until 1998 there was a phase of slow down and uncertainty, followed by a breakthrough phase form 1999 until 2003 and from 2004 onwards a booming phase.

Since there is no clear distinction of the TLC phases in the literature, the technologies are separated in phases based on the diffusion and the political support they received in Germany (see Fig. 2 and Table 1).Footnote 4 For this purpose, especially the distinction between demand-pull and technology-push policies is useful (Mowery and Rosenberg 1979), since the policy support changed over time towards more demand oriented support. Several studies show that policy instruments decisively influenced the technological development, especially demand pull policies (Johnstone et al. 2010; Wangler 2013; Cantner et al. 2016). These policies induced demand for the technologies, which reaped economies of scale and helped to establish a dominant design.

In the case of WP, the technological development can be separated into three phases until today.Footnote 5 The era of ferment starts in Germany around 1970 and lasts until 1995. This period covers the experimental phase in the beginning of the 1980s where the large scale pilot turbine GROWIAN was constructed but failed in operation (Bergek and Jacobsson 2003). However, the first successful small scale applications were supported by the 100/250 MW wind program in the end of the 1980s, which proved the technological feasibility (Harborne and Hendry 2009). Additionally, the first feed-in tariff was introduced in 1991 and supported technology independent diffusion of renewable energy (see Bergek and Jacobsson 2003; Bruns et al. 2009, for a detailed discussion of the policy instruments). These instruments created a niche market that provided opportunities and testing ground for commercial applications. The emergence of a dominant design took place from 1996 until 2000 and is characterized by massive up-scaling of the turbine size and a surge in installed capacity in Germany due to the demand policies. The turbine design converged to a three blade rotor facing the wind with a variable-speed gearbox (Harborne and Hendry 2009; Milborrow 2011; Huenteler et al. 2016b). This so called Danish-design is used in nearly all wind turbines today. The era of incremental change starts in 2001 and is characterized by a reduced annual installed capacity, but increasing exports and further up-scaling. The focus of inventive activity switched to other components such as mounting and encapsulation or grid connection of turbines (Huenteler et al. 2016a), which are not fundamental to the technical principle. Also, offshore turbines were developed and installed, but they do not substantially differ from onshore turbines and a discontinuity seems not yet to have emerged.

In the case of PV, the era of ferment covers the years from 1970 until 1997 and is characterized by massive R&D subsidies and first experimental demand policies that created a niche market (Jacobsson et al. 2004).Footnote 6 In this phase, various actors engaged in PV R&D and research institutes were founded, providing scientific infrastructure and public funding allowed experimentation with the technology (Jacobsson et al. 2004; Herrmann and Töpfer 2016). The emergence of a dominant design lasted from 1998 until about 2006 and covered the vast increase in installed capacity due to implemented demand policies and cost reductions. The 100,000 roof program created favorable economic conditions to install PV and the later introduced renewable energy source act substantially improved the investment conditions and created strong market demand, which provided secure grounds to invest in R&D. During this period, manufacturing capacity and automation of production processes were established, which led to severe cost reductions and economies of scale. From 2007 onwards, the era of incremental change began with reduced policy support and international competition for German PV cell producers.

However, in PV, the phases represent only a general pattern, since there are several PV sub-trajectories with respect to the different cell types (Kalthaus 2019). For example, dye-sensitized solar cells were discovered in 1991 (O’Regan and Grätzel 1991) and the underlying principle is far different from the market dominating silicon wafer cells and their efficiency is far from conventional cells. These sub-trajectories emerged at different points in time and are in different phases of the development (see for example Lizin et al. (2013), who look at the life cycle of organic PV cells).Footnote 7

4 Econometric approach

In the following, data as well as variables and the econometric approach to test the extended TLC model for WP and PV are explained. Negative-binomial regressions are used to analyze the relationship between different sources of knowledge and the success of knowledge recombination. Descriptive statistics and correlations can be taken from Appendix A.2 and A.3.

4.1 Data and variables

4.1.1 Patent data

The technological advancement and evolution of the renewable energy technologies and their knowledge bases can be observed in patent data. Patents are, despite their broadly discussed disadvantages, a good proxy for inventive activity and a technology’s knowledge base (Griliches 1990; Hall and Harhoff 2012). Even though only a part of all inventions are patented (Arundel and Kabla 1998; Cohen et al. 2000), the codification of knowledge in a patent allows other inventors to utilize the knowledge and build upon it.

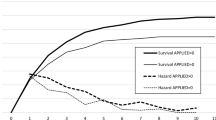

Patent data for the analysis is retrieved from the Worldwide Patent Statistical Database (PATSTAT) (EPO 2014). Patents for WP and PV are extracted by a combination of technology specific IPCs (International Patent Classification) and keywords (see Appendix A.1 for details). All priority application filed by German inventors in the period from 1970 to 2011 are considered. A patent is selected if at least one of its inventors resides in Germany. There are 3,765 WP and 3,589 PV patents in total (Fig. 3). However, for the following analysis, only a subset until 2006 is considered, since the patents need some time to receive forward citations, which are the information of interest. For the set until 2006, there are 1,984 WP patents and 1,691 PV patents that are the units of observation.

4.1.2 Dependent Variable: Forward citations

The success of knowledge recombination and the contribution of a patent to the knowledge base can be approximated by the forward citations it receives. A forward citation of a patent is a citation of this patent by another patent, which considers the cited patent as prior art. The general assumption is that the more forward citations a patent receives, the more valuable in technological terms it is for the evolution of a specific technology (Carpenter et al. 1981; Trajtenberg 1990; Harhoff et al. 1999, 2003; Czarnitzki et al. 2011; Jaffe and de Rassenfosse 2017). If a patent receives many citations it can even be considered radical or breakthrough (Ahuja and Lampert 2001; Conti et al. 2014), while if it receives no citations, it is most likely that the recombination was a failure and the patent has no value for the knowledge base or further inventions.

The forward citations are collected on the patent family level in the first five years after the priority application (Bakker et al. 2016). This five year truncation is used to grant all patents the same time span to receive citations and avoid a bias towards older patents (Lanjouw and Schankerman 2004). Forward citations added by examiners are not considered separately, even though they can indicate higher importance of the cited patent (Alcácer and Gittelman 2006; Yasukawa and Kano 2014). Figure 4 displays the distribution of forward citations by technology. The distribution is highly skewed and 33% of the PV and 40% of the WP patents receive no citation in the first five years after application. On average, WP receives about 2.6 citations and PV 2.7 citations per patent in the first five years after application.

4.1.3 Explanatory variables: Type of inventor

To understand the influence of different sources of knowledge on the technological development, the inventors on the patent are assigned to the four different groups, elaborated in Section 2.3. Since the assignment to the different groups is sensitive to the data quality, cleaning up the patent data is necessary. The inventor names were manually harmonized by correcting obvious typosFootnote 8, academic titles or name order, controlling for patent applicant, address and year of application, to avoid inflating the number of inventors.Footnote 9 In total, there are 1,675 unique inventors on WP patents and 2,203 unique inventors on PV patents.

All filed patents for each inventor are collected from PATSTAT to construct the inventor’s patenting history, similar to the approach used by Jones (2009). The patenting history is used to determine the type of inventor. Thereby, the type of inventor is reassessed with every new patent he files in the technology. The first type, New Inventors, are those without previous patenting experience who patent their first patent in the technology. The second type of inventors, Specialized Inventors, are inventors who patented previously only in the respective technology. If a New Inventor patents a second patent in the technology, he becomes a Specialized Inventor on this second patent. For the third and fourth type of inventors, who have an inventive history in either related or unrelated technologies, the distinction becomes a bit different: The field of former patenting activity of an inventor is indicated by the IPCs to which his previous patents are assigned.Footnote 10 The inventor is considered to be related to the technology, so a Related Inventor, if one of the IPCs on previous patents not belonging to the technology has also been used in the respective technology before; if not, the inventor is considered an Unrelated Inventor.Footnote 11 The IPCs of all previous patents in WP or PV are accumulated over time and compared to the inventor’s patenting history.Footnote 12 If any of the inventor’s patents IPCs coincides with an IPC that is already used in the technology, the inventor belongs to Related Inventors.Footnote 13 This approach allows a dynamic change of the criteria for Related Inventors and Unrelated Inventors if new concepts are introduced into the knowledge base. The first time an IPC is introduced by an inventor in the technology, it is no longer unrelated to the technology but related.Footnote 14 Since the empirical analysis is conducted on the patent level, the different types of inventors on a patent enter the regression as a count variable each.

The distribution of the different kinds of inventors over time is presented in Fig. 5. In both technologies, New Inventors are the largest group. This is persistent over time, indicating that there is a high number of new people starting inventive activity in these technologies. Furthermore, since inventions are a rare event, a considerable amount has only one invention, or they change their focus and continue their inventive activity in other domains (Menon 2011). Related Inventors are the second biggest group in both technologies. But in WP, Unrelated Inventors have a high share in the early years, indicating an experimental phase. Specialized Inventors are the smallest group in both technologies, indicating that specialization in one technology does not take place that much. Further information about the number of patents per inventor and the overall number of inventors is provided in Appendix A.4.

To understand better the effect of different kinds of knowledge embedded in the inventors, intermediate groups are created to assess the effect if inventors are separated into different types. Two intermediate groups are constructed: First, Experienced Inventors who are all the inventors who have patenting history (sum of Specialized Inventors, Related Inventors and Unrelated Inventors) to test if it matters if an inventor has previous experience. The second group, Knowledgeable Inventors, are the inventors who come from outside the technology’s domain and patented in related and unrelated fields (sum of Related Inventors and Unrelated Inventors).

4.1.4 Control variables

While the source of knowledge embodied in inventors and their success of recombination has an influence on the received forward citations, other influential factors may be related to the patent itself. In the following, relevant control variables are discussed.

Team Size: An influential factor for the success of a patent, and also for knowledge recombination, is invention in teams. Patents invented in teams have usually a higher technological value than inventions by a single inventor (e.g. Wuchty et al. 2007; Jones 2009). The number of inventors on the patent is the sum of the different types of inventors.

Foreign Inventors: International collaboration has a positive effect on research and inventive activity in general (Adams 2013; Kerr and Kerr 2018). Patents might be invented in international teams and inventors from other countries are counted.

Number of IPCs: The technological breadth of the patent influences its technological importance. More basic patents, which can be applied to different kinds of technologies, might be more relevant for future development than highly specified patents (Lerner 1994). To approximate the breadth of the patent, the number of IPC groups to which a patent is assigned are counted.

Family Size: The size of the patent family to which the patent belongs is considered to be relevant for the technological importance of a patent. The bigger the family of a patent, which means that the priority patent is registered in other patent offices as well, the higher the number of forward citations (Putnam 1996; Lanjouw et al. 1998; Harhoff et al. 2003). Here, the size of the DocDB family is considered (Martínez 2011).

Backward Citations: The previous patents the inventor relied on to create the patent may influence its technological value (Harhoff et al. 2003). Lanjouw and Schankerman (1999), for example, show that patents with many backward citations are rather incremental compared to patents with no or only a few backward citations.

Granted Patent: If the patent is granted it usually is a good indicator of its novelty and relevance (Guellec and van Pottelsberghe de la Potterie 2000).

PCT Patent: If a patent is filed under the Patent Cooperation Treaty (PCT) the technological value can be higher (Guellec and van Pottelsberghe de la Potterie 2000).

New Combination: A patent can introduce a new IPC into the knowledge base that has not been used in the technology before. This might be a new combination that can be of higher value. Arts and Veugelers (2015) use a similar idea to capture previously uncombined technologies. A dummy variable is constructed by comparing all previous IPCs used in the technology and the patent under consideration. The dummy variable turns 1 if a patent introduces a new combination into the knowledge base.

USPTO: Patents filed at the United States Patent and Trademark Office (USPTO) receive usually a higher number of forward citations, since the USPTO requires indication of all prior art that could be relevant and this leads to a higher number of forward citations than a patent from the German or European patent office would receive (Michel and Bettels 2001; Nagaoka et al. 2010).

Year Effects: Year dummies capture time variant effects such as macroeconomic changes, political support, patent legislation changes or other factors that may influence patenting activity and quality in a specific year. Furthermore, the variable captures also the effect that due to the general increasing patenting trend younger patents have a larger pool of patents that could cite them.

PV Sub-trajectories: A PV system consists of different components and cell technologies, which develop intertwined with each other. There are different approaches to utilize the photovoltaic effect based on different light-absorbing materials. Simple PV cells use silicon wafers to produce electricity, while nowadays also thin-film materials and very recently organic and nano materials are used. Since they emerge at different points in time, they might require different kinds of inventive activity and have overlapping life cycle phases. To account for this, the patents for PV are distinguished into PV Modules, which is generic for each cell type and deals with the overall construction and installation of the cell, and the cell sub-trajectories, which can be distinguished based on their material into Silicon Wafer Cells, Thin-Film Cells and Emerging Cells. However, not all patents can be attributed to a specific technology and the distinction serves only as a rough indicator. Details about the distinction are provided in Kalthaus (2019).

4.2 Econometric approach

The dependent variable, the forward citations per patent, measures the success of the knowledge recombination and the resulting technological contribution to the knowledge base. Forward citations are non-negative and discrete and require non-linear count data models. Poisson distributions and regression models based on them are the natural starting point for econometric analysis of such data. However, Poisson regressions require equidispersion of the data. I test for equidispersion in the data and have to reject it, so the data are over-dispersed (the conditional variance exceeds the conditional mean of the data) and the standard errors are biased. This requires a negative binomial distribution, which allows for a more flexible parametric regression model, accounting for overdispersion (Cameron and Trivedi 1986; Hilbe 2011). Since the patent is the object of analysis (i), the data set is cross-sectional but has time information that allows separation of different life cycle stages. The stylized regression model is:

where Inventor Type is a vector of the four different kinds of inventors, namely, New Inventors, Specialized Inventors, Related Inventors and Unrelated Inventors, the explanatory variables of interest.

In the following, seven models for WP and six models for PV are estimated to analyze the relationship of different types of inventors and the number of forward citations. The first four models (see Section 4.3.1) cover the full period and are used to elaborate the relevance of the different inventor types in general. The first model uses only the Team Size of the inventor team to estimate whether the number of inventors on a patent has an effect. In the second model, the inventors are separated into New Inventors and Experienced Inventors to see if it makes a difference whether previous knowledge is present.Footnote 16 The third model separates the Experienced Inventors into Specialized Inventors who only invent in the respective technology and Knowledgeable Inventors who have experience in other fields. Model four furthermore separates the Knowledgeable Inventors into Related Inventors and Unrelated Inventors to estimate whether the kind of previous knowledge has an effect. In the case of PV, two alternatives are estimated, distinguishing PV in sub-trajectories. Model 4a controls for patents that belong to PV Modules and the three PV cell sub-trajectories Silicon Wafer Cells, Thin-Film Cells and Organic Cells to account for different developments between cell technologies.

The next models (see Section 4.3.2) cover the different periods of the TLC derived in Section 3. In models five to seven for WP, the first three stages of the TLC are analyzed. For PV, only two periods are considered. Model five covers the period 1970-1997 and model six 1998-2006. Again, distinctions between the PV module and different cell sub-trajectories are made.

Since the proposed sub-periods in the last models are static and results could be sensitive to the exact separation of periods, rolling-window regressions are used to illustrate the importance of different types of inventors over time. Rolling-window regressions (alternatively called moving-window regressions) are usually applied to time series data to analyze whether structural changes occur in a specific subsample of a time-series (Fama and MacBeth 1973; Nyakabawo et al. 2015). The approach uses a fixed window of years sequentially from the start to the end of the overall observation period by dropping one year from the end and adding one to the beginning. In the current case, a time-series is not present, but based on the filing year of the patent, time periods can be constructed. When using this method, the selection of the window of years is of importance and has to make a trade-off between the accuracy of the effect, the degrees of freedom, and the coverage of the relevant period. This is especially a problem for time-series (see Pesaran and Timmermann(2005) for a discussion), but not necessarily for the current case, since multiple observations are present in each period, providing a sufficient degree of freedom. However, if the selected time period is too short, overall time variant effects that are otherwise captured by year dummies might influence the result. In the following, a time period of eight years is considered covering a sufficient large time period and degree of freedom per window. Furthermore, robustness tests for five and eleven years are discussed in Section 4.4.

4.3 Results

4.3.1 General influence of different inventor types

The regression results for the influence of different types of inventors for WP and PV are presented in Table 2. In the case of WP, the first model, the baseline, illustrates the overall influence of patent characteristics on forward citations. As suggested in the literature, most control variables influence the number of forward citations positively except PCT Patent, which does not have a significant coefficient. However, the negative coefficient of New Combination is surprising. The introduction of a new IPC into the technology seems to have a negative influence on the contribution to the knowledge base. This indicates that the extension of the knowledge base by bringing in new principles seems not beneficial. This is, however, in line with the argument of Fleming (2001), who claims that recombination is risky and may lead to failure. The negative effect can also indicate that the trajectory is already defined and integrating further technological principles in the knowledge base does not provide useful recombinations. In model 2, the inventors are separated into New Inventors and Experienced Inventors. We see that both have a highly significant coefficient, indicating that both sources of knowledge are relevant. This influence sustains if Experienced Inventors is further separated in Specialized Inventors and Knowledgeable Inventors in model 3. However, in model 4, the separation of the Knowledgeable Inventors reveals that only Unrelated Inventors has a weakly significant coefficient, while the Related Inventors has no significant influence in WP. In all models, Foreign Inventors has a significant coefficient, too, indicating that international collaboration are relevant for the technological development.

The regression results for PV show that, in the baseline model 1, the results are nearly similar to the ones for WP, but here, Granted Patent does not have a significant coefficient. Again, New Combination has a negative coefficient, which is significant, indicating that inducing new principles into the PV knowledge base is also not successful or necessary. Model 2 shows that, in PV, New Inventors does not have a significant coefficient, while Experienced Inventors does. This indicates that recombination in PV is only successful, if inventors possess previous experience and knowledge. Model 3 presents the distinction between Specialized Inventors and Knowledgeable Inventors. Both are statistically significant, but the Specialized Inventors has a comparably large coefficient, indicating that knowledge accumulation seems to matter more than a diverse set of knowledge. In model 4, only Specialized Inventors contributes to the technological development and the distinction between Related Inventors and Unrelated Inventors seems not to explain recombinatorial success. However, controlling for different sub-trajectories in model 4a reveals that Related Inventors has a weak significant coefficient, indicating that sub-trajectories have distinct recombination pattern and that the relevance of related knowledge is conditioned on the sub-trajectory. Contrary to WP, Foreign Inventors is not significant and inventive activity for PV in Germany does not benefit from international collaboration.

Overall, different sources of knowledge are relevant and the distinction reveals that knowledge embodied in different types of inventors influence recombinatorial success. There are differences between the technologies as well. While in WP New Inventors has a significant coefficient, it does not matter in PV. Also, the kind of knowledge from domains external to the technology’s knowledge base matters. While in WP Unrelated Inventors is relevant for useful recombinations, in PV Related Inventors is relevant. Also the difference concerning Foreign Inventors is remarkable. However, the technological difference between WP and PV has also been shown by Cantner et al. (2016) and Huenteler et al. (2016b), but not with respect to the process of knowledge recombination.

4.3.2 Technology life cycle phases

In this section, the phases of the TLC are analyzed and regression results are presented in Table 3. For WP, model 5 shows the era of ferment in which New Inventors and especially Unrelated Inventors show significant coefficients. While it was proposed in the extended TLC model that Related Inventors and Unrelated Inventors are decisive in this phase, only Unrelated Inventors seems to be able to successfully integrate distant knowledge into the knowledge base. The significance of New Inventors is interesting, since it shows that the technology benefited from inventors who started their inventive activity in WP. Here, anecdotal evidence supports the results. Inventors in the era of ferment were tinkerers and engineers who wanted to improve environmental conditions and provide technical alternatives to conventional energy production (Simmie et al. 2014). Concerning the control variables, Number of IPCs and Backward Citations lose their significance as well as the negative coefficient of New Combination compared to the full model. Interestingly, Foreign Inventors has a negative coefficient, indicating that knowledge from other countries goes along with lower recombinatorial success in this phase. Here, it could be that German inventors follow their own trajectory, and concepts developed in other countries seem not to be relevant in this phase.

Model 6 presents the results for the emergence of the dominant design. New Inventors as well as Specialized Inventors are decisive. It is, however, proposed in the model that Specialized Inventors and Related Inventors are relevant sources of knowledge in this phase. The results indicate that the dominant design in WP emerges out of the established trajectory and rely on acquired and accumulated knowledge and does not rely on further knowledge from related fields. Concerning the control variables, Foreign Inventors still has a negative coefficient, but the effect size decreases. Also, PCT Patent shows a significant negative coefficient.

In the era of incremental change, presented in model 7, again, New Inventors and Specialized Inventors have significant coefficients, which is in line with the proposed model. Additionally, Related Inventors seems to be able to integrate knowledge from adjacent technologies into the WP knowledge base, as indicated by the weakly significant coefficient. This could hint towards an upcoming discontinuity, maybe related to offshore WP. There is some evidence that the struggling German ship-building industry diversifies in offshore WP and provides competences for the development of offshore turbines and components (Fornahl et al. 2012). In this phase Foreign Inventors has a positive and significant coefficient, possibly integrating knowledge, which is not present in the knowledge base yet and increases the knowledge base. The other control variables show no unusual pattern, except Granted Patents, which is no longer significant.

For the different phases of the TLC in PV, model 5 and 6 present the results for the era of ferment and the emergence of a dominant design. Model 5 indicates that only New Inventors contributes to technological development. However, controlling for different sub-trajectories in model 5a reveals that also Specialized Inventors and Related Inventors have a positive and significant coefficient. Unrelated Inventors, as proposed in the model, does not matter, but New Inventors as well as Specialized Inventors do. Overall, a diverse set of knowledge is integrated in the knowledge base in this phase. Related literature shows that especially in the 1980s and 1990s a diverse set of actors (firms, research institutes, universities, ...) engage in PV R&D (Jacobsson et al. 2004) and the Fraunhofer Institute for Solar Energy Systems ISE was founded, which is until today central in Germany’s PV research (Herrmann and Töpfer 2016). Furthermore, contrary to WP, PV had in the era of ferment various applications to power off-grid solutions from calculators to satellites (Perlin 2002; Jacobsson et al. 2004). These diverse areas of application could explain the different sources influencing the technology, especially at the sub-trajectory level where either costs (mass production) or efficiency (space application) are relevant. The control variables show except from the very large coefficient for PCT Patents no unusual results and are invariant towards controlling for sub-trajectories. Similar to the overall models, Foreign Inventors is not significant.

During the emergence of the dominant design, only Specialized Inventors contributes to the technological development, whether controlling for sub-trajectories or not. Contrary to the theoretical expectation, Related Inventors shows no significant coefficient. The shift towards the Specialized Inventors from experimentation in knowledge recombination to a more routinized inventive process could be a result of the complexity of PV. If the basic principle of the material to convert radiation into electricity is understood, improvements require a sound understanding of the material to improve it further. This specialized knowledge seems to be generated according to (Jacobsson et al. 2004) by inventors in research institutes and universities. Considering the control variables, it is interesting to see that the negative coefficient of New Combiantions is not significant anymore.

Overall, it is immanent for both technologies that the knowledge relevant for further development changes over time from an explorative way to a more exploitative or routinized approach, as suggested by March (1991). Partially in line with the proposed model, the relevant sources shift from knowledge outside the knowledge base towards knowledge present in the knowledge base over the course of the TLC. In WP, the era of ferment is influenced from knowledge provided by New Inventors and Unrelated Inventors and in PV New Inventors, Specialized Inventors and Related Inventors. The dominant design is shaped in both cases by Specialized Inventors, in WP also by New Inventors. Related Inventors as proposed in the model does not matter in both cases. The era of incremental change in WP is as proposed influenced by New Inventors and Specialized Inventors, but also by Related Inventors which could lead the way towards a discontinuity. Noteworthy is also that in WP Foreign Inventors becomes important over time, indicating that either knowledge from outside the country’s domain becomes relevant, or inventors emigrate but still collaborate with German inventors.

4.3.3 Rolling-window regressions

The dynamics along the technological development can be analyzed fine grained by rolling-window regressions. They allow us to analyze changes in the coefficient sizes of the different types of inventors, also inside the TLC phases. The rolling-window regressions here use an eight-year windowFootnote 17 sequentially from the start to the end of the overall observation period by dropping on year from the end and adding one to the beginning. For WP, model 4 is used and for PV, model 4a to estimate the rolling-window regressions. Figure 6 presents the results for WP and PV graphically.Footnote 18 The coefficients for the different inventor types of the regressions are plotted along with the 10 % confidence intervals for each eight-year period. To test the proposed TLC model, the time periods in which the respective inventor type should be relevant are non-shaded in Fig. 6. Since the periods are overlapping, the transition periods are symbolized by an increasing brightness, indicating the increasing relevance of the respective inventor type.

In the rolling-window regressions for WP, New Inventors should have an effect in the era of incremental change, which begins in 2001. There is a significant coefficient already from the end of the 1980s onward, which is persistent until the end of the observation period. This indicates that fresh knowledge is constantly recombined and introduced into the knowledge base. Shedding more light on the results from the analysis of the TLC phases, we see that in the era of ferment, the coefficient for New Inventors is not significant for about the first 15 years, but has a comparable large coefficient onward, which is partly captured by the regression of the complete era of ferment. The influence of New Inventors can be the result of the changing approach towards WP in Germany after the failure of the GROWIAN project in the beginning of the 1980s. Since this large scale wind turbine failed, focus was put on small scale turbines and new actors entered the technology (Bergek and Jacobsson 2003). Specialized Inventors is supposed to be relevant in the emergence of the dominant design and the era of incremental change. The results show that the coefficient for these inventors become significant from the beginning of the 1990s onwards and contribute substantially to the technological development until the end of the observation period. Besides two periods in the 1980s, they are not significant in the era of ferment. Here, the results are in line with the results from the TLC regressions.

Related Inventors should play a role in the era of ferment and the emergence of the dominant design. In the era of ferment they have a significant coefficient only in a few periods and even reduce the number of forward citations a patent receives in some periods covering the emergence of the dominant design. Only towards the end of the observation period, Related Inventors becomes slightly significant and seems to play a role again, which is also shown in the TLC regression. The rolling-window regressions reveal a significant negative coefficient in some periods, which is unnoticed in the TLC regressions. Unrelated Inventors is supposed to have an effect in the era of ferment. The results show basically no significant coefficient at all. Only in some periods in the era of ferment, the coefficient is close to being significant. This contrasts with the results from the regression for the era of ferment, which estimates a significant coefficient. However, the number of observations are quite low in these rolling-window regressions and the power of the regression could be too low. Towards the end of the observation period, there is no significant coefficient of these inventors at all, indicating that knowledge from outside the technology’s domain does not matter and Unrelated Inventors seems not to disrupt the technology until then.

In PV, only the first two phases can be analyzed in which New Inventors is not supposed to have an influence. Concerning the results, this seems to be the case. Only in a few periods in the beginning of the 1990s is there a significant positive coefficient. This significant coefficient is also present in the TLC regression. Specialized Inventors is supposed to matter while the dominant design emerges. Here, we can see an increase of the coefficient in this period in line with the model. In the earlier periods, there are only a few periods in which these inventors have a significant coefficient, which is also reflected in the TLC regression for the era of ferment.

Related Inventors should have an influence in both phases. However, the results indicate only a few periods where these inventors actually have a significant coefficient. While the TLC regressions show that in the era of ferment the Related Inventors has a quite large coefficient, the rolling-window regressions reveal that, in the different periods, the coefficient is not that large, although this might be influenced by the low number of observations in each window. Unrelated Inventors is supposed to recombine successfully knowledge in the era of ferment. The results indicate that especially in the early years this is the case, although later on, the significance of the coefficient vanishes. Contrary, the TLC regression finds no significant coefficient in the era of ferment at all, neglecting an influence in the early years of this phase.

Overall, the rolling-window regression provide further insights into the dynamics of knowledge recombination. In both technologies we see shifts of relevance of different inventor types over time. For WP, we can observe that New Inventors and Specialized Inventors become relevant, New Inventors even much earlier than expected. In line with the model, but only partially significant in the era of ferment are Related Inventors and Unrelated Inventors. Contrary to the expectation, Related Inventors has a negative coefficient in some periods of the dominant design. In PV, the results are in general not that pronounced, but partially in line with the model. New Inventors plays basically no role, as expected, and Specialized Inventors has a significant coefficient only while the dominant design emerges. Related Inventors should have had an influence along the whole observation period, but shows only a significant coefficient in some periods. Unrelated Inventors shows as expected an influence early on, but not during the whole era of ferment. The results of the rolling-window regression mirror pretty much the results of the TLC phases in WP, while in PV there are some differences which show up in the era of ferment and are not captured by the TLC regressions.

4.4 Robustness

Several robustness test are performed concerning the distinction of inventors, possible team effects and the rolling-window regression length. The distinction of the inventors into Related Inventors and Unrelated Inventors is based on the presence of the IPCs in the knowledge base of the technology. This criterion changes over time as the knowledge base grows. A robustness test is done to see if this distinction and the change of classification criteria influences the overall results. The assignment of inventors to the two groups is in the following exogenously imposed using technology fields based on an extended version of the OST-INPI/FhG-ISI technology nomenclature classification (OECD 1994; Schmoch 2008). This classification contains five main technological fields and 35 subgroups. The subgroups provide the possibility to assign the inventor type according to the general field of previous application. To distinguish between Related Inventors and Unrelated Inventors, inventors who possess experience in the technological field “electrical machinery, apparatus, energy” for both technologies, and “engines, pumps, turbines” for WP and “semiconductors” for PV are assigned to be Related Inventors. These fields cover the underlying principles of the technologies and most IPCs of the WP and PV patents are assigned to these fields. If inventors do not have experience in these fields, they are supposed to be Unrelated Inventors.

Table 10 shows the results for WP and PV for model 4 and the TLC phases. For WP, we see in model 4 that Unrelated Inventors is no longer significant. In the first phase of the TLC, the coefficient of Unrelated Inventors becomes slightly larger, but New Inventors is no longer significant. In the second phase, the coefficient for Unrelated Inventors becomes significant, however, with a negative coefficient. In the last phase, no changes occur. In PV, Model 4a shows basically no differences, while in the era of ferment Specialized Inventors loses its weak significance. In the second phase, no changes occur. In general the results show that there is some sensitivity towards the distinction between Related Inventors and Unrelated Inventors, but the effects are only marginal and do not affect the overall pattern.

While the results show that different kinds of inventors are relevant for successful knowledge recombination along the TLC, inventive activity is increasingly conducted in teams (Wuchty et al. 2007). While the general trend of increasing team size over time is captured by the year dummies, the team composition is not accounted for. The effect of team composition and heterogeneous teams on knowledge recombination and creativity is an increasing stream of literature (Singh and Fleming 2010; Uzzi et al. 2013; Lee et al. 2015). To account for possible effects of team composition, interactions between the different kinds of inventors are estimated.