Abstract

Forging is a traditional and important manufacturing technology to produce various high strength products and is widely used in engineering fields such as automotive, aerospace and heavy industry. To produce highly accurate product, underfill that the material is not filled into the cavity should strongly avoided. For material saving and near-net product, flash should be minimized. To make the tool life long, it is preferable to produce product with low forging load. It is also preferable to uniformly deform the billet as much as possible for high strength product. Crack is a crucial defect and should strongly be avoided. Therefore, many requirements are taken into account in order to produce the forged product. To meet the requirements, design optimization in forging coupled with computer aided engineering (CAE) is an effective approach. This paper systematically reviews the related papers from the design optimization point of view. For the billet or die shape optimization, the papers are classified into four approaches. The process parameters optimization such as the billet temperature, the die temperature, the stroke length and the friction coefficient is conducted, and the related papers are also classified into four categories. The design variables and the objective function(s) used in the papers are clarified with the design optimization technique. The multi-stage forging including the hammer forging for producing complex product shape is also briefly reviewed. Finally, major performance indexes and the future outlook are summarized for the further development of design optimization in forging.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Forging compressing a billet is a traditional manufacturing technology to produce net-shape or near-net shape product. The forging is roughly divided into three categories according to the working temperature, that are called cold, warm and hot forging respectively. Among them, the cold and hot forging is major and thus this paper mainly focuses on them. The cold forging produces product under room temperature and consequently the productivity is high. In addition, high dimensional accurate product with smooth surface is generally produced, but large forging load is required. On the other hand, high strength or large scaled product is produced in the hot forging. The billet is heated up above the recrystallization temperature and consequently the deformability of billet is enhanced. As the result, it is possible to produce the product with low forging load. However, compared to the cold forging, the productivity is low and the product surface is generally rough. To produce net-shape or near-net shape product, it is preferable to minimize flash that is trimmed off for the final product shape. The flash is related to the billet shape, and thus the determination of billet shape minimizing the flash is a crucial issue in forging. To produce high dimensional accurate product, it is also important to avoid underfill that the billet is not filled into the cavity. The underfill is closely related to the billet shape, the die shape, the forging load and the friction coefficient. In the case of hot forging, the billet temperature also affects the underfill. It will be easy to produce a product without the underfill with high forging load, but high forging load makes the tool life short. To make the tool life long, it is important to produce the forged product with low forging load. The risk of crack in billet is high when high forging load is applied. The crack is one of the crucial defects and this should strongly be avoided. Thus, it is important to produce product without the underfill and the crack with low forging load. As described the above, several concerns are so closely related to each other and thus the forging is multi-objective in nature. Then, to resolve the issues in forging by design optimization, it is suitable to consider multi-objective optimization. The comparison between the cold and hot forging and the common issues are summarized in Table 1.

To produce complex shaped product, multi-stage forging using different dies shape is used. In the multi-stage forging, the process parameters such as the stroke length at each stage, the billet temperature and the friction coefficient play an important role for successfully producing the product. The process parameters as well as the billet or die shape in forging are conventionally determined through the worker’s experience based on the trial-and-error method. A great deal of know-how is accumulated in the worker through the trial-and-error method, but this is very time-consuming and hard task.

Computer aided engineering (CAE) is an alternative [1] and is widely used in various manufacturing fields such as sheet metal forming [2] and plastic injection molding [3] as well as forging [4, 5]. It is also possible to conduct numerical simulation of complex forging process consisted of five stretch-rolling and die-forging steps for producing a connecting rod [6]. Three-dimensional forging simulation is computationally so expensive that response surface (also called surrogate or meta-model) is valid to the design optimization [7] and the approach is also widely used to resolve several issues in manufacturing [8]. Note that, for example, the response surface using the neural network (NN) is adopted to obtain the relation between the process parameters (the die corner radius, the gap height, the friction coefficient, the hardening coefficient, the gap between billet and die and the punch load) and the flange shape in radial forging [9]. However, the optimal process parameters are not discussed in the paper. To determine the optimal process parameters, it is necessary to apply optimization method to the response surface. The physical phenomena in forging are highly nonlinear, and thus the response surface using the quadratic polynomial is insufficient. However, the response surface using the quadratic polynomial is still used, and this is described in the Sections. 3 and 4. The response surface using the Gaussian kernel such as the Kriging, the radial basis function (RBF) network, the support vector regression (SVR) and the least square support vector regression (LSSVR) is preferable in order to obtain highly accurate response surface. These methods are well summarized in Refs. [8, 10]. The response surface using the Gaussian kernel generally results in highly nonlinear, and thus the genetic algorithm (GA), particle swarm optimization (PSO) and differential evolution (DE) should be adopted to find the optimal solution. Recently, sequential approximate optimization (SAO) that the response surface is repeatedly constructed and optimized by adding new sampling points has been recognized as an attractive approach to resolve some issues in manufacturing such as sheet metal forming [11] and plastic injection molding [12]. The SAO can be regarded as one of the intelligent forging technologies, and it is then expected that the SAO will be able to resolve several issues in forging.

Design optimization coupled with numerical simulation in forging is certainly an effective approach to determine the optimal process parameters as well as the optimal billet or die shape, and thus it is important to review the related papers from the design optimization point of view. Note that Ref. [13] mainly focuses on the methods to reduce the forging load for precision forging, but the paper does not always discuss the design optimization in forging. Reference [14] is also a review paper in forging, but the paper belongs to the trend analysis in forging and does not review the related papers from the design optimization point of view.

This paper provides a technical review on design optimization in forging. As already described, there are many requirements in forging. To meet these requirements, it is important how to formulate the design optimization problem. Then, this paper clarifies the design variables and the objective function(s) and provides useful information. It is difficult to review all papers on design optimization in forging, and thus representative papers are selected in this paper. In particular, the billet or die shape optimization, the process parameters optimization and the multi-stage forging are discussed in Sections 3, 4 and 5, respectively. Finally, major performance indexes and future outlook for design optimization in forging are discussed. Note that various forging processes using mechanical, hydraulic or servo press are assumed. In addition, the air or hydraulic forging is used in the hammer forging. It is difficult to clearly distinguish among them in the numerical simulation, and thus the forging process is described when the press type is clearly described in the related paper.

2 Multi-objective optimization

As described in introduction, it is suitable to formulate the design optimization in forging as multi-objective optimization. Multi-objective optimization is generally formulated as follow.

where \(\boldsymbol{x}={\left({x}_{1},{x}_{2}, \cdots ,{x}_{n}\right)}^{{\text{T}}}\) denotes the design variables and xi is the i-th design variable. xiL and xiU are the lower and upper bounds of the i-th design variable, n represents the number of design variables. fi(x) is the i-th objective function, K represents the number of objective functions. When the k-th objective function fk(x) is maximized, it is equivalent to minimize the function –fk(x). gj(x) is the j-th design constraint, and ncon represents the number of design constraints. When K equals to 1, a single optimal solution is determined. Otherwise, a set of optimal solutions called the pareto-optimal solutions are determined. See Refs. [15, 16] for the methods to determine the pareto-optimal solutions. Through the numerical simulation, the objective functions and the design constraints are evaluated. In the case of two-dimensional forging simulation, mathematical programming or evolutionary algorithm such as the GA is often used to determine the optimal solution. On the other hand, in the case of three-dimensional forging simulation, the objective functions and the design constraints are numerically evaluated at the sampling points due to the expensive computational cost. Then, the response surface is constructed, and the optimal solutions are determined using optimization method.

3 Billet or die shape optimization

Billet or die shape optimization is the major issue in forging, and thus this section mainly focuses on the billet or die shape optimization. This paper classifies the related papers into the following four approaches.

-

(a)

Approach using mathematical programming or GA: This approach is mainly applicable under two-dimensional forging simulation. When the GA is used, a large number of simulations are required without the sensitivity information of objective function. On the other hand, the sensitivity information is required when mathematical programming is used.

-

(b)

Approach for single objective using response surface: This approach is applicable under two- and three-dimensional forging simulation. Since the response surface is used, the sensitivity information of objective function is not necessary. In addition, the response surface approach is strongly recommended under three-dimensional forging simulation. This class considers a single objective function. After constructing the response surface of objective function, optimization method is applied to the response surface in order to determine the optimal solution.

-

(c)

Approach for multi-objective using response surface: This approach considers more than two objective functions. Like (b), this approach is applicable under two- and three-dimensional forging simulation. Multi-objective optimization method is applied to determine the pareto-optimal solutions.

-

(d)

Approach using closed-loop type algorithm: Billet or die shape optimization is performed by developing a closed-loop type algorithm. Billet or die shape optimization using evolutionary structural optimization (ESO) belongs to this class.

3.1 Approach using mathematical programming or GA

Zhao et al. performed a die shape optimization [17], in which the difference between the actual and desired shape was considered as the objective function to be minimized and the several control points on the die were selected as the design variables. In other words, the underfill was minimized. The B-spline was used to represents the die shape. The sensitivity of objective function on the design variables was introduced, and the design optimization tools (DOT) by mathematical programming was used to determine the optimal die shape. The proposed approach was applied to an upsetting process in two dimensions. The crucial point in the paper was to derive the sensitivity of objective function, and the sensitivity could be obtained with the explicit form of design variables. It was reported that it would be possible to reduce the material loss and the potential machining cost by using the optimal die shape.

Kim et al. determined an optimal billet shape so as to minimize the unfilled volume of an axisymmetric rib-web product under a constant volume [18], in which various billet shapes with different aspect ratios were prepared and the unfilled volume was numerically evaluated. After obtaining the training data, the aspect ratio of billet minimizing the unfilled volume was determined using the back propagation neural network. In the paper, the number of design variables was one, and thus it was easy to understand the relation between the objective function and the design variable as shown in Fig. 1(a). Optimization method to determine the optimal aspect ratio was not used. They also investigated the relation between the aspect ratio of billet and the forging load, and clarified that (1) the higher aspect ratio decreased the forging load but (2) the higher aspect ratio made the average effective strain high. In other words, the lower aspect ratio was preferable for the uniform deformation. The result implied that the trade-off between the forging load and the uniform deformation would be observed. After that, the authors extended the methodology to the simultaneous billet and die shape optimization of an axisymmetric rib-web product, and they concluded that it was possible to determine the optimal billet and die shape using the neural network with a small number of simulations and the optimal billet and die shape led to the uniform distribution of effective strain [19].

For two-stage hot forging, Chung and Hwang optimized the die shape at the first stage and the billet temperature using the GA [20], in which five control points on the die (di, i = 1,2,…,5) shown in Fig. 1(b), the billet temperature and the stroke length were handled as the design variables. They considered that the recrystallized grain size distributions strongly affected the mechanical properties of forged product and these were closely related to the temperature distribution. Then, the billet temperature as well as the control points on the die was selected as the design variables. The stroke length strongly affected the underfill, and thus this was also selected as the design variables. Note that the forging using a mechanical press was assumed in the paper. To produce highly accurate product, the underfill was considered as the design constraint. In order to improve the mechanical properties, the temperature distribution after the forging process was minimized for uniform temperature distribution. Though a large number of simulations were required to determine the optimal solution, the temperature after the forging was uniformly distributed, compared to the forging without optimization. The idea considering the die shape and the billet temperature was well accepted, and the total energy and the shape error between the current and prescribed shape were simultaneously minimized under an allowable temperature in Ref. [21], in which, like Ref. [20], the two-stage hot forging was considered and the die shape at the first stage was optimized.

Ou et al. performed the die shape optimization of an aerfoil blade in hot forging [22, 23], in which the nodal points on die shape were selected as the design variables. They considered that the die-elastic deflection caused the shape error, and the compensation approach minimizing the difference between the actual and desired shape was newly proposed. To represent the die-elastic deformation, a spring element shown in Fig. 1(c) was added and the finite element analysis was conducted. Like Ref. [17], DOT was used as the optimizer. As the result, the aerofoil thickness error was much improved with the optimal die shape. It was found that the die-elastic deformation affected the numerical result in forging, and the tools were modelled using the elastic elements in Ref. [24].

Castro et el. performed billet shape optimization in hot forging so as to minimize the shape error between the current and prescribed shape and the barreling effect in upsetting of a cylinder [25], in which six control points on the billet were selected as the design variables and the billet shape was expressed by the B-spline. In the paper, the barreling effect was introduced but this was equivalent to the forging energy. Therefore, the objective functions were completely same in Ref. [21]. However, Ref. [21] considered the die shape optimization in two-stage hot forging, whereas the paper considered the billet shape optimization in one-stage hot forging. Therefore, to produce near-net shape product in upsetting, the billet shape optimization was performed. As shown in Fig. 1(d), it was possible to obtain near-net shape product. Similar approach for an upsetting process assuming the use of mechanical press could also be found in Ref. [26], in which the friction coefficient was selected as the design variables as well as the control points on die shape. The forging energy described in Ref. [21] and the folding defect defined by the shape error were minimized in the paper, and the weighted sum was used to determine the optimal solution. Note that the pareto-frontier between the forging energy and the folding defect is not identified.

Knust et al. adopted the GA for a cross-wedge-rolled billet shape optimization in multi-stage hot forging [27], in which the radii at many cross sections were handled as the design variables and two-dimensional simulation was performed for the symmetry of the cross-wedge-rolled billet. Three objective functions (the form-filling, the billet volume and the complexity) were considered and single objective function was minimized by the GA with the weighted sum. The form-filling was considered in order to minimize the flash, and the billet volume was directly related the material cost. The final objective function called the complexity was newly introduced to evaluate the suitability of the billet regarding the manufacturing costs. The final billet shape was shown in Fig. 1(e), from which it was found that the forged product along to the product shape could be obtained. After that, beside the three objective functions in Ref. [27], the folding defect evaluated by the distance between the boundary points on the forged product was added in Ref. [28] and the same procedure was performed to determine the optimal cross-wedge-rolled billet shape.

3.2 Approach for single objective using response surface

The above papers directly optimized the billet or die shape using the mathematical programming or the GA. Forging simulation is so computationally expensive that the response surface approach for billet or die shape optimization is also performed.

Tang et al. performed the die shape optimization of intermediate stage in three-stage hot forging process so as to minimize the underfill (fill ratio) using the SAO with the neural network [29], in which the use of a mechanical press was assumed. For the die shape optimization, like Ref. [20], nine control points on the die shape were selected as the design variables. The neural network was then adopted to obtain the response surface of underfill. Then, the pattern search algorithm was applied to the response surface in order to determine the optimal solution. When the error between the objective value at current optimal solution and the target objective value was small, the algorithm terminated. Otherwise, the current optimal solution was added in order to improve the response surface. The process was repeated till the error was small. Therefore, the SAO approach was adopted in the paper. As shown in Fig. 2(a), the die shape optimization at intermediate stage was effective to diminishing the underfill. It was also reported that the die shape optimization was useful for the flash minimization.

The billet shape optimization using the basis vector method was performed in Ref. [30]. In the basis vector method, several shape candidates called the basis vector were prepared and a shape was defined as a linear combination of basis vectors with the weights. In general, the shape B using the basis vector method is expressed as follow.

where B0 is called the reference vector denoting the basis shape, Bi is called the i-th basis vector, xi is the weight of the i-th basis vector, and n is the number of basis vectors. Various shapes are obtained by changing the weights. Therefore, the weights are the design variables in the basis vector method [31]. In Ref. [30], as shown in Fig. 2(b), four basis vectors were prepared, and the weights were determined so as to minimize the strain variance of a target product under the underfill constraint. One of the advantages using the basis vector method was drastically able to reduce the number of design variables, compared to the shape optimization using the control points. On the other hand, the optimal shape depends strongly on the basis vectors determined by the engineer. The response surface using the quadratic polynomial was used to determine the optimal weights. After that, they applied the proposed approach to the billet shape optimization of a three-dimensional steering link product [32]. The SAO approach was adopted in Refs. [30, 32]. However, the response surface for the objective function (strain variance) was constructed whereas the one for the design constraint (underfill) was not constructed. Therefore, the response surface of objective function was repeatedly constructed and optimized till the design constraint was satisfied.

To reduce the number of press-forging stages, die shape optimization in three-stage forging was performed in Ref. [33], in which the use of a mechanical press was assumed. As shown in Fig. 2(c), three-stage cold forging was assumed and the morphing technique was introduced to determine the die shapes at 2nd and 3rd stage and the billet shape. Therefore, to remove the 1st stage in Fig. 2(c), the die shapes and the billet shape were optimized. The upper limit of forging load and the risk of crack based on Oyane’s ductile fracture [34] was considered as the design constraints. The morphing technique was similar to the basis vector method, and this technique could express various die shapes by changing the parameters which corresponded to the weights in the basis vector method. As the result, it was possible to express various shapes with a small number of design variables. The response surface using multiplicative functions was adopted, and new sampling points were added to improve the response surface like the SAO. Unlike Refs. [30, 32], the response surface of both the objective function and the design constraints was constructed. It was reported that it was possible to reduce the number of stages from three to two by changing the die shapes and the billet shape while satisfying the forging load and underfill constraints.

Guan et al. proposed a new billet shape optimization method using the quasi-equipotential field and the response surface for three-dimensional product [35], in which the use of a mechanical press was assumed. Based on the comparability of the filed equations and the minimum energy theory, it was considered that the equipotential lines in an electrostatic filed were similar with the minimum deformation paths between the initial and final shape. Then, it was assumed that the minimum equipotential surfaces would be the optimal billet shape. The potential value of equipotential surface and the volume ratio between the pre- and final forging were selected as the design variables. The electrostatic field simulations under various potential values were conducted to obtain the distribution of equipotential surface, and one of the examples was shown in Fig. 3(d). The underfill was then approximated by the second-order polynomial and was minimized. It was clarified from the numerical result that the forged product using the optimal billet shape has smaller flash without the underfill.

3.3 Approach for multi-objective using response surface

As described in introduction, the forging process is multi-objective in nature. Then, multi-objective optimization under various objectives using the response surface is valid.

The billet shape optimization for an aerofoil blade using the quadratic polynomial was performed in Ref. [36], in which the target product was produced through two-stage hot forging shown in Fig. 3(a) and the use of a mechanical press was assumed. The first stage was the extrusion and the second one was the forging. In the paper the billet shape in the forging process was discussed. Three objective functions (the distribution of effective strain, the flash volume and the lateral force) were simultaneously minimized under an allowable forging load and an underfill volume. Equation (3) was considered for the distribution of effective strain.

where \(\overline{\varepsilon }_{i}\) and \(v_{i}\) denoted the effective strain and the volume of the i-th element respectively. \({\overline{\varepsilon }}_{{\text{avg}}}\) denoted the average effective strain of all elements, and nelm denoted the total number of billet elements. The volume of the i-th element was considered in the paper, and it would be valid when the coarse mesh was used for the billet. The dimensions of billet for aerofoil were taken as the design variables. After constructing the response surface of three objective functions and two design constraints, NSGA-II was applied to identify the pareto-frontier. Compared with the result by the trial-and-error method, the flash and the lateral force were drastically improved, whereas the distribution of effective strain was little improved. After that, the authors extended the methodology to three-stage hot forging process [37], in which four objective functions (the flash volume, the distribution of effective strain, the lateral force at first-stage and the one at second-stage) were considered. Unlike Ref. [36], the neural network was used for the response surface. In addition, the intermediate die shape optimization was also performed. It was reported in Ref. [37] that the distribution of effective strain and the flash volume were drastically improved by the three-stage optimization, compared with the ones of single-stage optimization (Fig. 3(b)). The numerical validation was examined through the experiment using a hydraulic press.

Torabi et al. simultaneously minimized four objective functions which were the underfill, the flash, the forging load and the strain variance of a turbine blade [38], in which the quadratic polynomial was used for the response surface of objective functions and the NSGA-II was applied. As shown in Fig. 3 (c), the dimensions of billet shape were taken as the design variables. Compared to the conventional billet shape, the radius denoted by R and the different diameters denoted by D1 and D2 were newly introduced in the paper. Due to four objective functions, the pareto-frontier among the objectives was not clarified, but it was reported that, compared to the initial billet shape, 61% reduction of the flash, 20% reduction of the forging load and 31% reduction of the strain variance could be achieved with the optimal billet shape. On the other hand, the underfill was not discussed. The experiment based on the numerical result was also carried out by using a mechanical press.

Shao et al. optimized the intermediate die shape for an aerofoil in four-stage hot forging shown in Fig. 3(d) [39]. During the forging process of target product, the wrong die shape led to high material damage, that resulted in the crack. Then, to avoid the crack, the material damage and the distribution of effective strain were simultaneously minimized under the underfill constraint. Nine control points on the intermediate die shape and the radius of the billet were taken as the design variables. Unlike Eq. (2), Eq. (3) was used to evaluate the distribution of effective strain.

On the other hand, various criteria for ductile fracture have been proposed [96], among which the material damage was numerically evaluated by Eq. (5) (which is called the normalized Cockcroft and Latham) and this was considered as the risk of crack.

where \(C_{i}\) is the material damage (damage value) of the i-th element, \(\sigma_{i}^{*}\) is the principal stress of the i-th element (if \(\sigma_{1} \ge 0\) then \(\sigma_{i}^{*} = \sigma_{1}\). Otherwise, \(\sigma_{i}^{*} = 0\)), \(\overline{\sigma }_{i}\) is the equivalent stress of the i-th element, \(\varepsilon_{f}\) is the equivalent fracture strain, and \(\varepsilon\) is the equivalent strain of the i-th finite element of the billet. The concept of material damage has already been adopted in the case of multi-stage forging [40], in which it was pointed out that stress concentration led to the crack and Eq. (5) was valid to numerically evaluate the risk of crack. This criterion was widely used in Refs. [54, 57, 62] in the following section. All functions (the distribution of effective strain, the risk of crack and the underfill) were approximated by the RBF, and the weighted sum was used. Then the pareto-frontier between the objective functions was identified by applying various weights. Multi-island GA (MIGA) was used as the optimizer. Unfortunately, the SAO approach to obtain highly accurate pareto-optimal solutions was not used. In addition, no comparison between the optimal die shape and the conventional one was made.

Meng et al. optimized the complex shaped billet shown in Fig. 3(e) [41], in which the distribution of effective strain and the risk of crack given by Eqs. (4) and (5) were simultaneously minimized. As for the risk of crack, the material damage of all elements was evaluated, and the maximum value was considered as the objective function. To define the design variables of the complex shaped billet, the billet was divided into three regions. Then, the volumes of three regions and the geometrical parameters denoting the curves were used for the design variables. As the result, the complex shaped billet was expressed by four design variables. The quadratic polynomial was used for the response surface, and the weighted sum was used to determine the optimal billet shape. In the paper, the underfill or the flash was not considered in the design optimization, but it was reported from the experimental result that the underfill was not observed and near-net-shape product could be produced with the optimal billet shape.

Forging load and fillet clearance to minimize underfill were simultaneously minimized in Ref. [42], in which a clutch outer gear hub shown in Fig. 3(f) was considered as the target product. High dimensional accuracy was required to the target product, and thus the fillet clearance was minimized. To minimize the fillet clearance, high forging load was generally required. However, it was important produce the product with low forging load. Therefore, trade-off between the fillet clearance and the forging load was asummed. The effect of (1) the entrance angle of punch, (2) the wall thickness of billet, (3) the length of calibration band and (4) the friction coefficient on the fillet clearance was numerically investigated. The response surface using the quadratic polynomial for the fillet clearance and the forging load was constructed, and the MOGA was applied to identify the pareto-frontier. Like Ref. [38], the SAO approach to obtain highly accurate pareto-optimal solutions was not used. It was reported through the experiment using a hydraulic press that 16% reduction of forging load could be achieved with the optimal solution.

Deng et al. adopted a feed forward neural network called the extreme learning model and the billet shape of a gear product was optimized [93], in which the design variables shown in Fig. 3(g) were selected. The maximum finisher forming force (maximum forging load) and the maximum finisher die stress (die stress) were simultaneously minimized. These objective functions were useful for making the tool life long. In the paper, highly response surface was constructed the weighted sum was used to determine the pareto-optimal solutions. The pareto-frontier between the forging load and the die stress was not clearly shown, but it was reported that highly accurate response surface could be obtained and the pareto-optimal solution was determined with a small number of generation.

3.4 Approach using closed-loop type algorithm

Other approaches for billet shape optimization are to develop a closed-loop type algorithm [43] or to use the ESO [44].

Billet shape optimization called the equivalent static loads method was proposed in Ref. [43], in which the dynamic loads for nonlinear analysis were transformed into the equivalent static loads for linear analysis. They mentioned that the nonlinear analysis was performed under dynamic loads in analysis domain whereas the design optimization was performed under the equivalent static loads in design domain. To transform the nonlinear analysis into the design domain, the equivalent static loads were introduced, and then the design optimization was performed under the equivalent static loads. The result of design optimization was then fed back to the nonlinear analysis. The analysis domain and the design domain were alternately performed till a terminal criterion was satisfied. Finally, the billet shape was optimized. The billet shape optimization in the design domain was not computationally so expensive that it was possible to handle a large number of design variables. In the paper, a simple billet shape optimization to avoid the underfill was performed as shown in Fig. 4(a). The interesting point of this result indicated the relation between the underfill and the flash was trade-off. In addition, it was pointed out that the optimal billet shape made the distribution of effective strain uniform.

On the other hand, billet shape optimization using the ESO is performed based on the stress-based element addition and removal, and a closed-loop type algorithm is developed. Lu et al. performed the optimal billet shape optimization of a two-dimensional rail wheel using the ESO (Fig. 4(b))[45], in which the objective function considering both the flash and the underfill was proposed. For the region under tensile stresses, it implied that there was insufficient material in the region so elements would be added. On the other hand, for the region under compressive stresses, it implied that elements would be removed from the region. The hydrostatic stress defined by the average principal stress was used to evaluate the stress condition of an element. When the average principal stress was positive, the material was under tensile stress. Otherwise, the material was under compressive stress. The addition and removal of elements was repeated, and thus the billet surface was generally not smooth. To obtain the smooth surface, the B-spline surface approximation method was adopted. The algorithm using the ESO was applied to the billet shape optimization of a rail wheel and the result was shown in Fig. 4(b). It was found from the figure that three underfill regions were observed with the initial billet shape. After applying the ESO algorithm, the underfill regions were completely diminished.

Unlike Ref. [45], Shao et al. proposed a strain-based element addition and removal criterion [46], in which Eq. (4) was used to evaluate the overall deformation. Thus, an element with higher equivalent strain was removed whereas an element was added around the lower equivalent strain. The billet shape optimization for an axisymmetric plane disk was performed and the result was shown in Fig. 4(c). Note that the die shape is different from the one in Ref. 4(b). They investigated the forging load with the stress- and strain-based element addition and removal criterion, and they concluded that almost the same forging load was required. The use of both the stress- and strain-based element addition and removal criterion was found in Ref. [47].

Yang performed billet shape optimization using the ESO [48], in which the modified strain-based element addition and removal criterion was proposed. Unlike Refs. [45, 46], the objective function considering the distribution of effective strain and the cavity filling (underfill) was newly introduced. The proposed approach was applied to two-dimensional H-shaped billet optimization (Fig. 4(d)). It was found from the figure that underfill was completely diminished and the flash was much reduced with the optimal billet shape.

The papers on billet or die shape optimization described above are summarized in Table 2 with the friction type (coulomb or shear) and the value, from which it is found that many papers on billet or die shape optimization have been published. Therefore, the billet or die shape optimization is still the major topic in forging.

4 Process parameters optimization

Not only the billet or die shape but also the process parameters such as the stroke length, the billet temperature, the tooling temperature and the friction coefficient have an influence on the forged product quality [49]. Many papers on the process parameters optimization in forging have been published, and they are classified into four categories in this paper. Note that extrusion is also reviewed in this section, but the objective functions and the process parameters in extrusion are applicable to design optimization in forging, and thus they are reviewed in this section.

-

(a)

Process parameters optimization considering billet temperature or friction coefficient: It is clear from the title that the billet temperature or the friction coefficient is considered as the process parameters. Single or multi-objective optimization is then performed.

-

(b)

Control of forging load including back-pressure: To produce high quality product, the forging load is controlled. However, the load control is generally determined through the trial-and-error method. To determine the optimal load control, design optimization is performed.

-

(c)

Die cavity optimization: Cavity shape affects the product quality, and thus the dimensions of die cavity are optimized. Though it is possible to consider the die cavity optimization as the die shape optimization, the objective functions considering the process parameters are discussed. Then, in this paper, the related papers are classified into this category.

-

(d)

Optimization of heater system or billet position: Initial position of billet affects the flash and the underfill, and this is conventionally determined by the trial-and-error method. This paper considers that the initial position of billet is one of the process parameters in forging. To determine the optimal position of billet, design optimization is performed. The process parameters of incremental die forging process for helical tubes are also investigated [94], in which the orthogonal array is used but design optimization is not performed. However, this will play an important role for the development of incremental forging and is briefly reviewed in this category.

4.1 Process parameters optimization considering billet temperature or friction coefficient

The process parameters (the billet temperature, the mandrel length, the convex angle and the tooling temperature) for hot extrusion of hollow section tube was optimized by using the Taguchi method [50], in which the process parameters minimizing the forging load was determined based on the experiments. It was reported from the result of analysis of variance (ANOVA) that the significant process parameter on the forging load was the convex angle, followed by the billet temperature and the mandrel length. Therefore, the tooling temperature was less effective to the forging load. To examine the effect of parameters on the mechanical property, the tensile strength was also investigated. It was then reported that the most significant process parameter was the mandrel length, followed by the billet temperature and the tooling temperature. The paper considers the forging load and the tensile strength separately, but the forging process is multi-objective in nature as described in introduction. Thus, it is preferable to consider the significant process parameters considering both the forging load and the tensile strength.

Zhou et al. performed the multi-objective design optimization of extrusion forging for a steering knuckle [51], in which four process parameters (the extrusion temperature, the extrusion speed, the mold temperature and the friction coefficient) were selected as the design variables and the filling distance (underfill) and the forging load were considered. Based on the orthogonal array using L9, the underfill and the forging load were numerically evaluated. After that, the evaluation called the comprehensive balance method that converted multiple indexes to a single index according to certain rules was conducted and the optimal level of each process parameters was determined. It was found from the method that the higher extrusion temperature, the higher extrusion speed, the higher mold temperature and the lower friction coefficient were effective to the underfill and the forging load. It was also pointed out that the high extrusion temperature enhanced the formability and resulted in the low forging load, whereas the excessively high mold temperature made the tool life short due to the wear. However, design optimization was not performed in the paper.

Gao et al. investigated the effect of process parameters (the thickness of a billet, the deformation temperature, the loading speed and the friction coefficient) on the folding and the underfill of a rib-web component using a hydraulic press [52], from which it was reported that the thickness had an influence on the folding significantly and the increasing friction coefficient resulted in the decrease of folding. On the other hand, the deformation temperature and the loading speed had little influence on the folding and the underfill. Therefore, they concluded that the thinner thickness and the greater friction coefficient were beneficial to suppress the defects. Unfortunately, design optimization was not performed like Ref. [51].

Sharifiar and Mousavi optimized the process parameters in extrusion process of a rectangular waveguide [53], in which the friction coefficient, the billet temperature, the die length and the billet diameter were selected as the design variables and the forging load was minimized. The neural network was adopted as the response surface and the optimal solution was determined using the GA. First, the orthogonal array using L18 was adopted and the significant process parameters were selected by the ANOVA. As the result, the friction coefficient and the billet temperature were effective to the forging load. After that, these process parameters were fixed and the effect of the rest process parameters (the die length and the billet diameter) on the forging load was investigated using the neural network. The GA was applied to the response surface in order to determine the optimal die length and billet diameter. Though the current process parameters were not clear, the experiment using the optimal die length and billet diameter was conducted. Consequently, it was reported that the experimental result had a good agreement with the numerical result.

Zhu et al. performed the multi-objective optimization of precision forging of a hollow shaft [54], in which the authors clearly claimed that the criterion of the product quality was multi-objective design optimization. Then, two objective functions to evaluate the product quality were defined. One was to minimize the distribution of effective strain given by Eq. (4) for the uniform deformation and the other was to minimize the risk of crack. In particular, the maximum value of Eq. (5) was considered as the risk of crack. High material damage led to the crack, and it was considered that the minimization of material damage was equivalent to the minimization of the risk of crack. The response surface using the quadratic polynomial was adopted, and the pareto-frontier was identified using the NSGA-II. As shown in Fig. 5(a) the trade-off between the objectives was clarified. Based on the numerical result, the experiment was conducted. It was reported from the experimental result that no visible crack could be found. Design optimization using the response surface was conducted, but the SAO was not performed in the paper.

The process parameters optimization in twist extrusion was performed in Ref. [55], in which three objective functions were considered. In the twist extrusion, the grain structure became finer and mechanical properties was improved with the increase of imposed effective strain increased. Then, the imposed effective strain was maximized as the first objective function. The distribution of effective strain given by Eq. (4) for the uniform deformation was considered and was minimized as the second objective function. Finally, the forging load was selected as the third objective function and was minimized. The response surface using the quadratic polynomial was used and the pareto-frontier among the objectives was identified using multi-objective particle swam optimization or NSGA-II (Fig. 5(b)). Like Ref. [54], the SAO was not performed.

The forging load in cold forward extrusion process was minimized in Ref. [56], in which three process parameters (the logarithmic strain, the half-die angle and the friction coefficient) were selected as the design variables. The quadratic polynomial was used for the response surface, and the optimal solution was determined. It was reported from the numerical result that the low logarithmic strain and the low friction coefficient led to the low forging load. The paper mainly discussed on the comparison of optimization algorithms such as PSO, Cuckoo search algorithm (CSA) and flower pollination algorithm (FPA), and concluded that the CSA was robust optimization method.

Alimirzaloo et al. investigated the effect of process parameters on the forging load and the risk of crack given by Eq. (5) [57], in which the extrusion process of a compressor blade was considered and the ram velocity, the billet temperature, the die temperature and the friction coefficient were selected as the design variables. The quadratic polynomial was used for the response surface of objective functions. The effect of process parameters on the objective functions was investigated separately, and it was reported that the die temperature had little influence on both objective functions. It was also reported that high friction coefficient resulted in low risk of crack and high forging load. In the paper, the pareto-frontier between the objectives was not clarified through multi-objective optimization was performed.

Many papers on the process parameters optimization described the above adopt the response surface based on the quadratic polynomial, and multi-objective optimization is performed. However, the SAO approach is not adopted. It is considered that the SAO will be able to identify highly accurate pareto-frontier.

4.2 Control of forging load including back-pressure

Recently, mechanical servo press that can control the load or the slide motion during forging is widely used in industry. In particular, the servo press can vary the back-pressure during the process, and thus it is possible to produce high dimensional accurate forged product by controlling the back-pressure or the slide motion [58]. Unfortunately, it is difficult to know in advance how to control the back-pressure or the slide motion. As the result, the trial-and-error method is used to determine the back-pressure control or the slide motion. It is possible to determine the back-pressure control or slide motion using design optimization.

Okada et al. determined the variable back-pressure profile that the back-pressure varies during the forging process using a mechanical servo press [59], in which the back-pressure profile was selected as the design variables, and the underfill shown in Fig. 6(a) and the total forging energy was simultaneously minimized. To express the back-pressure profile, the total stroke was divided into four sub-stroke and the back-pressure at each sub-stroke was taken as the design variables. The SAO using the RBF network [60] was then adopted to determine the optimal back-pressure profile. The optimal back-pressure profile with the experimental result was also shown in Fig. 6(a), from which it was clarified that the target product was successfully produced without the underfill. After that, Kitayama et al. determined the optimal back-pressure profile and the slide motion simultaneously using a mechanical servo press [61], in which the processing time and the distribution of effective strain by Eq. (4) were minimized. Thus, short processing time was equivalent to high productivity, whereas it was considered that the minimization of distribution of effective strain resulted in high product quality. The SAO procedure in Ref. [60] was also adopted to identify the pareto-frontier, and the result was shown in Fig. 6(b). Based on the numerical result, the experiment was carried out to validate the proposed approach. The experimental result showed the good agreement with the numerical result.

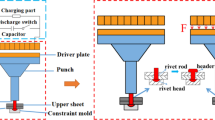

Kitayama et al. performed the process parameters optimization of complex forging process shown in Fig. 6(c) [62], in which three punches were used to produce the target product. Crack was observed around the earing, and this was considered as the defect. To avoid the crack, it was important to adjust the forging loads of three punches and the punch speed simultaneously. Then, to control the loads and the punch speed, five design variables were selected. The risk of crack given by Eq. (5) and the total forging energy were simultaneously minimized. Therefore, the multi-objective optimization was performed in order to determine the optimal process parameters. The SAO using the RBF network was adopted to identify the pareto-frontier. It was clarified from the numerical result that both the objectives were drastically improved, compared to ones using the conventional process parameters. Based on the numerical result, the experiment using a mechanical press was carried out to validate the process parameters optimization. It was also reported that smooth flow line along to the product shape could be obtained and consequently the crack around the earing was avoided.

The effect of back-pressure on the metal flow of a rib-web product was numerically examined in Ref. [63], in which the use of a hydraulic press was assumed and the back-pressure linearly increased. As shown in Fig. 6(d), the back-pressure was effective to not only the filling performance but also the distribution of effective strain. It was also reported that smooth flow lines along the product shape could be obtained by applying the back-pressure. Unfortunately, unlike Refs. [59, 61], the back-pressure profile was determined by the trial-and-error method. In the paper, it was possible to express the linearly increased back-pressure by introducing three design variables (the initial load, the final load and the stiffness). To evaluate the filling performance, the underfill was considered. To evaluate the uniform deformation, the distribution of effective strain was also considered. As the result, it was possible to determine the optimal load profile by solving the multi-objective optimization for minimizing the underfill and the distribution of effective strain.

It is clear from the above brief review on control of load or slide motion that design optimization can determine the optimal load control or slide motion when the issue can formulate as the design optimization problem.

4.3 Die cavity optimization

Optimization considering the total cost defined by the sum of material cost, forging cost, shearing cost and machining cost was performed in Ref. [64], in which cold forging for I-beam was handled. The billet dimensions and the die cavity of I-beam were selected as the design variables (Fig. 7(a)). The paper would be suitable for the billet or die shape optimization described in Sect. 2, but most interesting point in the paper was the objective function. As already described, four objective functions considering the whole process were considered. The material cost was directly defined as the volume of billet. Next, the forging energy was defined as the total strain energy of deformation. The shearing cost was defined as the energy required to cut the flash. Finally, the machining cost was defined as the cost to machine the total surface. Then, in this paper, the paper was classified into process parameters optimization.

The process parameters optimization in hot forging for a connecting rod were also performed in Ref. [65], in which the used of a mechanical press was assumed and the forging load and the tool wear depth were simultaneously minimized. In the paper, the cavity center distance (OE in Fig. 7(b)), the cavity rotation angles (∠BAD), and the flash thickness of cavity were selected as the design variables. The tool wear depth was measured by the hardness of die material, the normal pressure on the die surface and the material flow velocity on the die surface during the process. The response surface using the quadratic polynomial was adopted. The effect of process parameters was investigated by using the response surface, and it was concluded that the flash thickness of cavity was the most important factor for the forging load and the tool wear depth. The pareto-frontier between the objectives was not clarified, but the validity of the approach was examined through the experiment.

4.4 Optimization of heating system or billet position

Park and Dang optimized the process parameters of in-line induction heating system for an automotive crankshaft [66]. As shown in Fig. 8(a), the target product was produced through seven heaters. The frequencies of groups 1 and 2 and the voltage of all groups which were closely related to the billet temperature were selected as the design variables. It was important to improve the energy efficiency of heating system, and thus the energy efficiency defined by the ratio between the thermal energy stored in the forged product and the electrical energy input to inductors was maximized. On the other hand, the temperature distribution of forged product strongly affected the product quality, and thus the temperature deviation of forged product was minimized. The response surface using the RBF was adopted and the NSGA-II was applied to identify the pareto-frontier. It was reported that 15% energy saving could be achieved.

It is well known that not only the billet shape but also the initial position of a billet has strongly an influence on the flash and the underfill. However, this is conventionally determined by the trial-and-error method. Then, the initial position was optimized so as to minimize a filling index considering both the underfill and the flash [67]. As shown in Fig. 8(b), the difference from a reference position to top of forged product was considered. The underfill was observed when \(\eta_{1} < 0\) at the left cavity or \(\eta_{2} < 0\) at the right cavity. On the other hand, the flash was generated when \(\eta_{1} > 0\) at the left cavity or \(\eta_{2} > 0\) at the right cavity. Then, the filling index defined by \(\left| {\eta_{1} - \eta_{2} } \right|\) was minimized. The design variable in the paper was only the position of billet, and third-order polynomial was used for the response surface. Since the number of design variable was one, \(\eta_{1}\) and \(\eta_{2}\) could be expressed by the explicit form of design variable. The SAO procedure was then performed in order to determine the optimal billet position. It was reported that the complete filling could be achieved by the optimal billet position. The initial position of billet was also investigated in Ref. [93], in which a rib-web product in two dimensions was handled and the warm forging (the billet temperature was set to 500 \({}^{ \circ }C\)) was assumed. A simple closed-loop type algorithm to fill the right- and left-cavity was constructed, and the billet position to maximize the filling ratio was determined by the slab method.

The effect of process parameters for incremental die forging process of a helical tube was also investigated in Ref. [94], in which the use of a hydraulic press was assumed and four process parameters (the die pitch length, the tube thickness, the feed length for one reciprocation, and the ratio of sectional minor axis length) were selected and the effect to the shrinkage of pitch length was investigated using the orthogonal array. It was reported from the numerical results that the shrinkage of pitch length increased with the increase of thickness, the die pitch length and the ratio of sectional minor axis length. In addition, no interaction among the process parameters was not observed. Note that the optimal process parameters were determined without using design optimization technique in the paper.

The summary described the above is shown in Table 3, from which the response surface approach is widely used for the process parameters optimization. In addition, it is found from Refs. [59, 61, 62, 63, 67] that the SAO under multi-objective optimization is performed. This indicates that multi-objective optimization can provide flexible solutions in forging.

5 Multi-stage forging

Multi-stage forging is widely used to produce a complex shape product in both the cold and hot forging [6, 68]. Since several papers related to multi-stage forging have already reviewed in Sections. 2 and 3, other papers are reviewed in this section.

Roy et al. performed the die shape optimization of an automotive outer race in four-stage cold forging using the GA [40], in which the radius of initial billet, the angle of extrusion and the length of the extrudate at the extrusion stage and the guide length, the angle and the gap between the top and bottom die at the coning stages were selected as the design variables (Fig. 9(a)). The crack was often observed after the process, and the risk of crack given by Eq. (5) was selected as the objective function to be minimized. Since two-dimensional simulation was conducted, the GA was used for the optimization method. As the result, 42% reduction of risk of crack could be achieved.

Park et al. performed a numerical simulation of multi-stage forging for a constant velocity (CV) joint outer race [69], in which the process consisted of the forward extrusion, the closed die forging, the backward extrusion and the ironing as shown in Fig. 9(b). The aim of numerical simulation was to obtain the finding of intermediate billet shapes for producing near-net shape product. Then, the forging load, the effective strain and the underfill were investigated through the processes. In the forward extrusion, the effective strain increased as the stroke proceeded, and high effective strain appeared around the outside of the extruded product. In the closed die forging, the forging load was higher than that in the forward extrusion, and thus it was pointed out that the forging load at this stage could be reduced by controlling the stroke length. The effective strain was also higher than that at the forward extrusion. In the backward extrusion stage, it was important to diminish the underfill for near-net shape product with highest forging load. In other words, the billet shape at this stage strongly affected the final product shape. Since the objective of the paper was to obtain the finding of intermediate billet shape, design optimization for billet or die shape was not performed. After that, Ku et al. numerically and experimentally examined the multi-stage forging of the CV joint outer race [70], and they clarified that highest forging load was observed at the backward extrusion stage.

Brecher et al. developed an integrated three-stage forging system coupled with a hydraulic press machine [71], in which the numerical result of forging was fed back to the press machine and the ram displacement and the ram tilting were calculated in the press machine simulation. Then, the result in the press machine simulation was used in the forging simulation at the next stage. This process was repeated as shown in Fig. 9(d) till the forging process was completed. In the paper, it was reported that the stroke at each stage was optimized using the integrated three-stage forming system. Unfortunately, the objective function was not clearly described, and design optimization problem was not formulated. As the result, it is difficult to review the paper any more.

Hsu et al. numerically investigated the effect of chamfer and punch geometry on the material flow of a bearing ring in multi-stage warm forging [72], from which it was clarified the chamfer geometry was related to the thermal lapping that led to the folding defect. The material flow was closely related to the thermal lapping, and it was considered that the radius design on punch would effectively improve the material flow. By redesigning the radius geometry on punch, the material flow was much improved. Through the experiment, it was also found that the average grain size by redesigning the radius was more uniform than that by the redesigning the chamfer. The paper indicates that the punch geometry in multi-stage forging affects the material flow. It is possible to determine the optimal punch geometry using design optimization, but design optimization is not performed in the paper.

Cochet et al. numerically investigated the key process parameters in multi-stage hot forging of a shackle shown in Fig. 9(e) [73], in which the use of a mechanical press was assumed and the initial position of billet, the die temperature, the transportation time and the friction conditions were selected and the effect of them on the dimensions of the final product was investigated. The wrong initial position of billet in closed-die forging increased the elongation, and this implied that the underfill was generated and consequently a desirable product could not be produced. The low die temperature easily resulted in the underfill and the poor product surface. The forging load was related to the initial position and the die temperature, and the wrong position and the low die temperature led to high forging load. The folding effect was emphasized when the transportation time was long. However, it was reported that the transportation time has little influence on the dimensions of the forged product. Finally, the friction conditions both the Coulomb friction and the shear friction were numerically examined, and thus both affected the flash dimensions. Unfortunately, the process parameters optimization was not performed in the paper.

Unlike others, as shown in Fig. 9(f), Kitayama et al. optimized the process parameters in three-stage hot forging assuming the use of a mechanical press [74], in which the flash and the distribution of effective strain were simultaneously minimized under the underfill constraint. The diameter and the length of billet affected the flash, and thus they were selected as the design variables. In addition, the stroke length at the first- and second-stage and the billet and die temperature affected the distribution of effective strain and the underfill, and thus they was also selected as the design variables. The SAO using the RBF network was used to identify the pareto-frontier between the flash and the distribution of effective strain. The paper simultaneously determined the billet shape and the process parameters, and it was reported that the stroke length was effective to the reduction of forging load. As already reported in Ref. [67], the initial position of billet had strongly influence on the flash. However, the initial position of billet was not discussed in the paper. For further advance, it is preferable to perform the design optimization considering the initial position of billet.

The multi-stage forging in two- and three-dimensional simulation is summarized in Table 4, from which it is found that design optimization considering all (billet shape optimization, die shape optimization and process parameters optimization) is not reported. This indicates that design optimization considering all is one of the advanced research topics.

The hammer forging is also one of the crucial forging technologies. Since the forged product is produced through several blows, this paper categorized the hammer forging in the multi-stage forging. Unlike the forging using mechanical press that controls the stroke length, the air hammer forging utilizes the potential energy of die. In the case of hydraulic hammer forging, the potential energy is by the sum of hydraulic energy and potential energy of die. To produce highly accurate product, it is important to determine the potential energy at each blow. As far as we survey, design optimization in hammer foreign is limited and thus the related papers on hammer forging are briefly reviewed. The response of hammer foundations is mainly discussed in the literature by using a simple mathematical model consisting of mass, spring and damping element [75], in which the anvil and the foundation are modelled with two degrees of freedom and the pulse load is applied to the anvil. The forged product is neglected when the two degrees of freedom system is used.

EL Hifnawy and Novak investigated the response of foundation to a given pulse load using the two degrees of freedom system [76], in which it was shown that the response of foundation was given by (1) the response for time exceeding the duration of pulse and (2) the response during the duration of pulse. They assumed that the exact time history of pulse load might change from blow to blow, and a simple time history by sine curve was approximately used. Unlike Refs [75, 76], Li et al. analyzed the maximum blow force considering the elastic deformation of cushion under the foundation [77], in which it was assumed that the maximum blow force in final forging and the resistance to the billet deformation would be proportional to the magnitude of billet deformation. The maximum blow force was then predicted by using the two masses of anvil and foundation, the velocity of ram and anvil at the impact, the elastic modulus of die and a coefficient. Chehab et al. investigated the efficiency of mounting systems for different foundation configurations using the two degrees of freedom system [78], in which they clarified that the mounting damping increased the base vibration with the low spring ratio between the anvil and the foundation and the large mass ratio (mass of anvil with respect to the total mass) increased the isolation efficiency.

The papers described the above did not perform design optimization, but Wang and Dong performed the design optimization with two degrees of freedom system [79]. The mathematical model of two degrees of freedom system was used for the hammer forging, and the objective function was defined as the maximization of isolation efficiency. The isolation efficiency was affected by (1) the mass of foundation, (2) the spring stiffness and the damping coefficient of anvil, and (3) the spring stiffness and the damping coefficient of foundation. As the result, these were selected as the design variables. In addition, seven design constraints on the displacement and acceleration of foundation and anvil, the maximum load on the soil, the pace of impact cycle, the natural frequency of foundation, and the static deflection of isolator were considered. The simulated annealing was applied, and the optimal stiffnesses and damping coefficients were determined. It was reported that 22% improvement of the isolation efficiency was achieved in comparison with the conventional design.

Recently, unlike the above papers using the two degrees of freedom system (Refs. [75,76,77,78,79]), Fang et al. numerically investigated the effect of the number of blows and dwell time on the cumulative material damage during a hydraulic hammer forging [80]. The number of blows affected the growth of grains, and thus the dynamic recrystallization of material during the blow was considered based on the crystallization kinetics. Through the numerical simulation, they clarified that the cumulative material damage and the residual stress concentration in the forged product were reduced with the increasing the number of blows. In addition, it was reported that the coarse grains were removed, and the finer grain size could be obtained with the increase of number of blows. It was finally suggested that it was important to use the high-frequency hammer forging impact in order to enhance the forging performance. The paper does not perform process parameters optimization in hammer forging, but it is suggested that design optimization will be effective to enhance the mechanical properties of forged product by the hammer forging.

6 Performance indexes for design optimization in forging

As described in Sections 3, 4 and 5, various papers on design optimization in forging have been published. In this section, major performance indexes for design optimization in forging are summarized.

6.1 Underfill

First of all, highly accurate product is required to the forged product, and thus underfill should strongly be avoided. Therefore, it is preferable to handle the underfill as the design constraint in forging. To avoid the underfill, it is considered that billet shape or die shape will be redesigned. Generally, the redesign of die is so expensive that the billet shape should be optimized so as to avoid the underfill. When underfill is always observed, it is valid to handle the underfill as the objective function to be minimized. Thus, the underfill can be handled as the objective function or the design constraint.

6.2 Flash

To improve the material yield and produce near-net shape product, flash should always be minimized in forging. Therefore, the flash is a typical objective function to be minimized in forging. Both billet and die shape have an influence on the flash. It is easy to change the billet shape, compared to the die shape. This indicates that the billet shape should be optimized so as to minimize the flash. According to the billet shape, the design variables should be considered. As described in Sect. 4(d), the initial position of billet also affects the flash, and thus it is also important to consider the initial position as the design variables. Finally, the process parameters such as the billet temperature, the die temperature and the friction coefficient affect the flash, and thus the process parameters are also considered as the design variables.

6.3 Forging load

To produce highly accurate product, large forging load is generally required. However, the large forging load makes the tool life short. To make the tool life long, the forging load should be minimized. The risk of crack is also high when large forging load is applied during the process. Therefore, it is suitable to handle the forging load as the objective function to be minimized. On the other hand, the forging load is considered as the design constraint when the allowable forging load of a press machine is limited. The billet shape, the die shape and the process parameters have an influence on the forging load, and thus these should be considered as the design variables.

6.4 Uniform deformation

It is preferable to deform the billet as uniform as possible for producing high strength product. To numerically evaluate the uniform deformation, the distribution of effective strain given by Eq. (4) is widely adopted in the literature. To achieve the uniform deformation, the distribution of effective strain is handled as the objective function to be minimized. The uniform deformation affects the flow lines which are described below. In hot forging, the billet temperature and the die temperature strongly affect the deformation, and thus it is important to consider them as the design variables.

6.5 Risk of crack

Crack is a fatal defect of forged product, and this should strongly be avoided. Unfortunately, it is difficult to evaluate the crack in numerical simulation. Various criteria for crack are listed in Ref. [81, 96]. As the process parameters, the lubrication condition or the shape of target product are so closely related to crack, it is difficult to select a proper ductile fracture criterion in the numerical simulation in advance. This implies that high integrity numerical simulation model based on experimental result should be used. Among the criterion, the material damage by Eq. (5) is widely used to numerically evaluate the risk of crack in the literature as shown in Tables 2 and 3. In addition, the risk of crack is considered in multi-stage forging and hammer forging. Therefore, the risk of crack should be considered in the case of the multi-stage forging and the hammer forging. The risk of crack is a typical objective function.

6.6 Others

It is pointed out in Ref. [82] that the vortex defect, the fiber breaking and the outcrop defect of flow lines should strongly be avoided. It is also reported in Ref. [83] that these flow lines lead to folding defect, and thus the flow lines along the product shape are preferable for high strength. Therefore, it is important to observe the flow lines of forged product.

The major performance indexes are summarized in Table 5 with the references.

7 Concluding remarks and future outlook

Design optimization in forging is systematically reviewed in this paper. One of the major issues in forging is the billet or die shape optimization and is well discussed in the literature. Various approaches have been proposed, and they have been classified into four approaches. The process parameters such as the billet temperature, the die temperature, the stroke length and the friction coefficient also affect the product quality, and they should be optimized. It is found from Table 3 that various process parameters are considered in the literature and the response surface approach is widely used for the process parameters optimization. It is clear from the table that multi-objective optimization is widely used to determine the optimal process parameters. In this regard, it is considered that the multi-objective optimization in forging can provide flexible solutions. The multi-stage forging including the hammer forging is also reviewed and is summarized in Table 4, from which it is found that design optimization considering three topics (billet shape, die shape and process parameters) is not performed yet. This indicates that design optimization considering these three topics is a challenging issue in forging.

On the other hand, three important issues on design optimization in forging are described below:

First, the intermediate die shape optimization in multi-stage forging affects the product quality, and this should be optimized. In this regard, the die shape optimization using the control points has been performed in Refs. [20, 29, 39]. In the approach, several control points are considered as the design variables and the die shape can finally be determined by using the B-spline. To obtain the smooth die shape, a large number of design variables (control points) are generally required. When the response surface approach is used, it is important to perform the design optimization with a small number of design variables due to the curse of dimensionality [84]. To reduce the number of design variables, the basis vector method is valid. Therefore, the intermediate die shape optimization using the basis vector method is valid when design optimization using the response surface approach is performed.

Next issue is how to determine the energy distribution in hammer forging. As described in Sect. 5, the hammer forging generally utilizes the potential energy and thus the produce is produced. The forging using mechanical press produces the target product by controlling the stroke length, whereas the hammer forging cannot control the one. The energy at each blow should be adjusted to produce high dimensional accurate product, but this regard is rarely discussed in the literature. Design optimization can resolve this issue.

Finally, design optimization considering the variance of process parameters is rarely performed. In other words, robust design optimization of process parameters should be performed. By considering the uncertainty of process parameters (the billet temperature, the friction coefficient and the stroke length), the die shape optimization of an aerofoil shape in two dimensions was performed [85]. The importance of the process parameters optimization considering variance is pointed out in Ref. [86], but a large number of simulations are generally required. Using the robust design optimization based on the SAO [87], it is possible to perform the design optimization considering the variation of process parameters with a small number of simulations.

On the other hand, the current CAE technology is difficult handle fully the metallurgical aspects during the forging process, and thus this paper does not focus on the metallurgical aspects. The process parameters strongly affect the development of microstructure and the product quality of forged product. Recently, some papers perform the microstructure analysis [88, 89] and discuss the miscrostructural evolution [90]. In Refs. [91, 92], PSO is used to control the microstructure during hot forging process and the material model for uniform and fine microstructure is successfully developed. It is expected that CAE considering the microstructural evolution during the forging process will lead to further development of design optimization in forging.

Data availability

Not applicable.

Code availability

Not applicable.

References