Abstract

With the development of human-cyber-physical-production systems in intelligent manufacturing, cyber-supported production based on artificial intelligence is becoming an increasingly powerful means of controlling machines and collaborating with human users. Semi-autonomous systems with a medium degree of automation enable human-centered, flexible, and sustainable production, for instance, in hybrid decision-making. Especially in applications that do not meet the requirements for full automation and when humans are to be involved in their role as qualified decision-makers, teaming-capable systems are desirable and offer considerable advantages. This paper outlines the transdisciplinary concept of human–machine teaming and the role of human cognition in engineering tasks with multi-criteria decision-making. An illustrative real-life example from thermal spray technology is used to show how explainable artificial intelligence models offer targeted, hybrid cyber decision support. This new approach based on fuzzy pattern classifiers combines expert knowledge- and data-based modeling and enables a transparent interpretation of the results by the human user, as shown here using the example of test data from atmospheric plasma spraying. The method outlined can potentially be used to provide hybrid decision support for a variety of manufacturing processes and form the basis for advanced automation or teaming of humans and cyber-physical-production systems.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The current fourth technological revolution is enabling highly complex cyber-physical systems that are mainly driven by the development of powerful information and communication technologies and artificial intelligence (AI) algorithms. However, no matter how efficient and sophisticated these technological advances are or subsequently become, they must be responsibly controlled by humans, serve society and overarching, vital objectives (e.g., biosphere preservation [1]). As the planet’s resource limits are likely to be approached within the next few decades, the resulting global consequences such as climate change, scarcity of energy and water as well as social implications need to be stemmed and managed through appropriate corrective measures [2]. One field of application with huge impact and practical consequences from a sustainability and resource efficient management standpoint [3, 4] is intelligent manufacturing (cf. UN global sustainability development goals [5]). Therefore, approaches towards Industry 5.0 [6] emphasize sustainability, resilience, and strict human-centeredness as main criteria of future industries. These global goals (at abstract level) must be translated into explicit measures for specific manufacturing processes (at concrete level). This is only possible if a complementary top-down and bottom-up framework (see Table 1) links the different levels. As both levels involve complex decision-making processes, such as multi-criteria decision-making (MCDM), this is a key point of integration. Decision-making is a high-level cognitive process that is usually carried out by human experts who take responsibility for the resulting actions and consequences. As individual manufacturing processes and larger industrial production processes are becoming increasingly difficult to understand and control due to their high level of complexity, various options for human decision support (e.g., hybrid decision-making [7]) should be investigated on the basis of a holistic systemic approach (see Section 1.1 below: human-cyber-physical-production systems, HCPPS). The development of hybrid decision-making requires a transdisciplinary combination of competencies: (1) human-centered, psychological perspective, (2) modeling with AI, and (3) manufacturing process. One representative concrete-level manufacturing process from material engineering chosen here for the purpose of illustration is the thermal spray (TS) technology, particularly atmospheric plasma spraying (APS). TS technologies involve complex technical processes used to produce distinct protective and functional coatings to enhance performance or extend longevity of engineering components. For instance, these include thermal barrier, corrosion resistant, or wear resistant coatings for a wide variety of applications, with application-specific coating characteristics and performance attributes being required in all cases. Competing decision criteria are, for instance, deposition efficiency, coating quality, or specific functional properties in the TS coating at the concrete level and resource efficiency, product quality, environmental sustainability, or workers health at the abstract level. The consideration of both levels enables value-focused decision-making [8]. The aim of this paper is to present an AI-based approach to hybrid decision support using the example of TS, which represents a preliminary stage of human–machine teaming (HMT; see [9] and Section 2).

1.1 Abstract level: human-cyber-physical-production systems for sustainable manufacturing

The integration of human and cyber-physical capabilities is promising to deal with the challenges mentioned above. The human innovation power, cognitive strength, expert knowledge, and ability to take responsible decisions and actions are crucial in many applications. An anthropocentric perspective of production within Industry 4.0/5.0 is clearly favorable and represents an emerging paradigm [11, 12]. The human abilities should be combined with strengths of cyber-physical systems (CPS), for instance, repeatability without performance loss, high precision, and barely limited computational speed and power of CPS. The resulting HCPPS [13,14,15] brings together complementary strengths—in a situation-/context-sensitive, adaptive, and human-centered way [15]. Industrial engineering stands to considerably benefit from the purpose-oriented evolution of HCPPS as previously outlined for welding [16] and coating [14] technologies. This concept offers an opportunity to exploit the full human potential in its twofold role as “human creator” (innovation leader; expert) and “user” (crucial operator) [13, 14]. Here, we will focus on the human as expert (creator) as the starting point for the evolution of intelligent cyber-systems with teaming ability. The following ontology outlines main variables and their relations in the context of intelligent manufacturing (Fig. 1).

Teaming between humans and cyber-physical-production systems (HCPPS) motivated by global challenges. Constitution of, and cooperation between, HCPP system parts specified for intelligent manufacturing is illustrated on the right (ontology adapted from [15])

In many areas of industrial research and application, as shown below using the specific example of MCDM in materials engineering, various human expert capabilities (e.g., knowledge, skills, cognitive processes) are not yet taken into account, supported or specifically integrated due to a lack of (1) integration of cognitive engineering methods in the technical design process as well as (2) suitable explainable AI (XAI) modeling methods [17]. Beyond attempts involving full automation and delegation of decisions to algorithms (automated decision-making [18]), the potential of AI should be used to create various levels of automation to be combined with transparent, human-centered hybrid decision support. Tackling the challenge of highly complex input–output relations and multifaceted quality properties in many engineering applications is just one example where such AI support can bring immense value. Here, we focus on applications such as TS that seek medium levels of automation because fully autonomous performance of cyber-physical-production systems (CPPS) is not be beneficial due to the following reasons: (1) full autonomy will not work in the medium term in a safe and reliable way due to technical reasons; (2) automation costs are too high (e.g., insufficient flexibility and unfavorable cost–benefit ratio for small production batches); and (3) high levels of automation are likely to cause unintended disadvantages for humans (e.g., inappropriate level of human situation awareness concerning technical process dynamics [19] or over-trust in automation [20] resulting in human errors).

1.2 Concrete level: thermal spray coatings for sustainable engineering applications

The coatings market is of high industrial and economic importance and continues to develop rapidly as these technologies are crucial for many applications, ranging from the more conventional (aerospace, industrial gas turbines, and automotive) to those that are emerging (medical, fuel cells, solar and wind energy) [21]. The major objective of TS technologies is to either protect or functionalize component surfaces with coatings that exhibit a set of desired properties suitable for specified applications. Therefore, TS is essentially oriented towards resource efficient use of the inherent component and coating materials (e.g., enabling use of cheaper substrates by imparting their surface requisite functionality, extending longevity of expensive parts by depositing protective coatings, or even enabling repair/remanufacture of components that are rendered unusable) and are, hence, sustainable in nature. At the same time, TS is resource-consuming (e.g., high energy is needed to create the thermal plasma utilized in APS, and the powders used have a limited deposition efficiency). Therefore, the spray processes need to be controlled and optimized suitably to minimize use and wastage of such resources. This is often accomplished by human experts by performing elaborate time- and resource-consuming spraying experiments, followed by meticulous characterization and performance evaluation of coatings produced under different conditions. Subsequent decisions are based on expert knowledge, since often multiple competing quality criteria dictated by the targeted application need to be taken into account, making the task challenging and cognitively demanding. Given the complexity of the above, the human operator would greatly benefit from support by CPPS, for instance, during development of any new and more sustainable material-coating process solutions. Currently, a typical spraying unit (physical-production system; PP) is equipped with a cyber-linked part that only realizes basic control loops to stabilize the TS process itself. Cyber-support for human users, for instance, by suggesting alternatives, informing the human about facts that are decision-relevant, or even executing alternatives automatically after human approval, is not available at the moment. Thus, the spraying units’ cyber-linked part capable of providing hybrid decision support still needs to be developed.

1.3 Paper objectives

HCPPS enables holistic integration of essential competencies for human-centered Industry 5.0 use cases. This approach lays the foundation for hybrid decision-making of humans and AI-based cyber-systems and HMT. HMT is a form of support that transfers suitable criteria for cooperation in human–human teams to human–machine teams. The most promising criteria to be developed first are functional complementarity and shared knowledge/goals [9]. In view of the above identified need, the primary objective of this paper is to exemplify the development towards teaming-capable HCPPS for a certain identified task/problem, namely, MCDM for predictive quality, and for a specific engineering technology. While the technology chosen herein (TS) is merely for illustrative purpose, it must be emphasized that the HCPPS approach outlined is universally applicable for other engineering technologies as well. This paper seeks to address human-centered hybrid decision-making by combining different associated facets. Therefore, prerequisites for hybrid decision-making and HMT are outlined from the human decision-maker and model building points of view (Section 2). As elicitation and formalization of expert domain knowledge plays a key role, we illustrate this for the MCDM APS example (Section 3). Thereafter, we show the cyber-formalization procedure by using the transparent XAI method of fuzzy pattern classification (FPC, cf. [14, 22, 23]) for the chosen MCDM task (Section 4). Further, the paper presents specific FPC models for experimental data (e.g., measured particle velocity and temperature that constitute the indirect variable, coating quality characteristics and functional performance indicators) from a former APS study on ceramic coatings [24] in order to establish multidimensional shared goal spaces between human and C-system as one facet of HMT (Section 5). Finally, we interpret and discuss results, summarize limitations, future challenges for method development as well as integration potential for teaming-capable HCPPS (Section 6).

2 Human–machine teaming in industrial decision-making

Technical systems are usually regarded as “tools.” Current trends propose to develop automated systems that may act as “teammates” [9, 15, 25]. This is reasonable for intelligent manufacturing as well, because the overall complexity of production processes and systems is high and qualified, human-centered support for decision-making and control is needed. As one form of human-cyber integration in HCPPS realized using AI [9], HMT offers new opportunities for flexible human–machine co-working and has similarities with related concepts such as “augmented intelligence” [26]. In contrast, however, HMT is characterized by two facets that are clearly relevant: (1) non-redundant and complementary functions as well as (2) shared goals, knowledge, and situation awareness of human and cyber teammate [9, 15, 25, 27]. Hybrid decision-making in complex MCDM tasks is closely linked to these criteria because the cyber-linked part (AI model) should contribute both (1) complementary skills including insights from the evaluation of multidimensional patterns for high-frequency data whose cognitive processing exceeds the capabilities of humans and (2) build on joint goals and a shared domain knowledge, while transferring new insights for learning and knowledge adaptation. The AI model functions as the connection linking human cognition and physical production systems. Human reasoning is based on a complex hierarchy and interaction of cognitive processes (e.g., perception, attention, or decision-making [28]) as well as performance levels (e.g., Rasmussen model: skill-, rule-, and knowledge-based behavior [29]). Table 2 shows an integrative outline of the Rasmussen model for human performance and prevalent AI modeling approaches that may be seen as equivalents concerning basic characteristics and evaluations of levels of human consciousness and AI algorithm transparency [30]. Most black-box AI algorithms, such as artificial neural networks (ANN), “imitate” skill-based behavior that functions on a very basic level without conscious human attention or control. The sensory input and action output relations are highly automated and integrated patterns of behavior (comparable to certain human motor skills like assembly) resulting from extensive training (learning). The usage of skill-based behavior is only successful in familiar tasks and these patterns are not directly accessible by human consciousness [29]. Just like ANN layer structure, transfer functions and weights emerge from intense training (supervised/unsupervised learning) and result in a black-box model without transparency. ANN structure and parameters are often chosen quite subjective [31], prior knowledge cannot be implemented directly, and semantic interpretation is not given. Notwithstanding the above, ANN methods are very powerful for certain problems, showing high prediction accuracies [30] and recent developments towards gray-box models (e.g., hybrid neuro-fuzzy systems [31, 32]) are promising for HCPPS as well. The different cognitive facets must be the basis for choice of AI algorithms. For complex MCDM, this is predominantly the fully conscious knowledge-based level. Therefore, FPC modeling (see below) is used here.

Simple and routine decisions are rather easily done in an implicit and unconscious way while more difficult decisions in less familiar situations are cognitively demanding and require more conscious engagement. Therefore, the former may be fully cyber-automated for many applications but complex MCDM cannot. For MCDM processes in manufacturing that involve decisions between alternative options, e.g., between different sets of technical parameters, the human operator needs an understanding and a conscious mental representation (mental model) of the relevant information in order to make a correct decision. Hence, such processes are a subject for hybrid decision-making and HMT. Ideally, the AI-part should support the human to arrive at better decisions while also aiding to reduce human cognitive load and errors. This could be done, for instance, by offering a narrowed down selection of good alternatives to the human teammate or only suggest the best one in a certain situation and wait for human response concerning the final decision and action taking. In summary, the following principles of the human-AI relationship are necessary and justified for the application area addressed here:

-

Human-centeredness by integrating human cognition and performance explicitly using transparent AI algorithms. Still, transparency of knowledge-based engineering approaches [33] and enrichment of semantics of knowledge models are known to be research challenges [34]. As the human cognitive processes [18, 29] work together seamlessly within the human mind, combinations of different XAI methods need to be developed in the long run to achieve effective HMT.

-

Efficient AI performance for big and small/smart data problems. Today, AI algorithms succeed mainly due to the availability of large databases and computational power—both fundamental prerequisites for nowadays machine learning methodology. At the same time, further deployment in resource-restricted application areas may be hindered by the need for large data sets and high energy demand for computation (e.g., extensive training necessity for deep learning models) [35]. This holds true for many industrial manufacturing applications as well because experimentation and data acquisition are often highly expensive.

-

A combined expert knowledge- and data-driven AI modeling approach is worth aspiring. HMT will rely heavily on information from the CPPS in order to monitor and control complex technical processes (e.g., precise technical measurements such as process gas flow rate or voltage characteristics in APS). Although CPPS performance is superior to human cognition in certain characteristics (e.g., data mining, processing capacity, and speed), human knowledge and abilities superior to CPPS performance (e.g., rapid contextualization, uncertainty management, and holistic, linguistic evaluations of process characteristics) need to be integrated as well within one consistent modeling approach [14] to establish complementarity.

-

Robust AI algorithms to manage uncertainty and vagueness. This is of importance because industrial engineering issues involve dealing with different kinds of imprecisions. AI methods based on fuzzy sets [30, 36,37,38,39] are especially suitable for this purpose and some are able to combine the above-mentioned requirements like the FPC approach we chose here for illustration (see below).

We will address these four principles in the following with the help of the APS example. As the paper’s objective is to link the abstract level of HCPPS development with the concrete level (cf. Table 1), we explain the practical relevance of MCDM tasks in manufacturing with the help of the APS example, highlight the importance of human expert knowledge, and demonstrate how relevant parts of domain knowledge can be elicited and systematized (Section 3.1). Thereafter, MCDM is reflected from a methodical point of view leading to FPC XAI approach to formalize and enable hybrid decision-making (Section 3.2).

3 Formalizing expert knowledge for quality control in thermal spraying

3.1 Expert knowledge for hybrid decision-making in atmospheric plasma spraying

For many manufacturing technologies, a prototypical MCDM task is to choose between varieties of input parameter sets in order to obtain specific outcomes (e.g., coating properties). If these decisions have a higher degree of complexity (e.g., because the underlying technical process is not fully understood or controllable), they are often made by operators or operator teams only. Sometimes statistical experimental design procedures are used to reduce the large space of possible decision alternatives to reasonable ones (see [40] for a review of design of experiments in TS). These procedures remain meaningful even in the light of new AI possibilities and need to be implemented whenever suitable. Notwithstanding the above, the operator needs experience and a certain level of expert domain knowledge concerning technical process control to be capable of such decision-making. Furthermore, considerable experimental efforts are usually necessary to decide correctly, at least in non-routine tasks we focus on. To enable an optimal decision, the decision-maker (human or cyber) needs an in-depth understanding of the technical system and process involved (see short description of APS and Fig. 2 for basic systematization of relevant knowledge). For this, the human decision-maker needs to establish a correct mental situation model of the whole system, the joint working task, the current state, system dynamic and consequences of control actions etc. (= human situation awareness, SA [41]) to perform purposeful and with maximal efficiency. The human knowledge and SA need to be reflected in the cyber part to enable HMT. This is not state-of-the art in most engineering applications, specifically not for TS. A short description of the TS technology reveals why this is not yet the case and can be traced to high process complexity.

TS is used to protect components against wear and corrosion or to functionalize them [42,43,44]. Among the many TS variants, APS is the most versatile and is best suited for deposition of thick coatings (> 100 µm) of high melting point materials (e.g., ceramic surfaces for thermal barrier coatings [10, 45]). In APS process, an electric arc is struck between the cathode and anode of a “plasma torch” which serves to partially ionize the process gasses (e.g., Ar/H2 mixture), whereby a plasma comprising a mixture of partially ionized gasses is formed having locally very high temperatures (> 10,000 K). The coating material is injected into the hot plasma plume in powder form (particle size usually between 15 and 45 µm), and the plasma gases impart the individual particles thermal and kinetic energy, the extent of which is governed by the process conditions and the material used. As a result, the fine particles either fully or partially melt and are accelerated onto a roughened component surface (substrate) that is to be coated. When the particles impact the substrate, they are flattened into pancake-shaped “splats” that constitute the building blocks for coating formation. The extent of flattening depends on the material, the angle of impact and their thermal and kinetic energy conditions, and the “splats” result in the typical lamellar structure of an APS coating (see microstructure depiction in the background of Fig. 2, upper part, right). Numerous parameters such as current, total plasma gas flow rate, plasma gas composition, and wear condition of the cathode and anode influence the properties of the generated plasma plume (e.g., temperature, velocity, thermal conductivity [45, 46]). These indirectly govern the particle velocity and temperature at impact and, consequently, the resulting coating properties.

At present, the dialog between operator and machine in APS is only based on very elementary information exchange: the spraying unit receives and presents basic information about some of the input and control variables such as plasma gas composition, powder feed rate, or plasma power. Very relevant process-related variables, for instance, particle temperature or velocity, are currently not accessible as standard features and may not be controlled directly. Hence, this information must be either inferred by the human operator based on observation and experience in extremely broad terms (e.g., extent of melting of powder) or measured directly using process diagnostics (e.g., employing a camera system for in flight measurement of particle temperature and velocity). Any meaningful evaluation of the produced coating is also time-consuming and inevitably delayed because relevant coating properties/performance are usually assessed through complex destructive testing protocols. Currently, the spraying unit’s process control (cyber-linked part) has no shared knowledge or goals with the human; it does not “know” or “understand” anything about the objectives of the human operator or desired outcomes (e.g., to produce a ceramic thermal insulation coating with high wear resistance properties) and how they can be achieved (e.g., by adjusting particle temperature and velocity through control of plasma gas composition and its flow rate). Consequently, the working task that includes MCDM and dynamic balancing of multiple (competing) output criteria [47, 48] is currently challenging for humans and not resolvable for spraying units. Thus, the targeted evolution of the spraying unit’s cyber-linked part through implementation of human expert knowledge and shared goals (e.g., using FPC models) lays a foundation for hybrid decision-making support and HMT in APS.

From a psychological point of view, decisions addressed in the context of HMT in manufacturing are mainly deliberate and not just intuitive. The operator is able to verbalize main parts of his mental model explicitly and, hence, represents an active system part willing to cooperate with a CPPS teammate on a conscious level to achieve the shared objectives. This does not exclude the possibility to learn from subconscious human signals such as mimic or gaze pattern as well. Human-centeredness in HCPPS has many facets and could possibly be achieved in many different ways. Our approach concentrates on a subpart of human cognition, specifically human knowledge concepts, which are stored in long-term memory and accessed, for instance, in MCDM to build up a mental situation model. High-level human expertise is characterized by efficiently organized knowledge concepts for the specific domain (e.g., APS technology) that result from learning and experience and, therefore, are closely related to seniority [49, 50]. Mental models can be inferred from empirical evidence using methods from cognitive engineering psychology such as interviews [51]. Figure 2 shows a systematization of APS knowledge acquired from three APS experts. It illustrates a rough overview of basic declarative knowledge concepts and causal relations on different levels of generality. For instance, the classification of context factors, input variables, process dynamics, and output variables, is a very general one that holds true for all manufacturing technologies. Input variables, for instance, feedstock- or process-related direct variables, are specific to thermal spraying technology or even APS specific (e.g., total plasma gas flow rate) whereas output criteria are universally applicable for many coating technologies. Quality criteria are differentiated according to microstructure and coating properties which are related via a causal structure–property relationship (e.g., high microstructural porosity is associated with low hardness). According to the sustainability goals, resource efficiency criteria are highly relevant as well. Knowledge elicitation is purposeful and context or task specific. The systematization shown in Fig. 2 is very elementary and does not reflect an APS expert’s knowledge completely or entirely accurately but in a sufficient way to exemplify the basic principles relevant for human-centered AI modeling (a more detailed description of APS knowledge hierarchies and relations, and how they can be visualized, is being currently prepared for publication). The variables “total plasma gas flow rate,” “particle temperature,” and “particle velocity” are relevant to the following MCDM task. They were varied, measured, and selected for FPC modeling (see Section 4).

3.2 Approaches for multiple criteria decision-making

3.2.1 Formal model building approaches to MCDM problems

HCPPS complexity results from (1) the human interacting with (2) the technical process that may include several non-linearly and dynamically behaving subsystems, partly unknown parameters and relations as well as (3) context variables and disturbances influencing the technical process in an unknown, uncertain, or stochastic way. Therefore, the optimization of control decisions is methodically challenging as well. Often, there is not only one efficient solution or decision but, depending on the evaluation criteria and their importance (weights), a set of many decision alternatives may be present (Pareto set) and the optimal decision is to be assessed and chosen. The notion of Pareto optimality [52,53,54,55] is closely related to the concept of dominance, which is fundamental in complex decision-making [56] (see Fig. 3(a)).

Figure 3(b) shows the Pareto set with several efficient decision alternatives (gray points) including alternative x (red point) that do not dominate each other but are superior to the other alternatives (white points). The green point represents the theoretically best decision; the nadir point (black point) marks the worst one based on the goal of GC 1 and GC 2 maximization. These theoretical options are usually not practically realizable. Otherwise, the task would not be a MCDM problem. There is a large variety of different methods for poly-optimization such as multiple objective decision-making (continuous solution spaces) vs. multiple attribute decision-making (discrete solution spaces) including classical and outranking approaches (e.g., multiple criteria utility analysis vs. ELECTRE or PROMETHEE [57]). A state-of-the-art survey of MCDM methods can be found in [55] or [56]. Nevertheless, real-world MCDM is still challenging: “[…] Most real world decision problems take place in a complex environment where conflicting systems of logic, uncertain and imprecise knowledge, and possibly vague preferences have to be considered. To face such complexity, preference modelling requires the use of specific tools, techniques, and concepts which allow the available information to be represented with the appropriate granularity. In this perspective, fuzzy set approach has received a lot of attention […]” [55, pp. 21–22].

This is true for engineering applications as well (e.g., engineering design processes [56]). Next to multiple criteria utility analysis [58, 59], multiple criteria fuzzy set analysis [48, 53, 60, 61] is widely used. Besides other aspects, the approaches differ in the precision necessary for quantifying the preferred performance of each goal criterion. For utility analysis, the performance needs to be precisely defined numerically, which is often not possible (e.g., in early stages of research and for complex real-world applications [60]). On the contrary, the fuzzy set approach allows using qualitative performance descriptions such as linguistic terms as alternatives (e.g., “medium” proportion a chemical element in a coating, cf. Figure 5). As this is especially favorable for the APS application, we utilize a fuzzy modeling approach, namely, fuzzy pattern classification (FPC, see Section 4).

Human-centered model building needs to reflect the domain knowledge as well as basic principles of the human decision-making process. While the knowledge content is shown in Fig. 2, the decision process is specified in the following. From a formal, psychological point of view, deliberate, non-routine MCDM includes concurrent option evaluation. Other types of decisions, such as decision-making under time pressure, favor other normative model building approaches (e.g., serial option evaluation) [62]. In MCDM, the decision-maker considers more than one option at a time, compares them in terms of the goal criteria, and assesses the strengths and weaknesses of available options relative to each other in a complete way [63]. This procedure can be formalized by distinguishing between two spaces [54], between which the decision-maker constantly switches for simultaneous option evaluation (transformations): the space of decision alternatives (input space) and goal criteria (output space) as shown in Fig. 4:

The spaces are defined by the domain expert knowledge and their transformations can be modeled on the following basis:

-

(a)

Natural science laws that may be analytically derived and mathematically formalized (e.g., Ohm’s law)

-

(b)

(Large) statistical sets of input–output data (e.g., originating from real-world measurements or computer simulations) with relations (e.g., neural nets)

-

(c)

(Small or large) structured data sets and knowledge (e.g., combined data- and knowledge-based modeling approach with implementation of human expert knowledge)

In many manufacturing applications, the number of realizable input variations and basic data sets is limited because real-world experiments are time- and resource-consuming. Due to the high complexity of APS process, it is not possible to describe the spaces and transformations by analytical relationships or exhaustive experimentation and data collection in order to find all feasible solutions (model building variants (a) and (b), see above). Therefore, we chose approach (c) here to combine experimental data and human expert knowledge. We do not aim to find all multiple criteria solutions that may be optimal for the concrete-level APS task (e.g., result of exhaustive search algorithms). Instead, we intend to illustrate how the most preferred option out of the space of decisions can be selected (cf. Figure 8, upper left corner and step 1 as well as Tables 3, 4, 5 and 6 for relevant information). Thereafter, new alternatives that meet the goal criteria increasingly better can be iteratively assessed by using a pendular transformation procedure between decision and criteria spaces (see Fig. 8, orange and violet arrows). In subsequent steps (see Fig. 8, step 2 and n), new decision alternatives can be calculated that dominate the previous ones in the Pareto set and, hence, show higher optimality concerning all goal criteria. Starting point of the procedure is a discrete number of known input options (five levels of an APS input variable, cf. Table 4, left) that are described by process measurements (particle temperature and particle velocity data [24]). The data determine FPC classes in the decision alternative space. The goal criteria space is defined and structured semantically by APS experts in a knowledge-based way in three main parts (microstructure, coating properties, and resource efficiency, cf. Figure 2, right part). Goal criteria can comprise (multiple) subgoal criteria such as “porosity” or “phase constitution” for “microstructure” with preferred degrees of expression (e.g., maximum proportion of Al2O3 in resulting coating; see Table 3). The threefold structure is implemented in AI modeling using three separate FPC models in parallel based on either numerical experimental data or fuzzy linguistic term (see Table 4 for measurement methods used to determine goal criteria of coatings). Starting with three (partly multidimensional) transformations and back transformations between the FPC spaces, new decision alternatives can be planned by calculating corresponding (unknown) input variations (see violet arrows in Fig. 8).

Subsequently, we show how the four principles for human-centered hybrid decision-making mentioned in Section 2 can be taken into account using FPC models and specify this for the APS MCDM example (see Section 3.2.2). We then briefly summarize the methodological foundations of FPC AI modeling (see Section 4.1) and apply FPC to data from APS experiments (see Section 4.2).

3.2.2 MCDM in APS

A MCDM problem has structural elements such as shown in Table 3 (left column) for the APS example (right column). To figure out which decision alternative accomplishes the general objective best, multiple goal criteria (GC) and sometimes subgoal criteria (SGC) and their preferred degrees need to be defined and balanced. In the APS example, the GC hierarchy level is quite general and, hence, SGC level is used for MCDM-APS modeling instead (see below). As mentioned above, it is favorable to integrate linguistic terms for modeling as well because this seizes a very natural way of human communication. Linguistic terms can be “translated” and, hence, formalized for AI modeling using fuzzy membership functions (MF, e.g., two-step translation procedure shown in [64]). Therefore, straightforward modeling is possible despite the qualitative nature of linguistic expressions. Hence, uncertainties in the MCDM process can be taken into account in an explicit manner (cf. principles for human-AI relationship in Section 2). For the APS example, the SGC are partly competing. Therefore, the criteria need at first to be balanced before the decision can be reached.

Currently, this is done by the human operator without any support. The SGC were determined using the methods summarized in Table 4, which are standardized and commonly used in the field. We have used herein the data reported in [24] for reanalysis and modeling of FPC and fuzzy transformations to reveal the practical potential of XAI for MCDM problems in the context of hybrid decision-making.

4 Method

4.1 Fuzzy pattern classification

In order to describe uncertain information and systems behavior, such as measurement uncertainty or disturbances, fuzzy set theory [36], fuzzy rules, fuzzy cognitive maps and further developments to fuzzy pattern classifiers (FPC), FPC sequences or networks, adaptive FPC are established methods. This class of AI algorithms show high performance capabilities for many real-world applications including thermal spraying and is characterized by high cognitive transparency and explainability (e.g., [14, 22, 23, 30, 39, 65,66,67,68,69]). The FPC modeling approach is based on the concept of membership value (µ) which is an assessment of agreement to a context-related criterion from a certain point of view. Figure 5 presents the FPC parametric potential MF approach we use here exemplified for a one-dimensional problem such as linguistic terms for Al2O3 or TiO2 proportion (example SGC for APS, left side) as well as the extension to multidimensional patterns showing a joint SGC class of two potentially competing SGC (e.g., proportion Al2O3 and proportion TiO2, right side).

As real-world applications always contain uncertainties due to context influences, disturbances, measuring inaccuracy, and human-related factors, fuzzy definitions of categorical boundaries are more suitable than crisp ones and gradual µs are reasonable. Metric variables or non-metric linguistic expression can be formalized using fuzzy membership functions (MF). The parametric MF concept used here is very compact in its computational description. This facilitates porting on software platforms or technical control devices (e.g., in APS spraying units) for inline real-time applications. Furthermore, vector variables (e.g., particle temperature and velocity) can be handled efficiently. The parametric potential MF used here is presented in [23, 39] for one- and multidimensional modeling. All parameters are semantically interpretable and, hence, show maximum transparency and explainability (XAI approach). Parameters r and c stand for precise information: r typically shows positional values (e.g., mean or median value indicating MF center) and c represents measures of dispersion (e.g., range or standard deviation) whereas b and d express imprecision (fuzziness) such as density gradient. The description of fuzzy classes in an n-dimensional space is based on n one-dimensional MFs between which is approximated (see Fig. 5, right, two-dimensional example). Modeling for n > 2 is possible and translations and spatial rotations of fuzzy classes are feasible as well. The resulting fuzzy pattern classifier may comprise several classes with application-specific meaning, such as control, state, or quality classes formally described by multidimensional fuzzy patterns not fuzzy logic rules (cf. Figure 6(b) for APS input classes defined using particle temperature and velocity). FPC models match the requirements for AI suitable for hybrid decision-making mentioned in Section 2 (see above) additionally offering a compact computational description with remaining interpretability of classes and class relations (e.g., distances, overlapping) in multidimensional feature spaces. Furthermore, MFs are easily adaptable based on new information regarding either single MF parameters or whole classifier structures without effortful, resource-consuming relearning or training procedures [39].

Fuzzy pattern classifier model based on measured APS process variables “particle temperature” and “particle velocity” for decision alternative space with five input parameter sets (P1–P5; cf. Table 5, left column). The points (middle) represent measured data and lines indicate membership level µ = 0.5

4.2 Fuzzy pattern model building for decision-making in atmospheric plasma spraying

Subsequently we show how new input variations (plasma gas flow rate) can be calculated by a combined expert knowledge- and data-driven approach for the MCDM APS example. Beyond known and experimentally tested variations, a potentially optimized solution is to be identified using FPC modeling (see Fig. 8, calculation of new alternative, violet box). This suggestion from the cyber-linked model part of the HCPPS goes to the human operator and enables hybrid decision-making. Starting point is the computational specification of decision alternative and goal criteria spaces (Section 4.2.1). Thereafter, a pendular transformation procedure is outlined used to relate spaces and complete the decision process (Section 4.2.2).

4.2.1 Decision alternative and goal criteria spaces

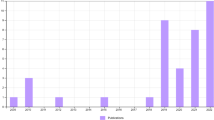

The decision alternative space in the example is defined by five discretely varied input rates of total plasma gas flow (cf. Table 5, left column, P1–P5) [24]. Hence, the FPC decision alternative space model is based on the APS process variables “particle temperature” and “particle velocity” measured for P1 to P5 (five data sets including 43 measurements each). Figure 6 shows the FPC model (for parametric description see Appendix Table 7).

The goal criteria space is modeled based on results of coating analyses of samples for relevant SGC (cf. Table 3). Figure 7 presents the goal criteria space models (for parametric description in Appendix, Tables 8, 9, and 10). According to the elicited APS expert knowledge, this space is divided into the three subspaces “microstructure,” “coating properties,” and “resource efficiency” and defined by the SGC variables. The FPC submodels “coating properties” and “resource efficiency” are purely data-based (cf. Table 4 or [24] for analysis methods). Submodel “microstructure” is determined by linguistic expressions (very low, low, medium, high, very high, cf. Fig. 5) originating from an expert assessment of experimentally measured Al2O3 and TiO2 proportions (cf. Table 5, right columns) since plasma instabilities and variations in other conditions like particle size distribution of spray powder that are not precisely controllable lead to some inevitable variations in the determined coating phase constitution. Hence, both structured and unstructured data can be used for FPC modeling.

Fuzzy pattern classifier models for the three subgoal criteria spaces based on experimentally determined subgoal criteria variables (see Tables 3 and 4) for five varied input parameter sets (P1–P5; cf. Table 3, left column). The three lines in figures (a) and (b) for Ps indicate membership levels for µ = 0.25 (outermost), µ = 0.5 and µ = 0.75 (innermost)

4.2.2 Fuzzy transformation procedure between decision alternative and goal criteria spaces

After modeling of decision alternative/goal criteria spaces, the transformation procedure between them needs to be specified as well to complete the decision formalization. Complex human decision process involves continuous (re-)assessments of the decision situation and context as well as coping with conflicts between multiple decision options or management of uncertainty (cf. integrative model of human decision-making [70]). For the APS example presented the decision-making process can be more specifically and formally described as stepwise, pendular transformation process between decision alternative and goal criteria spaces with various points where humans (re)interpret intermediate results and adapt decisions and actions accordingly (result interpretation, RI). Figure 8 shows this process schematically. It typically starts with a rather small set of real-world experiments (e.g., input variations of total plasma gas flow rate in space of decision alternatives, left above). The experimental results are modeled (data-based modeling 1) and interpreted. RI is the basis for the first transformation between spaces (step 1, orange arrows) and comprises the evaluation of the decision alternative space FPC model shown in Fig. 6 for the APS example (for discussion of specific results see Section 5).

Fuzzy classifier spaces of decision alternatives (blue box, left) and goal criteria (green box, right) with pendular transformations (orange and violet arrows), points for human result interpretation after each modeling and transformation step (RI) and possibilities for hybrid multiple criteria decisions (MCDM decisions, right)

Input variations in real-world experiments lead to differences in technical processes such as a lower total plasma gas flow rate (P1) leads to higher particle temperature compared to higher gas flow rates (P2-P5). This results in different outputs, for instance, concerning microstructural or coating properties of APS surfaces. The basic relation is shown by the orange arrows in Fig. 8 and relates the decision alternatives FPC model to the goal criteria space FPC models (see Fig. 7). The three GC submodels can be interpreted as well (see Fig. 8, step 1, RI on right side) and may lead to a first MCDM decision. MCDM decision 1 is the choice of the optimal setting out of five known experimentally varied inputs (P1–P5) and is based on real-world data as well as human assessments done with regard to certain goal criteria specifications (e.g., see Table 3). The decision process could end here or be continued in order to calculate new alternatives with potential to be even better candidate solutions beyond the already known input settings. This backward transformation starts in the goal criteria space and leads to decision alternative space again (Fig. 8 step 1: violet arrows from right part to left part). It is very important to note that the optimization result is transformed back into the input/decision alternative space. This fact allows humans to directly intervene in the control space through the hybrid decision proposal. Typically, this is not always the case with optimization methods, so that although an optimized alternative can be determined for the output criteria, the reference back for the human being as to what he should now do is not always given. The calculated new alternative input P6 could thereafter be experimentally validated (real-world experiment 2), modeled and transformed to the goal criteria space resulting in a new MCDM decision 2 that is a choice out of all known input variations (e.g., P1–P6). The process can be repeated until the satisfying MCDM alternative is found.

Schematic membership functions (MF, two-dimensional depiction) for two alternative MCDM options (blue vs. black) described based on measured variables (v1 and v2) in the decision alternative space. Points indicate MF centers with maximum membership values (µ = 1) and lines around the centers decreasing µs. The red crossing point of the bold lines at equal µs represents the new MCDM alternative searched for

The calculation of a new decision alternative is done using the FPC models. For this purpose, at least two (or more) alternative optimal solutions are chosen from each GC submodel if no alternative is clearly dominant concerning all defined GC/SGC specifications. In the goal criteria space, the criteria and chosen alternatives may be cooperative or concurrent in nature depending on the position in and contiguity of the Pareto set. A compromise solution lying between the selected options is now determined based on Pareto optimization principles in the decision alternative space (see Fig. 9).

To do so, the FPC model describing the chosen options in the decision alternative space is used. Starting from the MF center of each alternative option a1 and a2, indicated by the representative value r with maximum membership µ(r1) = 1 and µ(r2) = 1, the point of equal membership lying between a1 and a2 is searched for µ(a1) = µ(a2) (see Fig. 9, red point). It represents the new calculated MCDM alternative. The level of membership at which the compromise solution was found (Fig. 9, bold lines) can be interpreted as well: the nearer the new calculated alternative to a known option, the lower the decision risk because the former ones have already been experimentally realized. After having determined the compromise solution, its compatibility to the Pareto set is again to be proven based on half-order relation. By proceeding iteratively several times in the described way, the Pareto set can be found. This targeted approach supports experimental planning and, hence, saves efforts and resources as fewer technical experiments need to be carried out. Compared to stochastic search algorithms that require a significantly higher number of next experimental realizations (e.g., particle swarm, genetic algorithms), this method is more effective. The possibility for human involvement in the MCDM process is given at every point in time in a very transparent and cognitively plausible way. If the close engagement is not intended or needed, parts of the hybrid decision procedure could be done automatically by the model/cyber teammate. Subsequently, this methodical procedure is specified again for the manufacturing application in order to show and discuss results for the concrete-level APS example.

5 Results and discussion

Subsequently, results for two concrete APS scenarios that could comprise distinct targeted applications are presented and discussed. In general, scenarios may differ regarding the GC or SGC to be met depending upon the intended end-use of the APS coating. Hence, different human viewpoints or intentions might be reflected directly in specification of GC and SGC. The scenarios chosen are primarily illustrative to depict how the MCD designed to meet the requirements of a targeted application influences the end result. The scenarios in the present case are aimed at addressing the following requirements reflected as well in the SGC specified by the human expert (see Table 6):

-

Scenario I: develop a coating that has a high electrical resistivity to serve as dielectric and also combats wear.

-

Scenario II: develop a coating that has a high electrical resistivity to serve as dielectric; degradation or failure on account of wear is, however, not a consideration.

As mentioned in Section 4.2, the FPC models for decision alternative and goal criteria spaces were determined using experimental data [24]. Both FPC models (and submodels) are depicted in Fig. 10 for the first scenario and the initial first MCDM transformation and back-transformation step. Figure 10(A) (left) shows the measured data points for particle temperature (T) and velocity (v), for all five input variations (classes) P1–P5 reflected in Table 5. Obviously, the T and v measurements for some input classes are rather distinct (e.g., P1 and P2) while others overlap (P3–P5). This is a common finding in real-world technical processes.

(A) Measured process variables (particle temperature and particle velocity, see points) for five discretely varied input sets (total plasma gas flow rates, P1–P5; see Table 5) as basis for data-based modeling 1 (cf. Figure 8). Resulting fuzzy pattern classifier in decision alternative space depicted in two-dimensional (left), transformation (orange arrows) into goal criteria space (right) with three fuzzy classifiers (cf. Figure 7). For MF parameter set see Appendix Tables 7, 8, 9, and 10

Further, the total plasma gas flow rate effects particle temperature and velocity in a nonlinear way. Hence, FPC submodels for microstructure, coating properties, and resource efficiency show different performance patterns for P1 to P5. Concerning resource efficiency, inputs with low total gas flow rates are superior for this specific response because the deposition efficiency is higher and P1 as well as P2 show very similar thicknesses per pass followed by P3 and P4. The order is ranked and the optimal solution for this single GC is P1. This can be seen in Fig. 11(B). The r value for P1 is v = 146 m/s and T = 3353 °C (cf. Appendix, Table 7). The coating properties submodel (see Fig. 10(B) shows a non-contiguous Pareto set with competitive GC (cf. as well Fig. 3). For SGC “hardness” P1 (minimum gas flow rate) dominates the other input alternatives; for SGC “electric resistivity” the opposite setting P5 (maximum gas flow rate) is the best option. P2 and P3 show very similar performances. A MCDM solution for this submodel lies in-between P1 and P5—but because of the nonlinear relation—P2–P4 cannot be chosen without loss of performance for one of the GC. The model-based new compromise solution where MFs cross (cf. Figure 9) is shown in the Fig. 11(A) and equals v = 155 m/s and T = 3190 °C. In the FPC submodel, “microstructure” represents a more contiguous and cooperative Pareto set. In order to determine the Pareto compromise, P1 and P3 are activated. The solution is v = 155 m/s and T = 3190 °C (see Fig. 11, left above). The three calculated alternatives for the goal criteria submodels are summarized by weighted arithmetic mean according to the previously defined criteria values (cf. Table 6) resulting in final MCDM solutions that differ for each of the cases:

-

Scenario I v = 154 m/s and T = 3245 °C

-

Scenario II v = 171 m/s and T = 3143 °C (see Fig. 12).

Fuzzy pattern classifiers for goal criteria spaces (B) and (a) microstructure, (b) coating properties, and (c) resource efficiency with one- or two-dimensional depictions of MF for input sets (P1–P5; see Table 5). For MF parameter sets see Appendix Tables 8, 9, and 10. Pendular back-transformation (violet arrows) into decision alternative space (A) and calculation of new decision alternatives. Final MCDM alternative for scenario I (see Fig. 12) results from integration of compromise solutions

Final MCDM decision solutions for two scenarios (specifications of subgoal criteria see Table 6)

6 Summary, conclusions, and future directions

This paper highlights the potential of hybrid decision-making in HCPPS, by narrowing the issue down to a concrete-level challenge (cf. Table 1, Sections 3–5). We show how two aspects of HMT, namely, complementarity and shared knowledge/goals, can be utilized for hybrid decision support in case of MCDM. The suggested MCDM process reflects a pendular transformation from decision alternative to goal criteria spaces (see Fig. 4), with various points for human result interpretation to facilitate or stop decision-making (cf. Figure 8). The procedure was elaborated for APS (cf. Section 3.2.2.) and formally realized using FPC method (see Section 4). The data base [24] used was of a size typically for a real-world APS experiment, representing a small/smart data problem. The combined expert knowledge- and data-driven FPC approach successfully applied to the APS MCDM task shows first interesting and reasonable results for two different scenarios. Further experimental APS tests are now required to validate the results and optimize the FPC model. The transdisciplinary work presented leads to conclusions from different perspectives with the following implications for joint future endeavors.

6.1 Human perspective

Methods from cognitive engineering psychology can form the basis for targeted technical developments towards human-centered hybrid decision support and might be expanded to both human and technical data (e.g., gaze behavior indicating information search or attention processes or current voltage characteristics of technical units [14]). The analysis and partial formalization of expert knowledge and cognitive processes can help to design C- and PP-parts in an anthropocentric way [12, 71, 72]. Increasingly important is the relation of human and C-parts as the C-system is immaterial in nature and, hence, not “visible” in the way like the PP system. Failed C-system design may remain unnoticed for a longer time. Therefore, future research needs to focus on ways to make important information visible at the right point in time (cf. Figure 8, points of human result interpretation, RI, after semantically meaningful steps in MCDM process). This ensures that the human operator can easily understand the operations of the C-part, use and evaluate the cyber-support at a conscious level of cognitive processing, and calibrate its own trust in the cyber-linked assistance. Presented information need to be adequate (e.g., structured similarly to domain expert knowledge). Furthermore, acceptance of HMT in the working environment will depend on whether the C-system (1) complements the human abilities in a functional way like it is intended to be shown in this paper, (2) replaces human tasks which eventually leads to human identity threat, or (3) if it even generates new working tasks [73]. Outstanding abilities of human experts are flexibility and creativity in problem solving or decision-making and the capability of rapid contextualization and understanding of meanings in different contexts to adapt behavior accordingly. Here, the human is clearly superior to current AI and will almost certainly remain so in the next future [26]. In contrast, the C-part has high computational power and speed—a complementary strength for HMT. As overstressing of human cognitive processing capabilities (e.g., exceeding amount of processable information per time) needs to be avoided at all costs to keep humans psychologically healthy and in control of their working task, this point is very crucial and needs more research in concrete applications.

6.2 Cyber and model building perspective

The proposed MCDM procedure (see Fig. 8) with pendular transformations between decision alternative and goal criteria spaces is reasonable from a psychological [70] and formal methodical point of view [54] (e.g., keep three separate GC models during MCDM process, cf. Figure 8). Most of the FPC submodels were defined using numerical measurement data whereas one classifier (GC model “microstructure”) utilized linguistic terms to show model flexibility concerning input information, human-centeredness by using natural language and the capability to deal with real-world uncertainties. The method was outlined for the first transformation step representing a deterministic calculation of new solutions alternatives for the MCDM task given (e.g., new input P6) based on results from previous technical experiments. Pareto-optimal compromise solution candidates were activated from the entire set of options and, thereafter, MCDM optimization was achieved by matching compromise solutions in the goal criteria space with inputs in the decision alternative space (backward transformation). The calculated MCDM alternatives (see Fig. 12) are not yet experimentally proven. Hence, the suggested FPC models and MCDM approach cannot be evaluated completely in practical terms and more research is needed. Some considerable challenges concerning the development of C-system are the following:

-

(a)

Functional relations, model building, and simulations: We did not determine a functional relation for the transformations between decision alternative and goal criteria spaces and FPC models here although this would theoretically be possible and of interest in practical terms. In order to do so, the Pareto set of compromise solution candidates needs to be sufficiently empirically proven. Hence, more experimental data is needed for interpolation and prediction. As the interpolation of a function is closely related to APS process model building, this issue should be driven in accordance with developments of technical systems and processes (see below (3) physical-production system). Further, methodical research is needed as well, as both MCDM spaces include several multidimensional fuzzy classes for which appropriate transformation functions are searched (cf. fuzzy relations [74]). This may as well include comparisons between data from experiments and computer simulations such as shown for self-pierce riveting in [75] or other fuzzy MCDM approaches, for instance, using fuzzy triangular MF and fuzzy numbers for forming [76].

-

(b)

Model adaptation: At present, the FPC models are static in nature. Following recent approaches towards evolving intelligent systems and self-learning AI [37,38,39], the parametric and structural adaptation of FPC models based on new information and temporal changes in process behavior would be interesting as well. The MFs describing FPC models can easily be updated using new data so that classes may “move” and “breath.” Fundamental structural model changes based on supervised or unsupervised learning such as splitting, fusion, re-creation, or deleting of classes [39] or the creation of more complex knowledge structures and FPC-nets with parallel, sequential, feedback, or hierarchical classifier connections might be interesting as well [23, 77]. Further research on these topics would form a very valuable methodical basis for cognitive HMT because human expert knowledge is hierarchically structured [78]. Learning processes lead to knowledge structure and concept adaptation and, accordingly, to adjustment of MCDM processes and behavior. Further, flexible model adaptation (related to MCDM problems [79]) is of high practical relevance for APS and many other manufacturing technologies as well.

6.3 Perspective of the manufacturing technology

The proposed hybrid decision-making procedure was outlined for a concrete-level MCDM APS task. Researchers and developers of CPPS are confronted with the challenges of enhancing resource-efficient production and sustainable transformation of technical processes for many manufacturing technologies. Tasks and problems are similar, for instance, concerning lack of “big” data due to high costs and efforts of technical experiments (e.g., determination of coating quality). Hence, the proposed sequential MCDM approach is not only human-oriented and very close to psychological processes but a necessity and of great advantage in practical terms. Each MCDM step reveals a valuable interim result used by the human for further interpretation, experimental planning, and decisions (cf. Figure 8). In perspective, a large data pool can be build up successively—including results from many international working groups (e.g., open science initiative)— with this systematic and transparent approach. To do so, results need to be implemented in a suitable database system and structured according to the elicited expert knowledge and MCDM process within the specified domain (see Section 3 and Fig. 8). The combined knowledge- and data-based modeling approach offers a high potential as all expert of a certain domain can interpret the XAI-based FPC models semantically and, with only little effort, all presented FPC models can be easily extended as well. Even variations of other input variables (e.g., power particle size) or measurement of new output criteria (e.g., defects) can be implemented and used for MCDM calculations because the basic structure of the decision alternative/goal criteria spaces and transformations remain and the FPC approach is flexible enough for model adjustment. Further, the systematic elicitation of human domain knowledge and explicit description of human mental models (cf. Section 2) opens up the possibility of comparing and reconciling even very different points of view. For instance, more application-oriented versus basic research-oriented viewpoints of different researchers are likely to vary according to GC, SGC, and weights (cf. Table 6). Hence, different MCDM scenarios can be compared using FPC models. The calculation of new compromise solutions may show how much the standpoints may differ in reality and, consequently, if further technical experiments are needed to clarify certain questions or not. In this paper, we focused on showing rather basic principles and procedures with the help of a small data set. Therefore, the interpretation and generalization of results (e.g., calculated MCDM alternatives for scenarios see Fig. 12) is currently only possible to a limited extend. Self-evidently, more technical experiments and research are needed for validation. But the potential of the outlined approach as preliminary stage to a domain knowledge model for APS and other comparable technical processes has become clear.

The concepts of HCPPS and HMT described in this paper need to be practically developed in an application-specific and suitable way. Currently, most physical systems such as spraying units are partly automated regarding some functionalities but, holistically assessed, are still far away from being a CPPS. This offers the opportunity for transdisciplinary and joint developments based on the HCPPS and HTM approach. In conclusion, it can be stated that the transdisciplinary approach favored and shown for a small-scale example application has high potential for a harmonic technological development towards more efficient, human-centered, and sustainable Industry 5.0 [12, 71].

References

Vester F (1988) The biocybernetic approach as a basis for planning our environment. Syst Pract 1(4):399–413. https://doi.org/10.1007/BF01066582

Randers J (2012) 2052: a global forecast for the next forty years. Chelsea Green Publishing. http://www.2052.info/wp-content/uploads/2019/05/p120801-2052-A-global-forecast-15p-illustrated-CPSL.pdf

Pinzone M, Albè F, Orlandelli D, Barletta I, Berlin C, Johansson B, Taisch M (2020) A framework for operative and social sustainability functionalities in human-centric cyber-physical production systems. Comput Ind Eng 139:105132

Ocampo-Martinez C (2019) Energy efficiency in discrete-manufacturing systems: insights, trends, and control strategies. J Manuf Syst 52:131–145

United Nations. Sustainable development goals. https://www.un.org/en/sustainable-development-goals, accessed 2022/12/21

European Union. Industry 5.0. https://research-and-innovation.ec.europa.eu/research-area/industrial-research-and-innovation/industry-50_en, accessed 2023/11/15

Psarommatis F, Kiritsis D (2022) A hybrid decision support system for automating decision making in the event of defects in the era of zero defect manufacturing. J Ind Inf Integr 26:100263

Keeney RL (2009) Value-focused thinking: a path to creative decision making. Harvard University Press

Bocklisch F, Huchler N (2023) Humans and cyber-physical systems as teammates? Characteristics and applicability of the human-machine-teaming concept in intelligent manufacturing. Frontiers in Artificial Intelligence 6:1247755

Pawlowski L (2008) The science and engineering of thermal spray coatings. John Wiley & Sons Ltd., England https://doi.org/10.1002/9780470754085

Rauch E, Linder C, Dallasega P (2020) Anthropocentric perspective of production before and within Industry 4.0. Comput Ind Eng 139:105644

Xu X, Lu Y, Vogel-Heuser B, Wang L (2021) Industry 4.0 and Industry 5.0—inception, conception and perception. J Manuf Syst 61:530–535

Zhou J, Zhou Y, Wang B, Zang J (2019) Human-cyber-physical systems (HCPSs) in the context of new-generation intelligent manufacturing. Engineering 5(4):624–636. https://doi.org/10.1016/j.eng.2019.07.015

Bocklisch F, Paczkowski G, Zimmermann S, Lampke T (2022) Integrating human cognition in cyber-physical systems: a multidimensional fuzzy pattern model with application to thermal spraying. J Manuf Sys. https://doi.org/10.1016/j.jmsy.2022.03.005

Madni AM, Madni CC (2018) Architectural framework for exploring adaptive human-machine teaming options in simulated dynamic environments. Systems. https://doi.org/10.3390/systems6040044

Wang B, Hu SJ, Sun L, Freiheit T (2020) Intelligent welding system technologies: state-of-the-art review and perspectives. J Manuf Syst 56:373–391

Li L, Zheng NN, Wang FY (2019) On the crossroad of artificial intelligence: a revisit to Alan Turing and Norbert Wiener. IEEE Trans Cyber 49(10):3618–3626. https://doi.org/10.1109/TCYB.2018.2884315

Karanasiou AP, Pinotsis DA (2017) A study into the layers of automated decision-making: emergent normative and legal aspects of deep learning. Int Rev Law Comput Technol 31(2):170–187

Miller CA, Parasuraman R (2007) Designing for flexible interaction between humans and automation: delegation interfaces for supervisory control. Hum Factors 49(1):57–75

Lee J, Moray N (1992) Trust, control strategies and allocation of function in human-machine systems. Ergonomics 35(10):1243–1270

https://www.fortunebusinessinsights.com/thermal-spray-coatings-market-102388, accessed 27.05.2022

Bocklisch SF (1986) A diagnosis system based on fuzzy classification. Comput Ind 7(1):73–82

Bocklisch F, Hausmann D (2018) Multidimensional fuzzy pattern classifier sequences for medical diagnostic reasoning. Appl Soft Comp 66:297–310. https://doi.org/10.1016/j.asoc.2018.02.041

Grimm M, Conze S, Berger LM, Paczkowski G, Drehmann R, Lampke T (2021) Changes in the coating composition due to APS process conditions for Al2O3-Cr2O3-TiO2 ternary powder blends. J Therm Spray Technol 30(1):168–180

Johnson M, Bradshaw JM (2021) How interdependence explains the world of teamwork. In: Lawless WF, Llinas J, Sofge DA, Mittu R (eds) Engineering Artificially Intelligent Systems. Lecture Notes in Computer Science, vol 13000. Springer, Cham. https://doi.org/10.1007/978-3-030-89385-9_8

Madni AM (2023) Augmented intelligence: a human productivity and performance amplifier in systems engineering and engineered human–machine systems. Systems engineering for the digital age: practitioner perspectives, pp 375–391. https://doi.org/10.1002/9781394203314.ch17

Christopher Brill J, Cummings ML, Evans III AW, Hancock PA, Lyons JB, Oden K (2018) Navigating the advent of human-machine teaming. In Proceedings of the human factors and ergonomics society annual meeting (Vol. 62, No. 1, pp. 455–459). Sage CA: Los Angeles, CA: SAGE Publications

Anderson JR (2005) Cognitive psychology and its implications. Macmillan

Rasmussen J (1983) Skills, rules, and knowledge; signals, signs, and symbols, and other distinctions in human performance models. IEEE Trans Syst Man Cybern 3:257–266

Hagras H (2018) Toward human-understandable, explainable AI. Computer 51(9):28–36

Kapetanovic IM, Rosenfeld S, Izmirlian G (2004) Overview of commonly used bioinformatics methods and their applications. Ann N Y Acad Sci 1020(1):10–21

Ibrahim SM, Ansari SS, Hasan SD (2023) Towards white box modeling of compressive strength of sustainable ternary cement concrete using explainable artificial intelligence (XAI). Appl Soft Comput 149:110997

Hayes-Roth F, Jacobstein N (1994) The state of knowledge-based systems. Commun ACM 37(3):26–39

Verhagen WJ, Bermell-Garcia P, Van Dijk RE, Curran R (2012) A critical review of knowledge-based engineering: an identification of research challenges. Adv Eng Inform 26(1):5–15

Samek W, Müller KR (2019) Towards explainable artificial intelligence. In: Samek W, Montavon G, Vedaldi A, Hansen L, Müller KR (eds) Explainable AI: Interpreting, Explaining and Visualizing Deep Learning. Lecture Notes in Computer Science, vol 11700. Springer, Cham. https://doi.org/10.1007/978-3-030-28954-6_1

Zadeh LA (1965) Fuzzy sets. Inf Control 8:338–353

Angelov P, Filev D, Kasabov N (2010) Evolving intelligent systems: methodology and applications. John Wiley & Sons, New Jersey

Lughofer E (2011) Evolving Fuzzy Systems – methodologies, advanced concepts and applications. In: Kacprzyk J (Ed) Studies in fuzziness and soft computing, Volume 266. Berlin: Springer https://doi.org/10.10007/978-3-642-18087-3

Bocklisch F, Bocklisch SF, Beggiato M, Krems JF (2017) Adaptive fuzzy pattern classification for the online detection of driver lane change intention. Neurocomp 262:148–158. https://doi.org/10.1016/j.neucom.2017.02.089

Pierlot C, Pawlowski L, Bigan M, Chagnon P (2008) Design of experiments in thermal spraying: a review. Surf Coat Technol 202(18):4483–4490

Endsley MR (1995) Measurement of situation awareness in dynamic systems. Hum Factors 37(1):65–84

Heimann RB (1996) Applications of plasma-sprayed ceramic coatings. Key Eng Mater 122–124:399–442. https://doi.org/10.4028/www.scientific.net/kem.122-124.399

Bolelli G, Cannillo V, Lusvarghi L, Manfredini T (2006) Wear behaviour of thermally sprayed ceramic oxide coatings. Wear 261(11–12):1298–1315

Cao XQ, Vassen R, Stöver D (2004) Ceramic materials for thermal barrier coatings. J Eur Ceram Soc 24(1):1–10

Fauchais PL, Heberlein JV, Boulos MI (2014) Thermal spray fundamentals: from powder to part Springer Science & Business Media https://doi.org/10.1007/978-0-387-68991-3

McPherson R (1989) A review of microstructure and properties of plasma sprayed ceramic coatings. Surf Coat Tech 39–40(Part 1):173–181. https://doi.org/10.1016/0257-8972(89)90052-2

Bell DE, Keeney RL, Raiffa H (1977) Conflicting objectives in decisions. John Wiley & Sons

Ester J (1987) Systemanalyse und mehrkriterielle Entscheidung. Verlag Technik, Berlin

Cellier JM, Eyrolle H, Mariné C (1997) Expertise in dynamic environments. Ergonomics 40(1):28–50

Proctor RW, Zandt TV (2017) Human factors in simple and complex systems (3rd ed.). CRC Press. https://doi.org/10.1201/9781315156811

Hoffmann R, Militello L (2008) Perspectives on cognitive task analysis: historical origins and modern communication of practice. Taylor & Francis, New York

Pareto V (1896) Manual d’´economie politique. F Rouge, Lausanne

Peschel M (1980) Ingenieurtechnische Entscheidungen: Modellbildung und Steuerung mit Hilfe der Polyoptimierung. Verlag Technik, VEB

Ehrgott M (2005) Multicriteria optimization (Vol. 491). Springer Science & Business Media

Greco S, Figueira J, Ehrgott M (2016) Multiple criteria decision analysis, vol 37. Springer, New York

Hung KC, Julian P, Chien T, Jin WTH (2010) A decision support system for engineering design based on an enhanced fuzzy MCDM approach. Expert Syst Appl 37(1):202–213

Hashemian SM, Behzadian M, Samizadeh R et al (2014) A fuzzy hybrid group decision support system approach for the supplier evaluation process. Int J Adv Manuf Technol 73:1105–1117. https://doi.org/10.1007/s00170-014-5843-2

Siddall J (1983) Probabilistic engineering design: principle and applications. Marcel Dekker, New York

Chen SJ, Hwang CL (1992) Fuzzy multiple attribute decision making methods. In: Fuzzy Multiple Attribute Decision Making. Lecture Notes in Economics and Mathematical Systems, vol 375. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-46768-4_5

Carnahan JV, Thurston DL, Liu T (1994) Fuzzing ratings for multi attribute design decision-making. ASME J Mech Des 116:511–521

Vinodh S, Sai Balagi TS, Patil A (2016) A hybrid MCDM approach for agile concept selection using fuzzy DEMATEL, fuzzy ANP and fuzzy TOPSIS. Int J Adv Manuf Technol 83:1979–1987. https://doi.org/10.1007/s00170-015-7718-6

Klein GA, Calderwood R, Macgregor D (1989) Critical decision method for eliciting knowledge. IEEE Trans Syst Man Cybern 19(3):462–472

Raiffa H (1993) Decision analysis: introductory lectures on choices under uncertainty. 1968. MD Computing: Computers in Medical Practice 10(5):312–328

Bocklisch F, Bocklisch SF, Krems JF (2012) Sometimes, often, and always: exploring the vague meanings of frequency expressions. Behav Res Methods 44:144–157

Kosko B (1986) Fuzzy cognitive maps. Int J Man Mach Stud 24(1):65–75

Felix G, Nápoles G, Falcon R, Froelich W, Vanhoof K, Bello R (2019) A review on methods and software for fuzzy cognitive maps. Artif Intell Rev 52(3):1707–1737

Mehlawat MK, Gupta P (2016) A new fuzzy group multi-criteria decision making method with an application to the critical path selection. Int J Adv Manuf Tech 83(5):1281–1296

Dubois D, Prade H (1996) What are fuzzy rules and how to use them. Fuzzy Sets Syst 84(2):169–185

Jayapal J, Kumaraguru S, Varadarajan S (2023) Evaluation of computationally optimized design variants for additive manufacturing using a fuzzy multi-criterion decision-making approach. Int J Adv Manuf Technol. https://doi.org/10.1007/s00170-023-12641-1

Lehto MR, Nanda G, Nanda G (2021) Decision‐making models, decision support, and problem solving. Handbook of Human Factors and Ergonomics, pp 159–202. https://doi.org/10.1002/9781119636113.ch6

Romero D, Stahre J, Taisch M (2020) The Operator 4.0: towards socially sustainable factories of the future. Comput Ind Eng 139:106128

Lu Y, Adrados JS, Chand SS, Wang L (2021) Humans are not machines – anthropocentric human-machine symbiosis for ultra-flexible smart manufacturing. Engineering 734–737. https://doi.org/10.1016/j.eng.2020.09.2018

Selenko E, Bankins S, Shoss M, Warburton J, Restubog SLD (2022) Artificial intelligence and the future of work: a functional-identity perspective. Curr Dir Psychol Sci 31(3):272–279

Bocklisch SF, Bocklisch F (2015) Fuzzy-Pattern-Klassifikatoren als Modelle. Informatik Spektrum 38(6):510–522

Nemati A, Jäckel M, Bocklisch SF et al (2022) Fuzzy pattern modeling of self-pierce riveting for data from experiments and computer simulations. Int J Adv Manuf Technol 122:2203–2216. https://doi.org/10.1007/s00170-022-09914-6

Zhu F, Wang Z, Lv M (2016) Multi-objective optimization method of precision forging process parameters to control the forming quality. Int J Adv Manuf Tech 83(9):1763–1771